Assessing novel thermoset materials from Brazil nut oil: Curing, thermal and mechanical properties

Aina Perez-Nakai, Alejandro Lerma-Canto , Acerina Trejo-Machín

, Acerina Trejo-Machín , Iván Dominguez-Candela

, Iván Dominguez-Candela , Jose Miguel Ferri

, Jose Miguel Ferri , Vicent Fombuena

, Vicent Fombuena

, Acerina Trejo-Machín

, Acerina Trejo-Machín , Iván Dominguez-Candela

, Iván Dominguez-Candela , Jose Miguel Ferri

, Jose Miguel Ferri , Vicent Fombuena

, Vicent Fombuena

Vol. 17., No.12., Pages 1224-1238, 2023

DOI: 10.3144/expresspolymlett.2023.93

DOI: 10.3144/expresspolymlett.2023.93

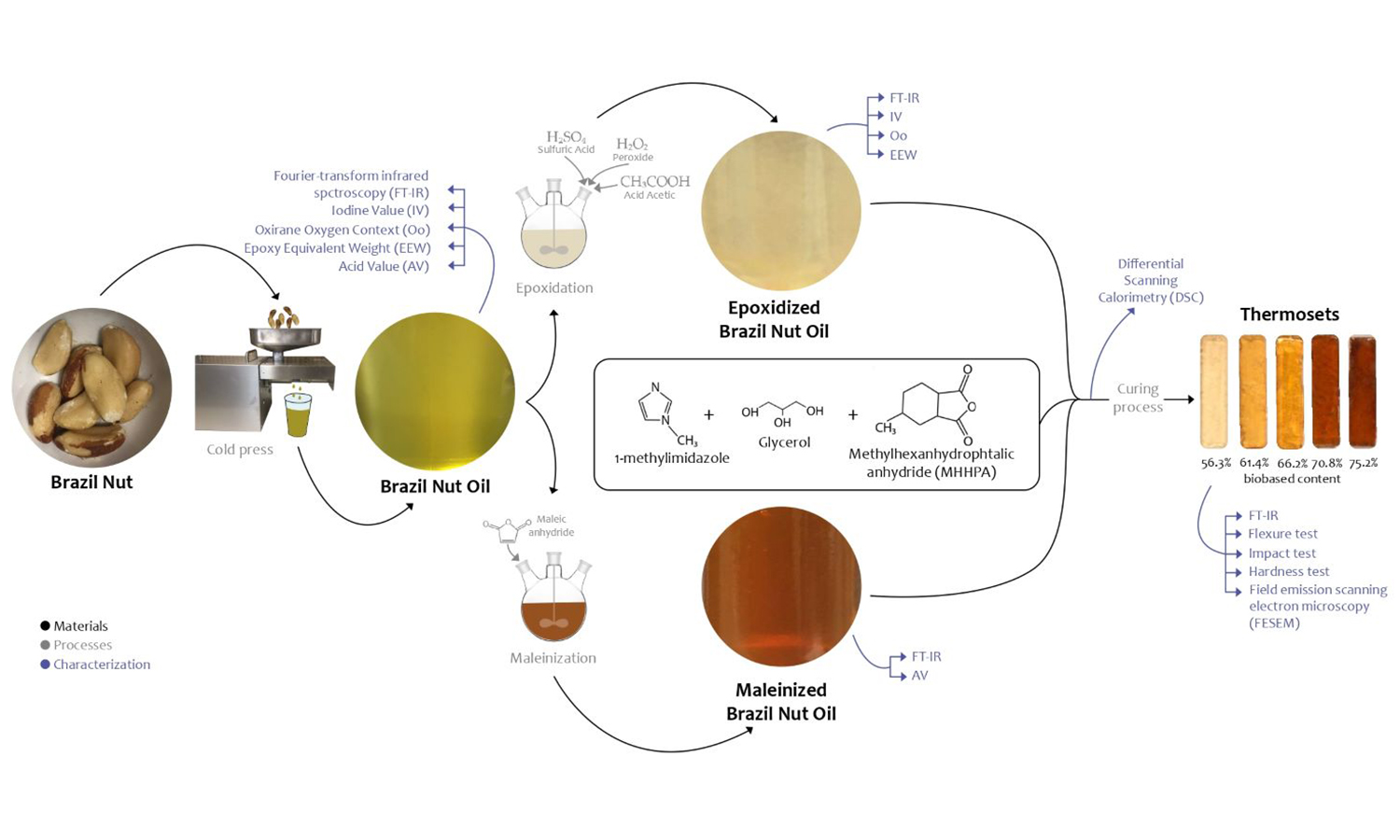

GRAPHICAL ABSTRACT

ABSTRACT

The present work describes, for the first time, the chemical modification and characterization of epoxy resins derived from Brazil nut oil (BNO). The development of a bio-based resin has been carried out by chemically modifying BNO, resulting in epoxidized Brazil nut oil (EBNO). Moreover, through a maleinization process, a crosslinker based on maleinized Brazil nut oil (MBNO) has been employed. Analysis using techniques like iodine value (IV) and oxirane oxygen content (Oo) indicate successful chemical modification. FTIR analysis confirms the presence of reactive functional groups in both EBNO and MBNO, which are responsible for resin crosslinking. Mechanical testing of the different bio-resins developed shows that, in the cured resins, flexural strength and modulus decrease with increasing MBNO content, indicating improved flexibility due to the introduction of MBNO as a crosslinker. Thermal analysis using differential scanning calorimetry (DSC) reveals exothermic peaks corresponding to resin curing appearing at progressively lower temperatures. Therefore, this study successfully modifies BNO and demonstrates its effectiveness as a precursor to develop bio-based epoxy resins. The resulting resins exhibit improved ductile and thermal properties, making them suitable for various applications requiring low mechanical stresses.

RELATED ARTICLES

Maciej Kisiel, Weronika Zając, Magdalena Włodarska, Łukasz Byczyński, Dominika Czachor-Jadacka, Beata Mossety-Leszczak, Gabriela Pietruszewska, Magda Droździel-Jurkiewicz, Jarosław Bieniaś

Vol. 18., No.5., Pages 516-532, 2024

DOI: 10.3144/expresspolymlett.2024.38

Vol. 18., No.5., Pages 516-532, 2024

DOI: 10.3144/expresspolymlett.2024.38

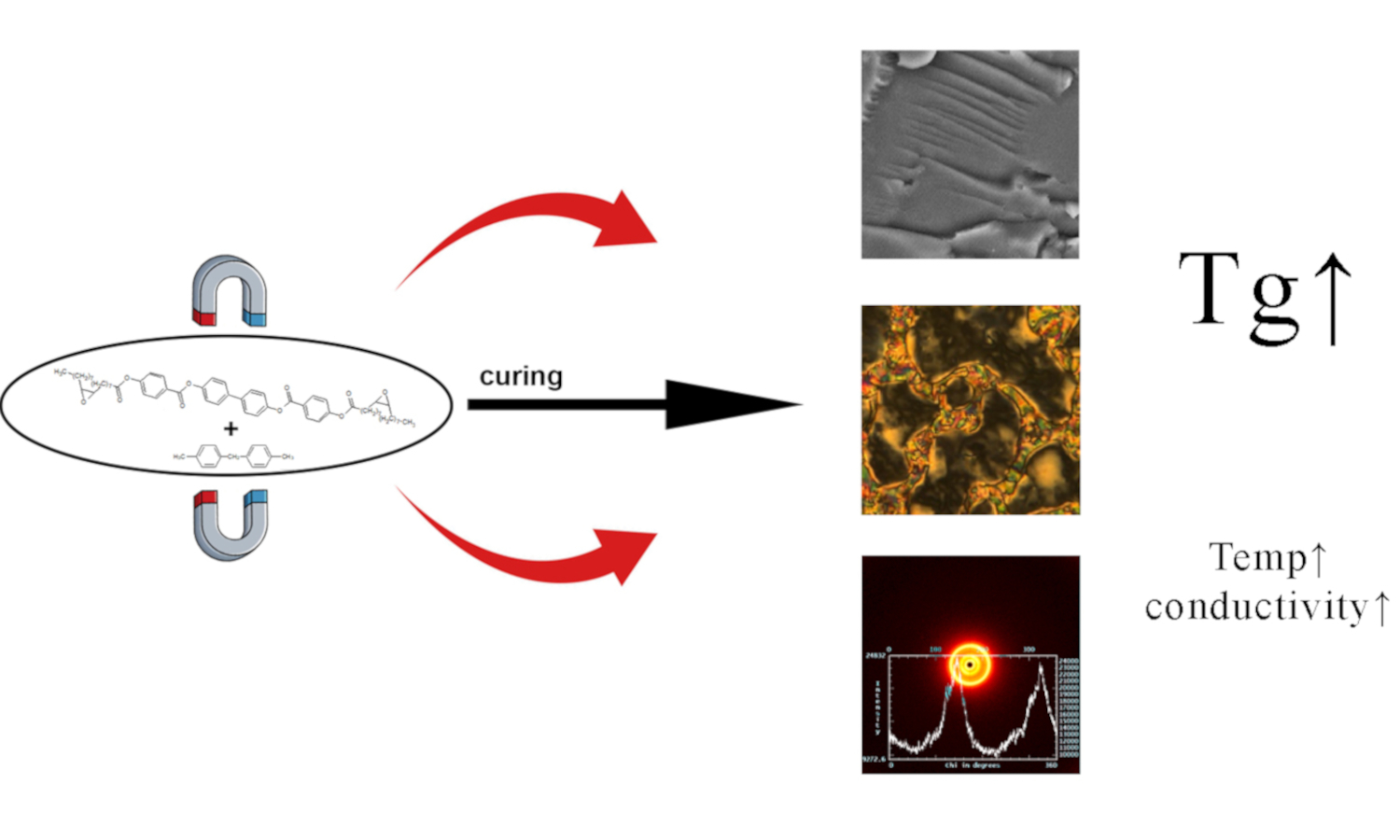

Novel nonterminal liquid crystalline epoxy resin has been synthesized, and its structure and nature have been determined via nuclear magnetic resonance (NMR) and polarized optical microscopy (POM). Then, it was cured with the use of 4,4′-diaminodiphenylmethane (4,4′-DDM). The curing process has been investigated via differential scanning calorimetry (DSC) and infrared spectroscopy (FTIR) methods. Polymerization has been conducted with (1.2 T) and without the presence of a strong magnetic field. The properties of the obtained polymers have been described using DSC, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), dielectric spectroscopy (DS) and X-ray scattering studies (WAXS/SAXS). It has been proved that the magnetic field induces molecular ordering and increases the glass transition temperature (Tg) by over 20 °C. The obtained ordered polymers are thermally stable up to over 300 °C, undergo vitrification at slightly elevated temperature (37.5 °C), and their electrical conductivity rises significantly at the transition to an elastic state, which, among other possibilities, makes them a proper candidate for a smart, lightweight polymers with tuneable properties by a subtle temperature rise and possibility of tailoring its structure by a magnetic field.

Jingwei Yu, Christian Breite, Frederik Van Loock, Thomas Pardoen, Yentl Swolfs

Vol. 18., No.2., Pages 133-143, 2024

DOI: 10.3144/expresspolymlett.2024.11

Vol. 18., No.2., Pages 133-143, 2024

DOI: 10.3144/expresspolymlett.2024.11

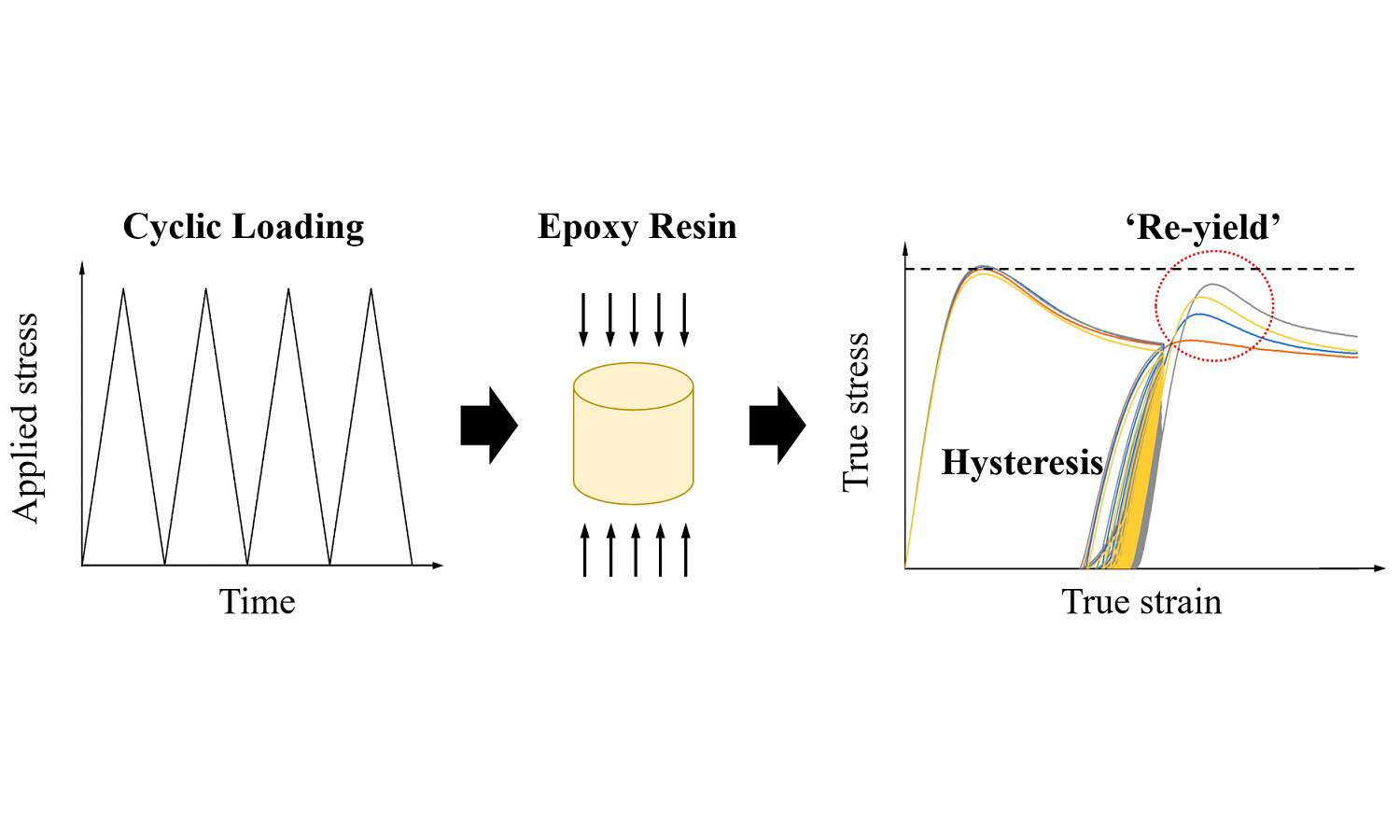

High-performance polymers are extensively used in various applications undergoing long-term cyclic loadings. The deformation behaviour of an amorphous thermoset epoxy resin undergoing cyclic compressive loading is investigated for a range of applied deformation levels. The measurements indicate significant hysteresis upon repeated loading and unloading cycles with progressive accumulation of plastic strain. Cyclic damage leads to a reduction of the stress needed to reach the peak strain per cycle, while cyclic stiffening corresponding to an increase of elastic modulus with increasing number of cycles is observed, attributed to chain orientation effects. The dissipated energy asymptotically decreases to zero under strain-controlled cycling conditions. Interestingly, when monotonically loaded after cycling, the epoxy exhibits an increase in yield strength. This ‘re-yield’ stress level is closely related to the selected value of the peak (unloading) strain level and increases with increasing number of loading cycles.