Aqueous-phase regulation in Pickering emulsions yields thermally expandable microspheres with high onset expansion temperature and high expansion ratio

Xin Liu, Liang Xu, Yu Bai, Wei Wang, Zheng Li, Jizhou Du, Jing Zhang, Junfeng Qian, Mingyang He

Vol. 20., No.3., Pages 292-310, 2026

DOI: 10.3144/expresspolymlett.2026.23

DOI: 10.3144/expresspolymlett.2026.23

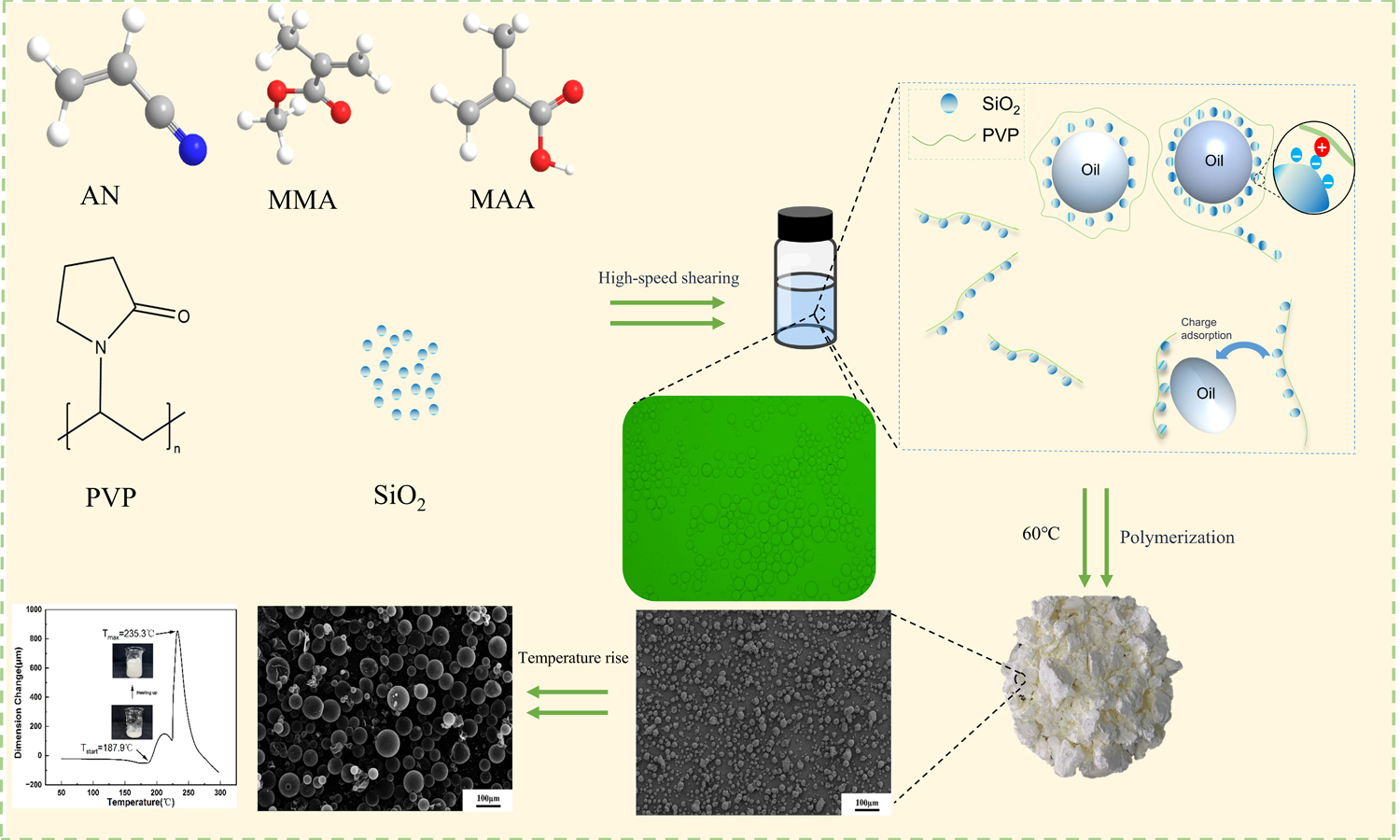

GRAPHICAL ABSTRACT

ABSTRACT

Thermally expandable microspheres (TEMs) are 5–50 μm core–shell particles that expand near the shell’s glass transition temperature (Tg). They are widely used as blowing agents in polymer foaming. Typically, TEMs are prepared by Pickering emulsion–based suspension polymerization. In this process, the oil phase contains monomers, a volatile blowing agent, and an initiator, and it is dispersed as oil-in-water droplets. The aqueous phase contains inorganic particles and an organic dispersant to stabilize the interface. However, solely regulating the oil phase has failed to deliver TEMs that couple a high onset expansion temperature (Tstart) with a large expansion ratio. Therefore, these materials remain unsuitable as blowing agents for high-processing-temperature polymers. This study systematically investigates how regulating the aqueous-phase environment affects Tstart and the expansion ratio of TEMs. Specifically, we tune silica concentration, pH, and ionic strength. By enhancing emulsion stability and optimizing emulsion morphology, we obtain TEMs that combine a high Tstart (188 °C) and a 12× diameter expansion. These findings highlight the importance of aqueous-phase regulation in controlling the Tstart and expansion ratio of TEMs, providing a promising route to microspheres suited for high-temperature polymer foaming.

RELATED ARTICLES

Shivapura Manchaiah Anush, Suchetha Naga Raju, Ballupet Honnapa Gayathri, Keresanthe Parameshwarappa Ajeya, Yarabahally Ravindranath Girish, Sanneerappa Darshan, Yelaware Puttaswamy Naveen, Kalappa Prashantha, Byrappa Krishnaiah Narendra, Aishwarya Jayaram

Vol. 18., No.1., Pages 102-115, 2024

DOI: 10.3144/expresspolymlett.2024.8

Vol. 18., No.1., Pages 102-115, 2024

DOI: 10.3144/expresspolymlett.2024.8

A novel adsorbent material for the effective removal of hazardous metal ions from aqueous solutions was developed through modifications to chitosan. The process involved the use of vanillin to create cross-linked chitosan, which was then combined with thiourea-based graphitic carbon nitride (g-C3N4) to form a gel matrix. The resulting composite material was thoroughly characterized using various techniques, including Fourier transform infrared spectroscopy, thermogravimetric analysis, scanning electron microscopy, energy dispersive X-ray spectroscopy, and X-ray diffractometry. To assess its efficacy, adsorption experiments were conducted to determine the capability of the synthesized compounds to adsorb Cu(II) and Cr(VI) ions. The observed results found that the adsorption process was found to follow pseudo-second-order kinetics and the Langmuir isotherm model. Through thermodynamic studies, it was revealed that the adsorption process was both endothermic and spontaneous in nature. Furthermore, desorption studies confirmed that the material could be regenerated, making it reusable. This characteristic allowed for the effective recovery of the adsorbate species and highlighted the potential for reusing the adsorbent material multiple times.