Fabricating multifunctional PLA textiles with advanced respiratory detection and environmental safety

Yunhui Wu, Chengkai Luo, Huanyu Liu, Wen Li, Jun-Wei Zha

Vol. 18., No.12., Pages 1265-1276, 2024

DOI: 10.3144/expresspolymlett.2024.94

DOI: 10.3144/expresspolymlett.2024.94

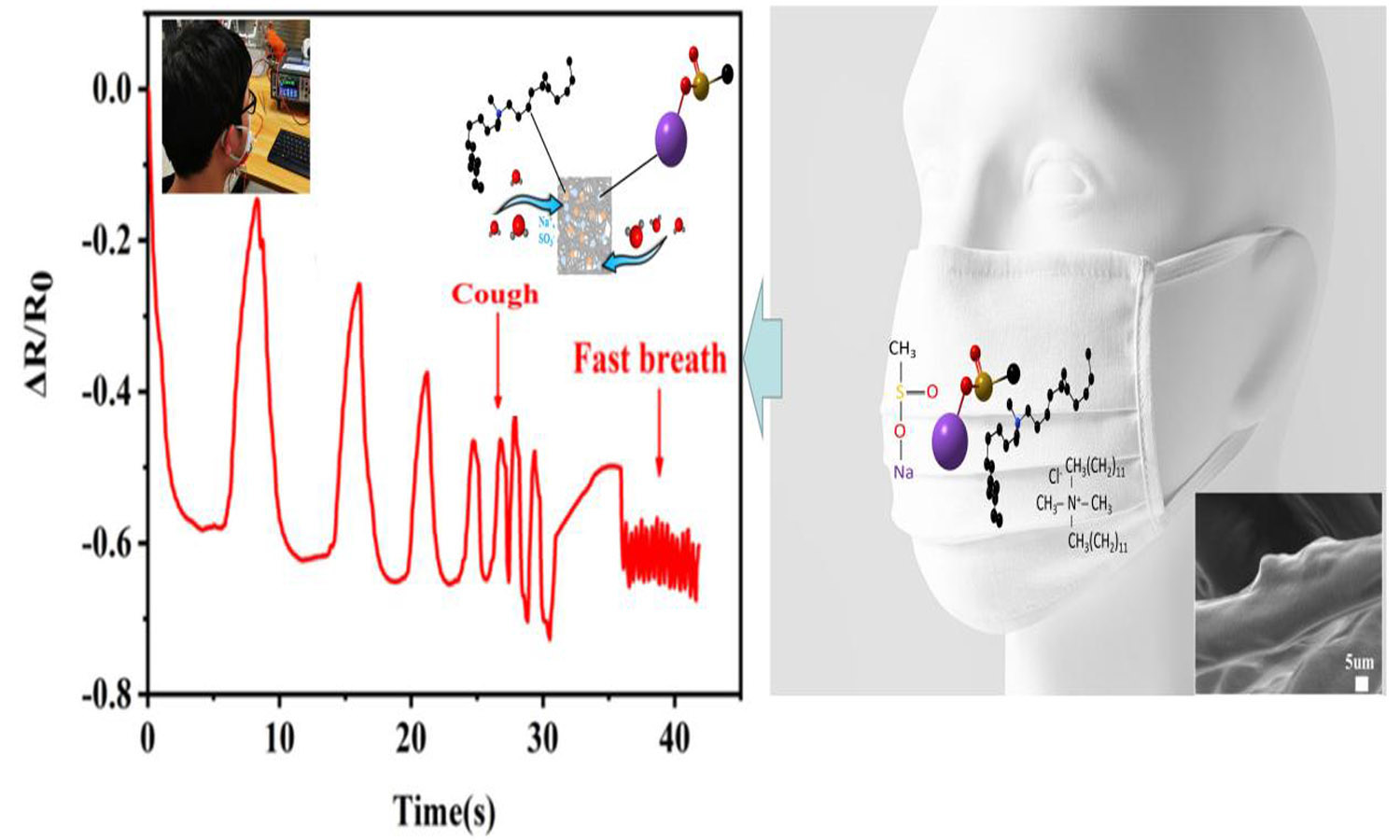

GRAPHICAL ABSTRACT

ABSTRACT

Currently, polylactic acid (PLA) is an attractive alternative to polypropylene (PP) because of its biodegradability. This study introduces a novel modification strategy for PLA by creating a multifunctional ionization layer with ionic salts. This approach achieves humidity sensing, reliable antibacterial properties, and excellent degradability simultaneously. The modified PLA textile sensor exhibits high sensitivity to respiratory humidity (0.92 at 90% RH), with ultrafast response (0.12 s) and recovery times (0.16 s). Additionally, the textile demonstrates excellent antibacterial performance against both E. coli (99.9%) and S. aureus (99.9%) after 1 h of contact. It also shows notable biodegradability with a weight loss rate of 60.38% after 30 days. Also, the ionic salt mechanism is explained through dynamic ionization interactions attributed to the modified ionic salts, which feature both long-chain alkanes and active ions. This work presents a new method to enhance the respiratory detection and antibacterial performance of biodegradable masks.

RELATED ARTICLES

Kai Du, Qiang Ben, Xiaoqiang Wang

Vol. 19., No.8., Pages 796-808, 2025

DOI: 10.3144/expresspolymlett.2025.61

Vol. 19., No.8., Pages 796-808, 2025

DOI: 10.3144/expresspolymlett.2025.61

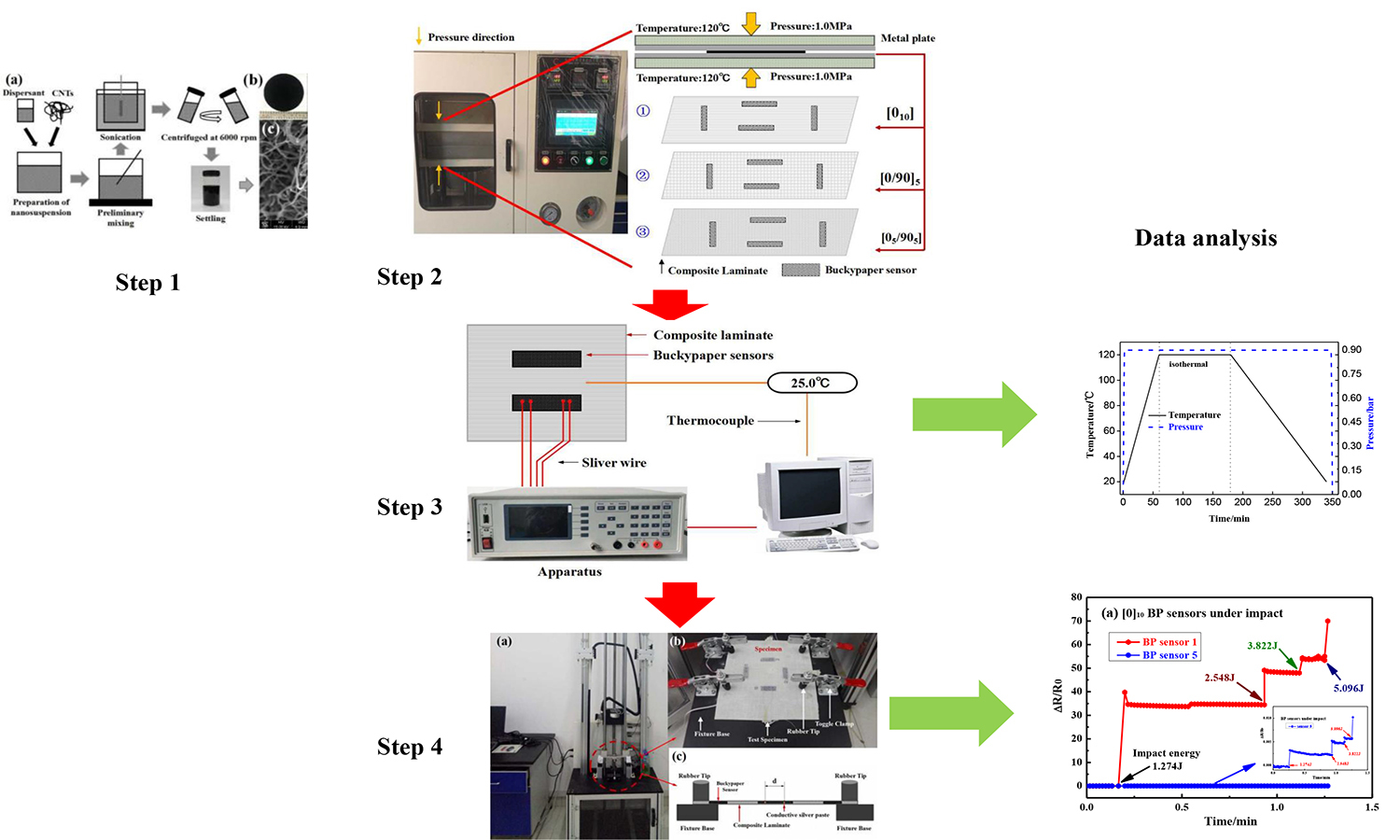

The main purpose of structural health monitoring (SHM) is to detect damage at its earliest possible stage to prevent severe deterioration and reduce subsequent repair costs. Carbon nanotubes (CNTs) buckypaper (BP) was embedded into different cross-ply glass fibre composites to monitor the curing process and impact damage as an in situ sensor in this research. BP sensor can capture the four stages of the curing process, the gel point of the resin and residual stresses of the composite structure can be achieved by analysing the change of the resistance curve. Numerical and experimental analyses were performed to predict the damage in composite structures subjected to low-velocity impact. BP sensors’ electrical resistance increases with repeated impact loading; composite structure elastic deformation and damage evolution can be identified from resistance change. Experiment results show that structure monitoring based on the BP sensors cannot only detect small, barely visible impact damage flaws and the damage evaluation of composite structures subjected to impact, but also provide a new method to monitor the curing process through the analysis of results. This work makes some constructive contributions to monitoring the manufacturing process of composites and long-term SHM to evaluate impact resistance and damage prediction of composite structures.

Mathew Olurotimi Adeoti, Tamba Jamiru, Taoreed Adesola Adegbola, Ibrahim Suleiman, Mohammed Abdullahi, Basiru Philip Aramide

Vol. 19., No.2., Pages 208-229, 2025

DOI: 10.3144/expresspolymlett.2025.16

Vol. 19., No.2., Pages 208-229, 2025

DOI: 10.3144/expresspolymlett.2025.16

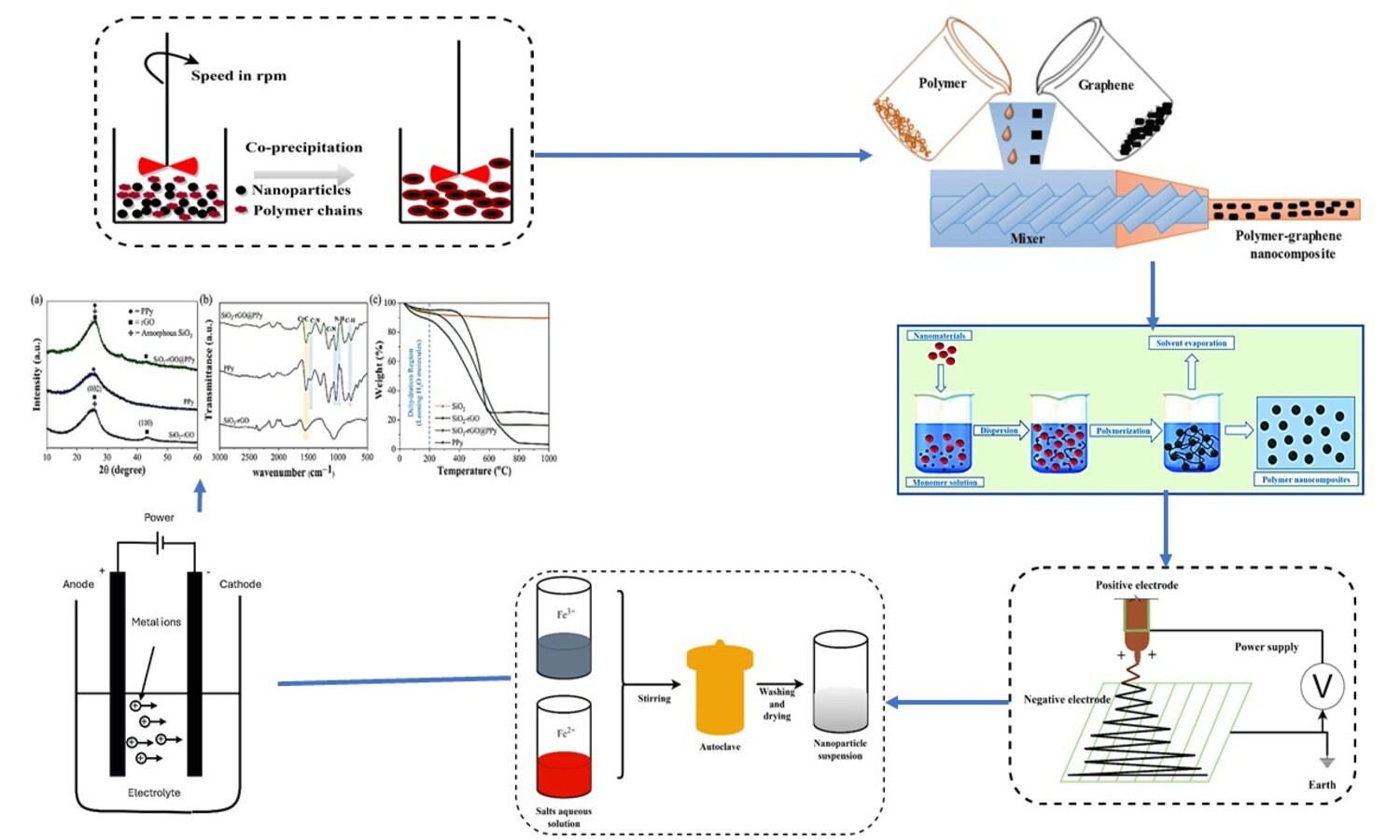

Polymer nanocomposites are drawing considerable interest in electrical energy storage research owing to their distinctive characteristics and promising roles in various devices, such as batteries, supercapacitors, and fuel cells. This review examines the selection criteria of polymer nanocomposites for electrical energy storage applications and the current advancements in developing and producing polymer nanocomposites specifically tailored for electrical energy storage applications. Key topics covered include the selection of polymer matrices, choice of nanofillers, fabrication techniques, characterization methods, and performance evaluation of the resulting nanocomposites. The impact of nanofiller dispersion, interface engineering, and morphology control on electrical storage properties is emphasized. Proper dispersion enhances uniformity and interfacial interactions, improving electrical, mechanical, and thermal properties. Interface engineering boosts polymer-nanofiller compatibility, while morphology control optimizes nanofiller structure and arrangement for better storage efficiency. Emerging trends, challenges, and future research directions are also discussed, providing insights for developing advanced polymer nanocomposites with improved electrical energy storage capabilities.