Content

All issues / Volume 17 (2023) / Issue 9 (September)

Attila Balaskó

Vol. 17., No.9., Pages 881-882, 2023

DOI: 10.3144/expresspolymlett.2023.65

Vol. 17., No.9., Pages 881-882, 2023

DOI: 10.3144/expresspolymlett.2023.65

This is an editorial article. It has no abstract.

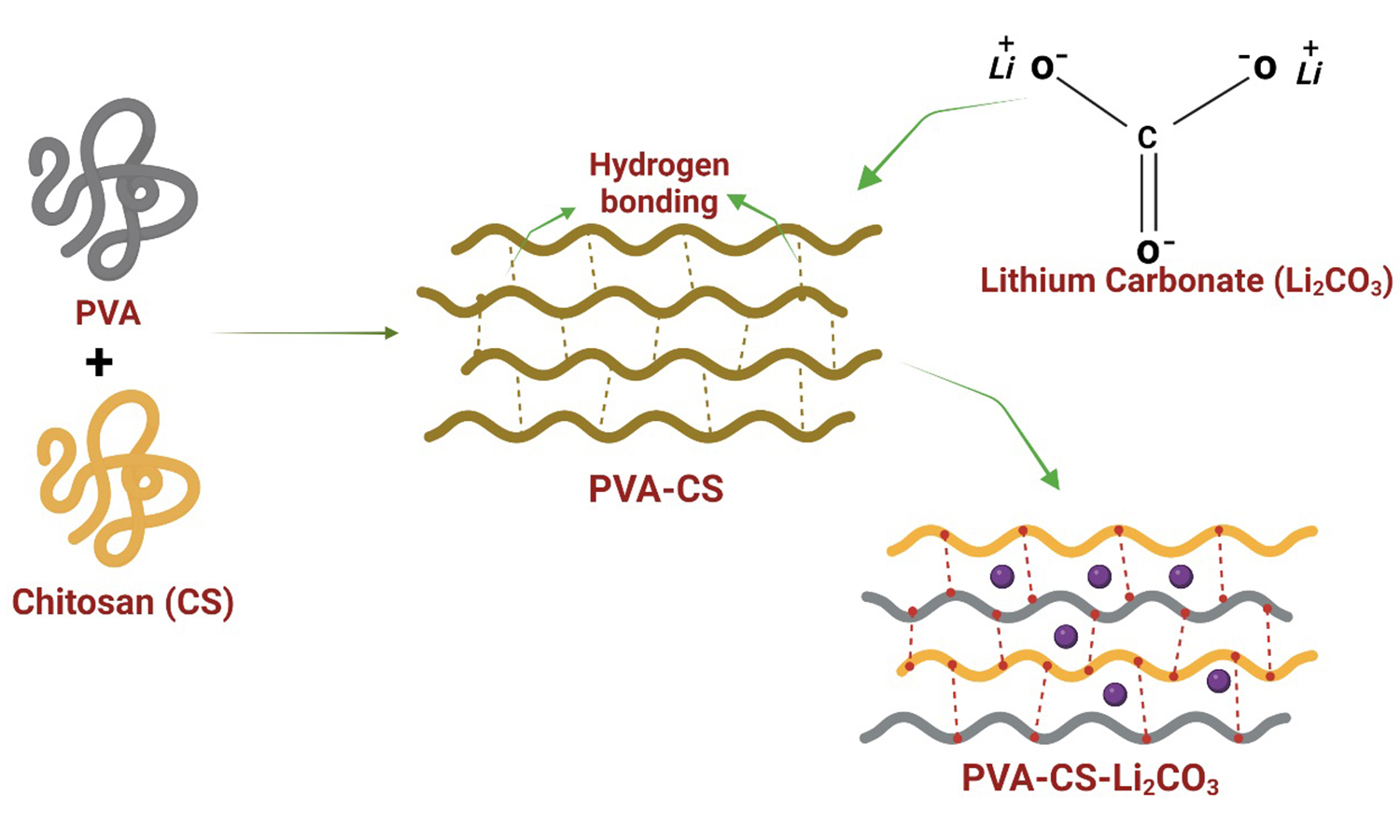

Rohan Nandeesh Sagar, Ravindrachary Vasachar, Shreedatta Hegde

Vol. 17., No.9., Pages 883-899, 2023

DOI: 10.3144/expresspolymlett.2023.66

Vol. 17., No.9., Pages 883-899, 2023

DOI: 10.3144/expresspolymlett.2023.66

Solid polymer electrolytes based on polyvinyl alcohol (PVA)–chitosan (CS) polymer blend and Li–salt doped blend electrolyte films are prepared using the solution cast technique. The Fourier transform infrared spectra showed that the absorption peaks shifted in Li–salt doped polymer blend composites compared to pure blend films: indicating the chemical modifications upon doping. From the UV–visible spectra, the spectral absorption response of Li+ salt–doped polymer blend composites showed a red shift in the absorption band. The optical band gap of the pure polymer blend decreased upon doping. X–ray diffraction studies showed the dopant-dependent structural modification of pure polymer blend upon doping. SEM images also showed the change in the surface morphology of the pure polymer blend upon doping. The termogravimetric analysis study revealed that the thermal stability of the pure polymer blend increases with Li2CO3 concentration. The ionic conductivity of PVA–CS increases with Li–salt concentration, and the maximum conductivity of 7.70·10–5 S·cm–1 is observed for 15 wt% of Li2CO3 salt concentration. The transport property study revealed that the ions are the majority conducting charge carriers in polymer blend composite.

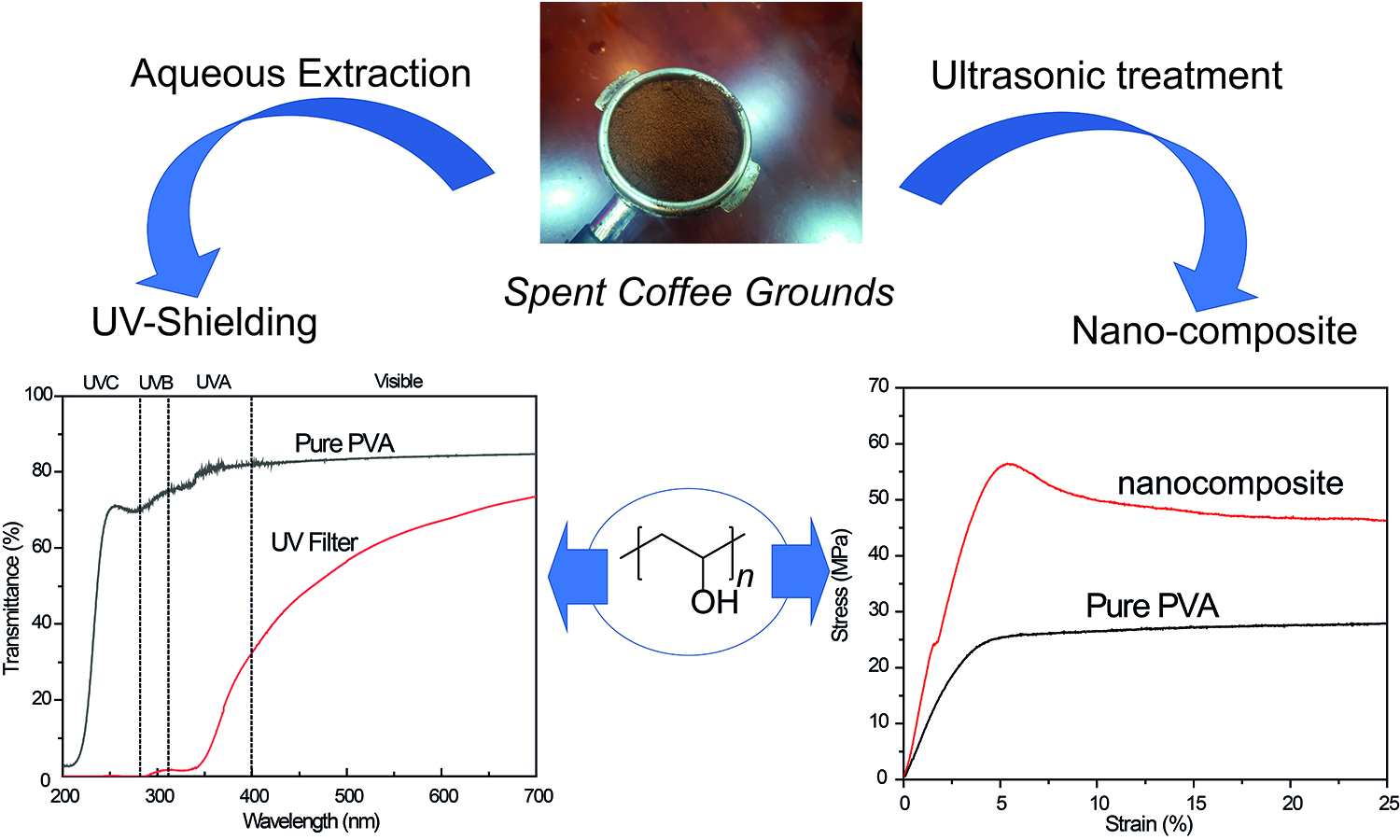

Ha Ngoc Giang, Chanh Cong Tran, Tuan Nguyen Anh Huynh, Phuong Thi Minh Doan

Vol. 17., No.9., Pages 900-912, 2023

DOI: 10.3144/expresspolymlett.2023.67

Vol. 17., No.9., Pages 900-912, 2023

DOI: 10.3144/expresspolymlett.2023.67

Spent coffee grounds (SCGs), the main by-product in the coffee industry, were proposed as a starting material to fabricate both ultraviolet (UV) shielding material and nanocomposite based on polyvinyl alcohol (PVA). The extract using low SCGs concentration (0.25 wt%) contains a significant amount of UV-absorbing substances. The UV shielding film from 5 wt% PVA solution and SCGs extract (1 g SCGs/200 ml water) could shield most of the radiation in UV-B and UV-C regions and maintain 63% transmittance at 550 nm. The SCGs after washing were ball milled and the ultrasonic liquid processor was applied to synthesize SCGs nanoparticle. The effects of ultrasonic amplitude and hexadecyltrimethylammonium bromide (CTAB) on the particle’s hydrodynamic diameter were investigated. The particle’s size of 148 nm was obtained with 50% ultrasonic amplitude. Fourier-transformed infrared spectroscopy (FTIR) results confirmed the presence of hydroxyl groups (–OH) on the SCGs-based nanoparticle’s surface. The tensile strength of PVA-SCGs nanocomposite was significantly improved. However, the presence of CTAB in the nano solution could not show a better tensile result. The organic compounds contained in the SCGs extract and even in the nano SCGs solution could enhance thermal oxidation stability for both UV shielding films and nanocomposites.

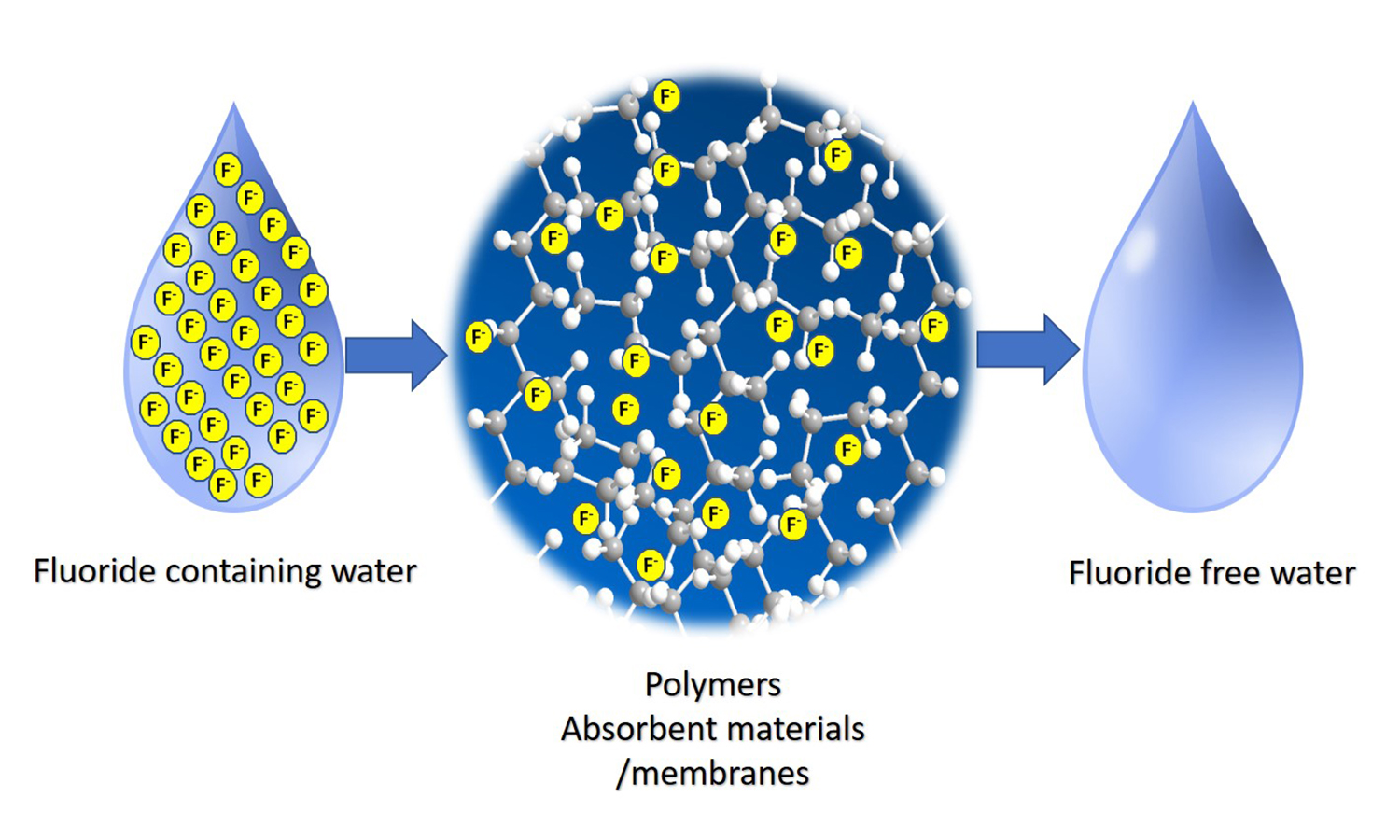

Vipin Chandra Joshi, Saroj Sharma, Amit Bhattacharya

Vol. 17., No.9., Pages 913-931, 2023

DOI: 10.3144/expresspolymlett.2023.68

Vol. 17., No.9., Pages 913-931, 2023

DOI: 10.3144/expresspolymlett.2023.68

There

are unequivocal shreds of evidence that polymers touched every sphere of life.

They are very versatile and used in many applications depending on the specific

intrinsic properties of the materials. Over the last few decades, there has

been growing evidence that applying polymer materials in water-purifying has

been adopted worldwide. Water fluorine toxicity is challenging us to develop

water-purifying polymeric materials. We are presenting the polymeric adsorbent

and membrane materials advancement in terms of defluoridation of water.

Preparation and properties of transparent poly(aryl ether ketone) films with low dielectric constant

Huijuan Li, Miao Yi, Xin Yin, Wenliang Wu, Shiai Xu

Vol. 17., No.9., Pages 932-943, 2023

DOI: 10.3144/expresspolymlett.2023.69

Vol. 17., No.9., Pages 932-943, 2023

DOI: 10.3144/expresspolymlett.2023.69

The objective of this study is to prepare a new poly(aryl ether ketone) (PAEK) with low dielectric constant, high transparency and heat resistance by introducing fluorine atoms and phenolphthalein (PHPH) groups into the polymer backbone. The chemical structure of PAEK random copolymers was characterized by Fourier transform infrared spectroscopy (FTIR), proton nuclear magnetic resonance (1H-NMR) and X-ray diffraction (XRD),, and the molecular weight of PAEK was determined by gel permeation chromatography (GPC). It is found that these random copolymers are soluble in common organic solvents, especially low boiling point solvents, such as CHCl3, tetrahydrofuran (THF) and dimethylacetamide (DMAc). Transparent, uniform and flexible films were prepared by casting from DMAc solvent. The PAEK copolymers exhibit high glass transition temperature (163–220 °C by differential scanning calorimetry (DSC) and 168–227 °C by dynamic mechanical analysis (DMA)) and thermal stability with 5% weight loss temperatures of 461–525 °C. The PAEK films show good mechanical properties with tensile strengths of 50–62 MPa. The dielectric constant (k) is only 2.31–3.08, and the loss tangent is only 0.003–0.009 at 1 MHz. All films exhibit excellent optical transparency, their UV cutoff wavelength is shorter than 386 nm, and the transmittance at 450 nm is higher than 80%.

Pornsiri Toh-ae, Raymond Lee-Nip, Yeampon Nakaramontri

Vol. 17., No.9., Pages 944-963, 2023

DOI: 10.3144/expresspolymlett.2023.70

Vol. 17., No.9., Pages 944-963, 2023

DOI: 10.3144/expresspolymlett.2023.70

Acrylonitrile butadiene rubber (NBR) films filled with zinc oxide (ZnO) were prepared via latex mixing. The ZnO of commercial ZnO (ZnOWH), ZnO nanoparticles (ZnOnap), ZnOnap-coated with calcium carbonate (ZnOnap-C), and titanium dioxide (ZnOnap-T) were investigated, and the mechanical and dynamic mechanical properties, crosslink density, and antibacterial activity of the resultant films were explored. The study found that the particle size and distribution of ZnO in the NBR films played a significant role in enhancing their properties. The incorporation of ZnOnap resulted in a greater enhancement in the properties of the composite film than the ZnOWH microparticles, with the greatest enhancement achieved with ZnOnap-C. Furthermore, the composite films filled with 1 phr of ZnOnap-C exhibited 99.9% bacterial reduction efficacy against Staphylococcus aureus and Escherichia coli according to ISO 22196:2011 due to the release of reactive oxygen species and zinc ions across the rubber film layers to the bacterial surfaces. In addition, the bactericidal efficacy on the surface of the composite films was investigated by varying the contact kill times in accordance with ASTM D7907-14. The addition of ZnOnap-C at 4 phr reduced both bacterial levels by 92.00 and 51.85%, respectively, within 30 min. Hence, this research aims to contribute to developing new medical disinfection products, such as medical gloves and multipurpose rubber sheets.

Jaka Fajar Fatriansyah, Elvi Kustiyah, Siti Norasmah Surip, Andreas Federico, Agrin Febrian Pradana, Aniek Sri Handayani, Mariatti Jaafar, Donanta Dhaneswara

Vol. 17., No.9., Pages 964-973, 2023

DOI: 10.3144/expresspolymlett.2023.71

Vol. 17., No.9., Pages 964-973, 2023

DOI: 10.3144/expresspolymlett.2023.71

The use of machine learning to fine-tune the properties of materials is a remarkable achievement in the 21st century. Three machine learning (ML) methods were used to fine-tune and optimize the impact strength of polylactic acid (PLA) with different plasticizers: KNN (K-nearest neighbors), SVR (Support Vector Regression), and ANN (artificial neural networks). The results demonstrated that, though ANN reached a higher R2 score of 0.901 than the other two ML methods, KNN, with an R2 score of 0.839, showed more stability than ANN. Based on the current research, KNN is recommended for experimentalists to fine-tune the impact strength of variational plasticizers. The experiment study case with polyethylene glycol 1000 (PEG1000) and octyl epoxy stearate (OES) plasticizer showed good agreement and prediction with experiments. It even showed the fine-tuned impact strength as a function of plasticizer content results, which cannot be achieved by only experiments.

Vincent Valette, Nasreddine Kébir, Fabrice Burel, Laurence Lecamp

Vol. 17., No.9., Pages 974-990, 2023

DOI: 10.3144/expresspolymlett.2023.72

Vol. 17., No.9., Pages 974-990, 2023

DOI: 10.3144/expresspolymlett.2023.72

A promising process to design non-isocyanate polyurethane (NIPU) foams has been developed. The transurethane polycondensation reaction between fatty biscarbamates, fatty diols, and diamines was used to synthesize a biobased aminotelechelic NIPU oligomer. The prepared oligomer (hard phase) was mixed with an amino-telechelic polydimethylsiloxane (PDMS, soft phase) and then reacted with a biosourced tri-epoxide molecule as crosslinking agent, in the presence of water/ethanol mixtures as physical blowing agents. The crosslinking reaction was followed by Fourier transform infrared spectroscopy (FTIR) and rheometry. The foams can be obtained in less than 2 hours at 95 °C. The prepared foams exhibited cell diameters ranging from 130 to 3090 μm, as well as densities ranging from 55 to 950 kg/m3. Their thermal stability thresholds were above 300 °C. They displayed glass transition temperature values ranging from –20 to –18 °C, and low values of the Young modulus ranging from 2.0・103 to 5.7・103 Pa. The hysteresis loss, the recovery time, and the firmness of these foams were dependent on the PDMS content and/or the morphological parameters.