Electrospun organically modified sepiolite/PVDF coating on polypropylene separator to improve electrochemical performance of lithium-ion battery

Xianli Sun, Jiahao Xu, Xiaoke Zhi, Jingpeng Zhang, Kangwei Hou, Yuhan Bian, Xiaolin Li, Li Wang , Guangchuan Liang

, Guangchuan Liang

, Guangchuan Liang

, Guangchuan LiangVol. 18., No.6., Pages 575-591, 2024

DOI: 10.3144/expresspolymlett.2024.43

DOI: 10.3144/expresspolymlett.2024.43

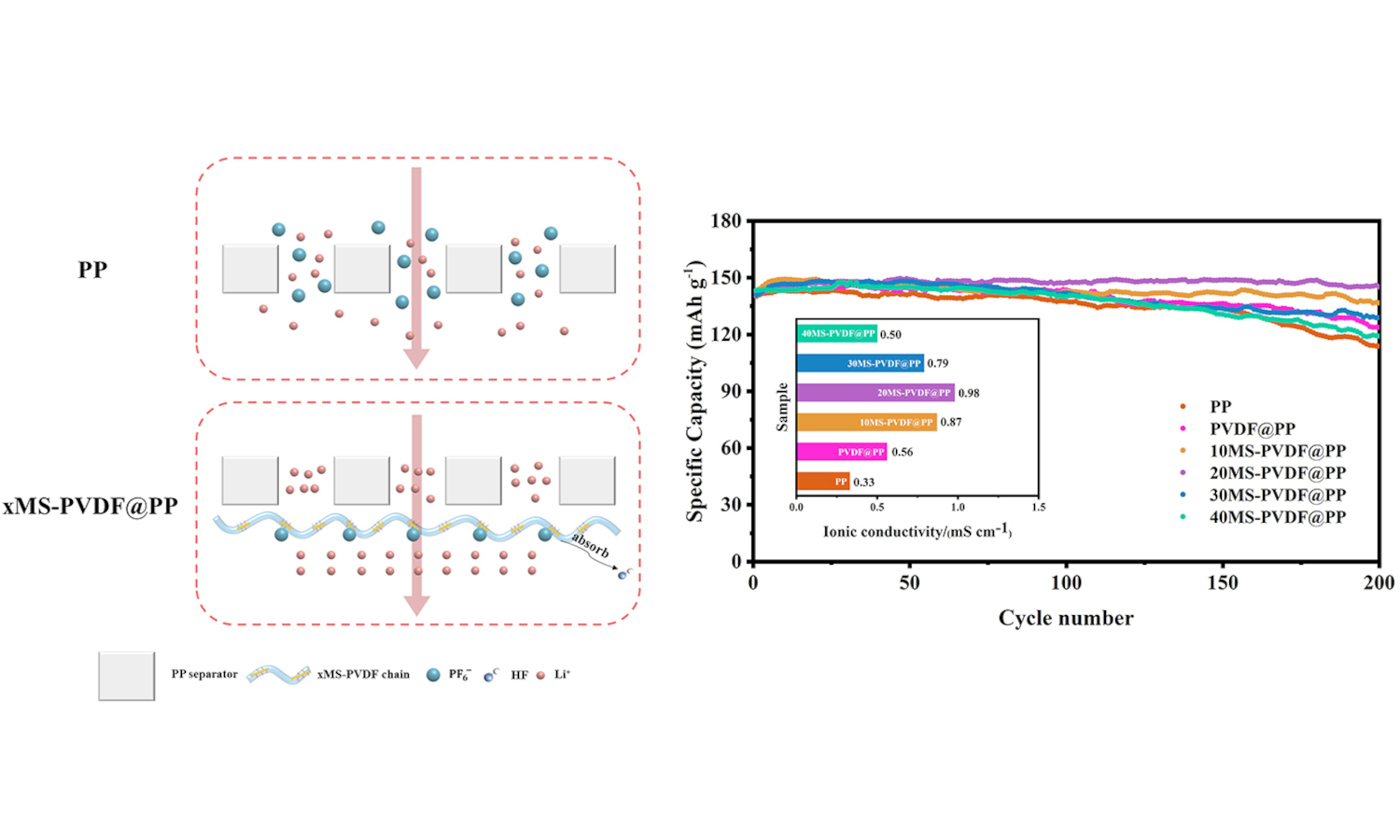

GRAPHICAL ABSTRACT

ABSTRACT

As a key component of lithium-ion batteries, a separator with excellent electrolyte wettability and good thermal stability has an important impact on the overall performance of lithium-ion batteries. Herein, a PVDF/sepiolite electrospun layer was coated on one side of the PP separator via electrospinning technology to prepare the composite separator (xMS-PVDF@PP) with sepiolite nanofibers modified with vinyltriethoxysilane (VTES) to ameliorate their dispersibility and compatibility with PVDF polymer matrix. The effect of modified sepiolite addition amounts on the physical and electrochemical properties of composite separator was intensively studied. It is found that the as-prepared xMS-PVDF@PP composite separator displays enhanced porosity, electrolyte uptake, thermal stability and Li+ ion transport kinetics than pristine PP separator. Specifically, Li|LiFePO4 battery with 20MS-PVDF@PP as separator shows the best rate and cycling performance, with a specific discharge capacity of 115.3 mAh·g–1 at 10C rate and a capacity retention rate of 97.06% after 200 cycles at 1C rate. The sepiolite in the electrospun layer can immobilize PF6– anion to facilitate the uniform distribution of Li+ ions and then inhibit the lithium dendrite growth, as well as absorb HF to alleviate Fe2+ dissolution from LiFePO4 cathode, thereby further improving the electrochemical performance of LiFePO4 battery.

RELATED ARTICLES

Shuang Gao, Yuan Lyu, Jieting Geng, Lin Xia

Vol. 20., No.3., Pages 279-291, 2026

DOI: 10.3144/expresspolymlett.2026.22

Vol. 20., No.3., Pages 279-291, 2026

DOI: 10.3144/expresspolymlett.2026.22

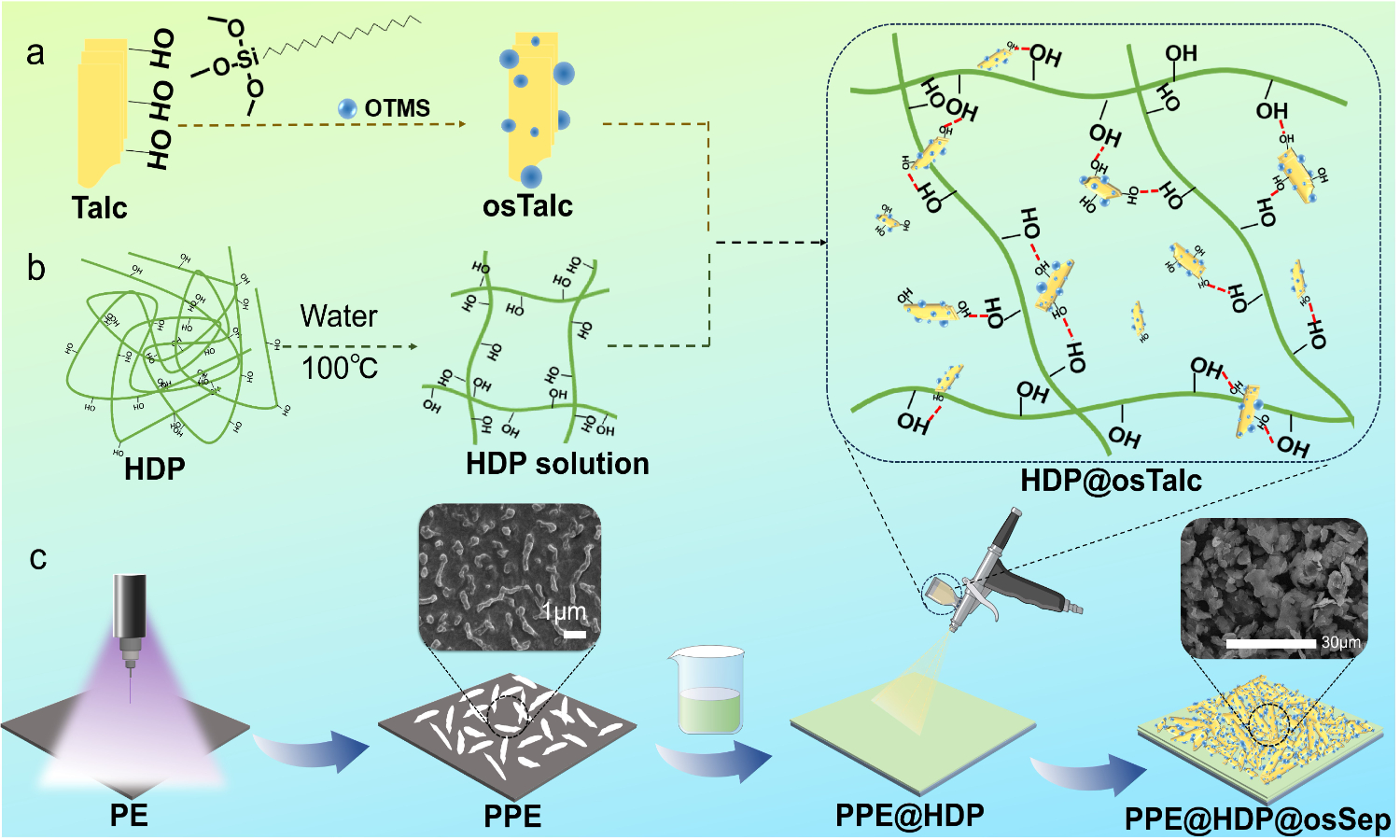

Inspired by natural structures, this study successfully developed innovative composites through the strategic integration of biomimetic concepts and advanced material engineering techniques. Using plasma-treated polyethylene (PPE) film as the substrate, hydroxypropyl distarch phosphate (HDP) as the bioinspired adhesive layer, and modified talc (osTalc) as the functional modifier, a series of PPE@HDP@osTalc composites were fabricated via an optimized spray-coating process. The as-prepared composite demonstrates exceptional superhydrophobicity and mechanical flexibility. Chemical stability assessment of the PPE@HDP@osTalc composites demonstrated strong interfacial bonding between the PPE, HDP, and osTalc components. The development of this bioinspired smart composite not only provides new insights for designing functional materials but also demonstrates significant potential for applications in emerging fields such as flexible electronics, marine engineering, and biomedical devices.

Nurul Ain Arjuna, Noor Maizura Ismail, S. M. Anisuzzaman, Rachel Fran Mansa, Murni Sundang, Akhtar Razul Razali

Vol. 19., No.4., Pages 441-454, 2025

DOI: 10.3144/expresspolymlett.2025.32

Vol. 19., No.4., Pages 441-454, 2025

DOI: 10.3144/expresspolymlett.2025.32

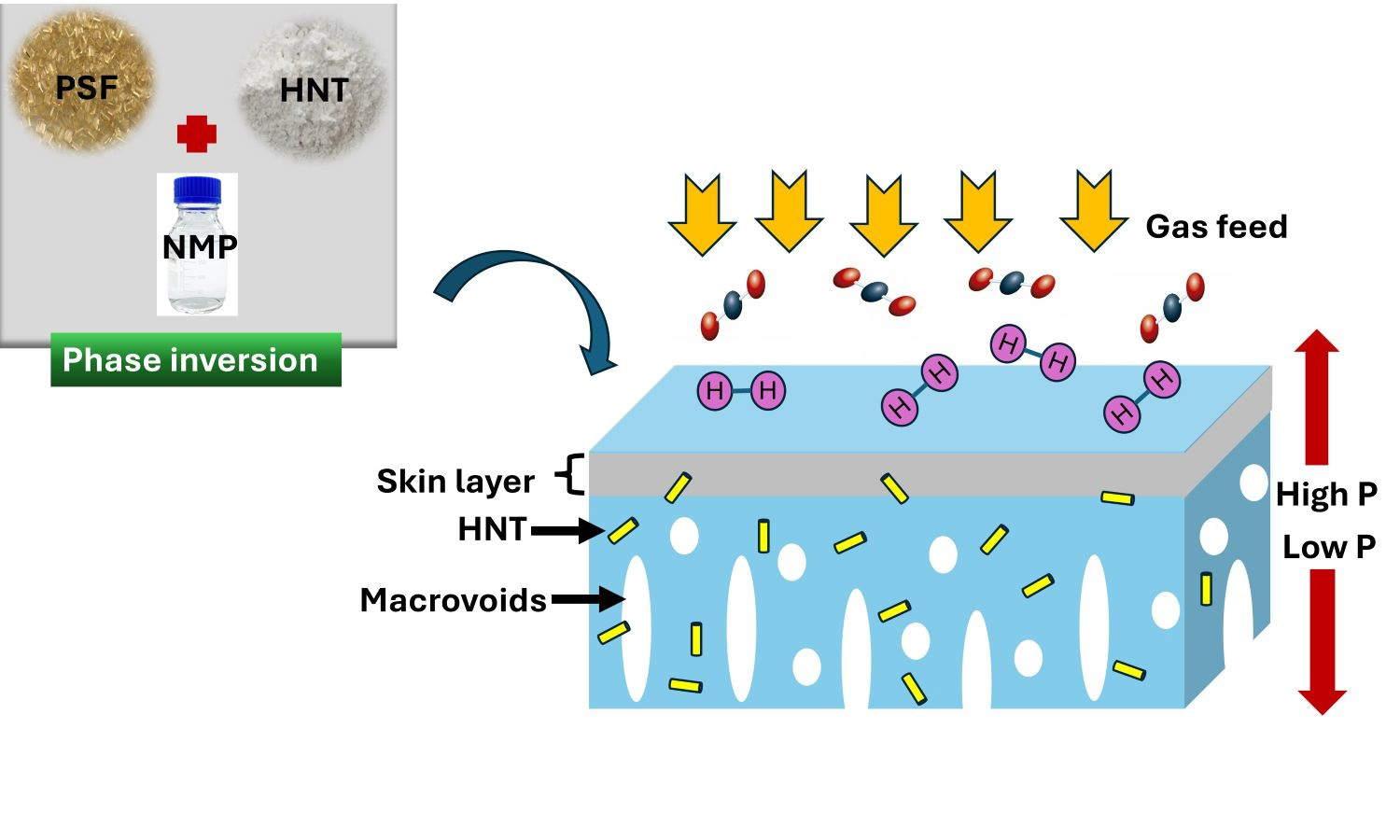

Membrane-based gas separation offers practical advantages for hydrogen (H2) and carbon dioxide (CO2) separation for steam methane reforming units. Modification of membrane materials can optimize membrane performance. In this study, the central focus is on investigating the effect of different loadings of halloysite nanotubes (HNTs) (0, 0.5, 1.0, 1.5, and 2.0 wt%) incorporated into a blend of cellulose acetate (CA) and polysulfone (PSF) polymers with the aim of improving the membrane properties. The Fourier transform infrared spectroscopy-attenuated total reflectance (FTIR-ATR) results confirmed that the primary functional groups of PSF and CA remained intact upon HNTs incorporation, with no distinct HNT peaks altering the main chemical functionalities. Field emission scanning electron microscopy- energy dispersive X-ray spectroscopy (FESEM-EDX) analyses showed that low concentrations of HNTs (0.5 wt%) improved surface smoothness and reduced macrovoids, beneficial for gas separation. Cross-sectional images of FESEM micrographs showed no evidence of obvious agglomeration, suggesting a good dispersion of HNTs. From the X-ray diffraction (XRD) analysis, all the membrane samples retained an amorphous structure, indicating that the incorporation of HNT has less effect on the polymer chain properties of the membranes.