Enhanced thermal stability and flame retardancy of PLA through intumescent flame retardant with B-modified ZSM-5 as a synergistic agent

Xiaokun Zhai, Qin Ma, Jing Lu, Yuwei Jin, Ruiyan Zhang, Faliang Luo

Vol. 18., No.3., Pages 326-336, 2024

DOI: 10.3144/expresspolymlett.2024.23

DOI: 10.3144/expresspolymlett.2024.23

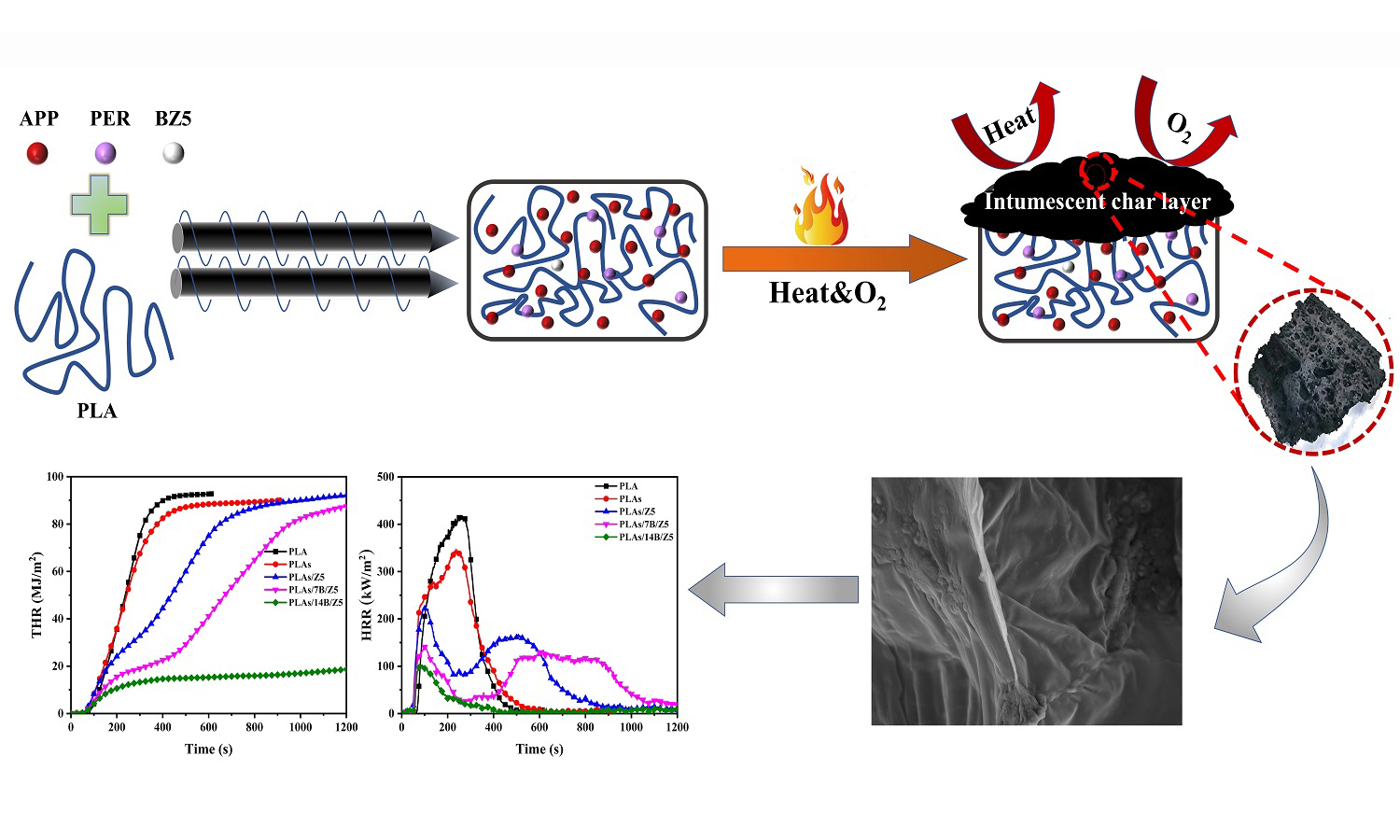

GRAPHICAL ABSTRACT

ABSTRACT

In order to improve the inherent flammability of polylactic acid (PLA) and make this new biodegradable material more widely used, B-modified ZSM-5 (B/Z5) was designed as synergistic agent of intumescent flame retardant (IFR), composed of ammonium polyphosphate (APP) and pentaerythritol (PER), and introduced into PLA/IFR (PLAs) to fabricate PLAs/B/Z5 composites by melt extrusion. The flame retardancy, surface morphology, and thermal stability of the composites were investigated by TG, LOI, UL-94, CCT, and SEM. The addition of B/Z5 makes the decomposition temperature of T5% as well as T10% of PLAs reduction in nitrogen atmosphere and carbon layer form in advance. UL-94 test shows the composites reach V-0 rating. LOI value also steadily increases, and the maximum value is 36.0% with B actual loading of 5.26% (recoded as 14B/Z5) in B/Z5. The PHRR decreases by 75% from 417.77 kW/m2 for pure PLA to 103.19 kW/m2 for PLAs/14B/Z5, and THR reduces from 92.78 to 19.26 MJ/m2, which decreases by about 80% and the char yield reaches 50%. This study provides a simple and green method for the preparation of high flame-retardant PLA, which has a broad practical application prospect.

RELATED ARTICLES

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

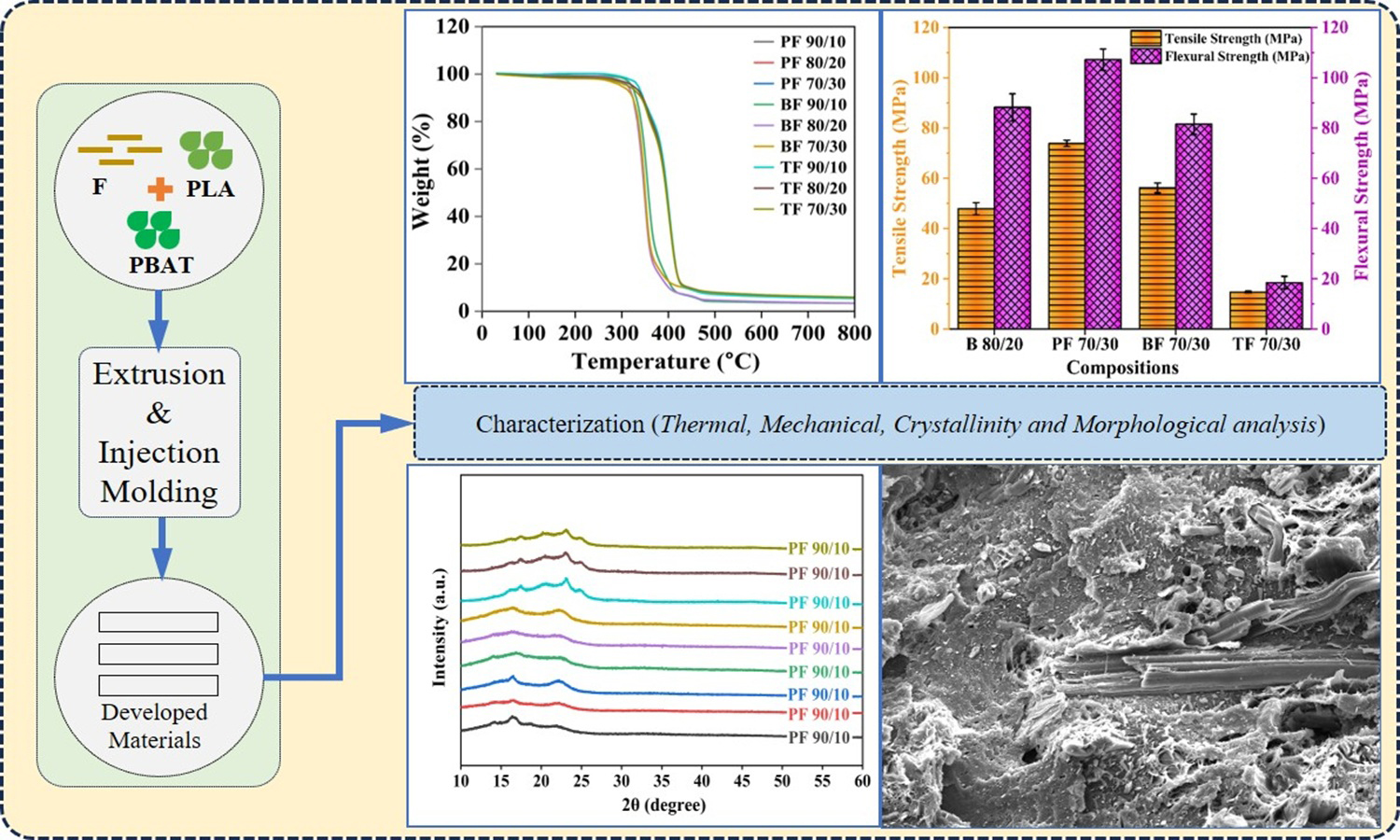

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Elumalai Vengadesan, Swaminathan Muralidharan, Dhanjit Das, Thirugnanasambandam Arunkumar

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

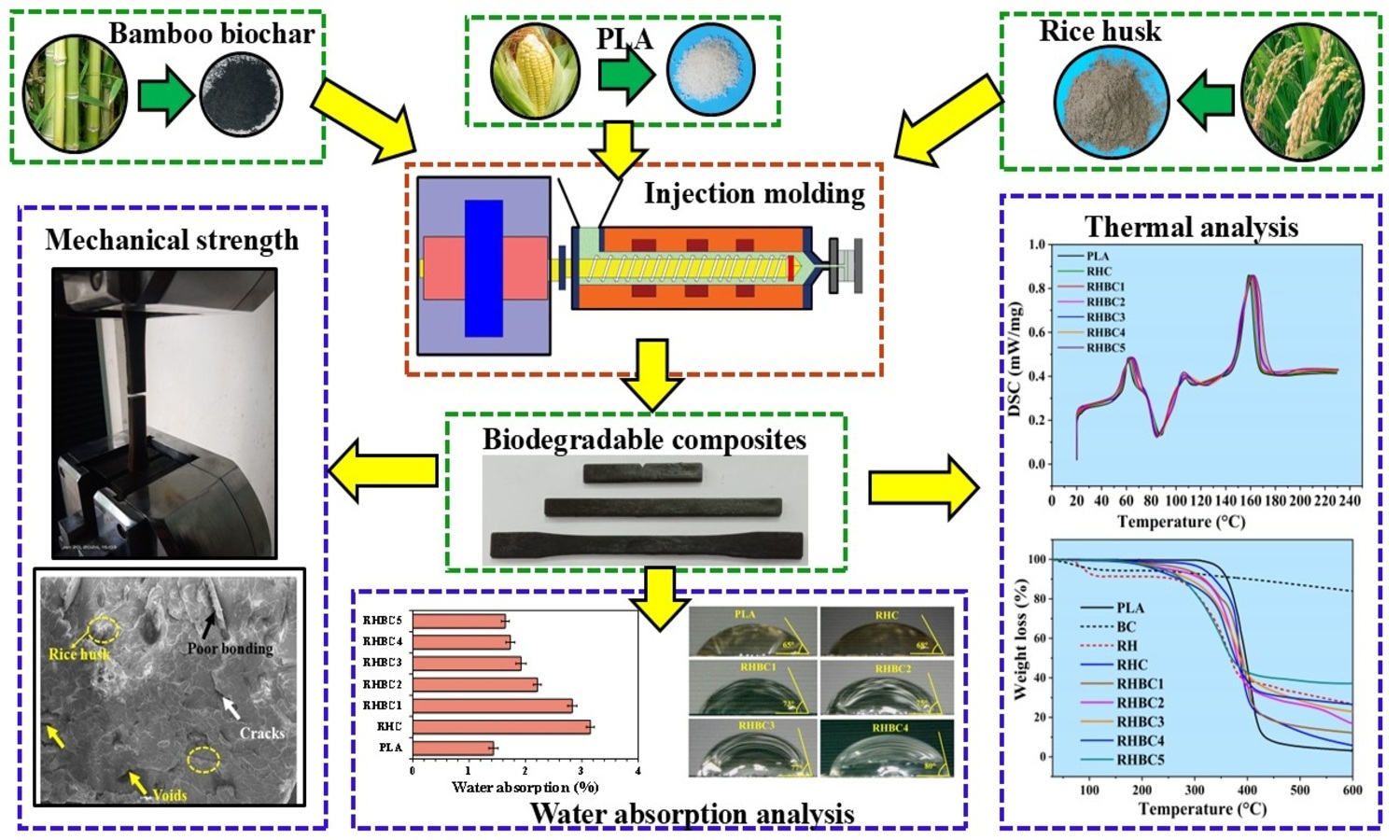

The growing need for sustainable materials has stimulated research into eco-friendly composites, with biochar emerging as an important reinforcement in polymer matrices. Biochar is a carbon-rich material produced by pyrolyzing organic biomass, offering various benefits over traditional fillers, including sustainability, waste reduction, and carbon sequestration. This study explores the effects of bamboo biochar as a hybrid reinforcement on the properties of polylactic acid (PLA)-rice husk composites. The present hybrid composites are prepared by varying the bamboo biochar from 5–25% and have better mechanical properties than PLA and its composite reinforced with a rice husk filler. The tensile, flexural, and compressive strengths of 51.5, 166.0, and 77.5 MPa are measured for the biochar percentage of 10%, representing increases of 73.1, 150.0, and 58.2% compared to PLA, and 158.2, 98.6, and 31% compared to the PLA composite with rice husk. Higher tensile and flexural moduli of 1.46 and 7.34 GPa are observed for 10 and 15%, respectively. However, the impact strength decreases with higher biochar content due to increased rigidity. The material’s hardness increases at higher biochar content due to enhanced stiffness. Thermal transition and degradation points rise due to increased crystallinity from the biochar reinforcement’s nucleation effect. Additionally, the hydrophobic biochar reinforcement reduces water absorption of PLA composite from 3.2 to 1.6%.