A comparison of the mechanical behaviour of natural rubber-based blends using waste rubber particles obtained by cryogrinding and high-shear mixing

Vol. 17., No.11., Pages 1135-1153, 2023

DOI: 10.3144/expresspolymlett.2023.86

DOI: 10.3144/expresspolymlett.2023.86

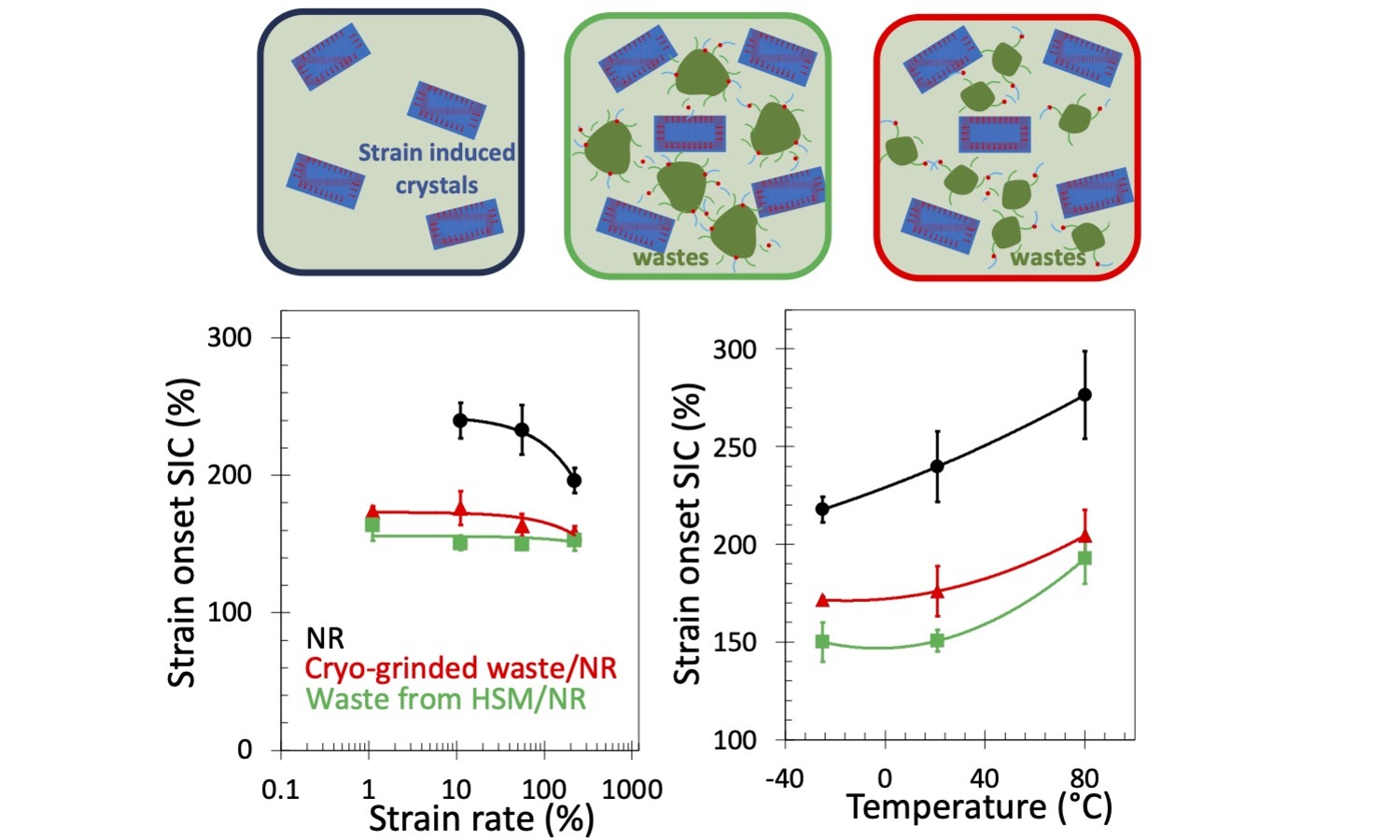

GRAPHICAL ABSTRACT

ABSTRACT

The

influence of the type of mechanical recycling of waste rubber particles on the

tensile properties of waste/natural rubber blends has been investigated. The

wastes originating from ground tyre rubber (GTR) had been treated by two

distinct processes: cryo-grinding and high shear mixing (HSM). For both

processes, the resulting composites show enhanced stiffness and strength for

all strain rates and temperatures tested. This is attributed to both the

reinforcing effect of the waste as well as the nucleation ability of the wastes

on strain induced crystallization (SIC) in the natural rubber (NR) matrix.

Cryo-grinding was shown to provide the finest particle size with an average

diameter of 34 μm, while the HSM process was found to show an elastic modulus

of aggregated GTR powder of 7 MPa at 1 Hz at room temperature. Within these

characteristics, the NR/GTR blends using the HSM process show the best tensile

performance under single loading, with the highest strength and highest ability

to crystallize under strain. Under cyclic loading, NR/GTR blends using

cryo-ground GTR particles show the best performance, which we ascribed to their

ability to better distribute and accommodate the stress from one cycle to another

owing to their finest size. Both explored recycling techniques provide the

natural/waste rubber blends interesting properties such as mechanical

reinforcement and strain-induced crystallization ability under various testing

conditions.

RELATED ARTICLES

Maja Csapó, József Gábor Kovács

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

Vol. 20., No.4., Pages 414-434, 2026

DOI: 10.3144/expresspolymlett.2026.32

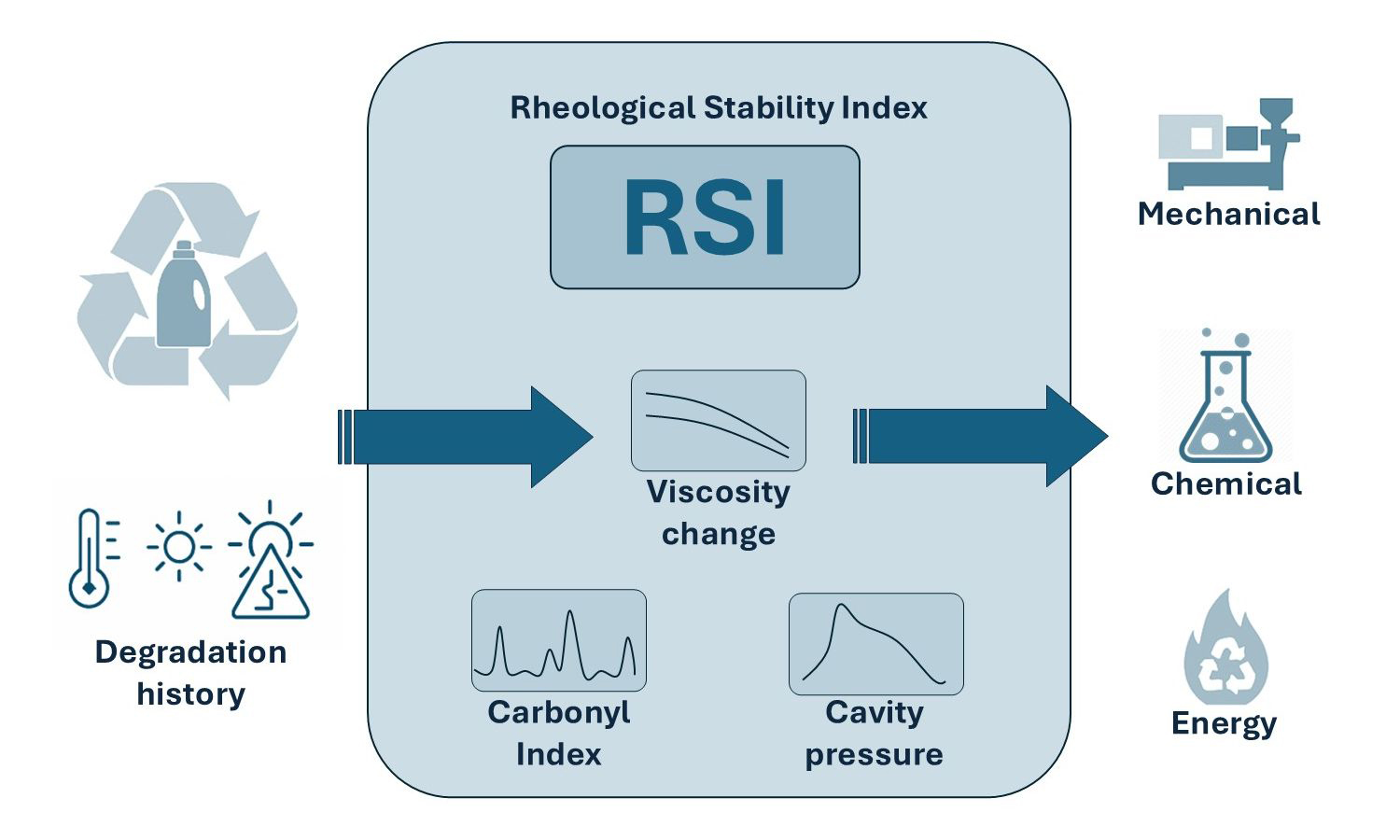

The greatest obstacle to recycling post-consumer high-density polyethylene (PCR-HDPE) is typically the degradation of properties caused by impurities and heterogeneity. However, a critical analysis of the literature reveals that the real bottleneck is not the material composition, but rather rheological stability, which simultaneously determines the degradation history of the waste stream, melt behavior, and processability at the cycle level. This review proposes a new perspective: the decision among mechanical, chemical, and energetic recycling is better made based on a unified rheological stability index (RSI), which integrates carbonyl index, viscosity change after multiple instances of melting, melt flow index (MFI) instability, in-mold pressure fluctuation, and the degree of polymer incompatibility. RSI enables the prediction of the processability of PCR-HDPE and identifies which recycling path a fraction is most suitable for. The study demonstrates how an RSI-based approach can reduce quality risk, improve cycle stability, and support circular decision-making in an industrial environment.

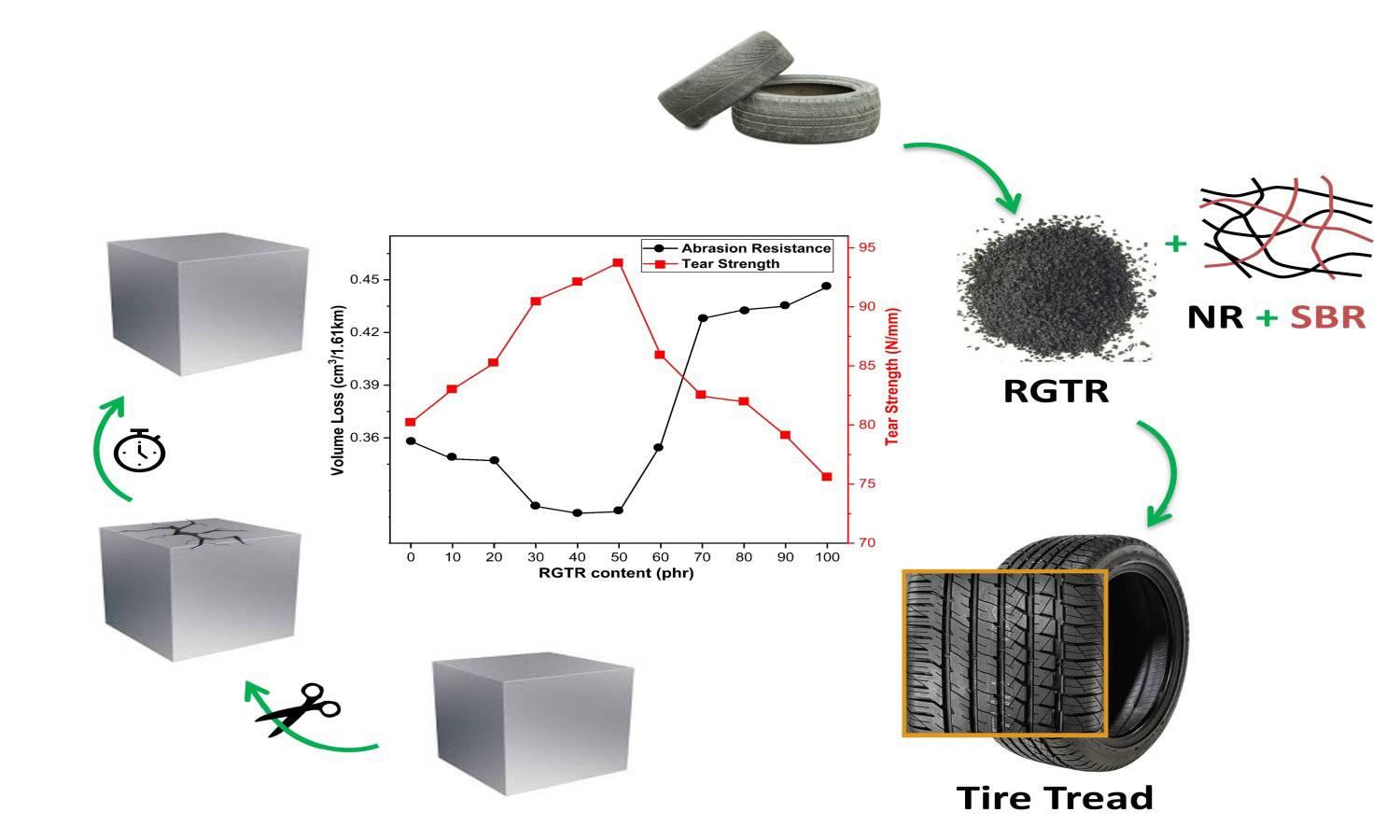

Reinforcing effect of thermo-oxidative reclaimed rubber on NR/SBR blends for tire tread applications

Yunhui Xu, Zaheer ul Haq, Junrong Li, Hui Tu, Zaixue Wang, Houluo Cong

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

This study explores the application of thermo-oxidative reclaimed ground tire rubber (RGTR) in natural rubber (NR)/styrene butadiene rubber (SBR) composite, focusing on its impact on morphology, mechanical properties, rheological behavior, vulcanization characteristics, aging resistance, tear strength and abrasion resistance. The findings revealed that RGTR enhances the tear strength and abrasion resistance of NR/SBR composites while maintaining comparable tensile strength, elongation at break, and modulus. The incorporation of RGTR reduced Mooney viscosity of the NR/SBR composites and improved flowability. It also shortened the vulcanization time and enhanced vulcanization efficiency. The NR/SBR composites with RGTR loadings below 60 phr exhibited optimal performance, achieved a maximum tear strength of 93.77 N/mm and improved abrasion resistance. However, higher RGTR content led to increased agglomeration, as evidenced by scanning electron microscopy (SEM), which showed finer dispersion at lower RGTR contents and larger aggregates at higher loadings. These findings demonstrate the potential of RGTR as a sustainable additive for enhancing specific properties in NR/SBR composites, contributing to both performance optimization and waste tire management.

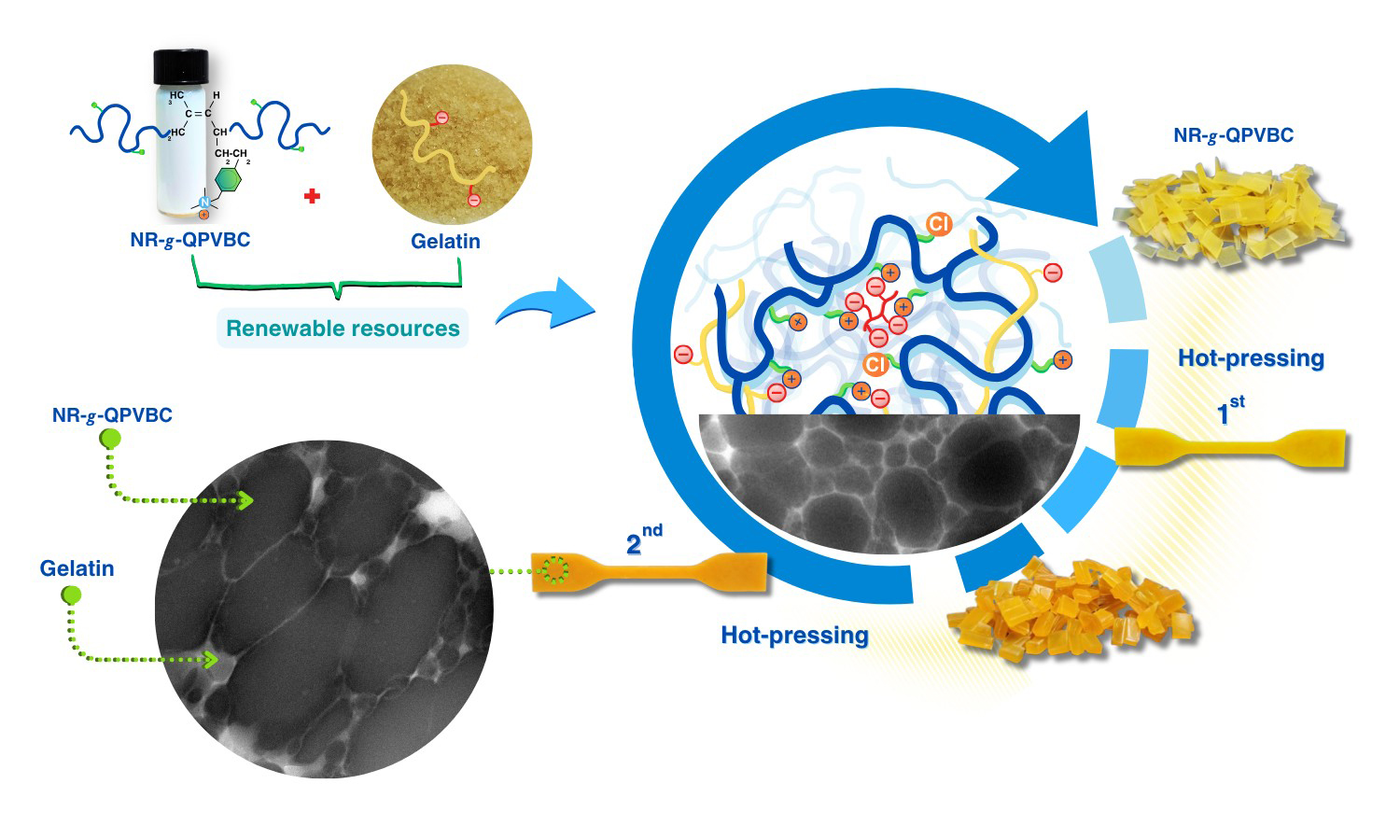

Rattanawadee Ninjan, Bencha Thongnuanchan, Phakawat Tongnuanchan, Subhan Salaeh, Jutharat Intapun, Abdulhakim Masa, Natinee Lopattananon

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

The present study has proposed a straightforward method to improve the reprocessability of modified natural rubber (NR) by blending it with gelatin (GT). The reprocessable characteristics of these blends were evaluated based on their remolding capabilities and mechanical recovery performance. In this method, poly(vinylbenzyl chloride) (PVBC) was first grafted onto NR chains to create graft copolymers known as NR-g-PVBC. The benzyl chloride groups in the graft copolymers were subsequently converted into quaternary ammonium groups, referred to as NR-g-QPVBC. This modification enabled ionic crosslinking when NR-g-QPVBC reacted with ethylenediamine tetraacetic acid. Blends were created by incorporating GT powder into the NR-g-QPVBC latex. The optimal loading level of GT was determined to be 30 wt%, as the resulting film exhibited the highest recovery of tensile properties. Initially, the film's tensile strength was measured at 15 MPa. After being remolded at 160 °C, the tensile strength decreased to 9.3 MPa, resulting in a recovery rate of 60.7% and withstanding a tensile strain of 144%. Although the NR-g-QPVBC/GT films could be remolded, their tensile properties declined with increasing remolding cycles. Therefore, this work demonstrated a practical method for producing NR-based films that could be reshaped through hot-pressing after being formed into products, increasing their reusability.

Wenhui Han, Yaqi Ge, Peng Wang, Haojun Zang, Shengqiang Xu, Huiguang Bian, Chuansheng Wang

Vol. 19., No.12., Pages 1274-1285, 2025

DOI: 10.3144/expresspolymlett.2025.94

Vol. 19., No.12., Pages 1274-1285, 2025

DOI: 10.3144/expresspolymlett.2025.94

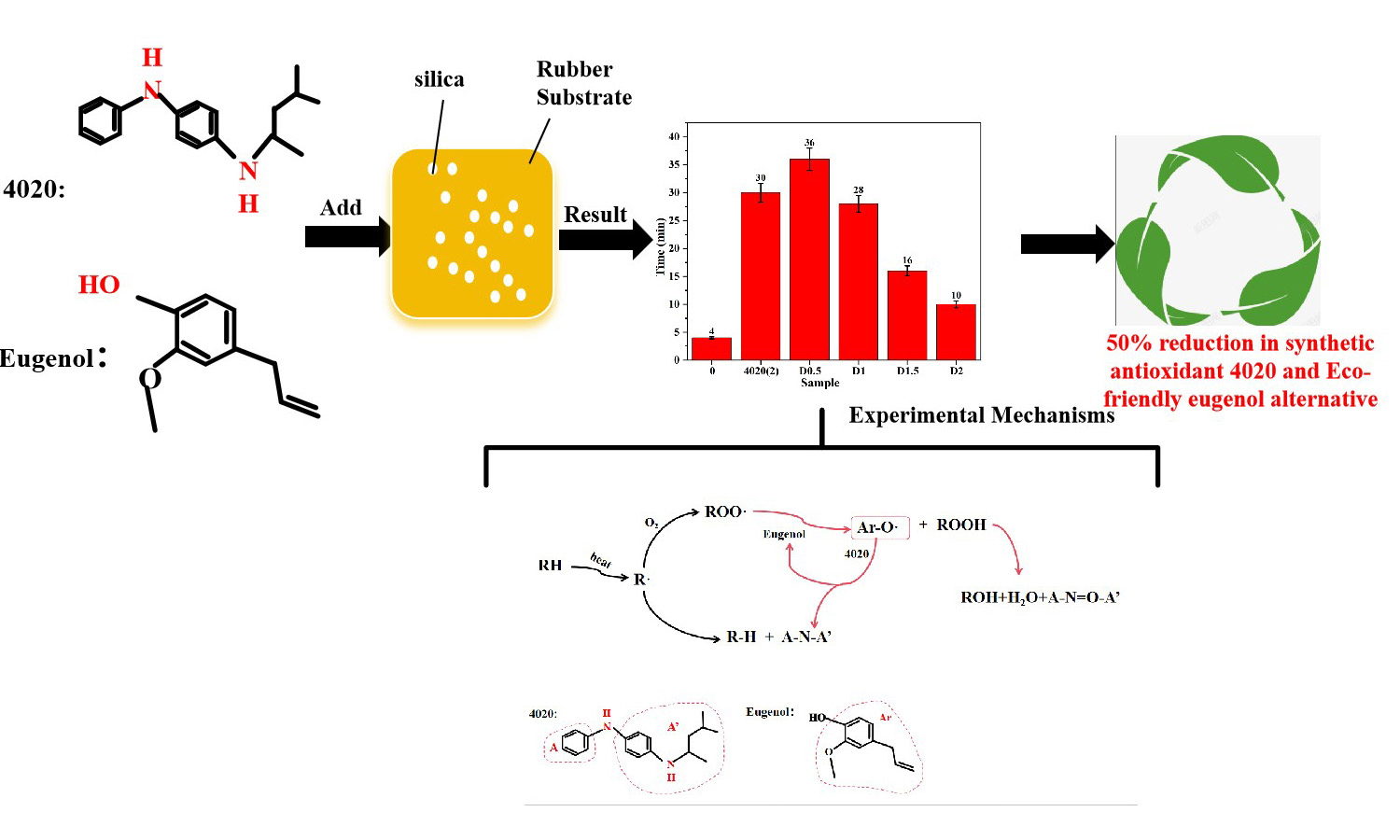

This study investigates eugenol as an alternative to mitigate environmental pollution and worker hazards associated with antioxidant N-(1,3-dimethyl)butyl-N′-phenyl-p-phenylenediamine (4020) while aligning with trends toward sustainable additives. Silica/natural rubber (NR) composites with varying ratios of eugenol and 4020 were prepared to assess their aging resistance, mechanical properties, and the synergistic antioxidant effects. Thermogravimetric analysis, cross-linking density experiments, thermo-oxidative aging tests, and oxidation induction tests revealed the highest thermo-oxidative aging resistance when 0.5 phr of 4020 was substituted with eugenol. When 1.0 phr of 4020 was replaced by eugenol, the antioxidant properties of the composites matched those containing 2.0 phr of 4020. However, when eugenol exceeded 1 phr, the antioxidant properties gradually decreased. DIN wear tests showed optimal wear resistance when 1 phr of 4020 was replaced with eugenol. These findings suggest that 50% of conventional antioxidants can be substituted with eugenol without compromising material properties. The partial substitution of eugenol in silica/NR composites proves eugenol can act as a sustainable alternative, providing comparable antioxidant capacity while reducing environmental impact.

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

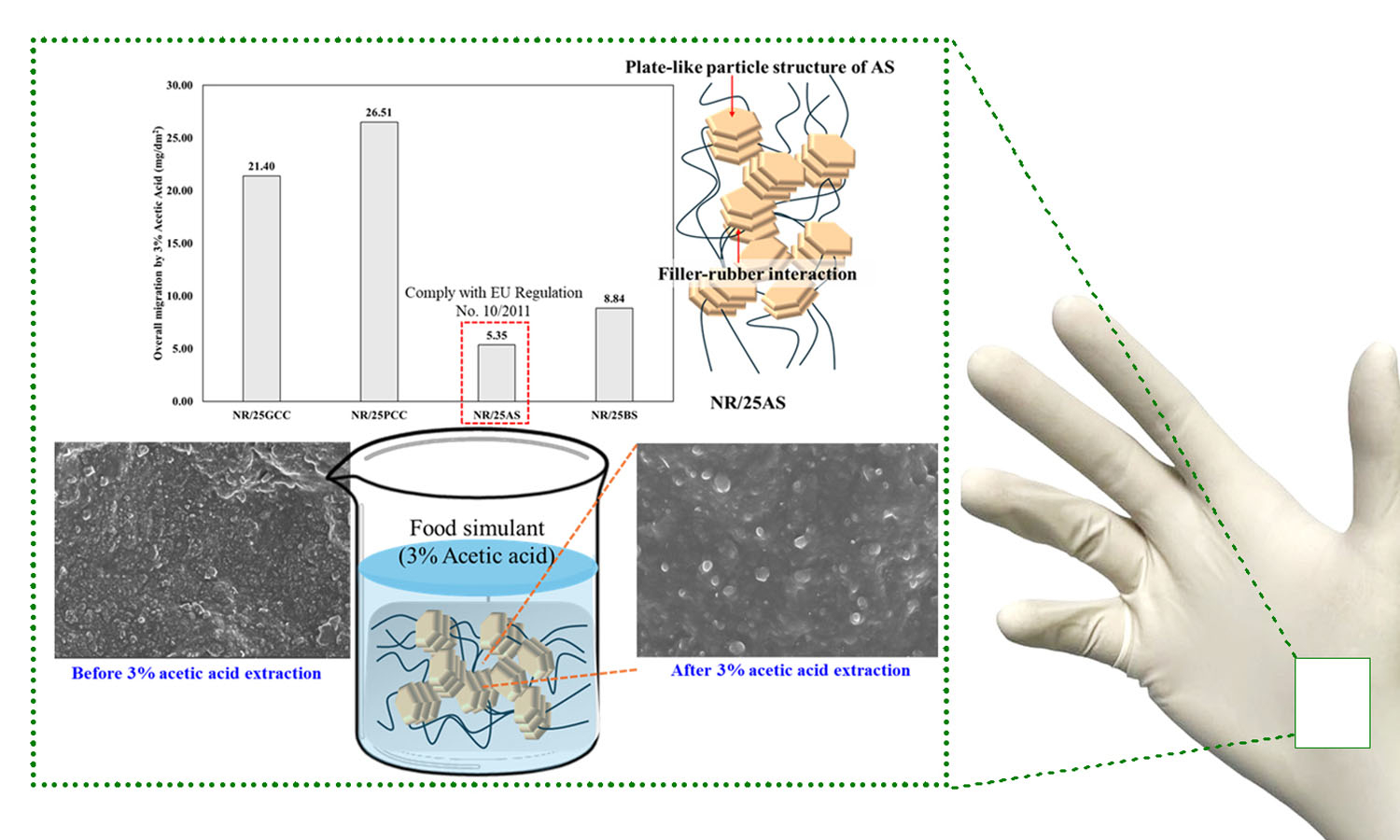

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.