Determination of the brittleness of glass fibers on selected mechanical and rheological properties of the polymer composite

Vol. 18., No.10., Pages 1051-1062, 2024

DOI: 10.3144/expresspolymlett.2024.80

DOI: 10.3144/expresspolymlett.2024.80

GRAPHICAL ABSTRACT

ABSTRACT

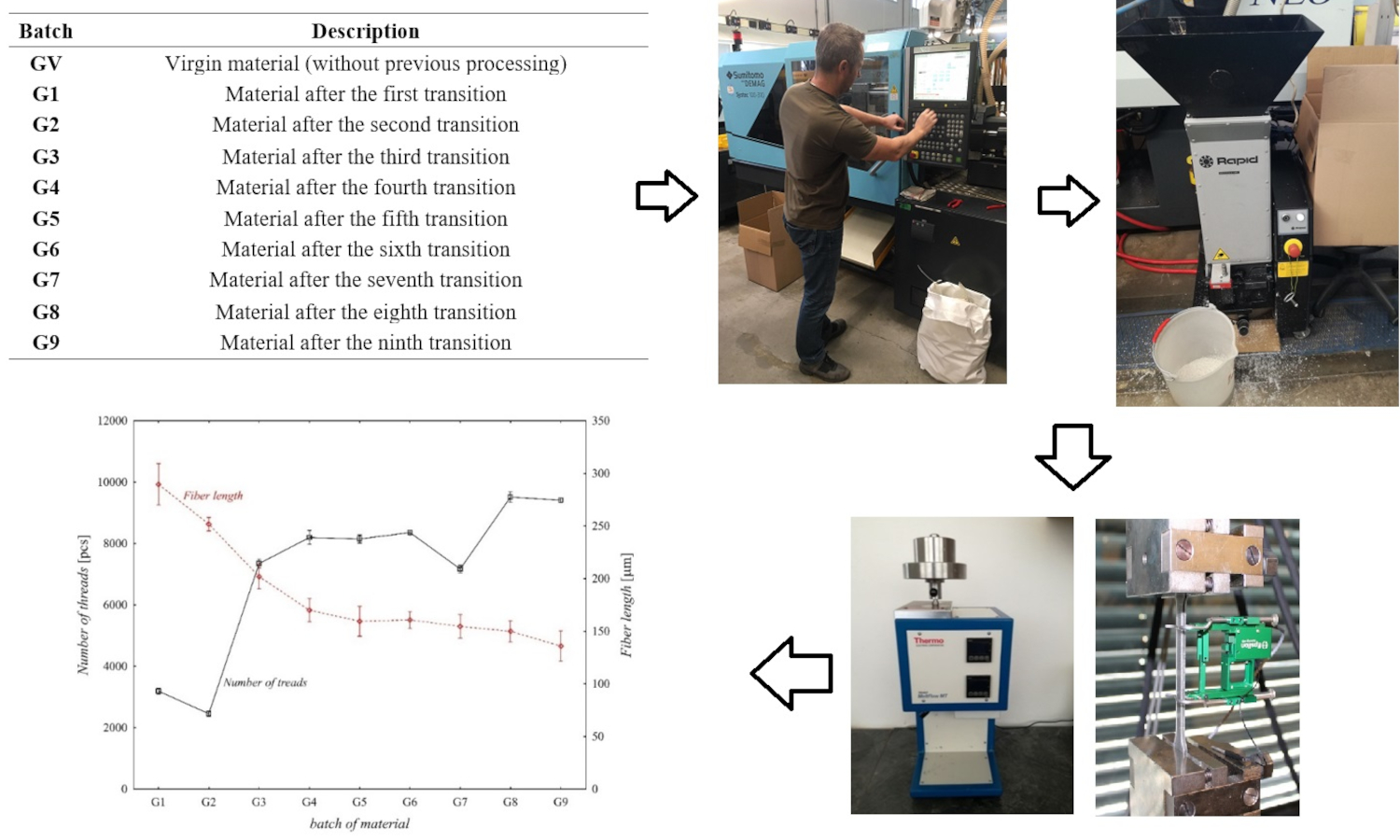

The paper deals with the influence of the brittleness of glass fibers on the selected performance properties of the fibrous polymer composite. Understanding the fatigue behavior of fiber-reinforced plastics is desirable for exploiting their features in safe, durable, and reliable industrial components. Based on the proposed methodology, it is possible to assess the impact of material reuse on selected mechanical and rheological properties. To verify the methodology by experimental analysis, homopolymer PP reinforced with chemically grafted glass fiber (30 wt%) was selected. The proposed methodology was subsequently verified by experimental analysis and evaluated statistically. The morphology of the fracture surfaces was evaluated, and the fiber-polymer matrix adhesion was monitored at the interface of the fracture surfaces. Based on the measured and evaluated values and fracture surfaces, we can say that the brittleness of the fibers significantly affects the performance properties of the tested polymer composite.

RELATED ARTICLES

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

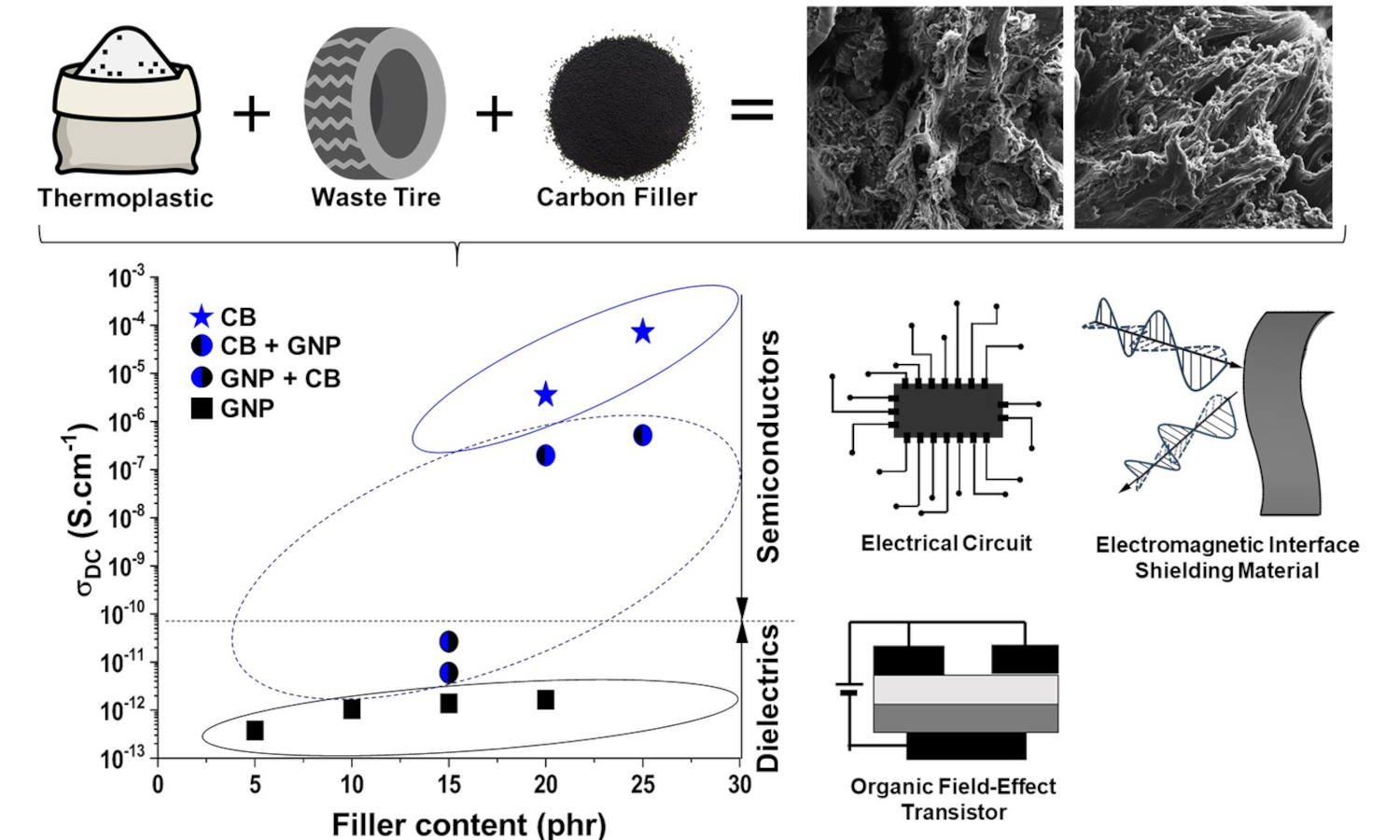

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

Enikő Hornyák-Mester, Miklós Varga, Lilla Márta Sőrés-Tölli, Dóra Mentes, Alpár F. Hatvani-Nagy, Peter Werner Groh, Béla Viskolcz, Gábor Muránszky, Béla Fiser

Vol. 18., No.10., Pages 964-975, 2024

DOI: 10.3144/expresspolymlett.2024.74

Vol. 18., No.10., Pages 964-975, 2024

DOI: 10.3144/expresspolymlett.2024.74

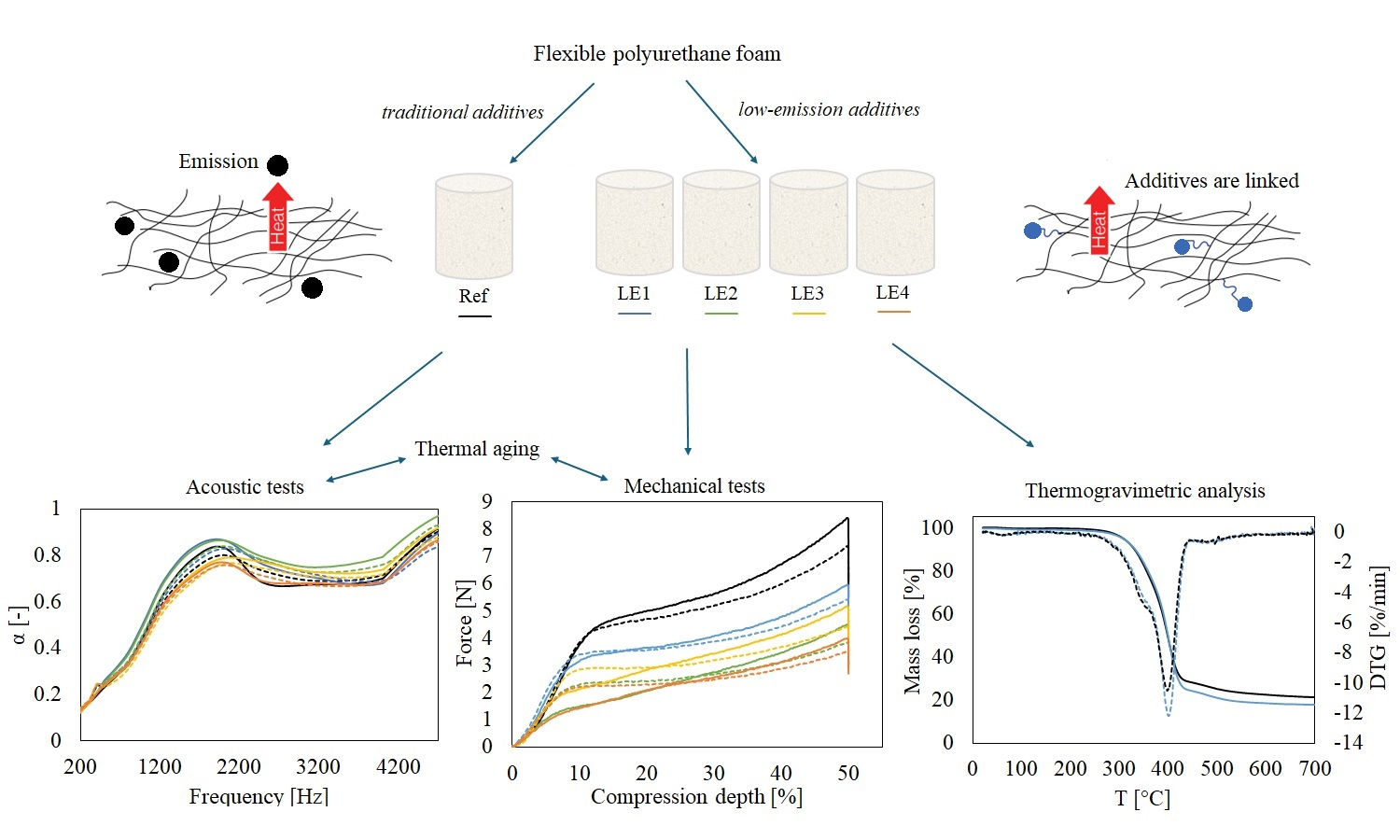

The degradation of different flexible polyurethane foams for molded application after thermal aging were compared. A reference sample using traditional higher emission additives and four samples of different composition using low-emission additives were compared. For the modified samples volatile organic compound (VOC) and semi-volatile organic compound (FOG/SVOC) contents fell well below the benchmarking limits, which indicates that the selected low-emission additives are incorporated into the polymer chain. To examine different material properties and for evaluating changes due to increased temperature exposure for a prolonged period of time mechanical and acoustic tests were carried out before and after dry heat aging. It was found that two low emission samples exhibited superior sound absorption compared to the reference sample along with less significant change after aging in the acoustic properties. The compressive strength was lower than the reference as a result of lower product densities. However, the change in compressive strength after aging was less than 15% (with one exception), which is acceptable according to the standard requirements. Thermogravimetric analysis was also performed and revealed that no significant difference can be observed between the examined samples due to heat degradation, indicating that the modifications made to reduce VOC content did not adversely affect the foam’s resistance to thermal degradation.