Controllable design and modeling of gradient porous structures by phase field theory

Hangming Shen, Xingzhe Zhao, Lihong Yang, Jiantao Yang

Vol. 18., No.9., Pages 942-949, 2024

DOI: 10.3144/expresspolymlett.2024.71

DOI: 10.3144/expresspolymlett.2024.71

GRAPHICAL ABSTRACT

ABSTRACT

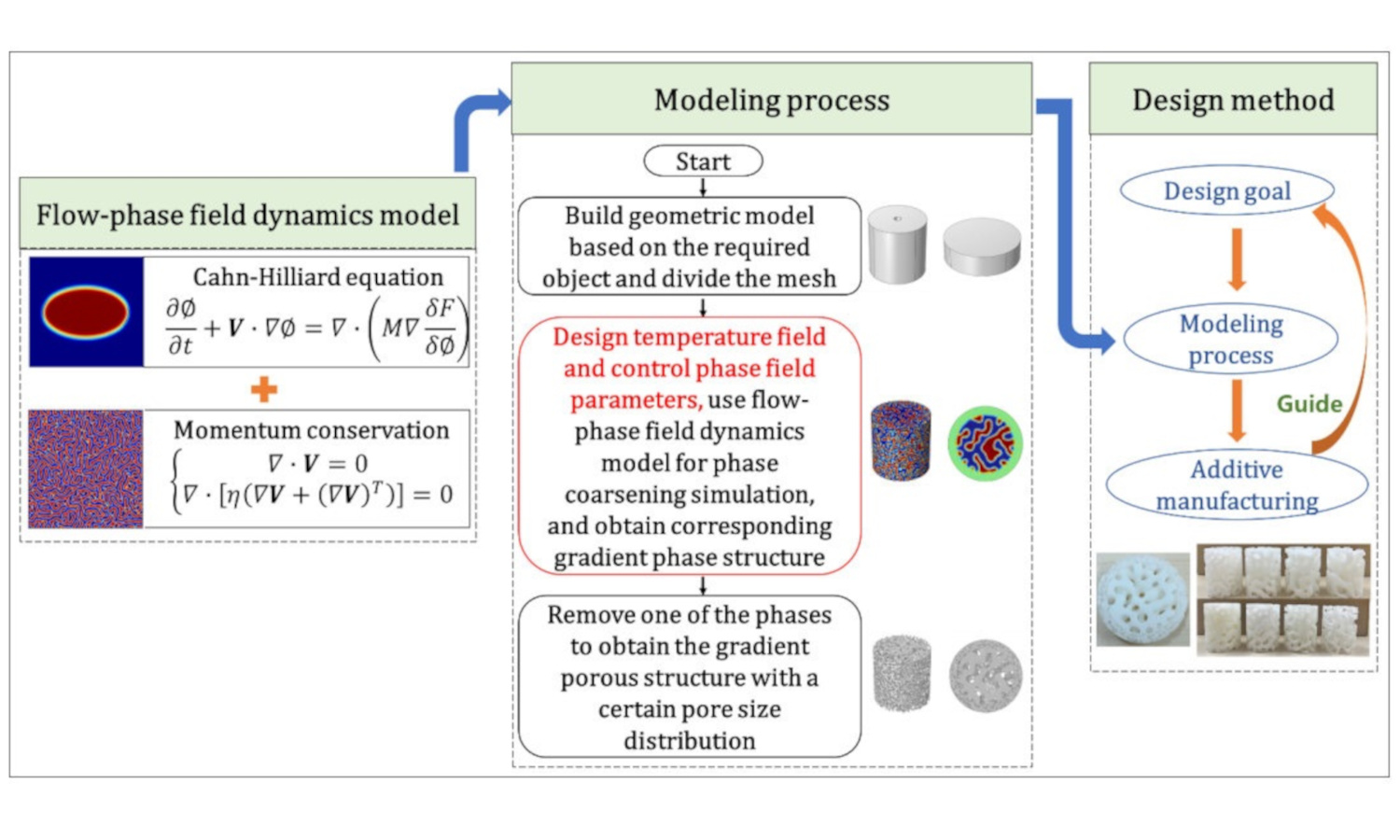

In this study, a novel methodology for the fabrication of gradient porous structures is introduced, predicated upon the phase evolution characteristics of immiscible polymer blends. Initially, a comprehensive flow-phase field dynamics model is developed. This model couples the principles of phase field theory and the dynamics of fluid flow to the two-phase evolution process, facilitating a numerical simulation of the phase evolution. Subsequently, the phase field parameters of model are determined and combined with the temperature field, thereby enabling a targeted and controlled fabrication of gradient porous structures. Finally, the efficacy and practical applicability of the proposed methodology are substantiated through the construction of illustrative examples. This approach, as delineated herein, provides a robust framework for the efficient design and realization of intricate, interconnected gradient porous structures with potential applications in various scientific and engineering domains.

RELATED ARTICLES

Zeshang Jiang, Jiacheng Yu, Wuchao Cheng, Zhenxiang Xin, Jieting Geng, Lin Xia

Vol. 19., No.4., Pages 372-385, 2025

DOI: 10.3144/expresspolymlett.2025.28

Vol. 19., No.4., Pages 372-385, 2025

DOI: 10.3144/expresspolymlett.2025.28

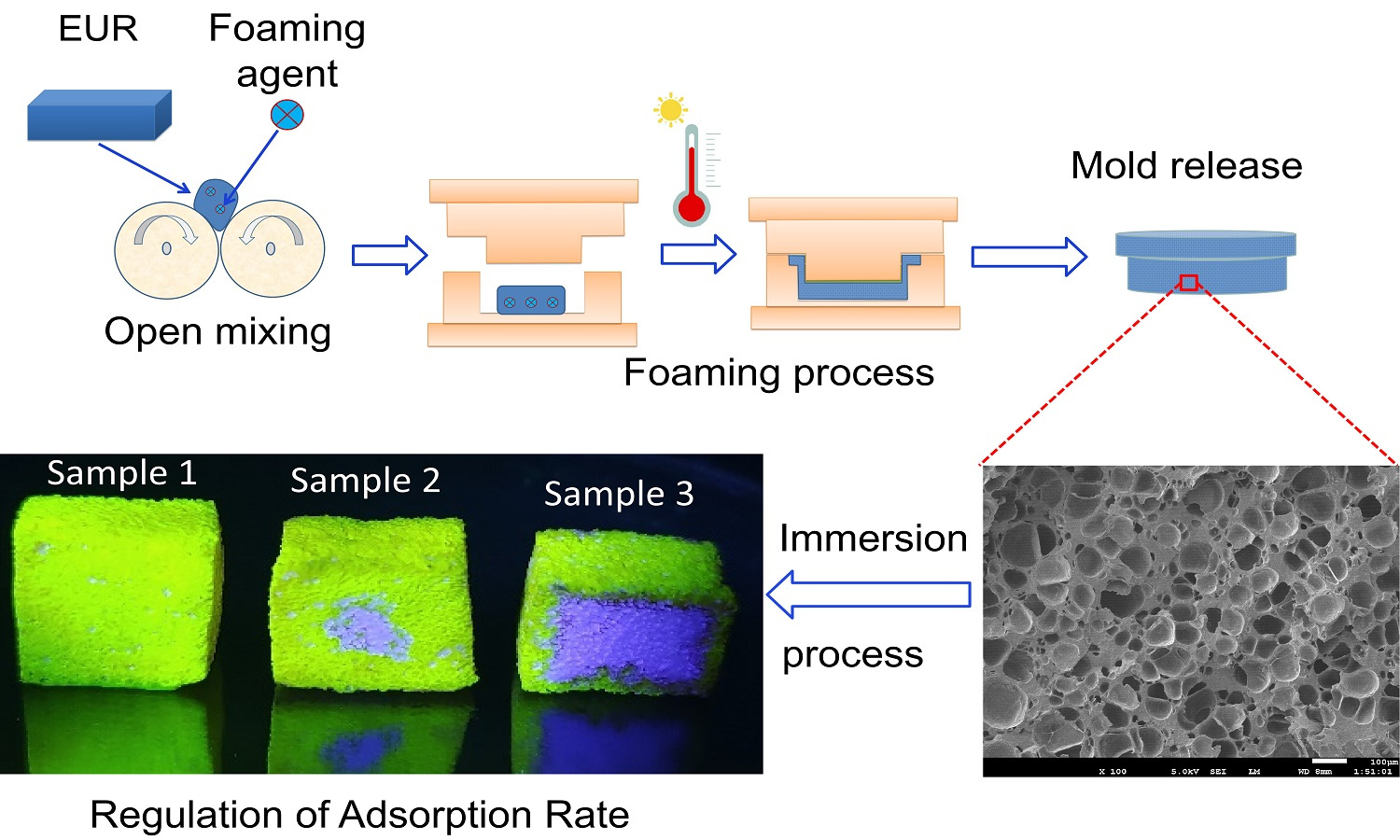

Inspired by the micro structure of loofah sponge in nature, this article successfully employs a biomimetic approach to develop a novel series of natural Eucommia rubber foamed materials with excellent shape memory properties. This article explores the characteristic features of natural Eucommia ulmoides rubber foamed materials, including the foaming process, mechanical properties, shape memory performance, and adsorption properties. This paper introduces the innovative use of natural Eucommia ulmoides rubber’s shape memory properties to create a temperature-responsive foam adsorbent material. The foamed material’s unique ability to modify its pore structure through simple compression and heating processes offers tailored adsorption speed and capacity for varied practical applications. The adjustable adsorption properties of this foamed material present novel opportunities for its utilization in adsorption applications.

Yuanyuan Zhang, Xiaojian Wang, Honghong Li, Xinru Fu, Simin Huang, Hao Zhou

Vol. 18., No.11., Pages 1065-1076, 2024

DOI: 10.3144/expresspolymlett.2024.82

Vol. 18., No.11., Pages 1065-1076, 2024

DOI: 10.3144/expresspolymlett.2024.82

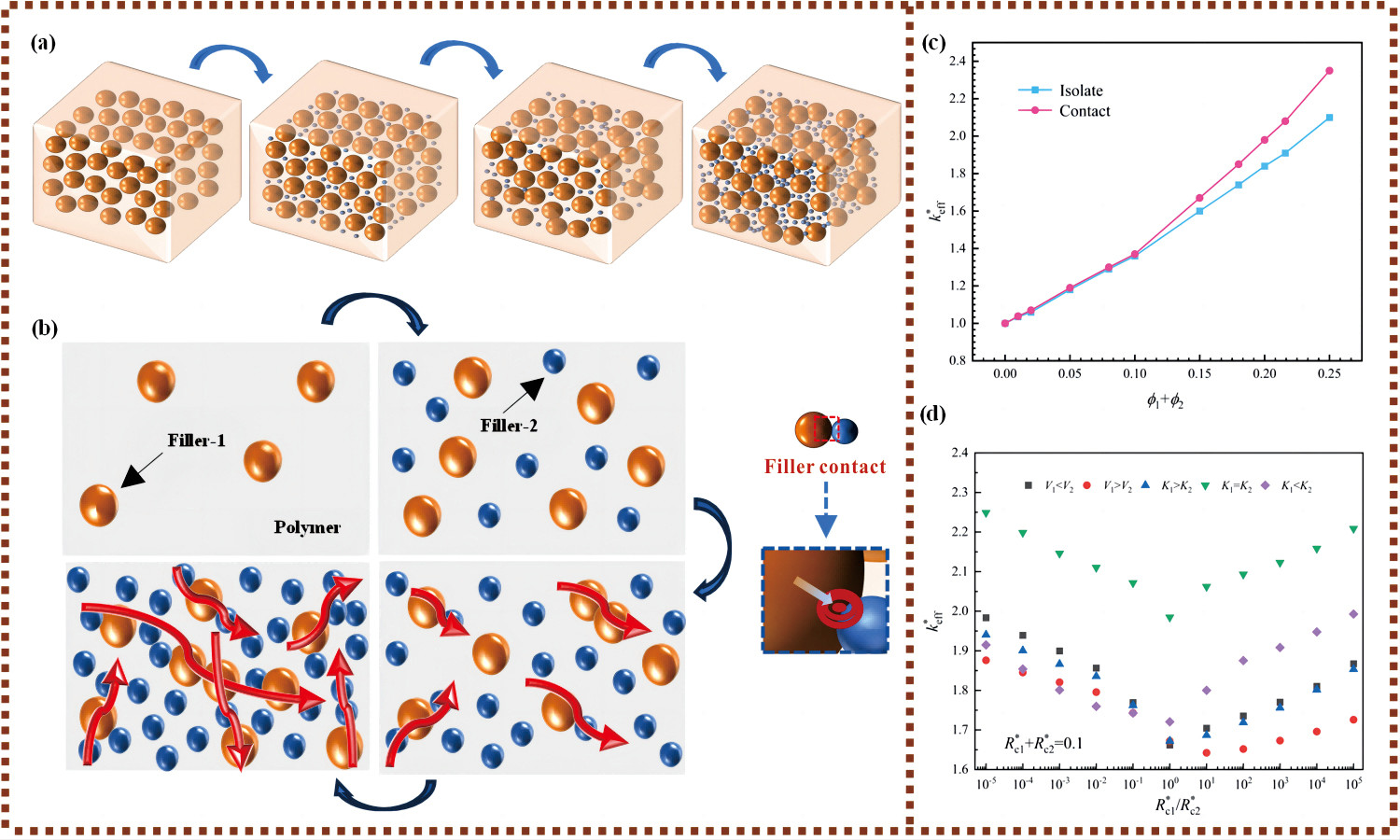

Adding heterogeneous fillers with high thermal conductivity (TC) to polymer has been recognized as an effective way to increase the effective thermal conductivity (ETC) of polymer composites. Extensive researches have been conducted on the ETC of composites with heterogeneous fillers. However, the heat transfer enhancement mechanism of heterogeneous fillers remains unknown, and the combined effects of filler size, filler contact, interface thermal resistance (Rc) and other parameters on the ETC have not been explored. In this study, above combined effects are investigated. The results show that the filler contact and Rc are the key factors determining the ETC. The ETC of composite with filler contacts reaches 2.35 at filler content of 25%, which is 11.9% higher than that without filler contacts. The ETC also strongly depends on the R*c (dimensionless form of Rc) ratio (R*c1/R*c2) between two fillers, with it becoming asymmetrical when the amount of R*c(R*c1 + R*c2) is larger. The ETCs decrease with the increase of R*c1/R*c2 when the R*c1/R*c2<1, while they increase with R*c1/R*c2 when the R*c1/R*c2>1. When R*c1 + R*c2 is a constant, the ETC increases with the competing effects of R*c. The models with filler contacts exhibit higher accuracy than other classical models in calculating the ETC across the entire range of filler content.