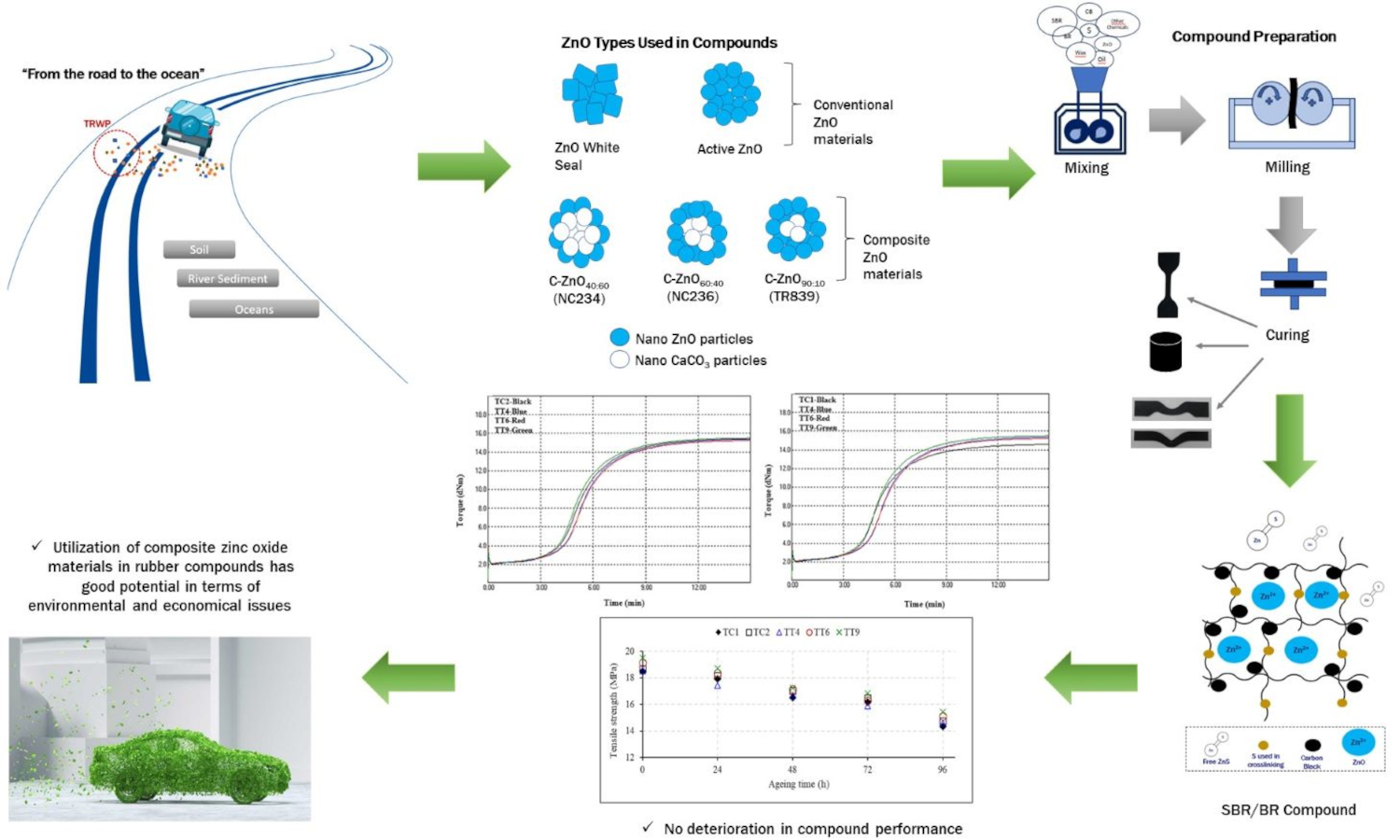

Utilization of composite ZnO in SBR/BR compounds and its effect on the cure and physicomechanical properties

Cansu Börüban Bingöl, Şeyda Polat, Ş. Hakan Atapek

Vol. 18., No.5., Pages 461-474, 2024

DOI: 10.3144/expresspolymlett.2024.34

DOI: 10.3144/expresspolymlett.2024.34

GRAPHICAL ABSTRACT

ABSTRACT

Zinc complexes have a considerable impact on human health and the environment, especially on aquatic wildlife. One of the primary sources of zinc release to the environment is worn rubber particles from tires. The environmental footprint of zinc oxide (ZnO) during production, use, and landfilling has prompted researchers to reduce its use in rubber formulations due to ecological and economic concerns. In this study, composite ZnO materials where ZnO particles are coated on precipitated calcium carbonate (CaCO3) are used in styrene butadiene rubber/butadiene rubber (SBR/BR) compounds, and their performance is compared with white seal ZnO and active ZnO. Trial compounds are prepared on a laboratory scale using composite ZnO materials with ZnO:CaCO3 ratios of 40:60, 60:40, and 90:10, and control compounds with white seal and active ZnO. All compounds are tested to evaluate their curing and physico-mechanical properties. It is observed that the surface area of ZnO plays an essential role in crosslink density and, hence, compound performance. Trial materials have no negative effect on the curing and mechanical properties of the compounds. Thus, it is concluded that composite ZnO materials can be used as alternatives to both white seal ZnO and active ZnO. They have environmental and economic advantages due to their lower ZnO content. The compound recipe has the potential to be used for tire tread compounds.

RELATED ARTICLES

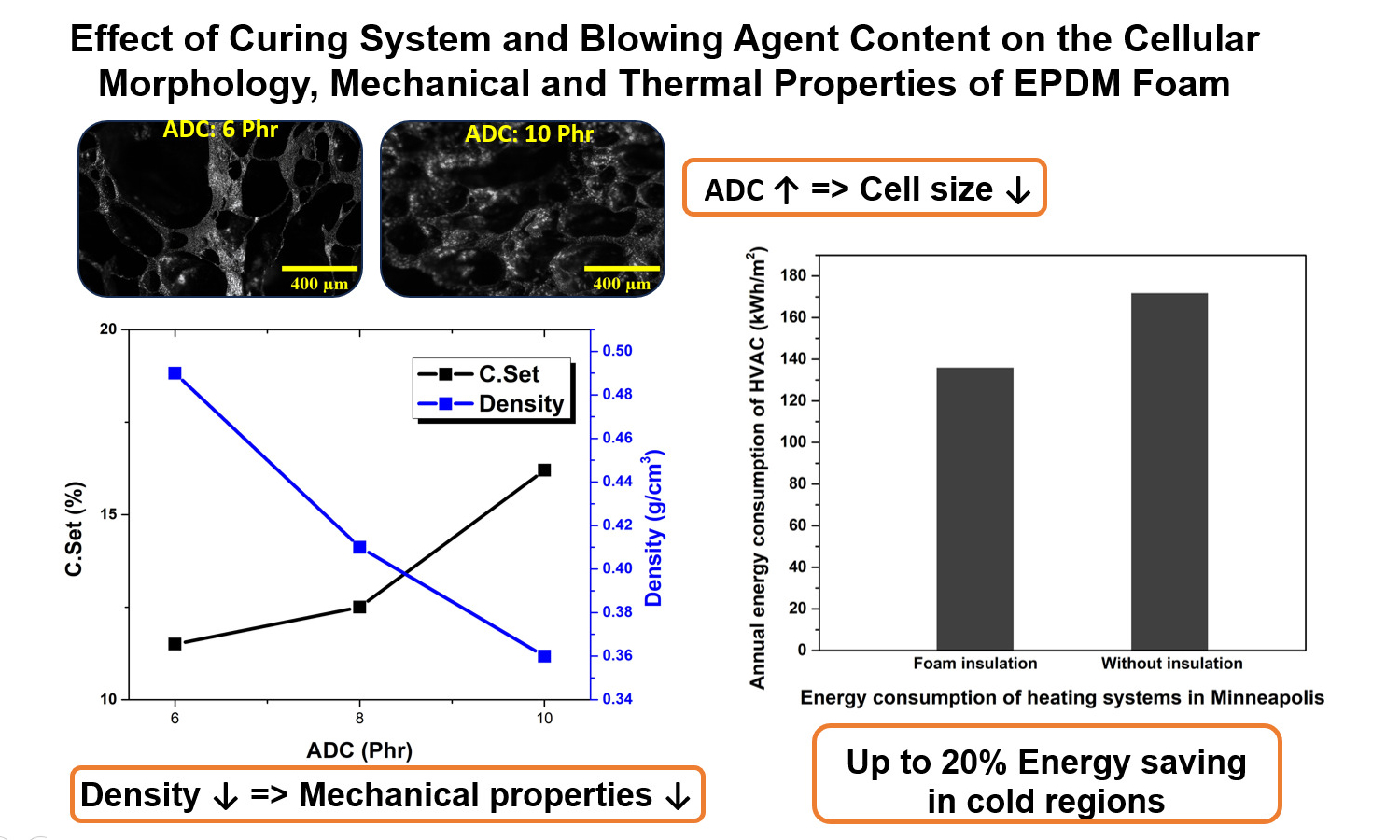

Kazem Honarkar, Mohammad Karrabi

Vol. 20., No.3., Pages 311-323, 2026

DOI: 10.3144/expresspolymlett.2026.24

Vol. 20., No.3., Pages 311-323, 2026

DOI: 10.3144/expresspolymlett.2026.24

In this study, the effect of the amount of blowing agent and the type of sulfur curing system on the cellular structure, thermal, and mechanical properties of ethylene-propylene-diene monomer (EPDM) foam was investigated. Three types of sulfur curing systems including efficient, semi-efficient and conventional and three variable levels of azodicarbonamide (ADC) were considered; as a result, nine EPDM foam formulations were evaluated. Curing process parameters were measured using cure rheometry and cellular structure was examined by optical microscopy images, determining the average cell size and size distribution. For evaluating physical and mechanical properties, density and compression set tests were performed. Thermal conductivity tests were conducted on selected samples. Building energy modeling was performed using DesignBuilder software to evaluate the thermal insulation performance of the foams. The results showed that the type of curing system and the amount of ADC significantly affect cell morphology, density, and mechanical properties. Overall, a decrease in density leads to reduced mechanical properties. The modeling results indicated that using EPDM foams as building thermal insulation can reduce the energy consumption of heating, ventilation, and air conditioning (HVAC) systems by up to 20%.

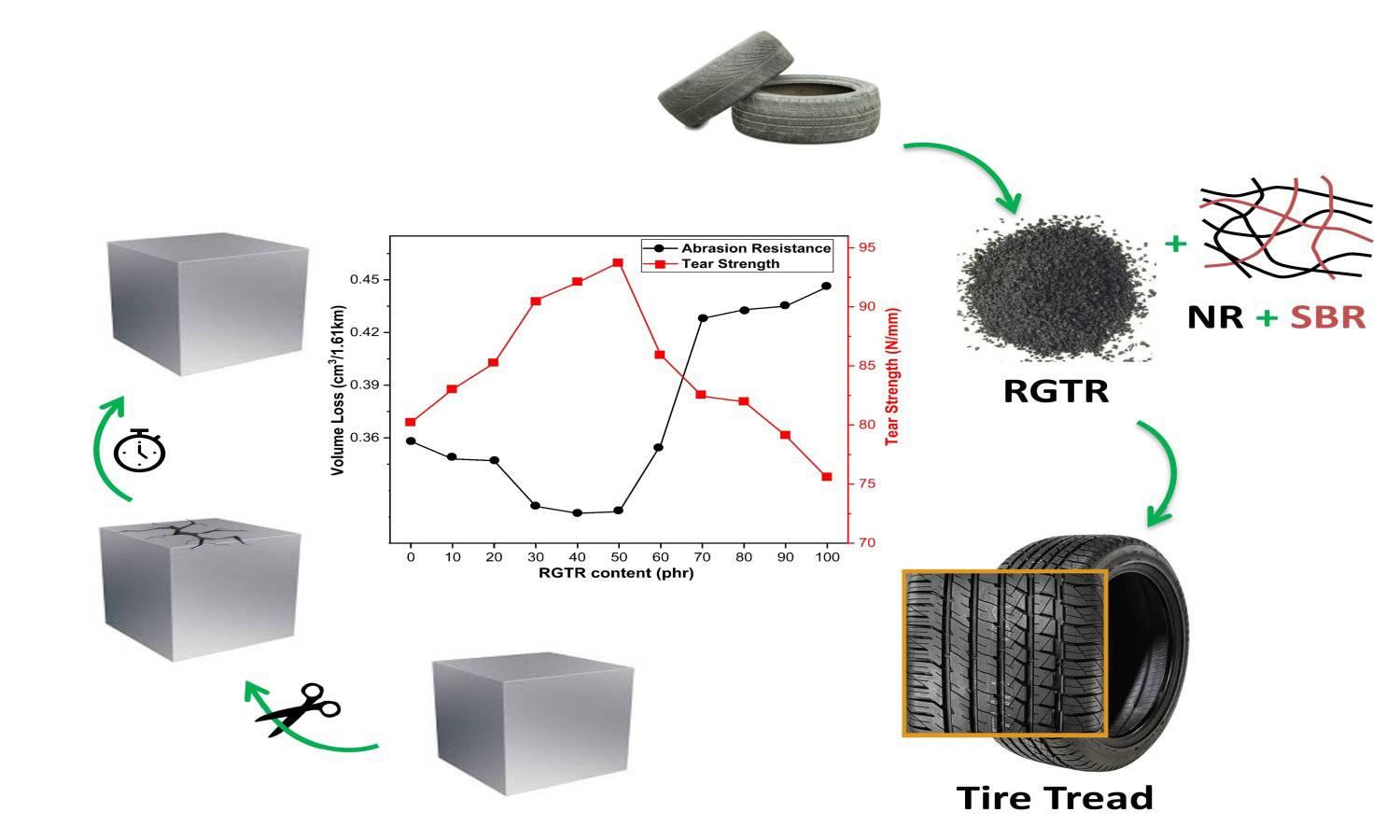

Reinforcing effect of thermo-oxidative reclaimed rubber on NR/SBR blends for tire tread applications

Yunhui Xu, Zaheer ul Haq, Junrong Li, Hui Tu, Zaixue Wang, Houluo Cong

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

This study explores the application of thermo-oxidative reclaimed ground tire rubber (RGTR) in natural rubber (NR)/styrene butadiene rubber (SBR) composite, focusing on its impact on morphology, mechanical properties, rheological behavior, vulcanization characteristics, aging resistance, tear strength and abrasion resistance. The findings revealed that RGTR enhances the tear strength and abrasion resistance of NR/SBR composites while maintaining comparable tensile strength, elongation at break, and modulus. The incorporation of RGTR reduced Mooney viscosity of the NR/SBR composites and improved flowability. It also shortened the vulcanization time and enhanced vulcanization efficiency. The NR/SBR composites with RGTR loadings below 60 phr exhibited optimal performance, achieved a maximum tear strength of 93.77 N/mm and improved abrasion resistance. However, higher RGTR content led to increased agglomeration, as evidenced by scanning electron microscopy (SEM), which showed finer dispersion at lower RGTR contents and larger aggregates at higher loadings. These findings demonstrate the potential of RGTR as a sustainable additive for enhancing specific properties in NR/SBR composites, contributing to both performance optimization and waste tire management.

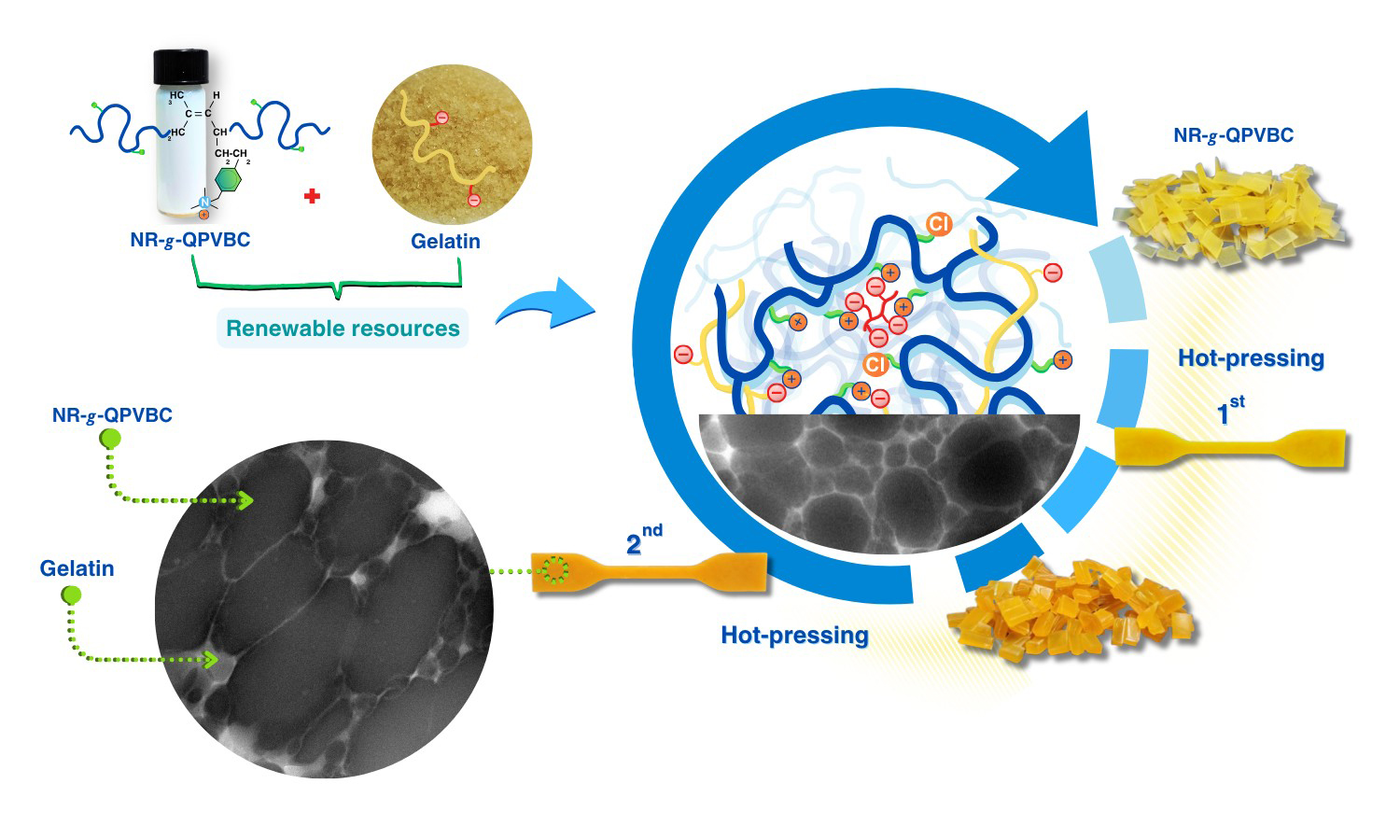

Rattanawadee Ninjan, Bencha Thongnuanchan, Phakawat Tongnuanchan, Subhan Salaeh, Jutharat Intapun, Abdulhakim Masa, Natinee Lopattananon

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

The present study has proposed a straightforward method to improve the reprocessability of modified natural rubber (NR) by blending it with gelatin (GT). The reprocessable characteristics of these blends were evaluated based on their remolding capabilities and mechanical recovery performance. In this method, poly(vinylbenzyl chloride) (PVBC) was first grafted onto NR chains to create graft copolymers known as NR-g-PVBC. The benzyl chloride groups in the graft copolymers were subsequently converted into quaternary ammonium groups, referred to as NR-g-QPVBC. This modification enabled ionic crosslinking when NR-g-QPVBC reacted with ethylenediamine tetraacetic acid. Blends were created by incorporating GT powder into the NR-g-QPVBC latex. The optimal loading level of GT was determined to be 30 wt%, as the resulting film exhibited the highest recovery of tensile properties. Initially, the film's tensile strength was measured at 15 MPa. After being remolded at 160 °C, the tensile strength decreased to 9.3 MPa, resulting in a recovery rate of 60.7% and withstanding a tensile strain of 144%. Although the NR-g-QPVBC/GT films could be remolded, their tensile properties declined with increasing remolding cycles. Therefore, this work demonstrated a practical method for producing NR-based films that could be reshaped through hot-pressing after being formed into products, increasing their reusability.

Xue Xu, Rujie Li, Li Gao, Beibei Sun, Hongming Liu, Shiai Xu

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

Vol. 19., No.9., Pages 959-976, 2025

DOI: 10.3144/expresspolymlett.2025.72

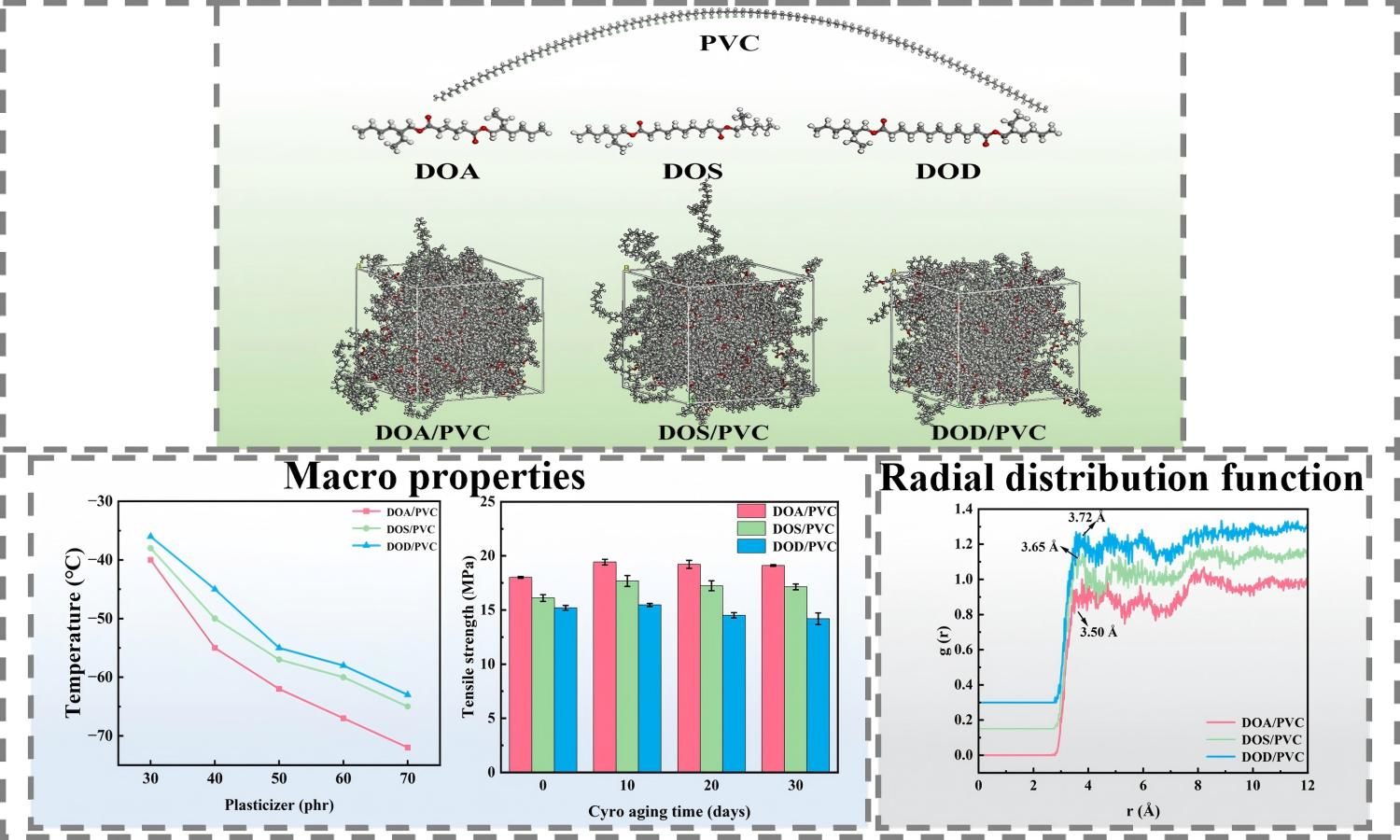

As polyvinyl chloride (PVC) films are hard and brittle in a low-temperature environment, aliphatic dibasic acid ester plasticizers with different acid chain lengths were fabricated, i.e. di(2-ethylhexyl) adipate (DOA), di(2-ethylhexyl) sebacate (DOS) and dioctyl dodecanedioate (DOD), and their effects on the cold-resistant properties of PVC were investigated using experiments and molecular dynamics (MD) simulations. The brittleness temperature and tensile properties of plasticizers/PVC are negatively related to the acid chain length of the aliphatic dibasic acid esters. The brittleness temperatures of the three systems are all below –50 °C. In-situ low-temperature tensile tests and aging tests indicate that DOA/PVC exhibits the best cold resistance and stability. MD simulations further reveal that the best compatibility between DOA and PVC is attributed to its strong binding energy and weak hydrogen bonding interactions, while van der Waals forces are dominant in DOS/PVC and DOD/PVC. This study elucidates the structure-property relationship between aliphatic dibasic acid ester plasticizers and PVC from the perspective of molecular interactions, and provides insights into the design of cold-resistant PVC plasticizers.

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

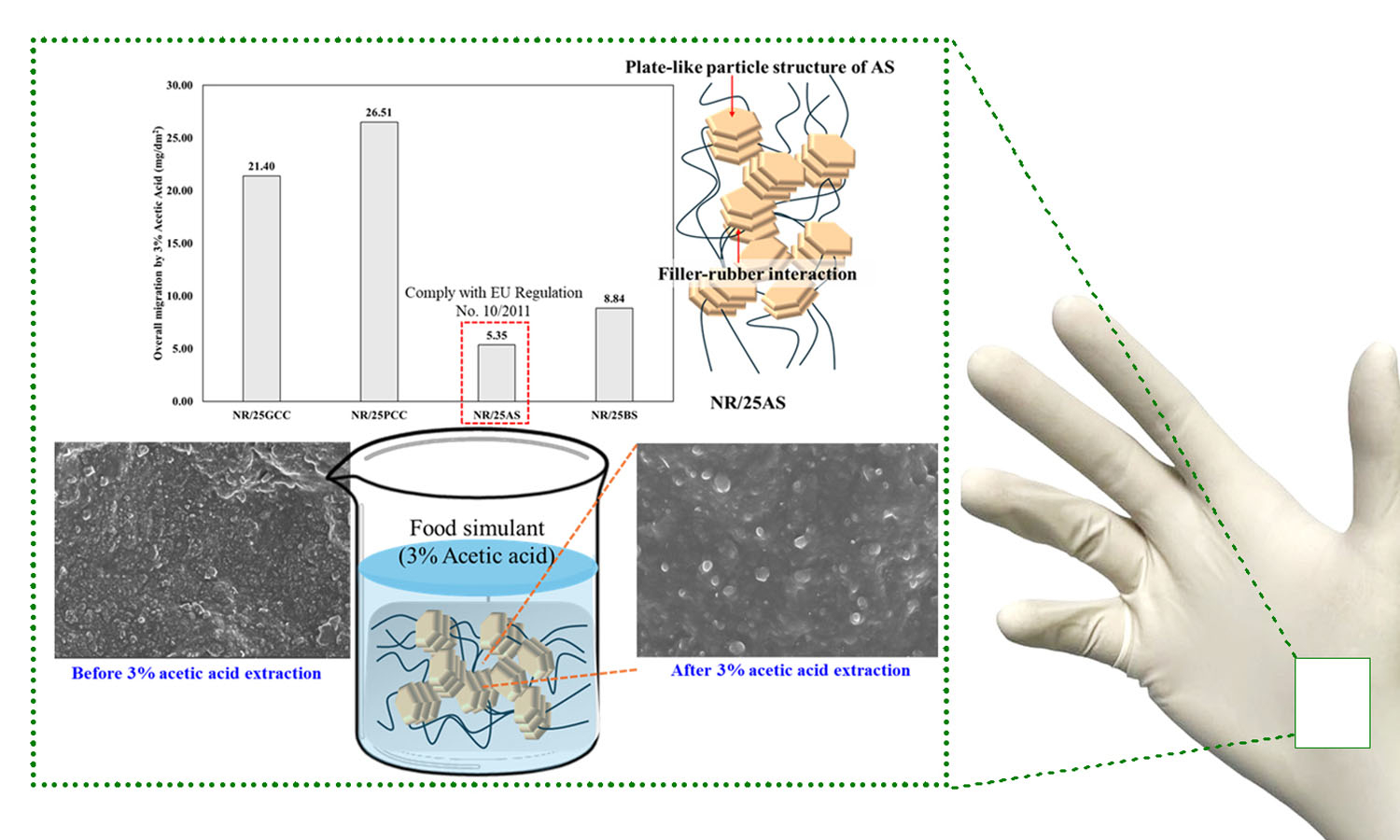

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.