Investigation of high-performance recycled carbon fibre reinforced aluminium core sandwich structures

Vol. 19., No.11., Pages 1202-1213, 2025

DOI: 10.3144/expresspolymlett.2025.88

DOI: 10.3144/expresspolymlett.2025.88

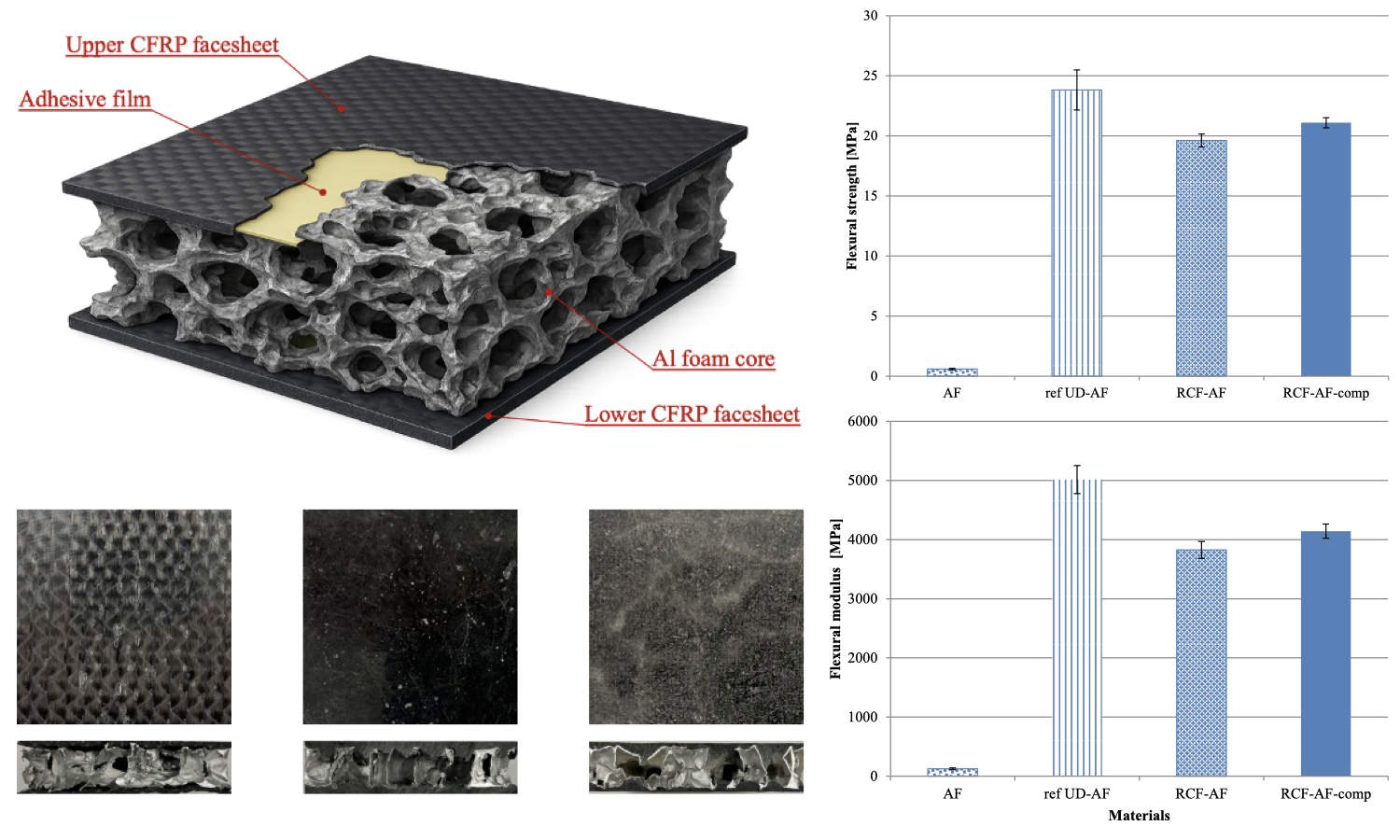

GRAPHICAL ABSTRACT

ABSTRACT

This study examines the performance of hybrid sandwich composites with a recycled aluminium foam (AlF) core and a recycled carbon-reinforced polymer skin layer. Three composite skin configurations were examined: (i) unidirectional (UD) carbon/epoxy sheets representing aligned virgin fibre reinforcement, (ii) randomly oriented recycled carbon fibre (rCF) mats consolidated by hand layup with epoxy, and (iii) randomly oriented rCF/epoxy sheets consolidated by hot pressing. The AlF core structure analysis revealed a low density and uniform open-cell structure ideal for lightweight cores. Comprehensive testing revealed significant performance differences between skin types and manufacturing methods, underscoring the critical role of processing – particularly hot pressing – in enhancing fibre compaction, matrix consolidation and interfacial bonding between the core and facesheets. Unidirectional carbon fibre skins achieved the highest flexural stiffness. In contrast, hot-pressed rCF mats provided the most balanced properties, combining high compression, damage resistance, and flexural strength, due to improved consolidation and reduced porosity in the face sheets. Thus, hybrid sandwich structures fabricated from recycled AlF core and rCF represent a viable, environmentally responsible alternative for aerospace, automotive, and protective applications requiring lightweight, high-strength, and damage-resistant materials.