Challenges and opportunities of polymer recycling in the changing landscape of European legislation

Vol. 17., No.11., Pages 1081-1081, 2023

DOI: 10.3144/expresspolymlett.2023.81

DOI: 10.3144/expresspolymlett.2023.81

GRAPHICAL ABSTRACT

RELATED ARTICLES

Sandra Paszkiewicz, Kamila Sałasińska, Zaida Ortega, Mateusz Barczewski, Jacek Andrzejewski, Konrad Walkowiak, Izabela Irska, Magdalena Jurczyk Kowalska, Anna Boczkowska, Marcin Borowicz, Joanna Paciorek-Sadowska, Elżbieta Piesowicz, Katarzyna Pokwicka-Croucher

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

Vol. 19., No.12., Pages 1286-1309, 2025

DOI: 10.3144/expresspolymlett.2025.95

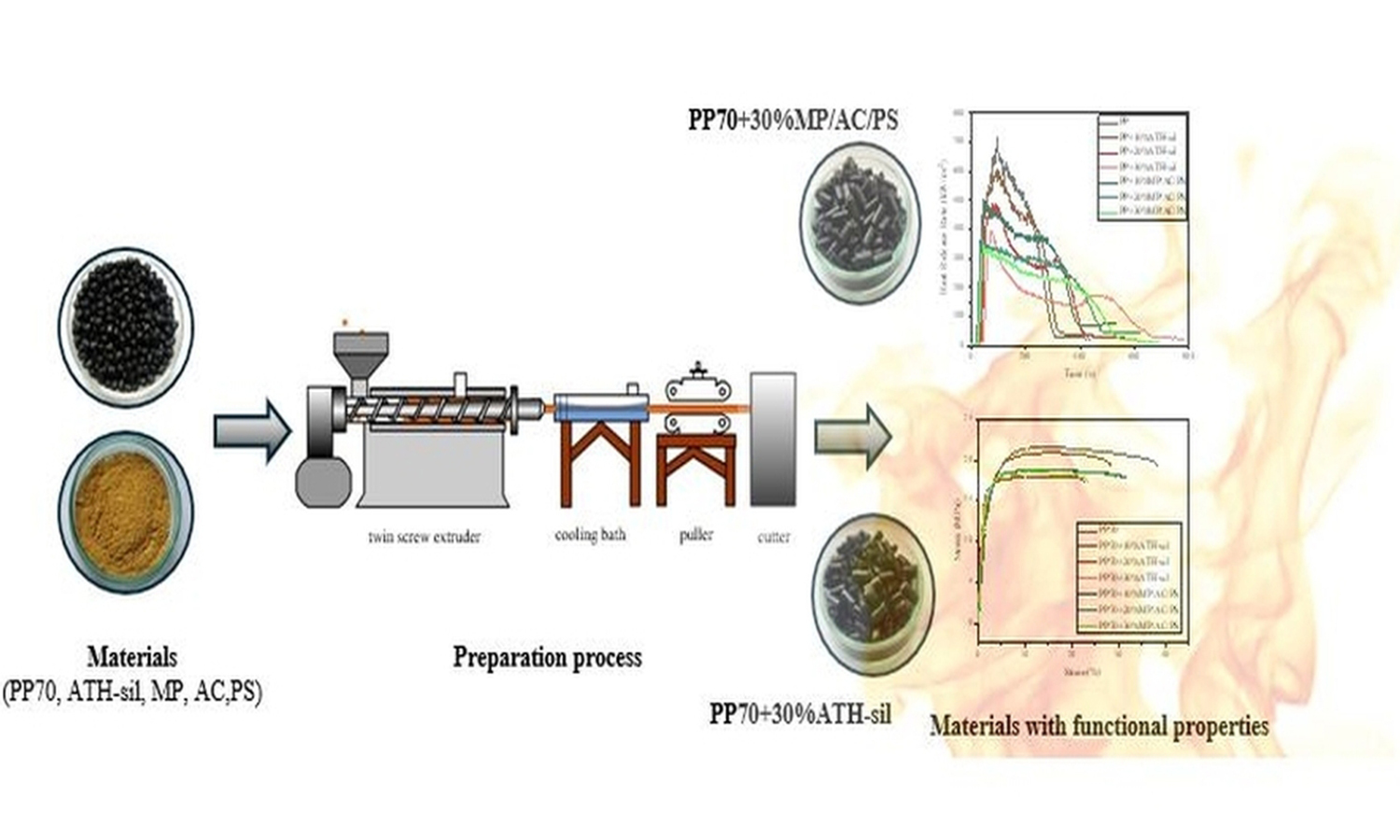

Two series of polymer blends based on post-consumer polypropylene (rPP) and tire rubber crumbs (Trc) under the trademark ECOPLASTOMER® PP70 with a mutual ratio of components 70/30 wt%, containing 10, 20, and 30 wt% of flame retardants, have been prepared using a twin-screw extruder. The influence of commercially available silane-treated alumina trihydrate (ATH-sil) with the eco-friendly system based on melamine phosphate (MP), aluminum hydroxide (AC), and peanut shells (PS), used as flame retardant agents, on the mechanical, thermal, and flammability properties of polymer blends was assessed – the incorporation of ATH-sil results in the appearance of peaks related to OH groups in the Fouriertransform infrared spectroscopy (FTIR) spectra. Similar observations are made for the MP/AC/PS system. differential scanning calorimetry (DSC) analysis revealed that using the selected flame retardants did not impact the melting and crystallization temperatures of the polymer. Tensile strength experienced a minor decrease, particularly in compositions containing more than 20 wt% of the flame retardants, while hardness remained unaffected by their share. Both flame retardants reduced the flammability of the modified polypropylene/rubber powder blends, and the most favorable outcomes were achieved with ATH-sil; however, only when employed at a minimum of 30 wt%. The formulated MP/AC/PS system proved more adept at reducing flammability and smoke emissions at lower flame retardant levels (up to 20 wt%).

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

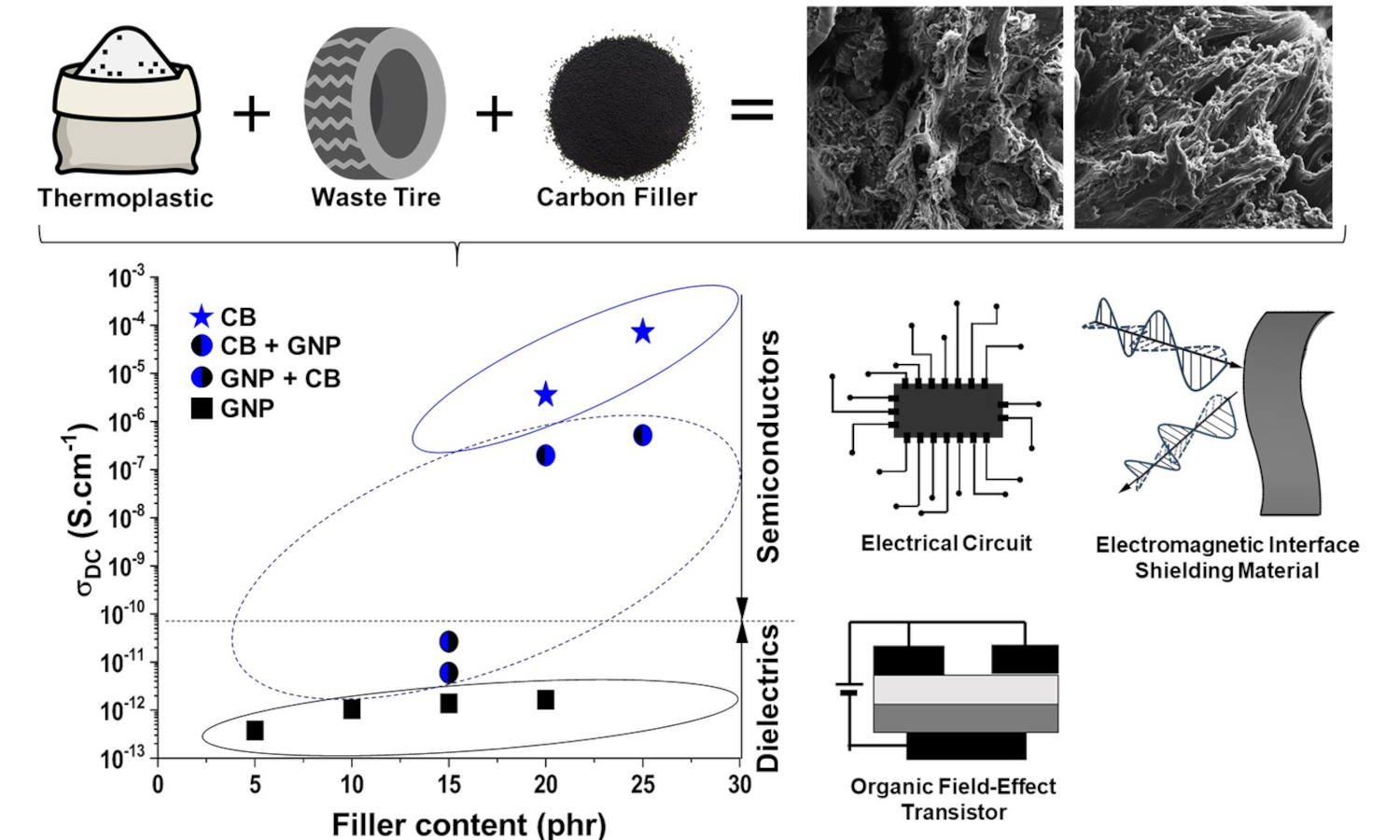

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

Katalin Bocz, Ferenc Ronkay

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

Vol. 19., No.9., Pages 860-861, 2025

DOI: 10.3144/expresspolymlett.2025.65

This is an editorial article. It has no abstract.

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.

Andrea Toldy

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

This is an editorial article. It has no abstract.