Development of natural rubber foam with water as a blowing agent via microwave and convection heating methods

Nur Syuhada Ahmad Zauzi, Zulkifli Mohamad Ariff, Raa Khimi Shuib

Vol. 16., No.3., Pages 296-317, 2022

DOI: 10.3144/expresspolymlett.2022.23

DOI: 10.3144/expresspolymlett.2022.23

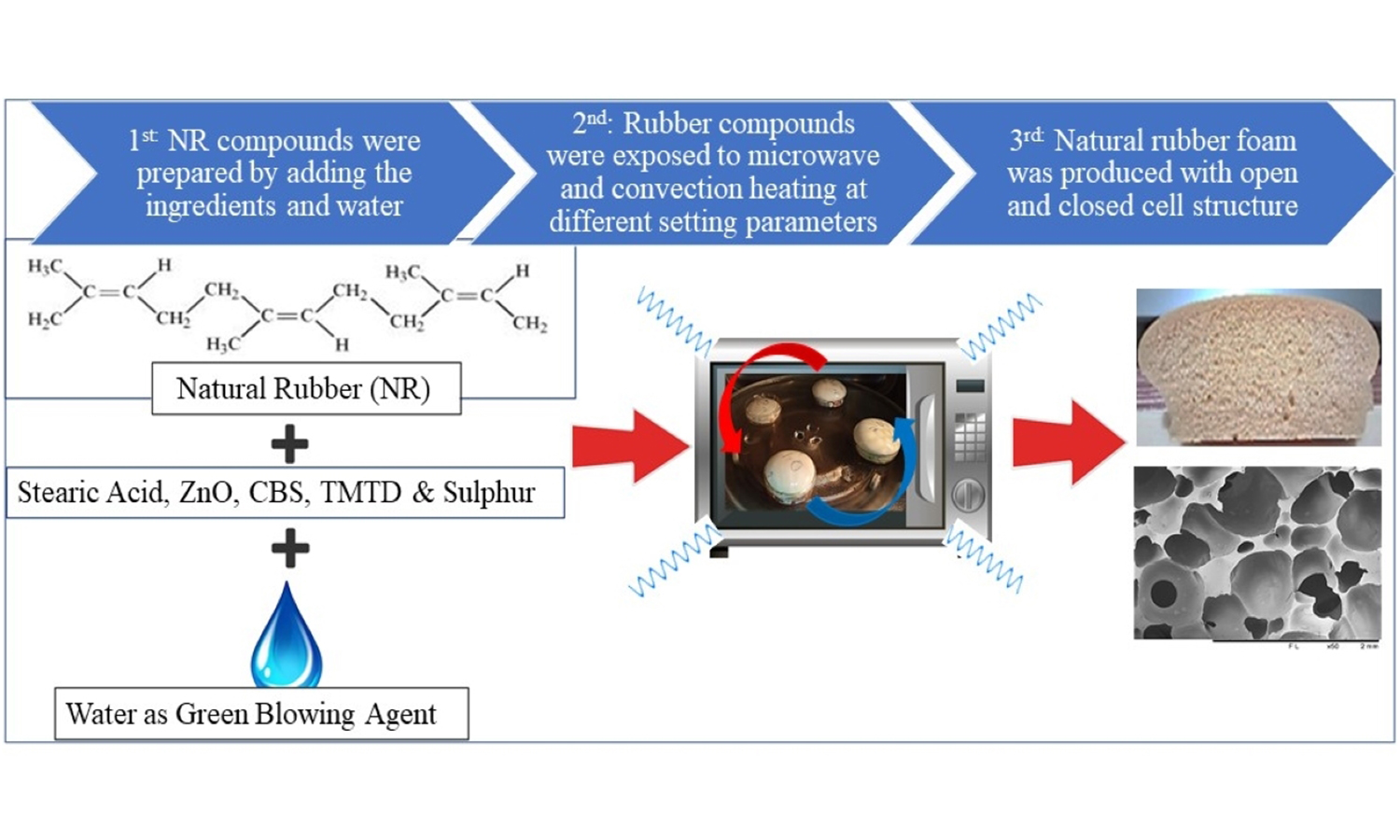

GRAPHICAL ABSTRACT

ABSTRACT

This study used water as the physical blowing agent as well as microwave heating (MH) and convection heating (CH) to simultaneously foam and cure natural rubber foam (NRF). Various processing methods and parameters, such as single heating and sequential heating using a mix of CH and MH; were investigated. The correlation between these processing methods as well as different water loadings was then evaluated and compared in terms of physical appearance, density, and morphology. The NRF samples produced using sequential MH and CH (SMC) heating exhibited better shape and structure than samples produced using single heating of either CH or MH only as well as sequential CH and MH (SCM) heating at all water loadings. NRF samples with water loadings of 1.5 and 2.0 phr had a density of less than 0.1 g/cm3. The potential heating mechanism of all the heating methods explored in this study was proposed and discussed to further understand the microwave heating process. The findings of this study proved that water could be utilized as a physical blowing agent in the production of NRF products with microwave-assisted foaming.