Increased processing temperature assisted reactive toughening of poly(lactic acid)

Nóra Lukács, Kata Enikő Decsov, Béla Molnár, Ferenc Ronkay, Katalin Bordácsné Bocz

Vol. 17., No.2., Pages 169-180, 2023

DOI: 10.3144/expresspolymlett.2023.12

DOI: 10.3144/expresspolymlett.2023.12

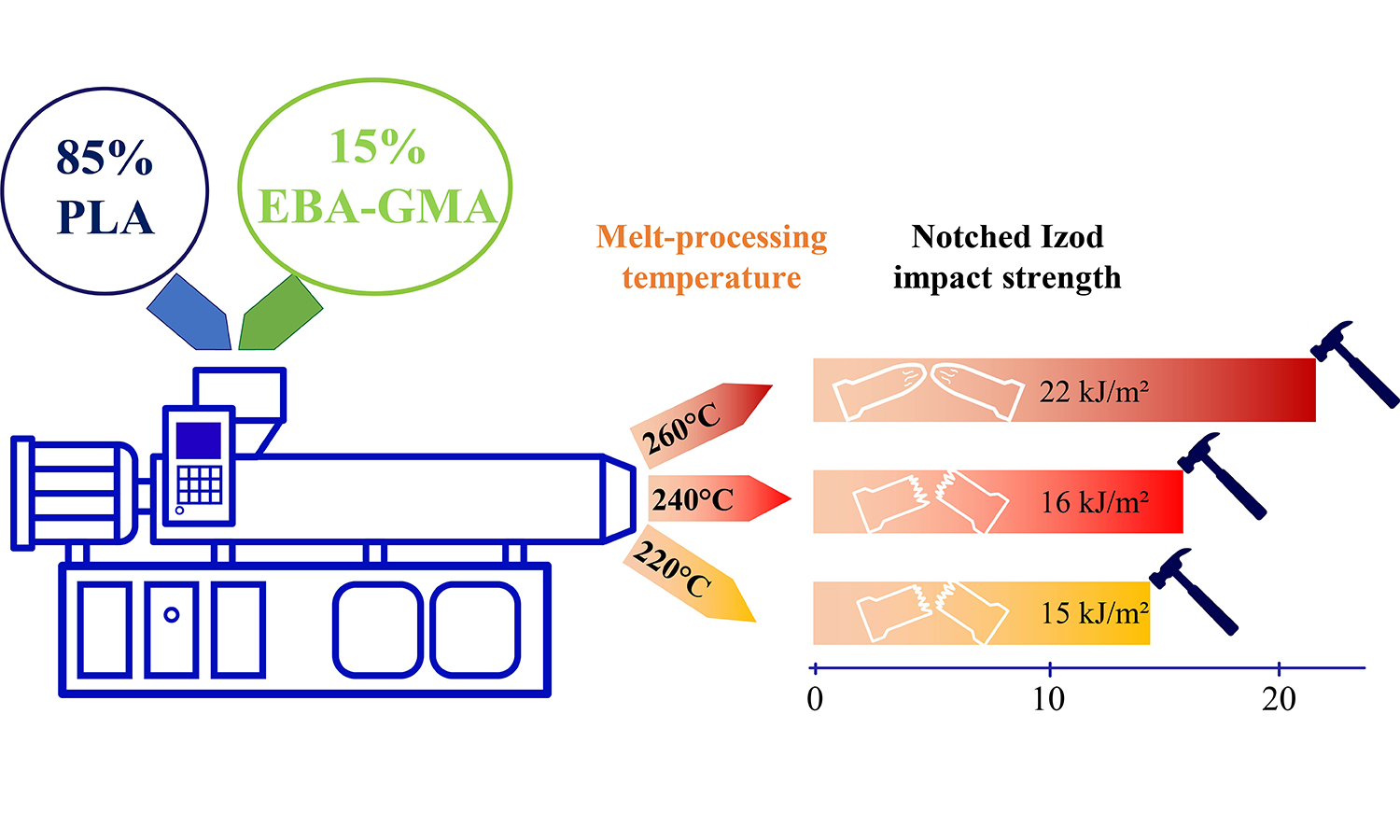

GRAPHICAL ABSTRACT

ABSTRACT

Toughening efficiency of poly(ethylene-n-butylene-acrylate-co-glycidyl methacrylate) (EBA-GMA) in poly(lactic acid) (PLA) matrix has been found to significantly increase at elevated blending temperature. In the case of PLA/EBAGMA blends having 10.0 or 12.5 wt% EBA-GMA contents, the accelerated PLA degradation at raised processing temperature resulted in reduced mechanical performance. At 15.0 wt% EBA-GMA ratio, however, increased elongation and by 250% improved notched Izod impact strength was achieved when the blending temperature was raised from 240 to 260 °C. This beneficial effect is attributed to the accelerated compatibilization reactions between the components in the presence of shortchain PLA molecules, which allow the rapid formation of a toughening enhancer interphase (TEI) during melt processing. As a result, the brittle-ductile transition can be reached at lower elastomer content than expected. Decreased melt flow index (MFI) values besides stabilized blend morphology indicated efficient PLA–EBA-GMA compatibilization at elevated processing temperature. Accordingly, enhanced nucleation ability of the PLA/EBA-GMA interphase and hindered chain crystallization of PLA were found by differential scanning calorimetry (DSC) analyses. In association with the intensified compatibilization reactions cross-linking of the terpolymer was also revealed using the thermally stimulated depolarization current (TSDC) technique.