Content

All issues / Volume 17 (2023) / Issue 3 (March)

Shipeng Wen

Vol. 17., No.3., Pages 236-236, 2023

DOI: 10.3144/expresspolymlett.2023.17

Vol. 17., No.3., Pages 236-236, 2023

DOI: 10.3144/expresspolymlett.2023.17

This is an editorial article. It has no abstract.

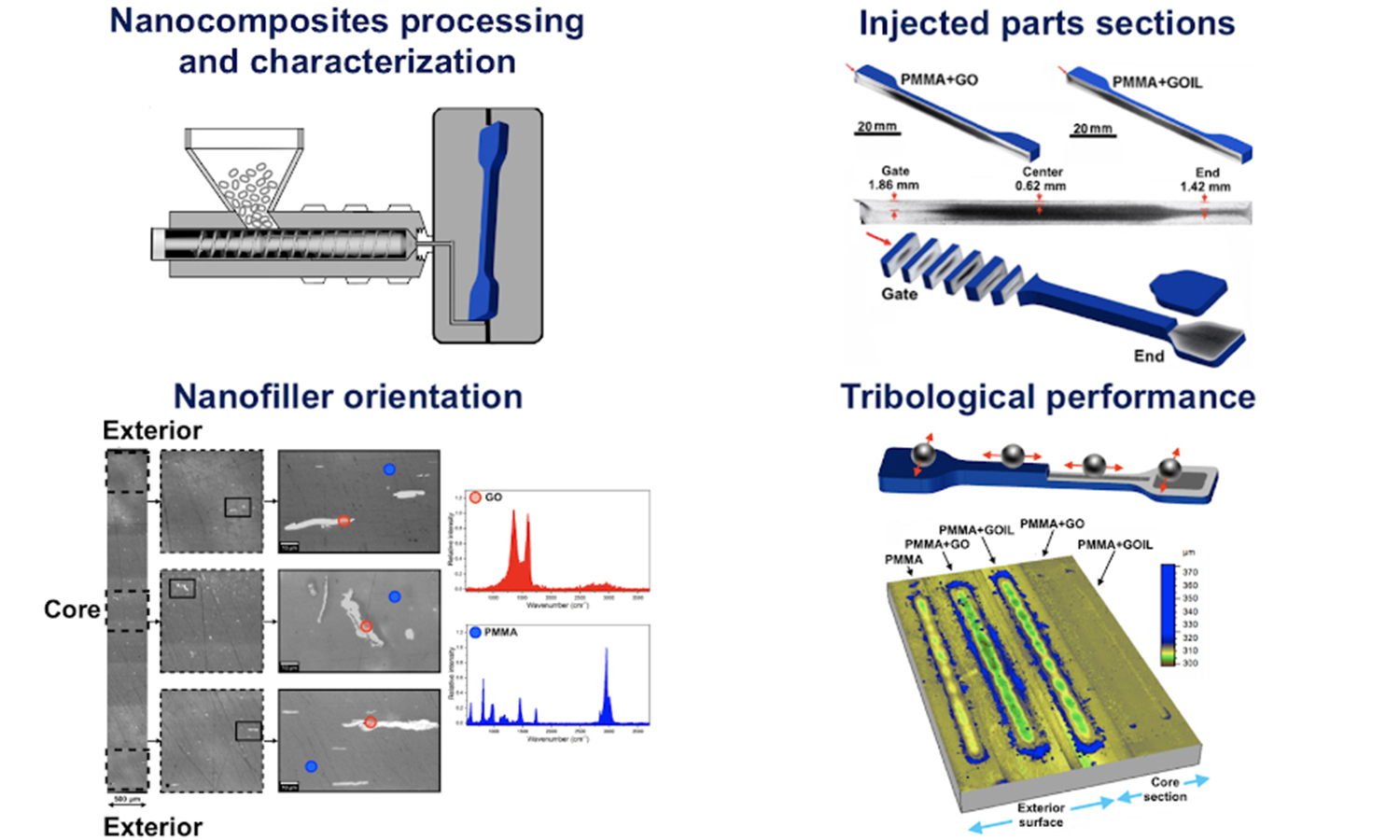

Luis-Francisco Minguez-Enkovaara, Francisco-Jose Carrión-Vilches, Maria-Dolores Avilés, María-Dolores Bermúdez

Vol. 17., No.3., Pages 237-251, 2023

DOI: 10.3144/expresspolymlett.2023.18

Vol. 17., No.3., Pages 237-251, 2023

DOI: 10.3144/expresspolymlett.2023.18

New polymethylmethacrylate (PMMA) nanocomposites containing 0.5 wt% graphene oxide (GO), or 1.5 wt% graphene oxide modified with the ionic liquid (IL) 1-octyl-3-methylimidazolium tetrafluoroborate (GOIL) have been processed by extrusion and injection molding to obtain PMMA+GO and PMMA+GOIL, respectively. Raman microscopy and mapping show that the additives align parallel to the flow close to the exterior surfaces, with an almost perpendicular orientation in the central core region. Reciprocating sliding tests have been carried out on the exterior surfaces and also on the surface of core sections of the injected parts. GO prevents surface damage, showing negligible wear on both section surfaces under sliding parallel and perpendicular to the injection flow. In contrast, the performance of PMMA+GOIL depends on the sliding direction. Under multiple scratching, both GO and GOIL reduced residual depth values and increased the viscoelastic recovery of PMMA, thus reducing permanent surface damage. PMMA+GOIL shows the highest viscoelastic recovery and the lowest complex viscosity values. Wear mechanisms are discussed as a function of materials properties, nanofiller type, and orientation and sliding direction.

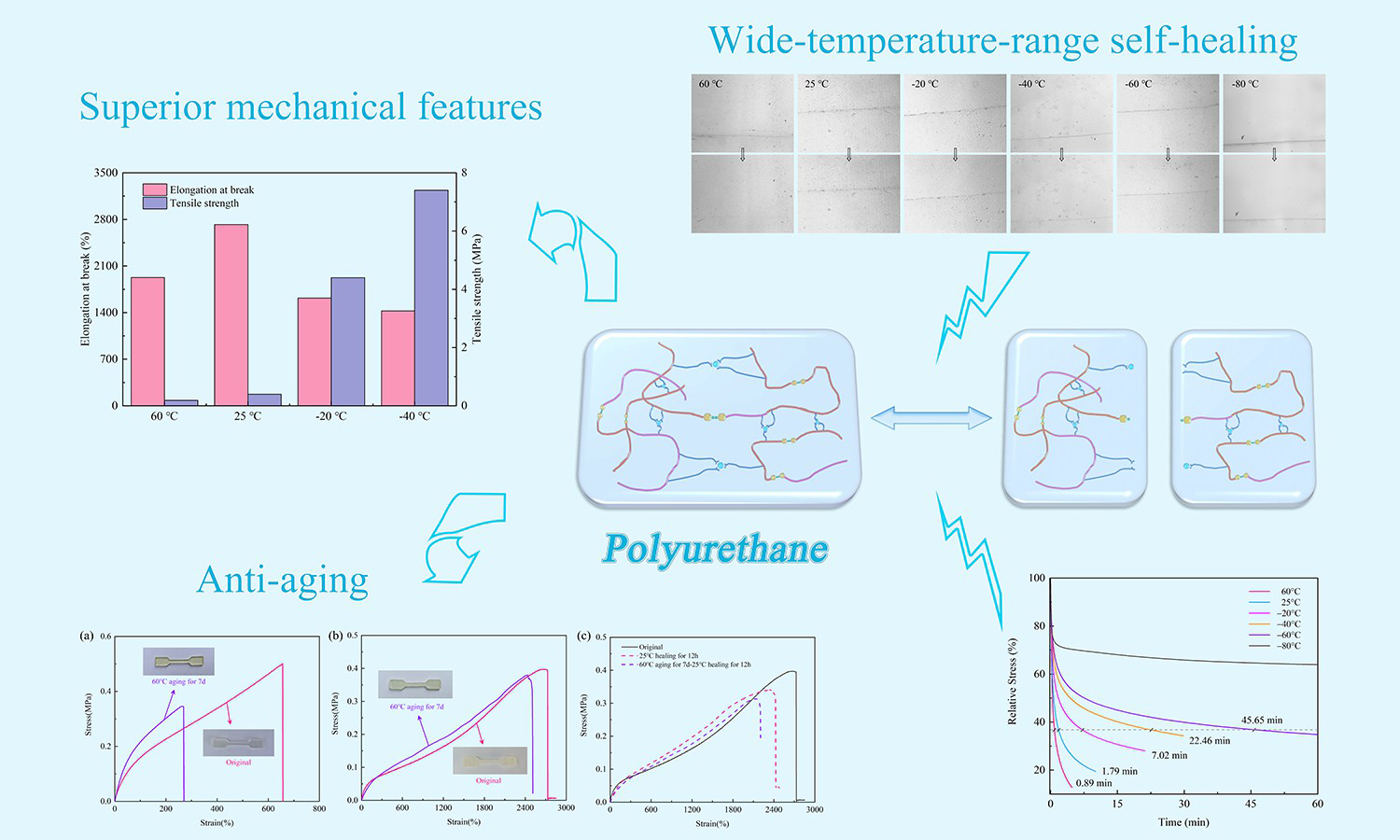

Yu Zhang, Jian Zheng, Wanli Ma, Xiao Zhang, Yongqiang Du, Ke Li, Yahao Liu, Guibo Yu, Yunfei Jia

Vol. 17., No.3., Pages 252-267, 2023

DOI: 10.3144/expresspolymlett.2023.19

Vol. 17., No.3., Pages 252-267, 2023

DOI: 10.3144/expresspolymlett.2023.19

The development of skin-compatible polyurethane materials with excellent wide-temperature range and anti-aging self-healing properties is considered crucial for modern applications. However, few polyurethane materials can achieve these characteristics simultaneously because of the chemical bond activity. Here, we report a wide-temperature range and antiaging self-healing polyurethane material with superior mechanical features. At –40 °C, the polyurethane exhibits a selfhealing efficiency of 72.6%, with a tensile strength of ~7.4 MPa and elongation at break of ~1424.5%. At 60 °C, its selfhealing efficiency reached 93.6%, with an elongation at break of 1922.2% without significant reduction of the tensile strength. Notably, its low-temperature self-healing efficiency was 79.3 and 72.6%, respectively, at –20 and–40 °C, and the samples showed some degree of self-healing, even at –60 and –80°C. Meanwhile, the polyurethane showed excellent anti-aging performance, and its self-healing properties were sufficiently high after aging at 60 °C for 7 days. The designed polyurethane is expected to offer a promising platform for fabricating materials for electronic skin applications, wearable electronic devices, flexible displays, and soft robotics.

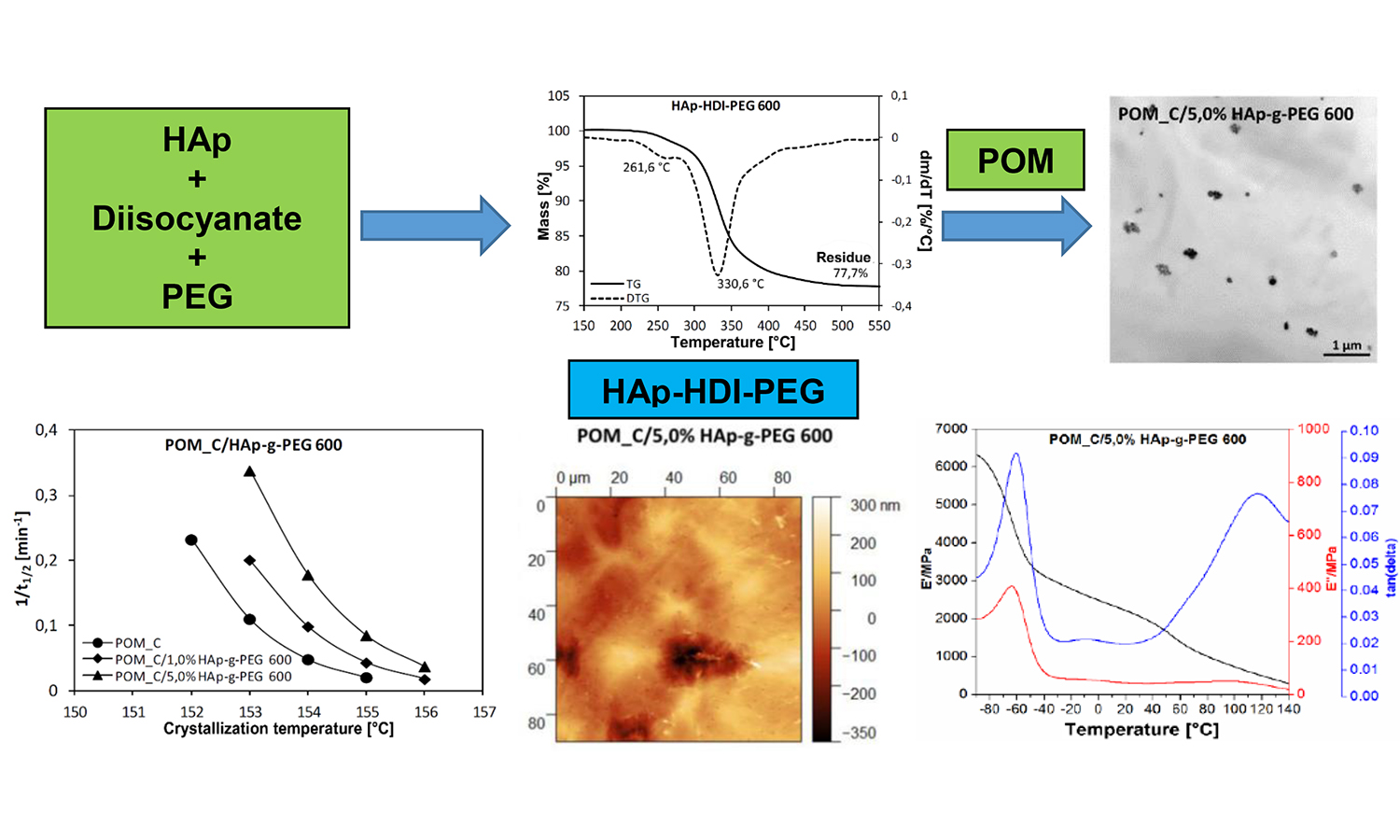

Klaudia Król-Morkisz, Monika Kuznia, Zbigniew Olejniczak, Malgorzata Lekka, Kinga Pielichowska

Vol. 17., No.3., Pages 268-289, 2023

DOI: 10.3144/expresspolymlett.2023.20

Vol. 17., No.3., Pages 268-289, 2023

DOI: 10.3144/expresspolymlett.2023.20

In this work, hydroxyapatite (HAp) was functionalized by using poly(ethylene glycol) (PEG) with different average molar mass and diisocyanates as linkers and then incorporated into the polyoxymethylene (POM) matrix by means of melt processing methods. The effectiveness of the functionalization process and the chemical structure of the obtained hybrid systems were analyzed using thermogravimetric analysis (TG), elemental analysis, and nuclear magnetic resonance (NMR) methods. In the next stage of research, the calculation of the POM crystallization kinetic parameters in the presence of the hybrid filler were calculated. Microscopic and dynamic mechanical analysis (DMA) tests, as well as 13C and 31P and nuclear magnetic resonance (NMR) analyses were done to show the effect of the HAp-g-PEG hybrid filler on the crystallization kinetics and crystallinity of the POM composites. Transmission electron microscopy (TEM) confirmed the uniform distribution of the HAp-g-PEG hybrid additives. Differential scanning calorimetry (DSC) tests did not show any significant effect on the key processing parameters, i.e. melting point and supercooling, which allowed the processing parameters to be maintained for all samples. The study of crystallization kinetics showed a three-dimensional process of POM crystals’ growth in the form of spherulites. The addition of HAp-g-PEG to POM significantly accelerated the crystallization process.

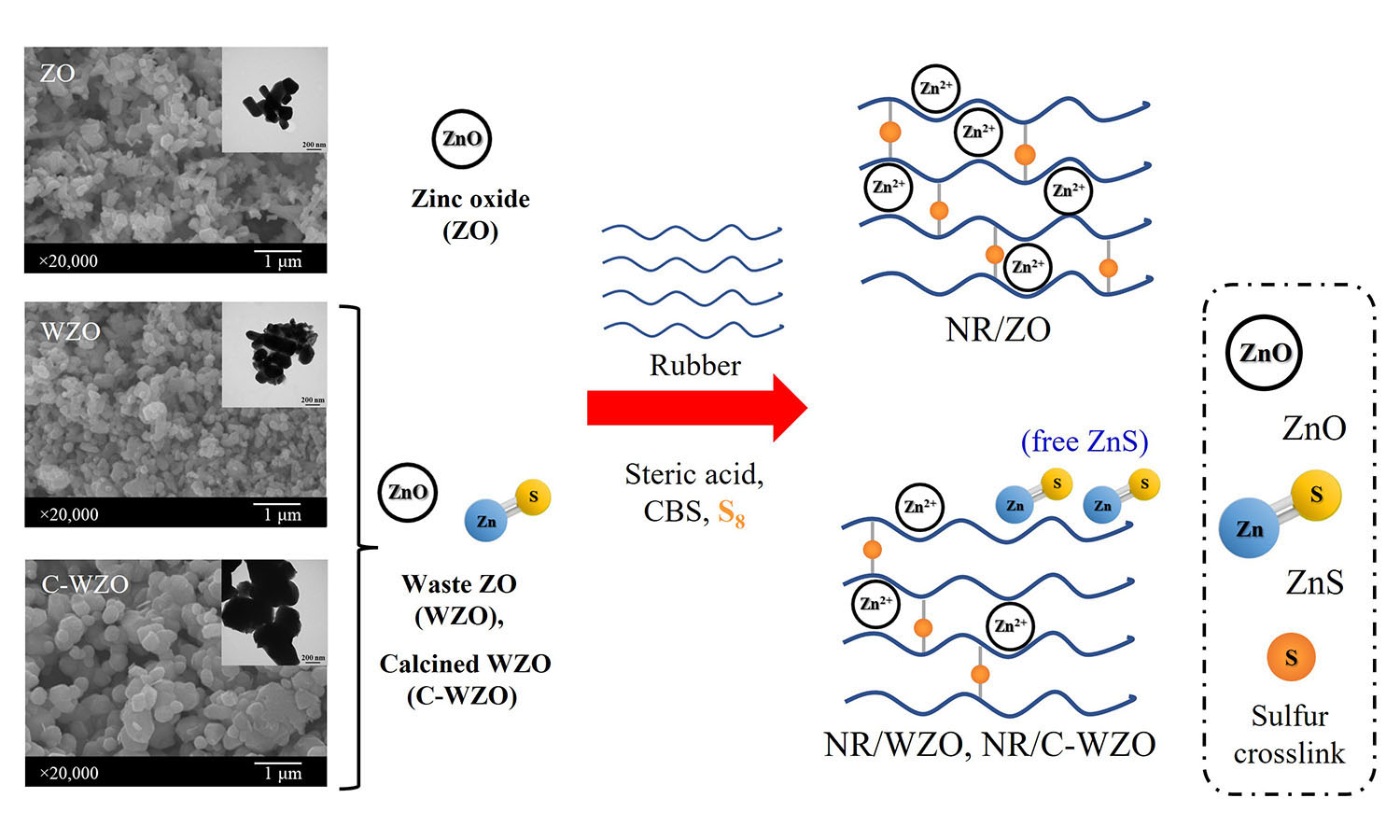

Dusadee Tumnantong, Pattarapan Prasassarakich, Sirilux Poompradub

Vol. 17., No.3., Pages 290-299, 2023

DOI: 10.3144/expresspolymlett.2023.21

Vol. 17., No.3., Pages 290-299, 2023

DOI: 10.3144/expresspolymlett.2023.21

Natural rubber (NR) vulcanizates with waste zinc oxide (ZnO) particles were prepared through a sulfur vulcanization process. This research aimed to investigate the effect of different ZnO sources as an activator: commercial ZnO (ZO), waste ZnO obtained from a ceramic industry (WZO), and calcinated WZO (C-WZO) on the properties of NR vulcanizates. The ZnO particles were characterized using X-ray fluorescence spectrometer, X-ray diffractometer, and transmission electron microscopy. It was found that the calcination at 800 °C for 6 h could reduce the sulfur components in WZO; consequently, the particle size and appearance were changed. For rubber vulcanizates, the composition of ZnO in the activator had an effect on the crosslink density of the obtained vulcanizates, resulting in changes to the mechanical tensile, thermal, and dynamic mechanical properties. The crosslink density, tensile strength, and tear strength of the rubber vulcanizate filled with C-WZO (NR/C-WZO (II), 0.18 mmol/cm3, 21.3 MPa, 68.4 N/mm, respectively) was acceptable for rubber products compared with those of the vulcanizate filled with ZO (NR/ZO, 0.19 mmol/cm3, 26.4 MPa, 71.6 N/mm, respectively). Accordingly, C-WZO could be used as an effective activator in rubber vulcanization.

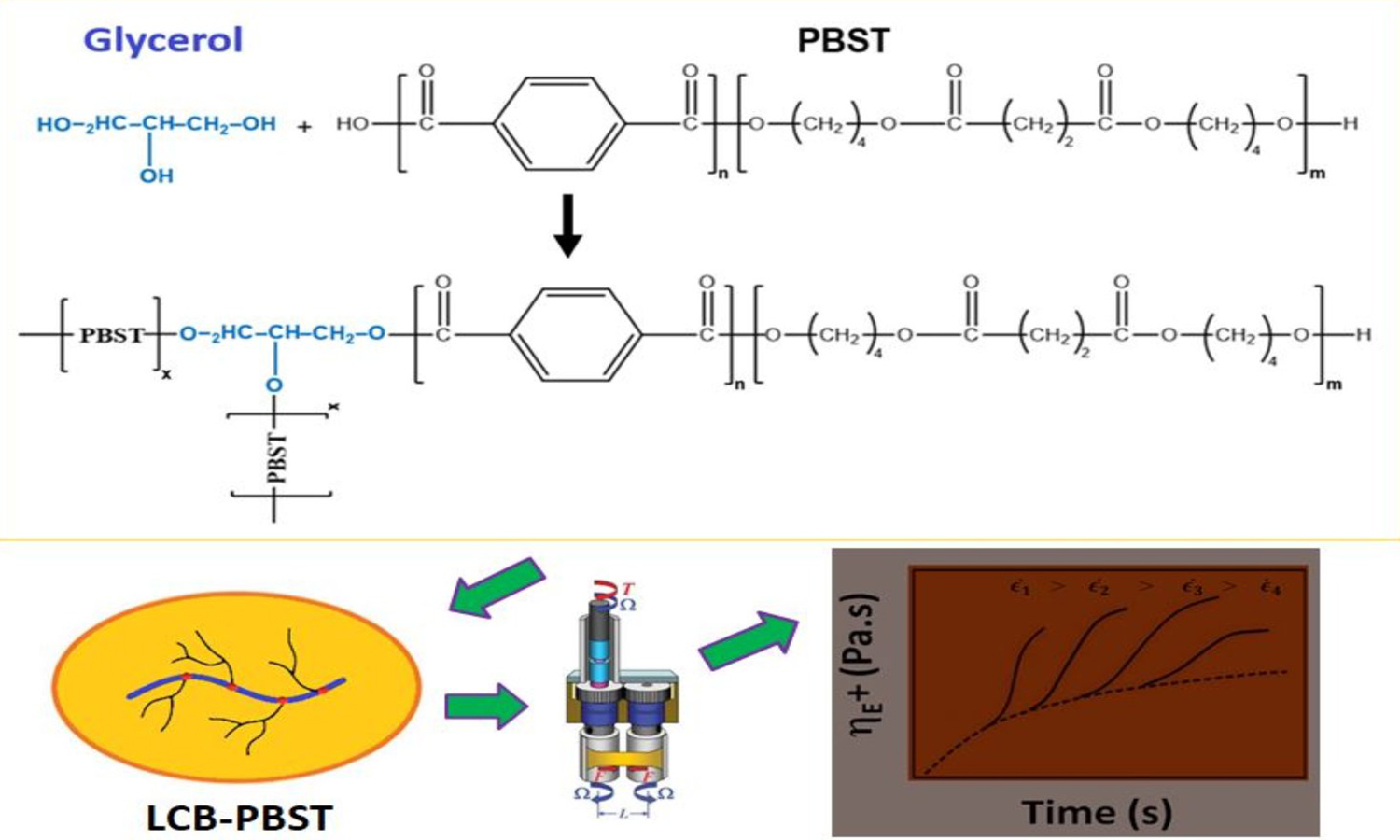

Mohamed Yousfi, Cédric Samuel, Tarek Dadouche, Rosica Mincheva, Marie-France Lacrampe

Vol. 17., No.3., Pages 300-316, 2023

DOI: 10.3144/expresspolymlett.2023.22

Vol. 17., No.3., Pages 300-316, 2023

DOI: 10.3144/expresspolymlett.2023.22

Highly biobased poly(butylene succinate-co-terephthalate) (PBST) with processing temperatures close to those of commodity polymers (160–180°C) and long-chain branched architectures (LCB) are synthesized by different strategies. Their rheological properties are investigated, in particular their melt strength properties. A two-step synthesis route is first proposed based on linear LCBs produced by polycondensation followed by reactive extrusion with an epoxy-based multifunctional agent Joncryl® at concentrations up to 2 wt%. A one-step synthesis strategy is also developed using glycerol as a branching agent, introduced at a low concentration (0.5 wt%) directly during the PBST polycondensation process. The molecular weights, LCB structures, and thermal properties are determined by triple detection size exclusion chromatography and differential scanning calorimetry. For PBSTs synthesized in two steps, gelation takes place simultaneously with the branching reactions. However, a concentration of Joncryl® close to 2 wt% is required to improve the melt strength properties, with strain hardening effects under elongation conditions. Interestingly, PBSTs synthesized by in-situ addition of glycerol show remarkable melt strength and a high melt stabilization process. Dynamic rheology investigations allow attributing these effects to statistical/homogeneous gel-free LCB architectures obtained during reactive extrusion without any additional post-processing. The effectiveness of approaches to easily improve the melt strength of highly biobased aliphatic-aromatic copolyesters (theoretical biobased content up to 85%) and to eliminate extrusion defects/instabilities in PBSTs is thus demonstrated, allowing the possibility of expanding the industrial application domains of these polymers in packaging and sustainable applications.

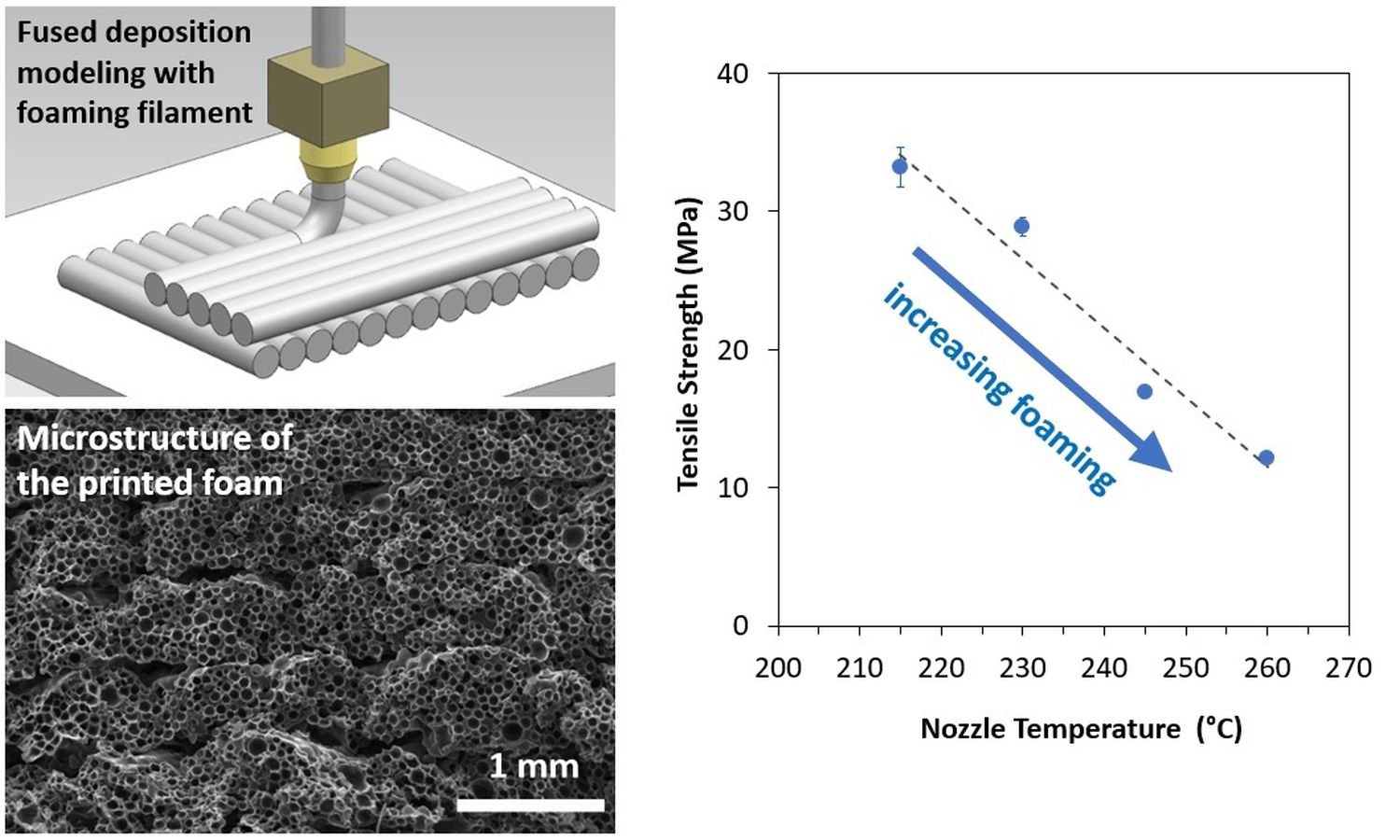

Abdullah Alduais, Sezer Özerinc

Vol. 17., No.3., Pages 317-333, 2023

DOI: 10.3144/expresspolymlett.2023.23

Vol. 17., No.3., Pages 317-333, 2023

DOI: 10.3144/expresspolymlett.2023.23

Fused deposition modeling (FDM) is a versatile additive manufacturing technique for producing polymeric parts. Incorporating a foaming agent into the filament material enables the FDM-printing of thermoplastic foams, which opens up new possibilities for achieving desired mechanical property combinations. This study explored the process-property design space of FDM-printed polylactic acid (PLA) foams. Tensile and compression specimens were produced at a wide range of printing parameters using a commercial thermoplastic filament containing a foaming agent. Increasing the nozzle temperature and decreasing the filament feed rate increased the extent of foaming. Adjustment of the nozzle temperature, feed rate, and infill ratio controlled porosity over a density range of 0.24 to 1.17 g/cm3. Tuning of the mechanical properties over an order of magnitude was demonstrated, with elastic moduli ranging from 0.24 to 3.7 GPa and tensile strength ranging from 4.2 to 34.5 MPa. The mechanical behavior closely followed the Gibson-Ashby model predictions. Foaming filaments provide a new tool for tuning the mechanical response of FDM-printed parts to achieve unique combinations of mechanical properties that are not attainable through conventional methods.

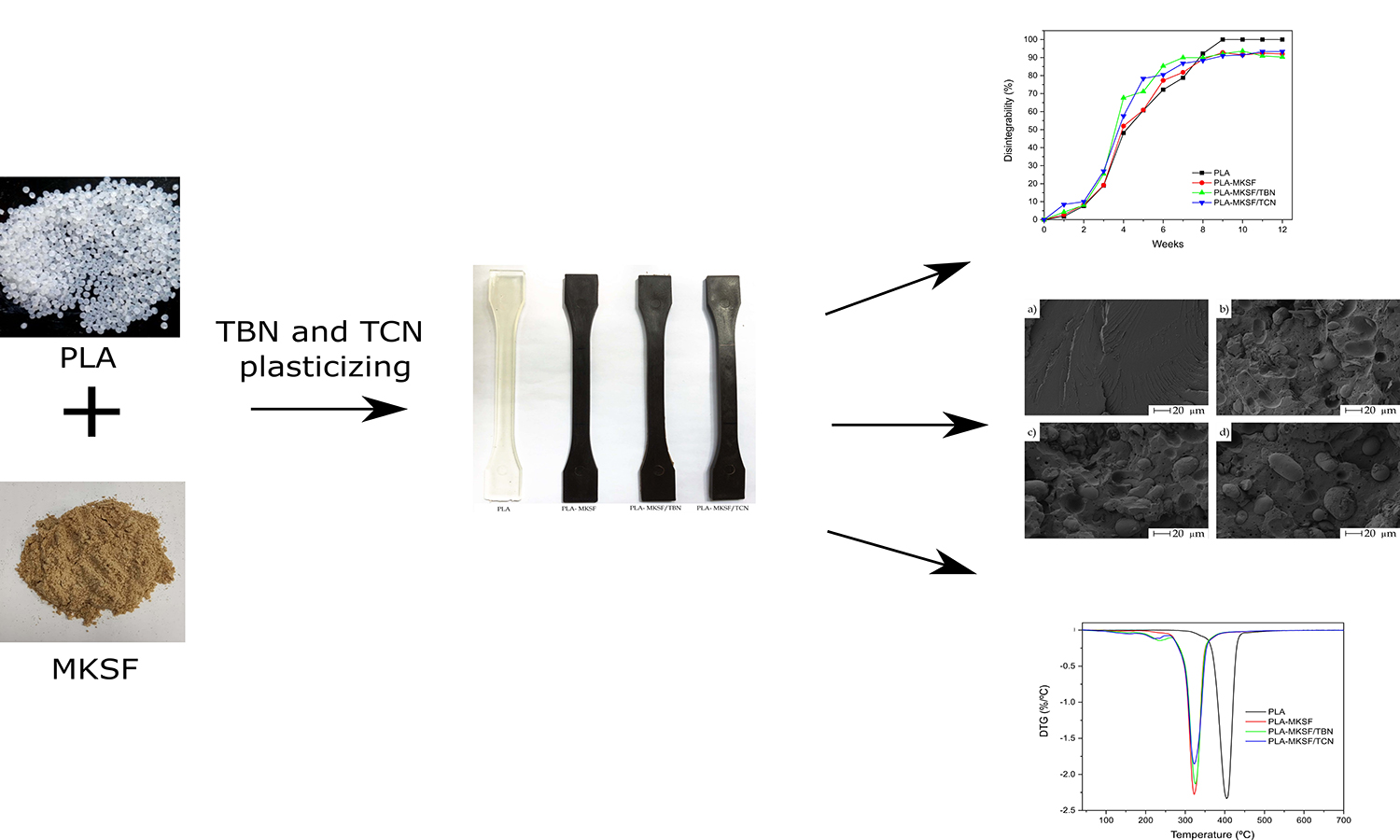

Jaume Gomez-Caturla, Diego Lascano, Nestor Montanes, Rafael Balart, Franco Dominici, Debora Puglia, Luigi Torre

Vol. 17., No.3., Pages 334-351, 2023

DOI: 10.3144/expresspolymlett.2023.24

Vol. 17., No.3., Pages 334-351, 2023

DOI: 10.3144/expresspolymlett.2023.24

This work reports on the development of polylactide (PLA)/mango kernel seed flour (MKSF) composites combined with tributyrin (TBN) and triacetin (TCN) as plasticizers. Thus, wood plastic composites (WPC) are obtained by extrusion and injection-molding processes. The solubility, mechanical, morphological, thermal, colorimetric, water absorbance, flowability, and disintegrability properties are evaluated. The ductility of the PLA+MKSF composite is improved by the plasticizing effect of TBN and TCN (10 phr (parts per hundred resin) each). Elongation at break is increased from 4.4 up to 9.5 and 8.3%, respectively. The theoretical solubility analysis supports the good miscibility between PLA with TBN and TCN (relative energy difference (RED) values of 0.86 and 0.73, respectively) deduced from the mechanical performance. Field emission scanning electron microscopy (FESEM) images also corroborate the mechanical findings, where a decrease in the presence of voids in the PLA matrix suggests certain compatibility between MKSF and TBN, and TCN. Differential scanning calorimetry (DSC) and dynamic-mechanical-thermal analysis (DMTA) results show that the plasticizers decrease the glass transition temperature and the melting temperature of PLA, thus improving its ductility. Thermogravimetric analysis (TGA) results indicate that the thermal stability of the composite is slightly decreased due to the relatively high volatility of the plasticizers, while MKSF does not affect this matter. The composites exhibit excellent biodegradability, presenting more than 90% of disintegration in compost soil conditions in 12 weeks. Finally, MKSF provided the composites with a wood-like dark brown color and with high water absorbance.