From scrap to structure: The challenges of carbon fibre recycling

Vol. 19., No.7., Pages 651-652, 2025

DOI: 10.3144/expresspolymlett.2025.49

DOI: 10.3144/expresspolymlett.2025.49

GRAPHICAL ABSTRACT

RELATED ARTICLES

Gergő Zsolt Marton, Fanni Balogh, Gábor Szebényi

Vol. 19., No.8., Pages 809-821, 2025

DOI: 10.3144/expresspolymlett.2025.62

Vol. 19., No.8., Pages 809-821, 2025

DOI: 10.3144/expresspolymlett.2025.62

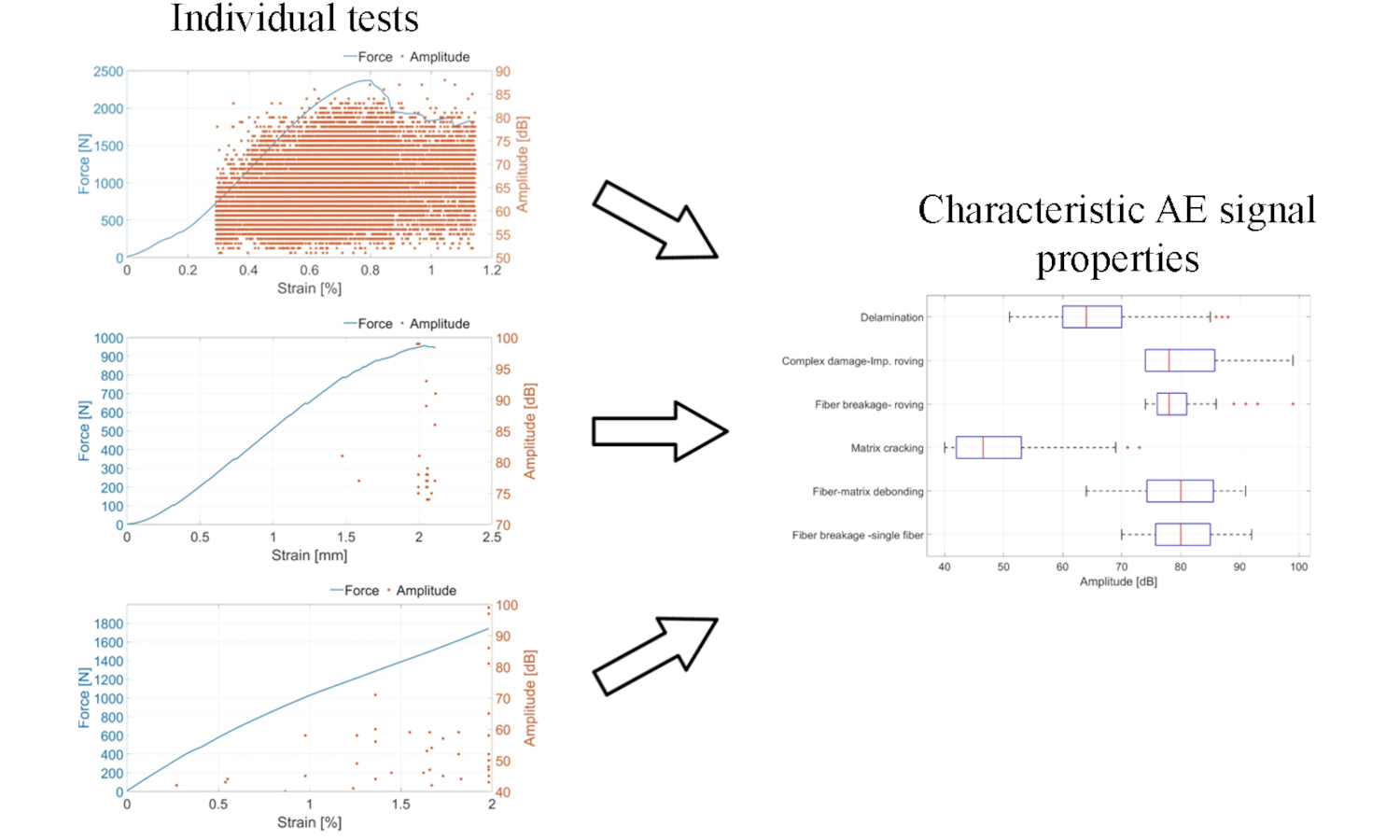

The failure of fiber-reinforced polymer composites is considered a complex process resulting from several concurrent damage mechanisms and their interactions. To better understand the damage modes of composites, which is necessary to ensure their structural health monitoring, increase their reliability, and validate different methods used for influencing their damage and failure process, it is crucial to detect, identify, and analyze different damage modes present in composite materials. The acoustic emission technique provides the opportunity to acquire damage-related data, which can be analyzed and associated with different modes of damage. In the current study, we conducted specific tests using the acoustic emission (AE) technique on the composite and its constituents, which can induce individual damage modes, thereby enabling the determination of their characteristic AE signal properties and their identification in complex composite structures.

Maria Casapu, Ion Fuiorea, Michel Arrigoni

Vol. 18., No.1., Pages 41-60, 2024

DOI: 10.3144/expresspolymlett.2024.4

Vol. 18., No.1., Pages 41-60, 2024

DOI: 10.3144/expresspolymlett.2024.4

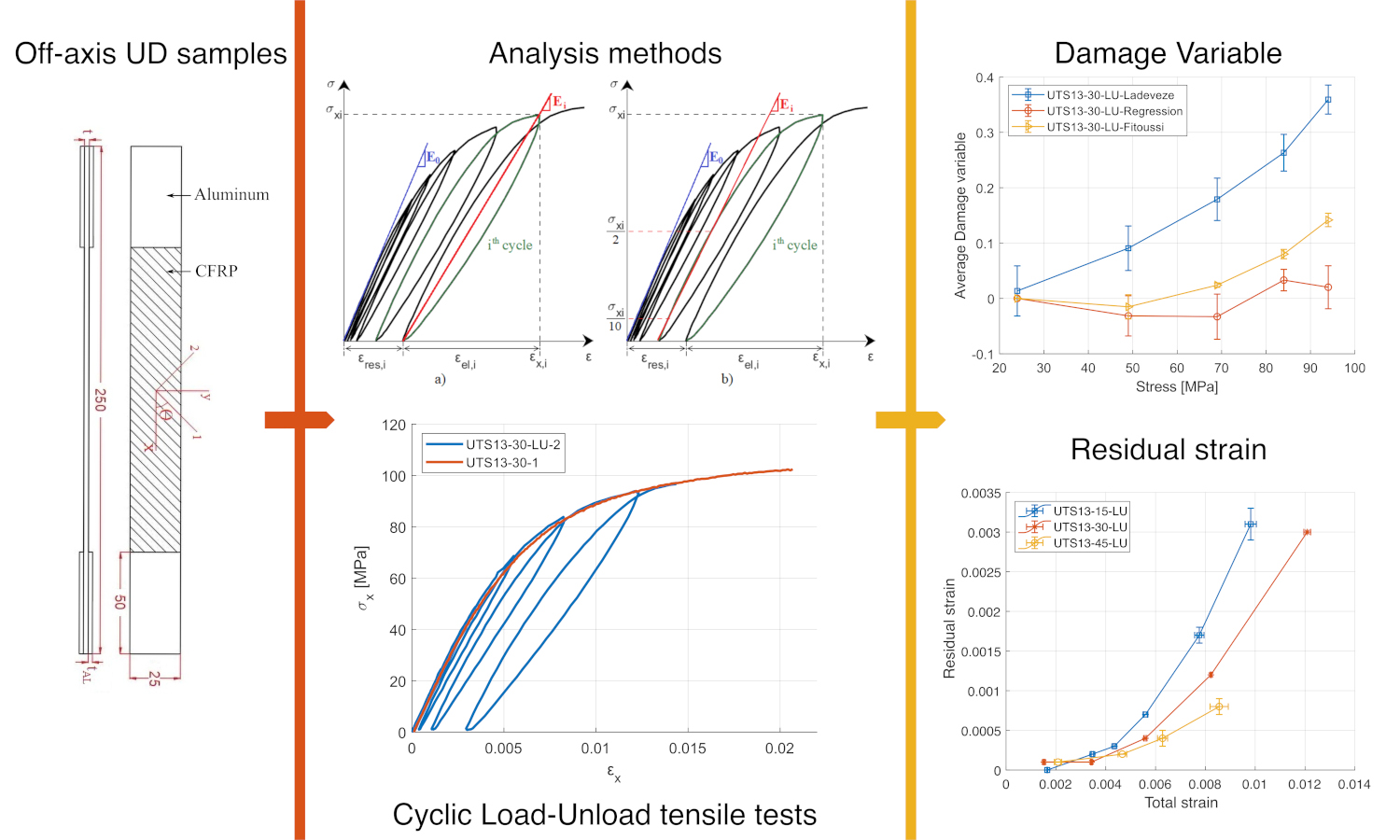

Composite materials are of increasing interest in aircraft and spacecraft structures, and carbon fiber reinforced polymers (CFRP) have emerged as materials meeting quality standards for structural applications in the aircraft industry. Despite their high mechanical properties, CFRPs are associated with high production costs. Building on recent research by the authors, this paper investigates the use of ply-level hybridization to reduce manufacturing costs while maintaining the mechanical performance of the manufactured material. Focusing on the causes of nonlinear response under off-axis tensile loading, the paper involves cyclic load-unload (LU) tensile tests conducted at off-axis angles of 15°, 30°, and 45° to predict mechanical characteristics and damage evolution. Residual strains are directly extracted from load-unload stress-strain responses. Three distinct methods for estimating cycle modulus are employed and compared for damage variable formulation. The research findings reveal dependencies of both the damage variable and residual strains on the off-axis angle. Furthermore, the method used to assess the modulus during cycling loading significantly influences the damage variable estimation. Encouragingly, the hybrid laminates exhibit reduced internal damage and matrix plasticity compared to reference counterparts, indicating a positive effect on the mechanical performances of hybridized CFRPs in addition to the cost reduction.