Recyclable epoxy-amine coating modified with an azobenzene for light-activated damage repair and enhanced degradation resistance

Juan Pablo Caclamanis, Gabriela Clarisa Campos, Ileana Zucchi, Silvia Cere, María José Galante, Valeria Pettarin

Vol. 19., No.11., Pages 1188-1201, 2025

DOI: 10.3144/expresspolymlett.2025.87

DOI: 10.3144/expresspolymlett.2025.87

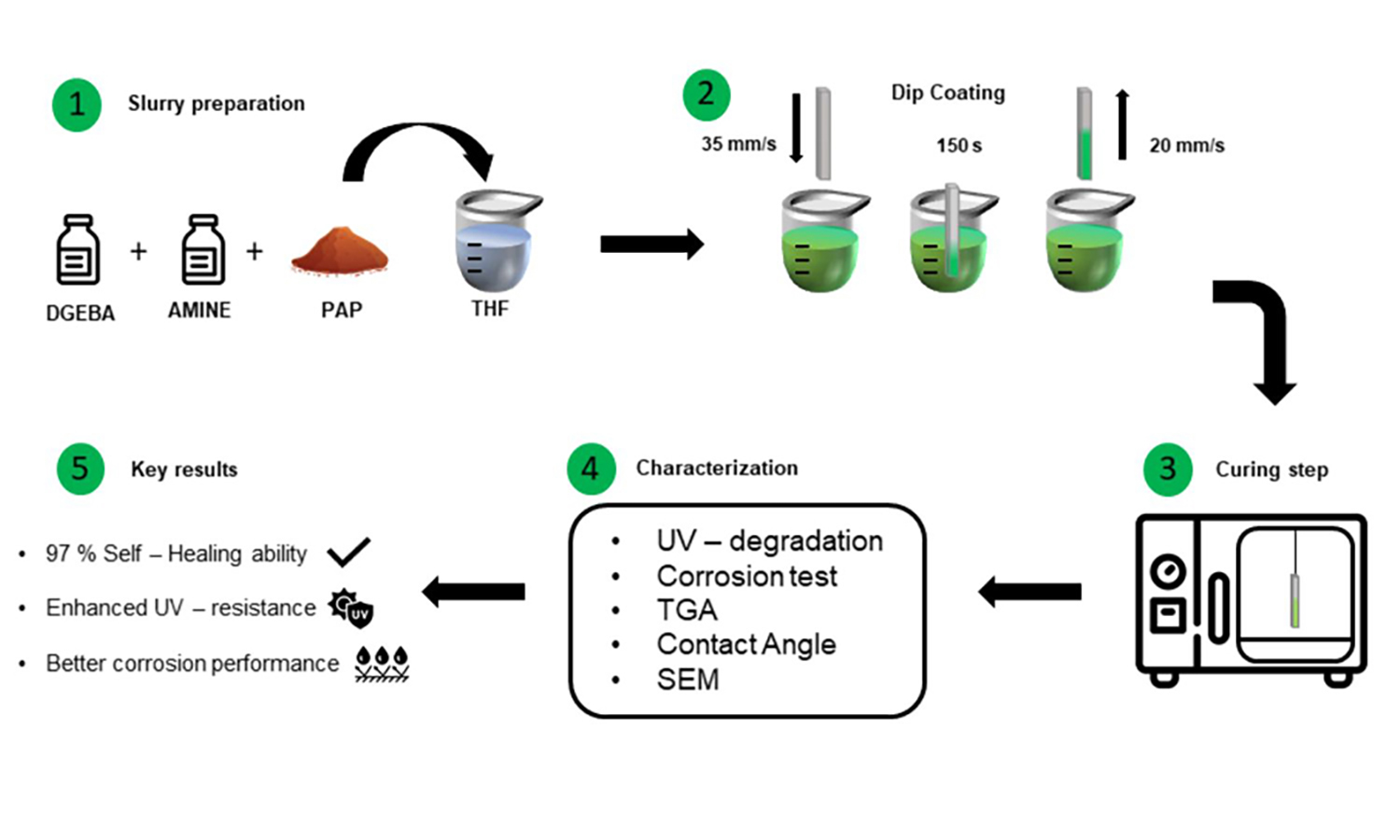

GRAPHICAL ABSTRACT

ABSTRACT

An epoxy-amine coating modified with 4-phenylazophenol (PAP) was developed on a steel substrate to promote self-healing capabilities. The self-healing mechanism is driven by light-induced trans–cis isomerization of the azobenzene moiety, enabling localized mobility of the polymer network and restoring surface integrity without thermal activation. The proposed epoxy–amine system combines thermoplastic-like processability with crosslinked mechanical stability, while its reversible physical crosslinks enable efficient recycling upon heating above the gel–liquid transition temperature. Furthermore, it was found that the modified coating enhanced corrosion resistance, UV stability, and durability. Electrochemical impedance spectroscopy (EIS) revealed higher low-frequency impedance values for PAP-epoxy, while Tafel analysis showed a significant reduction in corrosion current density, confirming enhanced anticorrosive performance. Compared to the unmodified epoxy system, PAP-epoxy exhibited reduced porosity and crack density, as well as more tortuous microcrack paths, thereby improving its barrier properties. The combined use of FTIR, TGA, and contact angle measurements demonstrated that PAP incorporation delayed the formation of oxidative degradation products and preserved thermal stability after prolonged UV exposure. The improved protective performance is attributed to the combined effects of microstructural refinement, reduced porosity, and UV-absorbing capability of PAP.

RELATED ARTICLES

Ming Qiu Zhang

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

This is an editorial article. It has no abstract.