Utilization of composite ZnO in SBR/BR compounds and its effect on the cure and physicomechanical properties

Cansu Börüban Bingöl, Şeyda Polat, Ş. Hakan Atapek

Vol. 18., No.5., Pages 461-474, 2024

DOI: 10.3144/expresspolymlett.2024.34

DOI: 10.3144/expresspolymlett.2024.34

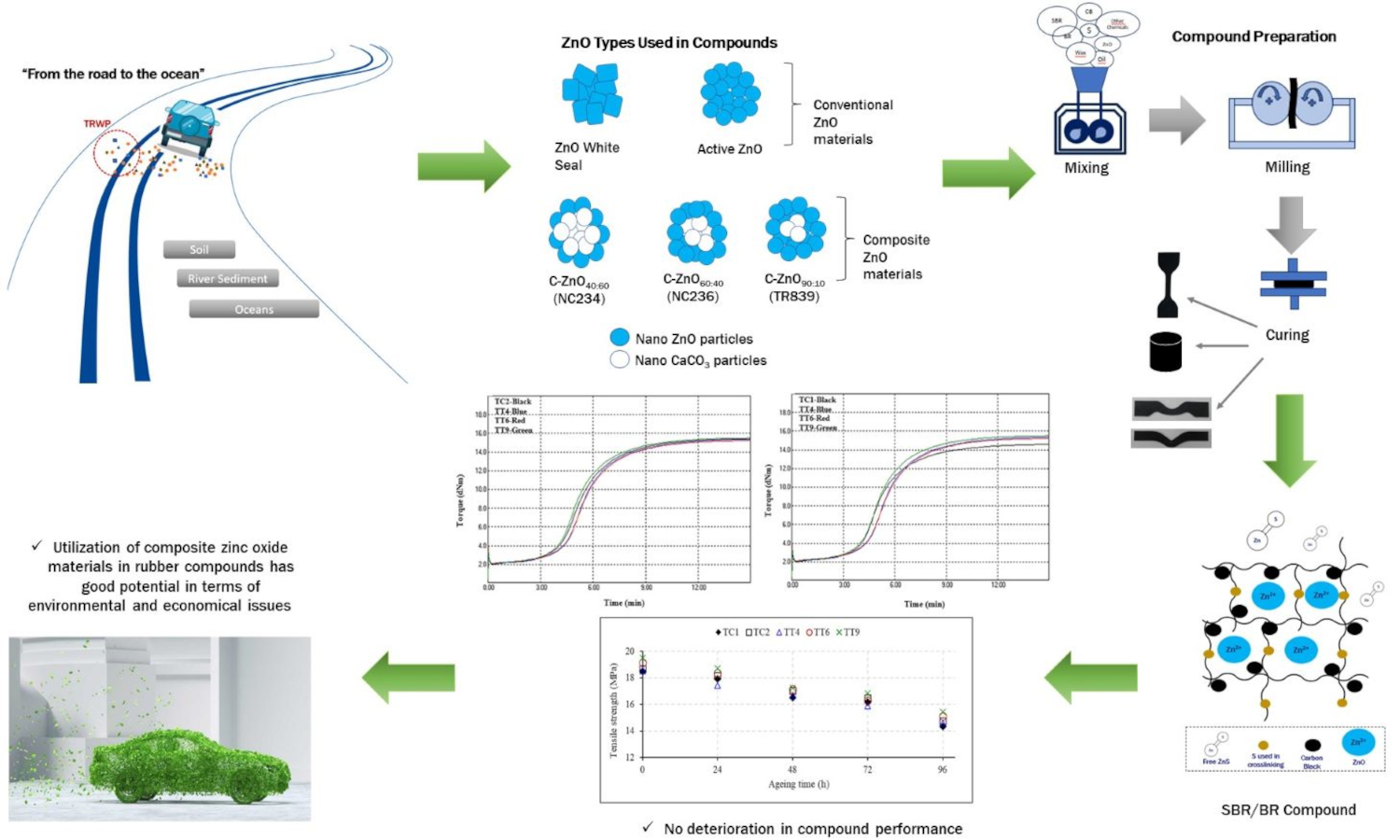

GRAPHICAL ABSTRACT

ABSTRACT

Zinc complexes have a considerable impact on human health and the environment, especially on aquatic wildlife. One of the primary sources of zinc release to the environment is worn rubber particles from tires. The environmental footprint of zinc oxide (ZnO) during production, use, and landfilling has prompted researchers to reduce its use in rubber formulations due to ecological and economic concerns. In this study, composite ZnO materials where ZnO particles are coated on precipitated calcium carbonate (CaCO3) are used in styrene butadiene rubber/butadiene rubber (SBR/BR) compounds, and their performance is compared with white seal ZnO and active ZnO. Trial compounds are prepared on a laboratory scale using composite ZnO materials with ZnO:CaCO3 ratios of 40:60, 60:40, and 90:10, and control compounds with white seal and active ZnO. All compounds are tested to evaluate their curing and physico-mechanical properties. It is observed that the surface area of ZnO plays an essential role in crosslink density and, hence, compound performance. Trial materials have no negative effect on the curing and mechanical properties of the compounds. Thus, it is concluded that composite ZnO materials can be used as alternatives to both white seal ZnO and active ZnO. They have environmental and economic advantages due to their lower ZnO content. The compound recipe has the potential to be used for tire tread compounds.

RELATED ARTICLES

Quentin Watel, Aurélie Cayla, Fabien Salaün, François Boussu

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

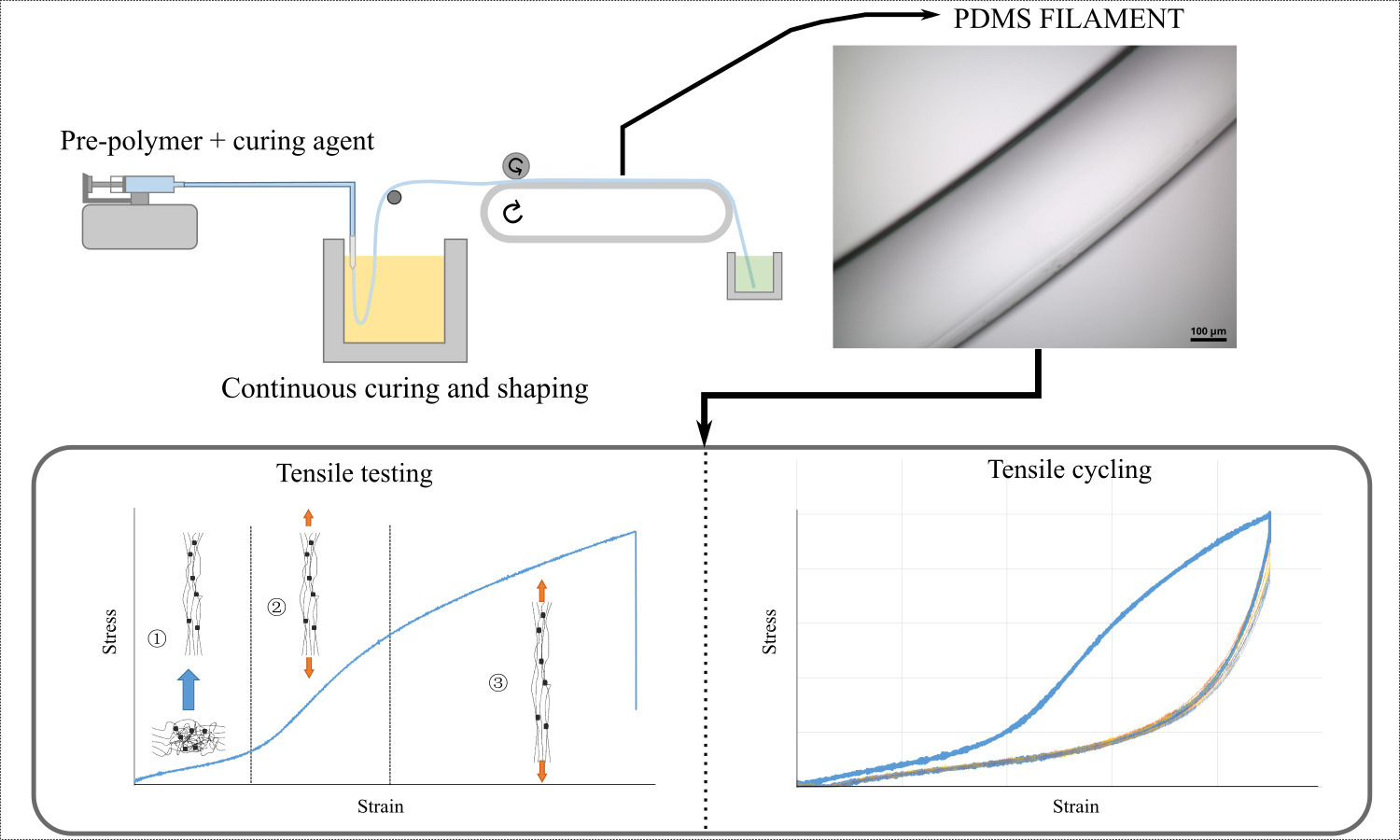

In this work, a PDMS spinning technique is developed and enables the continuous production of a filament with a circular cross-section (~500 μm diameter). The production of continuous silicone polymer filaments can be useful in the textile field to provide new properties in applications such as weaving, knitting or composite reinforcement. The method involves injecting the pre-polymer and curing agent mixture into a heated oil bath (202–215 °C) to simultaneously shape and cure the PDMS. The morphological and mechanical properties of the filament are studied regarding the production parameters (formulation, needle diameter, bath temperature, conveyor belt speed). The most homogeneous filament is produced at the highest temperature (215°C) and conveyor belt speed (13.6 m∙min–1). When subjected to cyclic mechanical stress, the PDMS filament produced exhibits stable mechanical behavior, making it suitable for a wide range of applications.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Anoma Thitithammawong

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

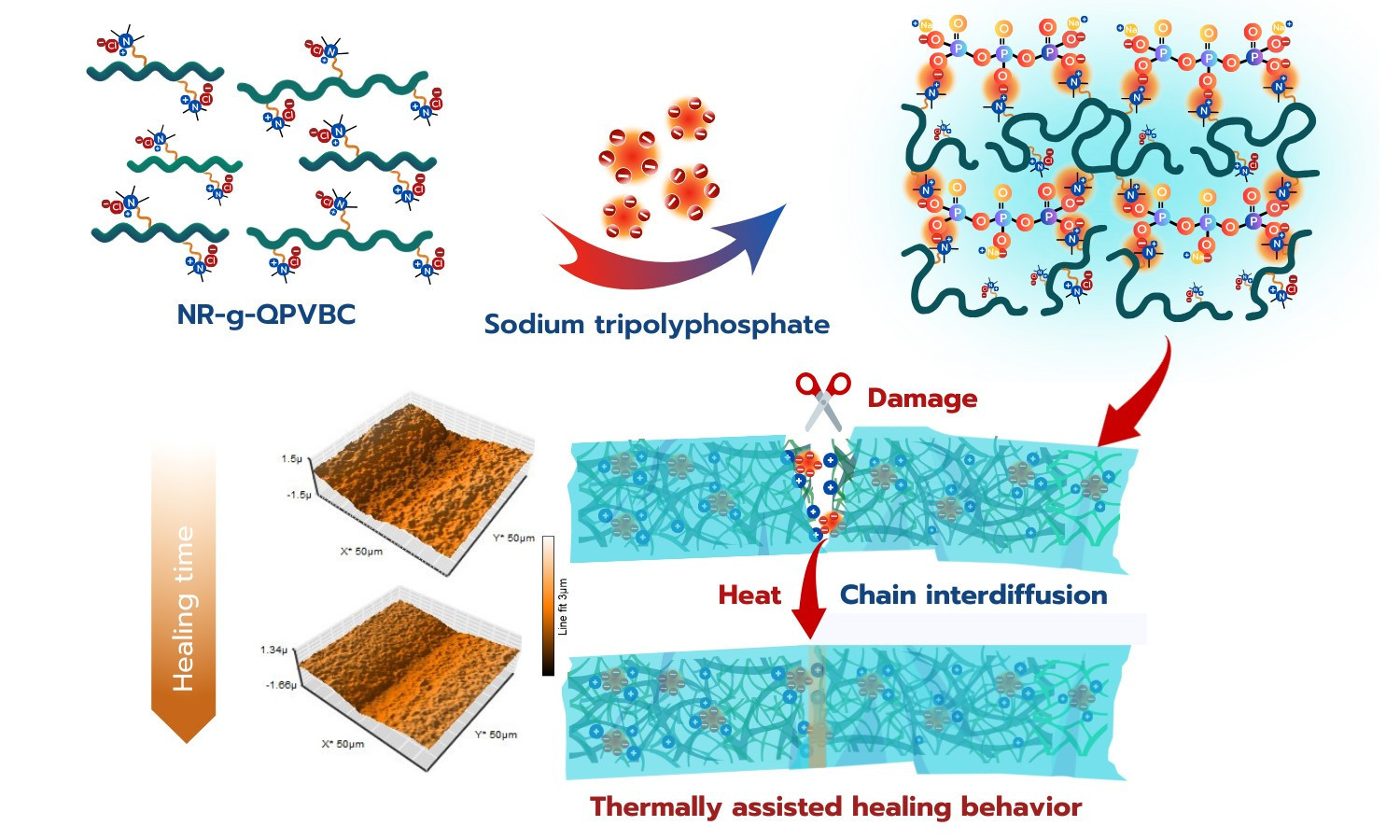

This work reported a practical approach to turning conventional natural rubber (NR) into a thermally healable rubber. 4-vinylbenzyl chloride was first polymerized in the NR latex to yield graft copolymers of NR and poly(vinylbenzyl chloride), NR-g-PVBC. The cutting and rejoining process was used to study the healing ability of latex film. The healing behavior was observed after the reassembled film was heated at 100 °C for 1 h and then allowed to heal continuously at room temperature (RT). The healed film displayed a 58.44% regain of the tensile strength (4.57 MPa) after being allowed to recover at RT for 72 h. Additionally, the chloromethyl moieties in the NR-g-PVBC could be converted into quaternary ammonium (QA) groups by reaction with trimethylamine, producing the quaternized NR-g-PVBC (NR-g-QPVBC). Ionic crosslinking of the NR-g-QPVBC film was achieved by incorporating sodium tripolyphosphate (STPP). The latex film had a tensile strength of 15.32 MPa and could withstand a strain of 868% when ionically cured with 2 phr of STPP. After the healing process, the cured film showed a healing efficiency of 49.67% in tensile strength (7.61 MPa). Furthermore, a suturing test was performed to investigate the feasibility of developing a suture training pad from the corresponding cured film. The film’s ability to heal with heat assistance was its significant practical advantage, enhancing its realism and mimicking the healing process in human skin.

Nursyafiqah Zaini, Saiful Amri Mazlan, Siti Aishah Abdul Aziz, Mohd Aidy Faizal Johari, Ubaidillah Ubaidillah, Nur Azmah Nordin, Muntaz Hana Ahmad Khairi, Megat Ahmad Kamal Megat Hanafiah

Vol. 18., No.7., Pages 728-741, 2024

DOI: 10.3144/expresspolymlett.2024.54

Vol. 18., No.7., Pages 728-741, 2024

DOI: 10.3144/expresspolymlett.2024.54

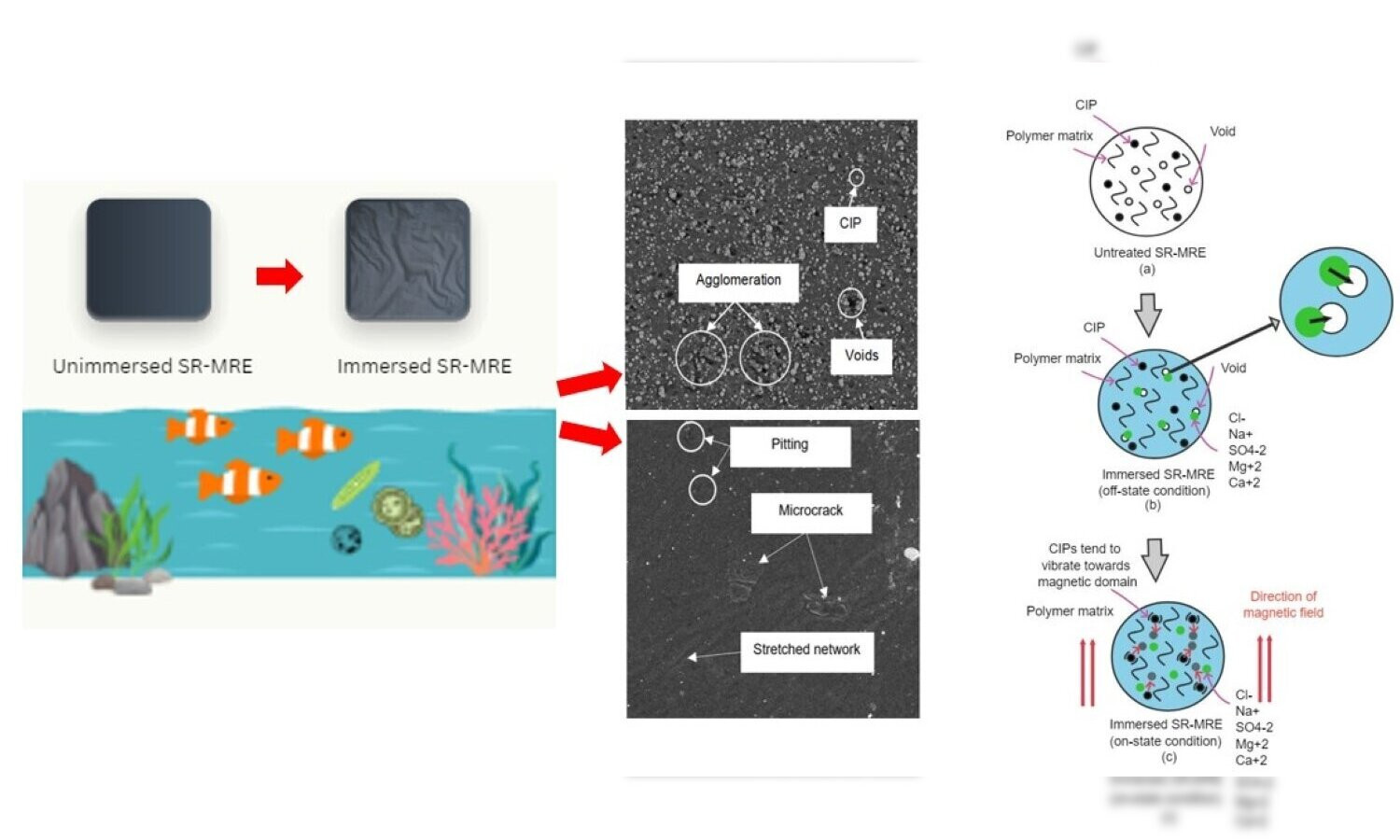

Silicone rubber magnetorheological elastomers (SR-MREs) are increasingly recognized for their resilience in marine conditions, offering prolonged service life and durability. This study evaluates the one-month durability of silicone rubber magnetorheological elastomers (SR-MREs) under seawater conditions. Results revealed a 6% reduction in hardness and an 8% decrease in Young’s modulus compared to unimmersed samples. Morphological and attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR) analyses supported these findings, revealing surface defects and chemical bonding changes. The immersed SR-MRE displayed a notable 250% increase in elongation at break, highlighting enhanced elasticity. Rheological properties revealed complex mechanical behavior, with an initial increase in storage modulus from 0.25 to 0.38 MPa in the presence of a magnetic field, followed by a gradual decrease to 0.15 MPa at 0 A and 0.52 Mpa at 5 A with strain. Additionally, this study proposes an illustrative mechanism to elucidate the relationship between seawater elements and SR-MRE behavior, enhancing our understanding of its mechanical properties and degradation in marine environments, thus highlighting SR-MRE’s potential as a durable material compared to traditional rubber composites.

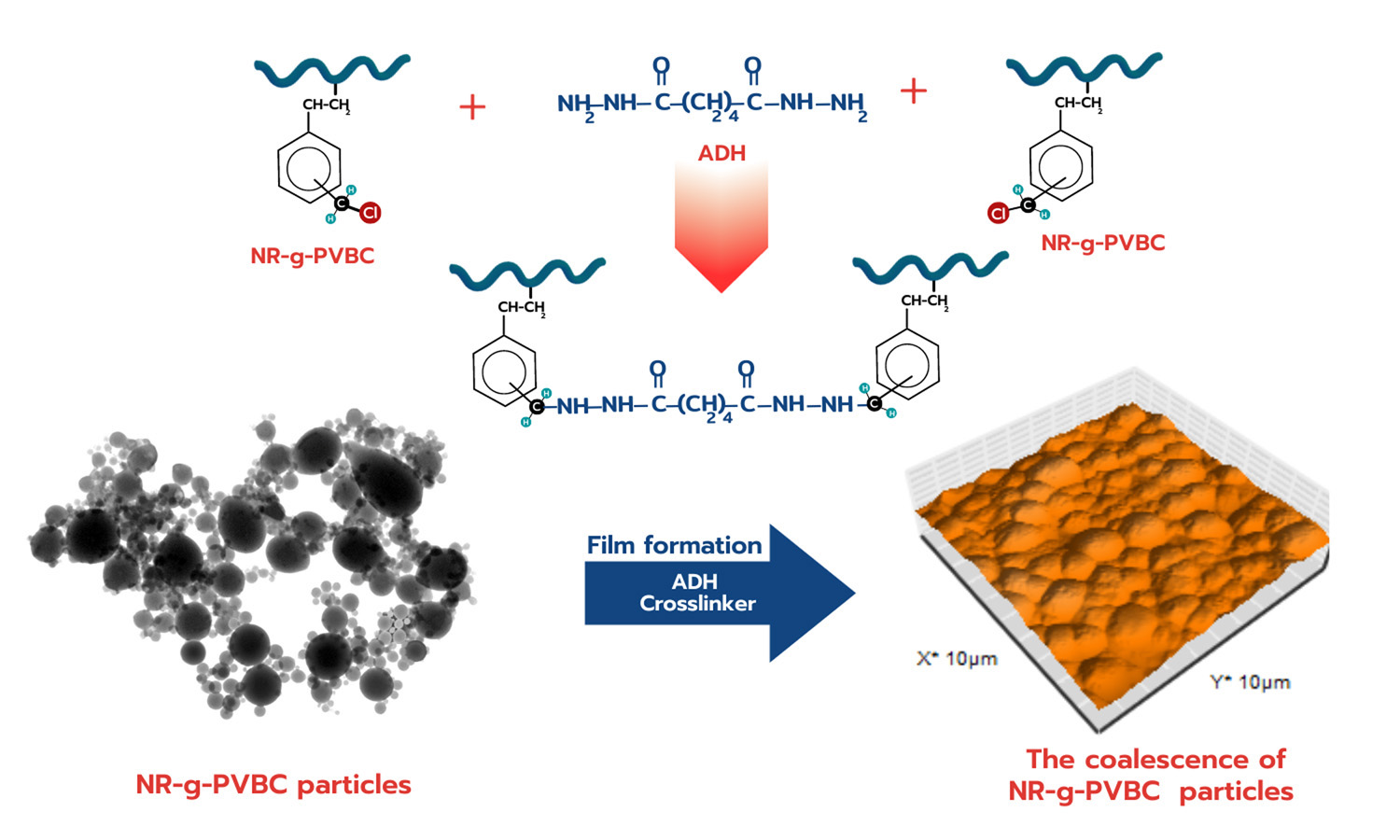

Accelerator and zinc-free prevulcanized latex based on natural rubber-bearing benzyl chloride groups

Anchisa Bunsanong, Bencha Thongnuanchan, Rattanawadee Ninjan, Subhan Salaeh, Natinee Lopattananon, Abdulhakim Masa

Vol. 18., No.2., Pages 229-242, 2024

DOI: 10.3144/expresspolymlett.2024.16

Vol. 18., No.2., Pages 229-242, 2024

DOI: 10.3144/expresspolymlett.2024.16

The present study aimed to prepare prevulcanized latex from modified natural rubber (NR) latex, graft copolymers of natural rubber and poly(vinylbenzyl chloride), NR-g-PVBC. The prevulcanized latex was prepared by heating NR-g-PVBC latex in the presence of adipic acid dihydrazide (ADH). The study showed that the tensile strength of the NR-g-PVBC films with ADH was significantly higher than that without ADH. Interactions of NR-g-PVBC with ADH were further investigated using X-ray photoelectron spectroscopy (XPS). Higher storage modulus (E′) in the rubbery plateau region was also observed for the films with ADH than that without ADH. These results corroborated that the crosslinking reaction occurred in the film with the addition of ADH. It was found that the optimal prevulcanization time was 20 min at 55 °C. After that, the effect of storage on the tensile properties of the prevulcanized latex was studied. Atomic force microscopy (AFM) analysis was performed to follow changes in the surface morphology of films obtained from the prevulcanized latex. A zeta potential value of –37.83 was observed for the prevulcanized latex after being stored for 60 days. Therefore, the present study demonstrated that grafting poly(vinylbenzyl chloride) onto NR particles offered an opportunity to prepare a new type of prevulcanized latex. This new system was accelerator-free and zinc-free, considered more environment-friendly than a sulfur-prevulcanization system.