Activated carbon nanofibers from lignin/recycled-PET and their adsorption capacity of refractory sulfur compounds from fossil fuels

Efstratios Svinterikos, Ioannis Zuburtikudis, Mohamed Al-Marzouqi

Vol. 16., No.3., Pages 248-264, 2022

DOI: 10.3144/expresspolymlett.2022.20

DOI: 10.3144/expresspolymlett.2022.20

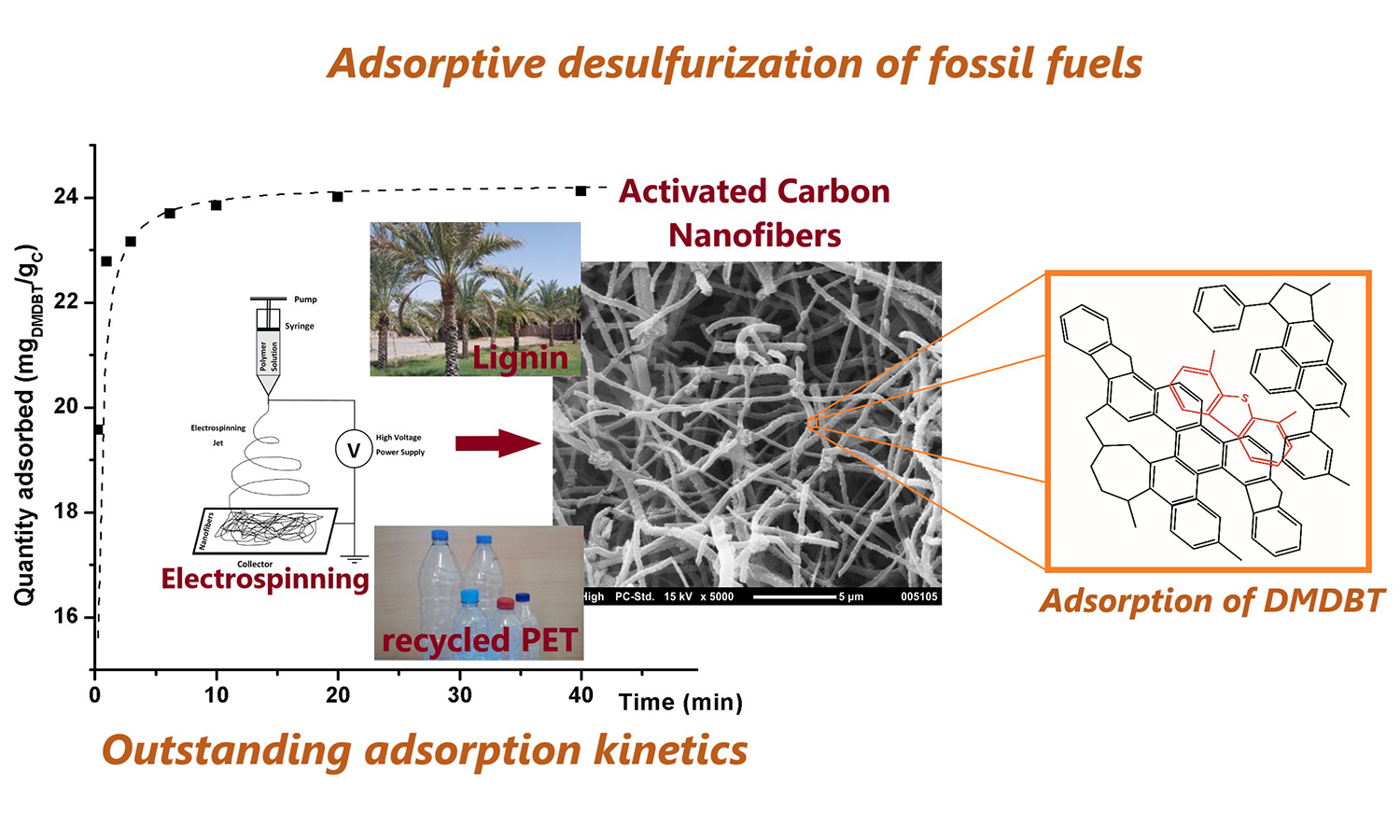

GRAPHICAL ABSTRACT

ABSTRACT

Carbon nanofibers (CNFs) from a blend of lignin with recycled poly(ethylene terephthalate) (r-PET) were produced from the thermal treatment of precursor electrospun lignin/r-PET nanofibrous mats. The impact of the lignin/r-PET mass ratio (ranging from 50/50 to 90/10) on the morphology, porosity and carbon structure of the CNFs was thoroughly investigated. The CNFs produced from a lignin/r-PET mass ratio of 50/50 possess the highest BET surface area (353 m2/g) as the presence of r-PET contributes to the development of microporosity, while all CNFs consist of disordered carbon structure. Their chemical activation with KOH boosted their BET surface area to 1413 m2/g and further treatment with HNO3 anchored oxygen functional groups on their surface. These activated CNFs were used for the adsorption of 4,6-dimethyldibenzothiophene (DMDBT) from a model diesel fuel (n-dodecane) and it was found that they exhibit a high adsorption capacity at ambient conditions (120.3 mgDMDBT/gC). This is combined with remarkably fast adsorption kinetics as 94% of the equilibrium concentration is reached after just 1 min. These outstanding kinetics are justified by the nano-structured morphology of the activated CNFs which translates into a very large specific surface area that minimizes mass transfer limitations.