Modification of waste PET based alkyd resins with aldehyde and ketone resins: A comprehensive and comparative study

Vol. 18., No.12., Pages 1224-1264, 2024

DOI: 10.3144/expresspolymlett.2024.93

DOI: 10.3144/expresspolymlett.2024.93

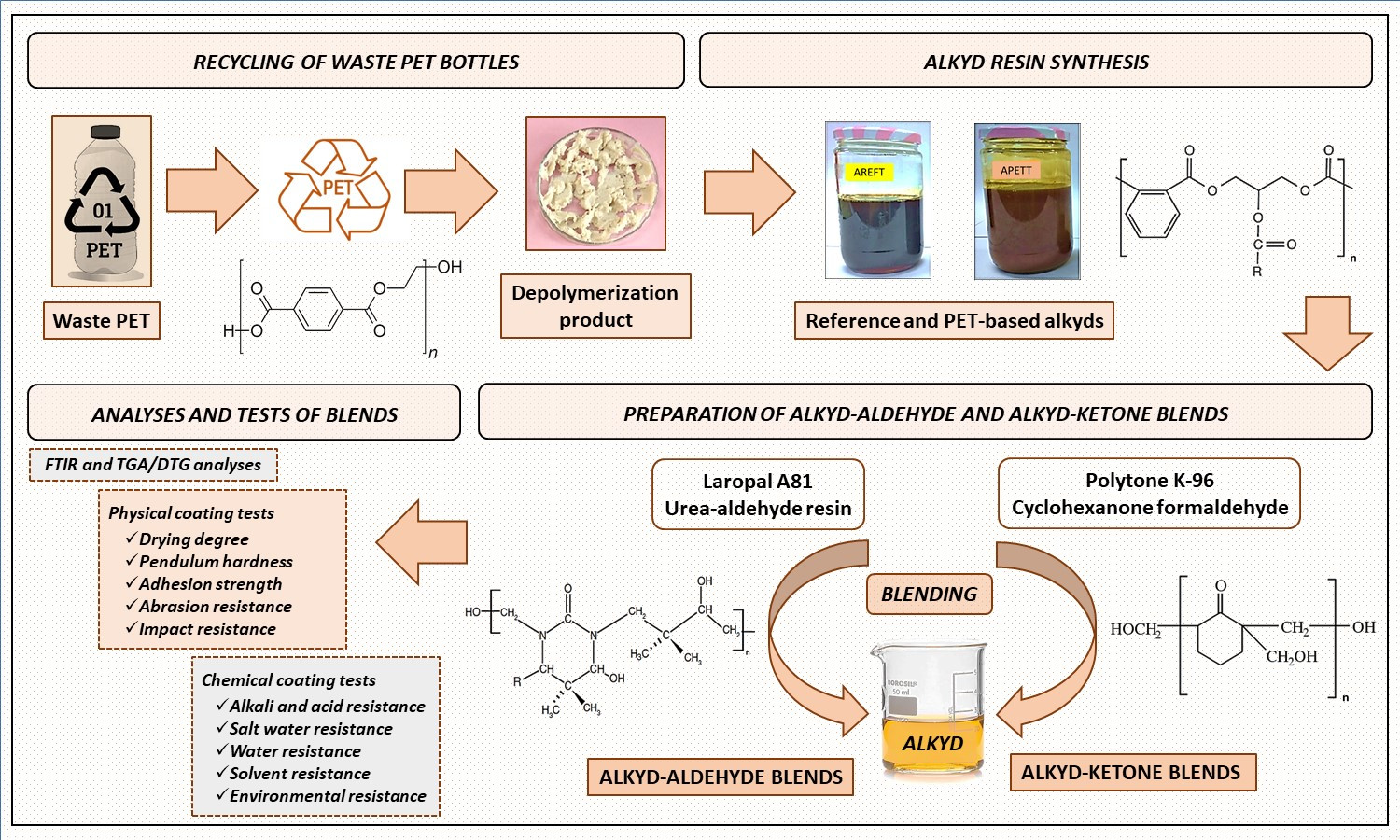

GRAPHICAL ABSTRACT

ABSTRACT

This study aims to develop alkyd-aldehyde and alkyd-ketone blends by modification of waste poly(ethylene terephthalate) (PET) based alkyd resin with urea-aldehyde (UA) and cyclohexanone formaldehyde (CHF) resins for use in coating applications. PET flakes were depolymerized by simultaneous hydrolysis-glycolysis reaction, and depolymerization product (DP) was used completely instead of the diol in the alkyd synthesis. For comparison, reference alkyds without PET were also synthesized. The effect of modifier resin at different ratios and the presence of DP on the coating and thermal properties of blend films were investigated. Medium-hard/hard and gloss/high gloss films with excellent adhesion and impact resistance were obtained from both blends. These films also demonstrated superior chemical and environmental resistance. Blends with CHF resin had better alkali resistance than those with UA resin. In PET-based blends, thermal resistance significantly increased with the addition of the CHF resin to the alkyd resin. Notably, the use of DP did not show a negative effect on the properties of alkyd resin and blend films. On the contrary, much better results were obtained than the alkyd resin alone. Overall, the modification with UA and CHF modifiers and using DP improved the coating properties of the blends. These blends are expected to be considered a sustainable and environmentally friendly alternative for designing versatile coatings for various applications.

RELATED ARTICLES

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.

Andrea Toldy

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

This is an editorial article. It has no abstract.