Effects of thermal treatment and nucleating agents on crystallinity, toughness, and stiffness of PLA/PCL blends

Aleksandra Ujcic, Ivan Fortelny, Sabina Krejcikova, Ewa Pavlova, Jiri Hodan, Miroslav Slouf

Vol. 16., No.3., Pages 221-233, 2022

DOI: 10.3144/expresspolymlett.2022.18

DOI: 10.3144/expresspolymlett.2022.18

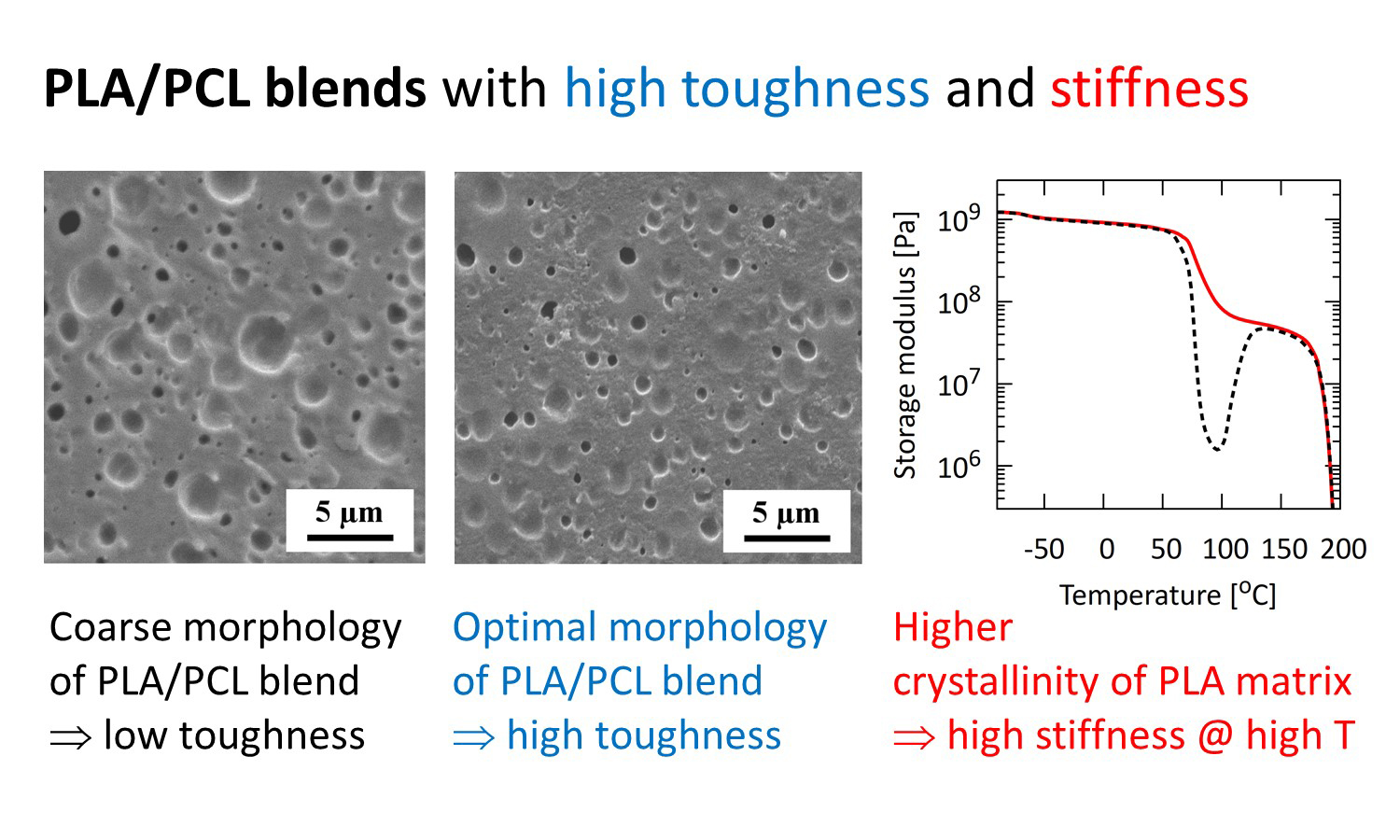

GRAPHICAL ABSTRACT

ABSTRACT

The effects of the thermal treatment and nucleating agents on the morphology, crystallinity, and mechanical propertiesp of poly(lactic acid)/poly(ε-caprolactone) (PLA/PCL) blends were studied in order to obtain PLA/PCL blends with both high stiffness and toughness. The standard thermal treatment of the melt-mixed blends (a compression molding without annealing) resulted in the systems with optimized morphology (at PLA/PCL ratio 80/20) and very high toughness (ca 16×higher with respect to neat PLA), but the stiffness at elevated temperatures (above Tg of PLA at 65 °C) was low due to the low crystallinity of the PLA matrix (<10%). The compression molding with annealing at 110 °C could increase the crystallinity of PLA (up to ~40%), but the toughness decreased steeply due to morphological changes (a coalescence of PCL particles associated with the structure coarsening). The lowering of the annealing temperature (to 80 °C) and addition of the PLA nucleating agent (1 wt% of talc) led to the blends showing both high toughness (9× with respect to neat PLA) and crystallinity (~35%). Dynamic mechanical analysis evidenced that the higher PLA crystallinity improved the storage modulus at temperatures >60 °C by ca two orders of magnitude. The achieved combination of the PLA/PCL toughness and stiffness was one of the highest, according to the available literature.