Factors and processes determining the impact resistance of PP impact copolymers with multi-phase structure

Milán Ferdinánd , Michael Jerabek, Róbert Várdai

, Michael Jerabek, Róbert Várdai , Emese Pregi

, Emese Pregi , Thomas Lummerstorfer, Markus Gahleitner, Gábor Faludi, János Móczó

, Thomas Lummerstorfer, Markus Gahleitner, Gábor Faludi, János Móczó , Béla Pukánszky

, Béla Pukánszky

, Michael Jerabek, Róbert Várdai

, Michael Jerabek, Róbert Várdai , Emese Pregi

, Emese Pregi , Thomas Lummerstorfer, Markus Gahleitner, Gábor Faludi, János Móczó

, Thomas Lummerstorfer, Markus Gahleitner, Gábor Faludi, János Móczó , Béla Pukánszky

, Béla Pukánszky

Vol. 18., No.4., Pages 406-419, 2024

DOI: 10.3144/expresspolymlett.2024.30

DOI: 10.3144/expresspolymlett.2024.30

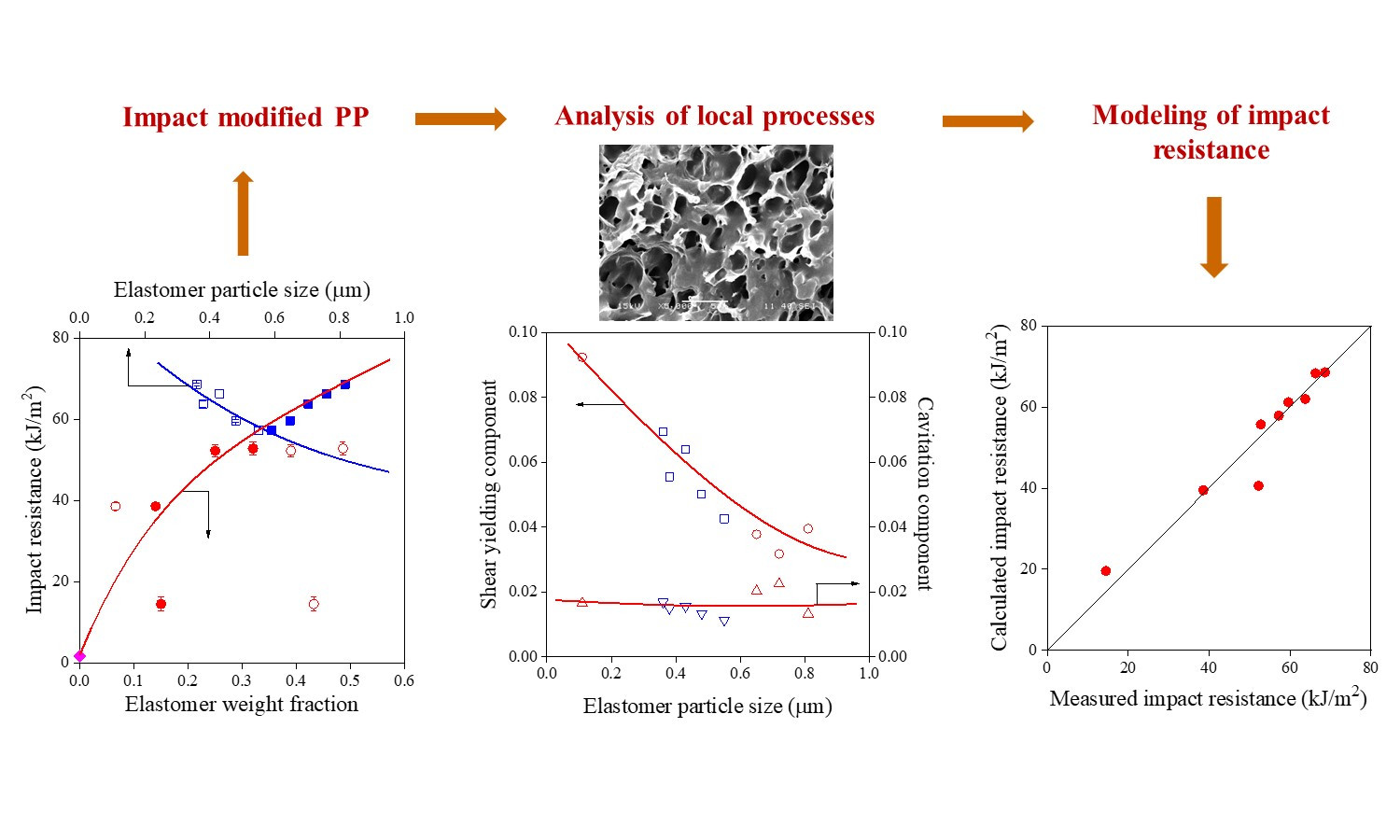

GRAPHICAL ABSTRACT

ABSTRACT

The

impact resistance of four polypropylene impact copolymers (ICPs) with

multi-phase structures and widely differing characteristics was related to

their structure. Blends were prepared from one of them and a high-density

polyethylene (HDPE) to improve impact strength further. The structure of the

materials was characterized by microscopy and dynamic mechanical thermal

analysis. Mechanical properties were determined by tensile and impact testing,

while local deformation processes were followed by volume strain measurements.

The results obtained in the study proved that the shear-yielding of the matrix

contributes the most among local processes to the increase of impact strength,

while cavitation has a small effect on this latter property since its energy

absorption is negligible. Both increasing elastomer content and decreasing

particle size favor shear-yielding, thus improving impact strength. Considering

the importance of elastomer content and elastomer particle size, a simple but

very good model was created describing the dependence of the impact strength of

ICPs on these latter two factors by using linear regression analysis. Although

the addition of HDPE increases the fracture resistance of ICPs further, the

extent of improvement is moderate, and the approach is economically

disadvantageous.