Hygroscopic elongation of moisture-responsive polyamide 6 fibers copolymerized with polyetherdiamine and adipic acid

Vol. 18., No.5., Pages 475-486, 2024

DOI: 10.3144/expresspolymlett.2024.35

DOI: 10.3144/expresspolymlett.2024.35

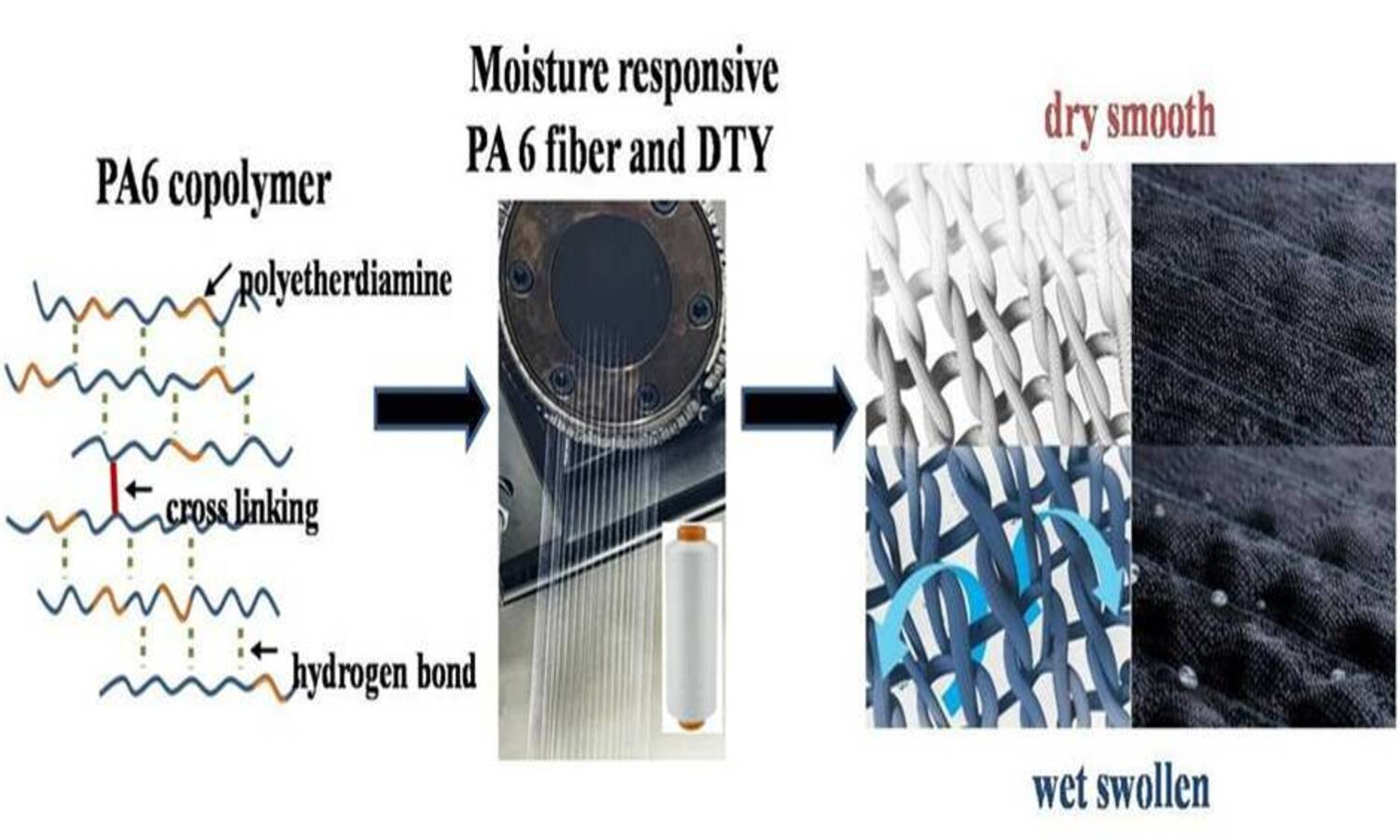

GRAPHICAL ABSTRACT

ABSTRACT

Smart materials represent an emerging and highly exploited category, particularly in the creation of textiles that can sense and respond to various external stimuli, such as temperature or humidity. This study introduces for the first time the hygroscopic elongation and drying shrinkage properties of stimulus-responsive single-component polyamide (PA) fibers copolymerized with polyetherdiamine and diethylenetriamine (DETA). PA copolymers containing 5–15% polyetherdiamine were comprehensively characterized, including nuclear magnetic resonance spectroscopy (NMR), Fourier transform infrared spectroscopy (FT-IR), relative viscosity, and differential scanning calorimetry (DSC) analyses. Subsequently, these PA copolymers were successfully melt-spun into fibers and knitted into double-layered fabrics. PA fibers containing 15% polyetherdiamine showed significant results, with a moisture-absorbing elongation of 15.6% and a drying shrinkage of 94.9%. The Qmax and moisture regain of the PA fabric are 0.206 W·cm–2 and 4.4%, respectively. These moisture-driven, fiber-based smart textiles exhibit changes in breathability and shape retention at different humidity levels, thereby maintaining a more comfortable microclimate. Such textiles have great potential for widespread use in clothing, helping to improve comfort and adaptability.

RELATED ARTICLES

Kankanok Longkaew, Philippe Daniel, Taweechai Amornsakchai, Thanchanok Ratvijitvech, Pranee Phinyocheep

Vol. 19., No.8., Pages 843-859, 2025

DOI: 10.3144/expresspolymlett.2025.64

Vol. 19., No.8., Pages 843-859, 2025

DOI: 10.3144/expresspolymlett.2025.64

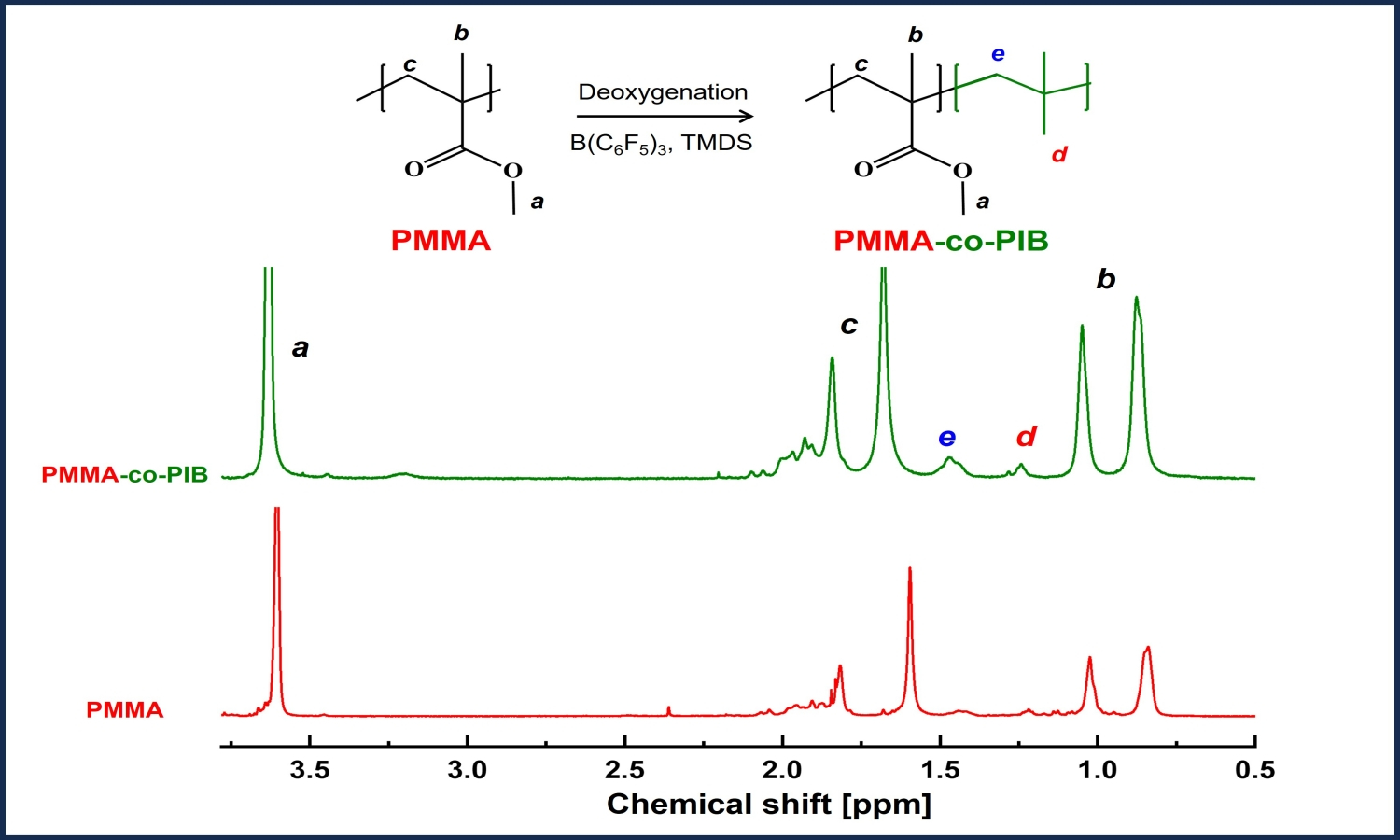

Poly(methyl methacrylate) or PMMA is a versatile material because of its ease of manipulation and biocompatibility. However, brittleness limits its applications; hence, copolymerization of PMMA with rubber such as polyisobutylene (PIB) is required. PMMA-co-PIB preparation by conventional copolymerization requires the purification of co-monomers under an inert atmosphere. In this study, the transformation of PMMA into PMMA-co-PIB was explored using a deoxygenation reaction. PMMA was treated with tris(pentafluorophenyl) borane and 1,1,3,3-tetramethyldisiloxane (TMDS) at room temperature, 50, and 70 °C for 1, 2, and 3 day reaction times. FTIR results revealed a reduction in the ester functional group of PMMA at 1724 cm–1. PMMA was partially converted into PIB moieties, forming PMMA-co-PIB. The highest degree of deoxygenation (48.2%) was obtained after a reaction for 1 day at room temperature. When the PIB structure was present in the PMMA backbone, the PMMA glass transition temperature (115.6 °C) was shifted to a lower temperature (83.7°C). A significant decrease in the modulus of PMMA from 3.40 to 1.29 GPa (PMMA-co-PIB) reveals improved toughness. This straightforward post-polymerization approach involving the deoxygenation of PMMA offers a promising, simple, and mild condition for synthesizing PMMA-co-PIB. This will enable new applications in medical appliances or high-value coating materials.