Four-dimensional printing of acrylonitrile butadiene styrene – thermoplastic polyurethane shape memory polymers with excellent material and interfacial adhesion performance

Kianoosh Soltanmohammadi, Mohammad Aberoumand, Davood Rahmatabadi, Elyas Soleyman, Sogol Ghasemi, Ismaeil Ghasemi, Majid Baniassadi, Karen Abrinia, Mahdi Bodaghi, Mostafa Baghani

Vol. 17., No.11., Pages 1082-1095, 2023

DOI: 10.3144/expresspolymlett.2023.82

DOI: 10.3144/expresspolymlett.2023.82

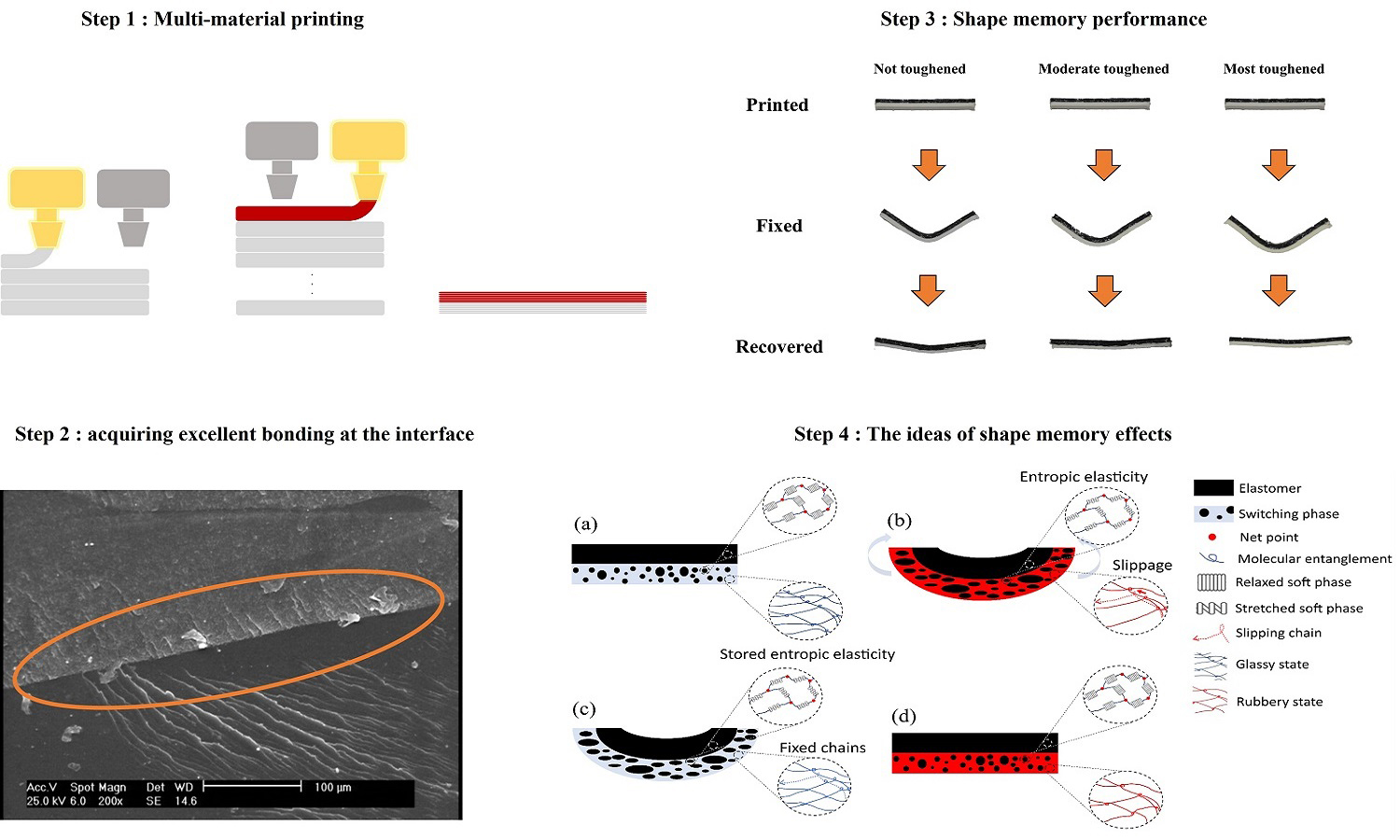

GRAPHICAL ABSTRACT

ABSTRACT

There

are a limited number of thermoplastics with intrinsic shape memory effect (SME)

that are four-dimensional (4D) printable. Development of other shape memory

polymers (SMPs) entails synthesis with a complicated chemical experimental lab

effort. In this paper, for the first time, a novel layered multi-material

structure is developed based on a deep comprehension of SMEs’ macromolecular

requisites. The fused deposition modeling (FDM) method is used for the

four-dimensional printing of layered structures whose base materials show no

SME. Commercial acrylonitrile butadiene styrene (ABS), toughened

ABS-thermoplastic polyurethane (TPU) blend, and TPU, all with no SME, are used

to fabricate bi-layers of ABSTPU blends and TPU with different volumetric

proportions. Different thermo-mechanical tests, including dynamic mechanical thermal

analysis (DMTA), and constrained and free shape recovery, are conducted. Also,

the interfacial properties of the layered 4D printed structure are assessed by

the mean of shear testing and scanning electron microscopy (SEM). Experimental results

reveal that the 4D printed bi-layer composites possess a high level of

programmability, SME (90–96%), and perfect interfaces without any porosity and

detachment between layers. The results of this research can potentially

eliminate the desperate need for SMPs for 4D printing and broaden the

opportunity to have smart parts using commercial thermoplastics.