Shape memory properties of polyamide/thermoplastic polyurethane films and sea-island fibers

Cheng-Chieh Chang, Chang-Mou Wu, Kei-Chieh Chang

Vol. 19., No.6., Pages 568-577, 2025

DOI: 10.3144/expresspolymlett.2025.43

DOI: 10.3144/expresspolymlett.2025.43

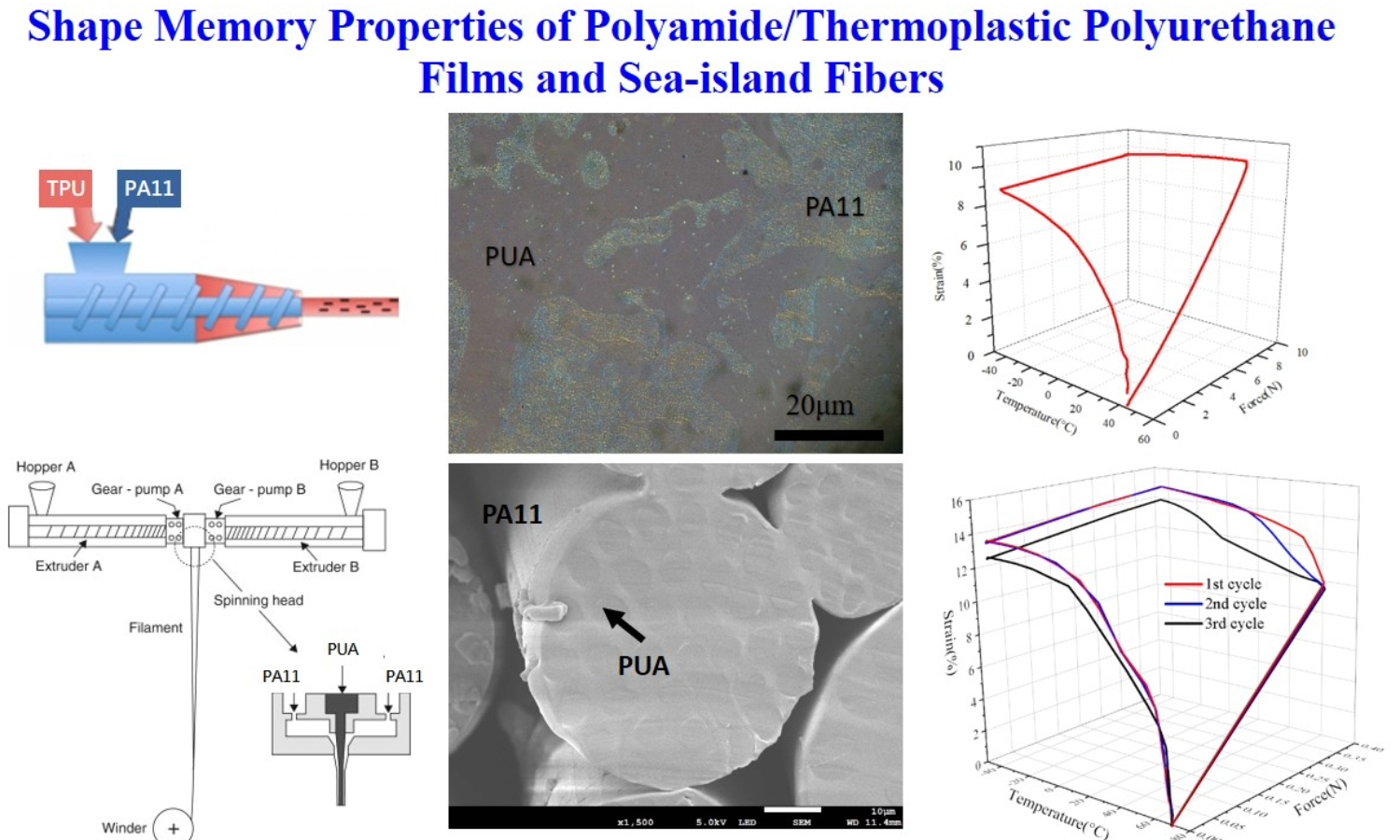

GRAPHICAL ABSTRACT

ABSTRACT

In this study, polyamide 11/thermoplastic polyurethane thermally responsive shape-memory composite fibers were fabricated using a bi-component melt-spinning machine with a sea-island spinning nozzle. Polyamide 11, a material with low water absorption and good oil resistance, was used as the ‘sea’, whereas the thermoplastic elastomer was used as the ‘island’ to provide shape memory performance. A film was prepared from these materials, and its suitability for preparing the fibers was determined using its shape memory behavior. The results demonstrated that the shape memory of the film fixation rate was 99.6% and the recovery rate was 92.3%, proving that polyamide 11/polyurea (PA11/PUA) has good shape memory fixation and recovery rates. During the melt-spinning and take-up processes, the as-spun fiber was collected into a roll with a certain draw ratio, resulting in a better molecular orientation and, consequently, an improved shape memory effect. After three shape memory cycles, the fixation rate of the PA11/PUA fiber was 98.8%, and the recovery rate was 99.9%. Thus, sea-island shape memory composite fibers were successfully produced, and are expected to enable shape memory materials to find a wider range of applications.