Biowastes as reinforcements for future development of sustainable polymer composites

Sanjay Mavinkere Rangappa, Suchart Siengchin

Vol. 18., No.12., Pages 1176-1177, 2024

DOI: 10.3144/expresspolymlett.2024.89

DOI: 10.3144/expresspolymlett.2024.89

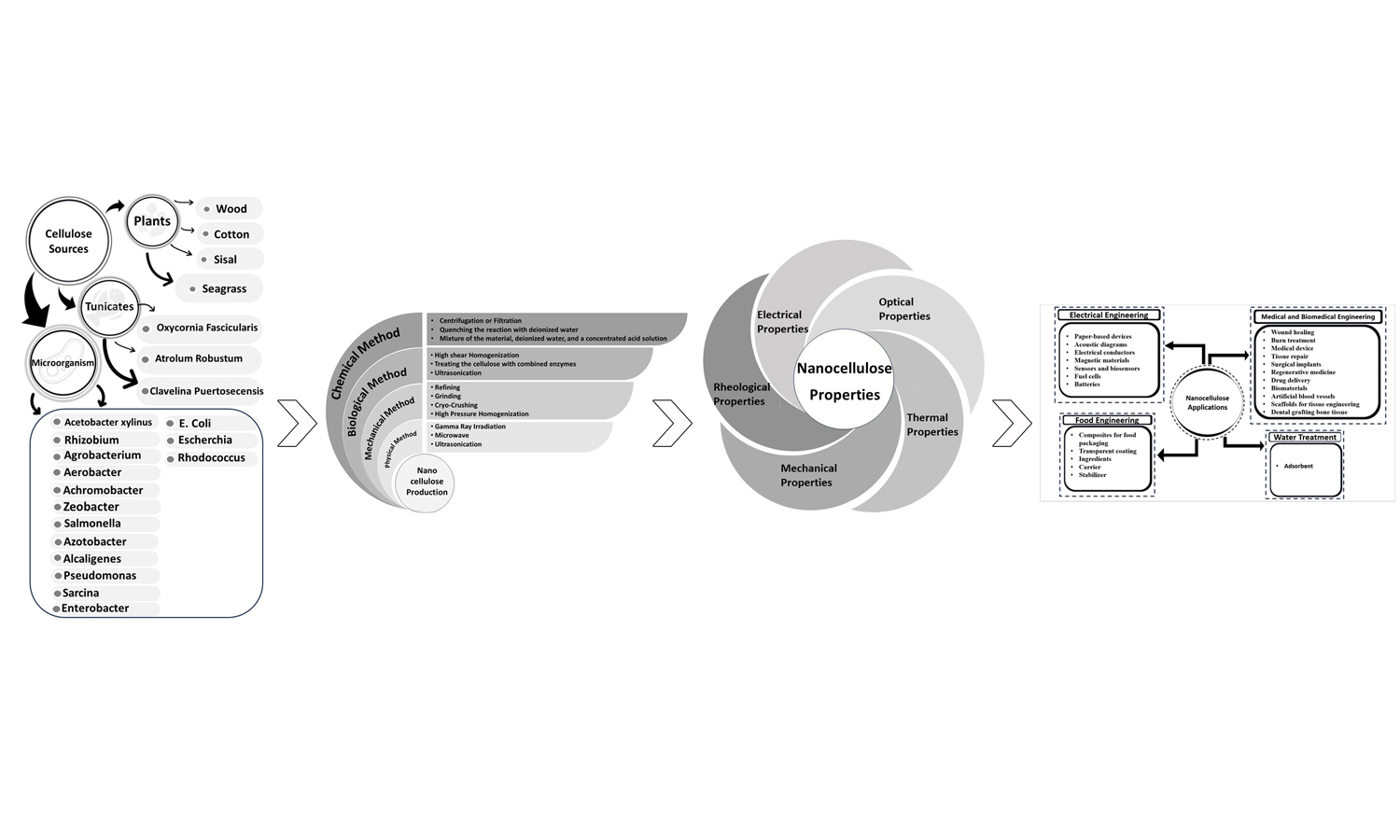

GRAPHICAL ABSTRACT

RELATED ARTICLES

Eva Kuželová Košťáková

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

This is an editorial article. It has no abstract.

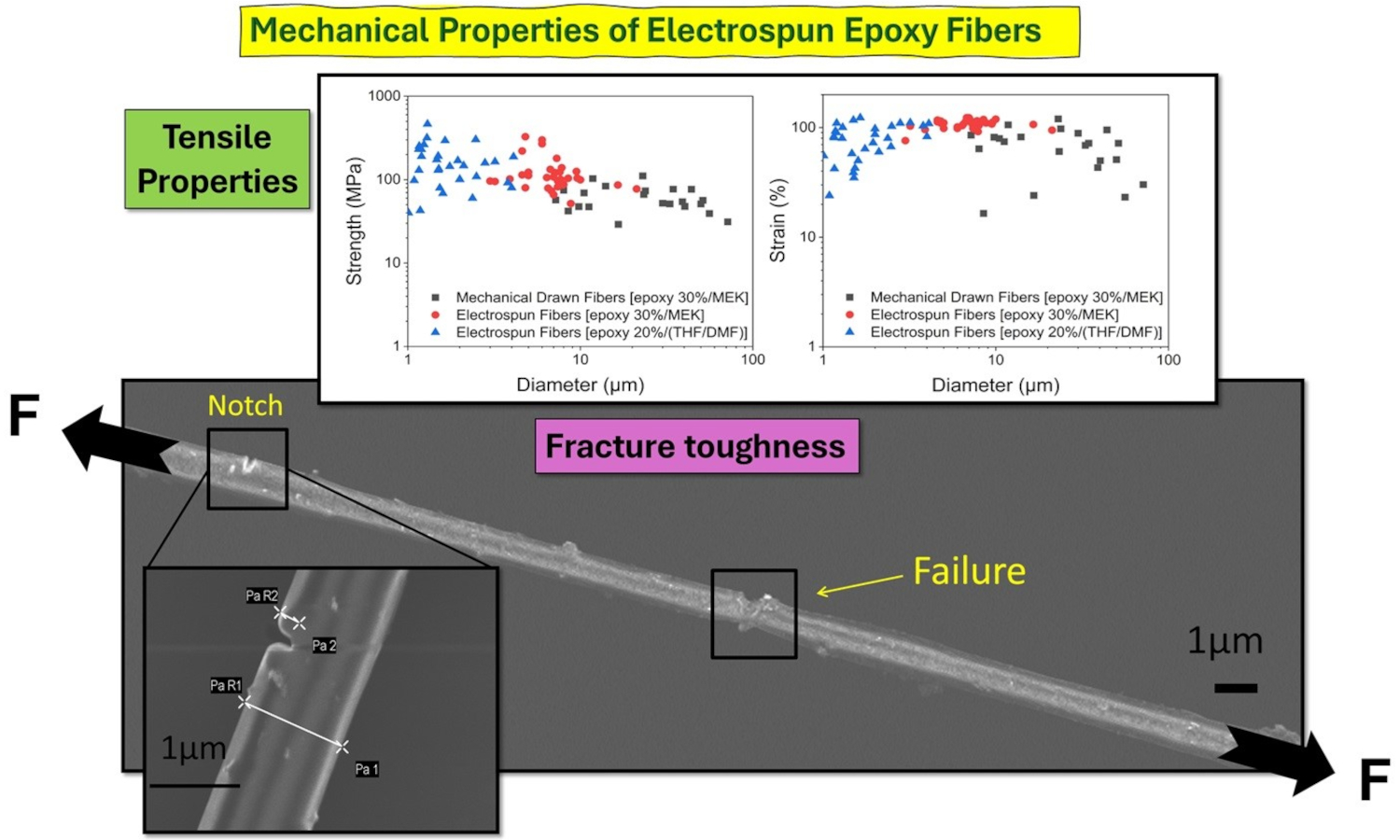

Mark Shneider, Xiaomeng Sui, Iddo Pinkas, Ulyana Shimanovich, Israel Greenfeld, Daniel Wagner

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Electrospinning is a widely used technique for manufacturing nanofibers from polymers. The formation of continuous fibers during the drawing of a viscous solution typically depends on entanglements between polymer chains, making thermoplastics the preferred choice. In this study, we have shown that thermosetting polymers such as epoxy, which have crosslinked covalent bonds, can also be electrospun. The resulting fibers have diameters ranging from 150 nm to 6 μm. Tensile mechanical properties of fibers with diameters varying between 410 nm and 4 μm are compared with those of molded epoxy bulk. The electrospun fibers exhibit approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to the equivalent properties of bulk epoxy. When compared with brittle molded bulk, these fibers showed ductile properties. We also observed a correlation between the fiber diameter and the mechanical properties. The molecular morphology of the fibers was monitored and analyzed using polarized micro-Raman spectroscopy to detect molecular orientation. A comparison with epoxy fibers of different diameters from previous studies was conducted to better understand the size effect. This study shows, explains and models the evolution of epoxy molecular morphology from the solution (soft matter) to fiber (solid-state), explaining the transition from brittle to ductile in epoxy fibers, and clarifying the molecular mechanisms that lead to improved mechanical properties.

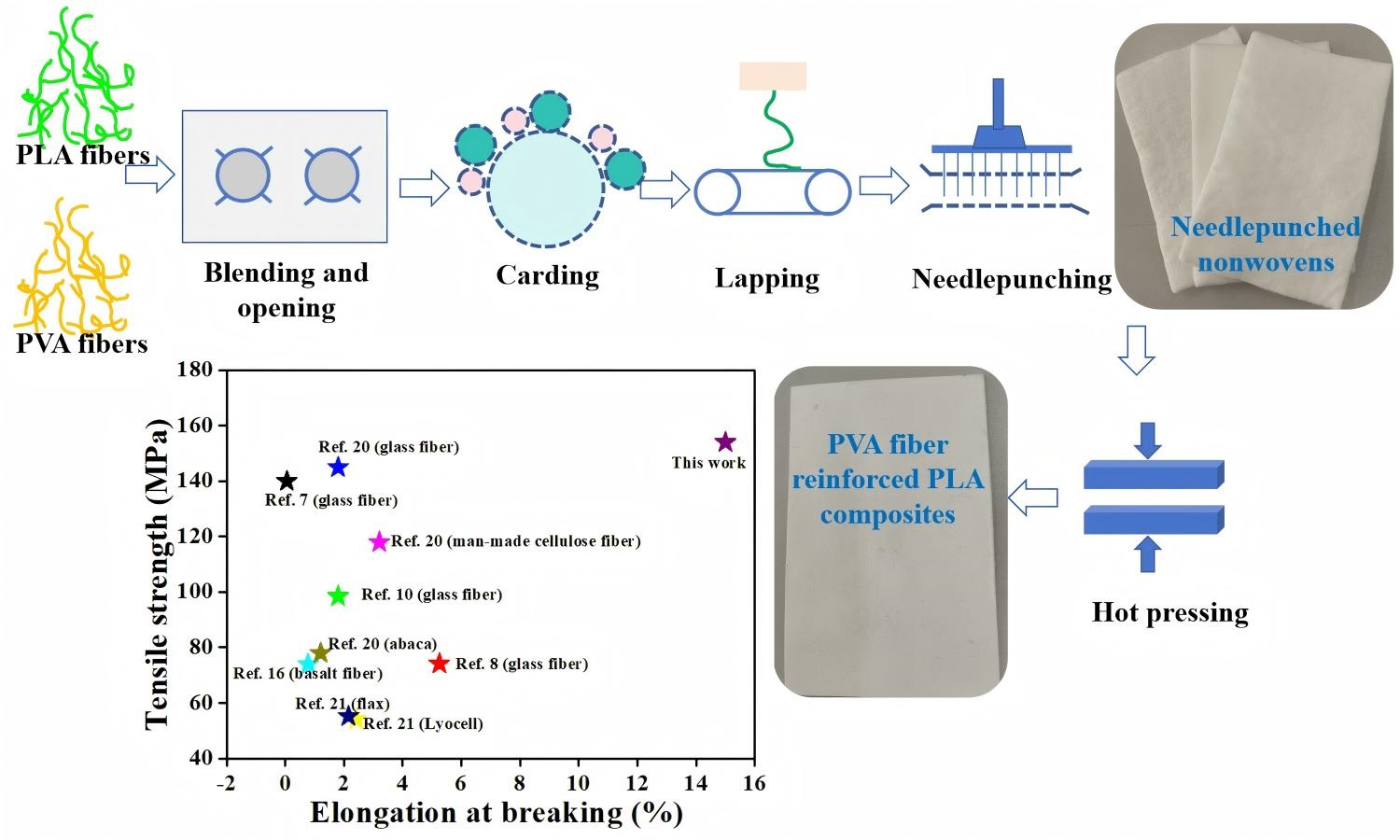

Qingsheng Liu, Yiqiang Yao, Shihua Qin, Zeping Duan, Qiaoxian Chen, Shiying Guo, Li Xing, Dawei Li, Helan Xu

Vol. 19., No.10., Pages 1027-1037, 2025

DOI: 10.3144/expresspolymlett.2025.77

Vol. 19., No.10., Pages 1027-1037, 2025

DOI: 10.3144/expresspolymlett.2025.77

High-strength and high-modulus polyvinyl alcohol fiber (PVAF) reinforced polylactide (PLA) composites (PVAF/PLA-FRPs) with different fiber content were prepared by needlepunching nonwoven process, followed by hot pressing using PVAFs and PLA fibers as raw materials. The obtained PVAF/PLA-FRPs had excellent mechanical properties and isotropic characteristics. The tensile strength and initial modulus of machine and cross-machine direction of PVAF/PLAFRP with 50% PVAF reached 154 MPa and 5.1 GPa, and 152 MPa and 5.2 GPa, respectively. The corresponding strain at break was 15.0 and 13.9%, respectively. PVAF/PLA-FRP with 50% PVAF presented higher tensile strength and strain at break than short fiber-reinforced PLA composites reported by other groups. The tensile destruction of PVAF/PLA-FRPs was attributed to both the pulling out of PVAF from the PLA matrix and the break of PVAF. In PVAF/PLA-FRPs, PVAF acted as an effective nucleating agent to promote the crystallization of PLA.

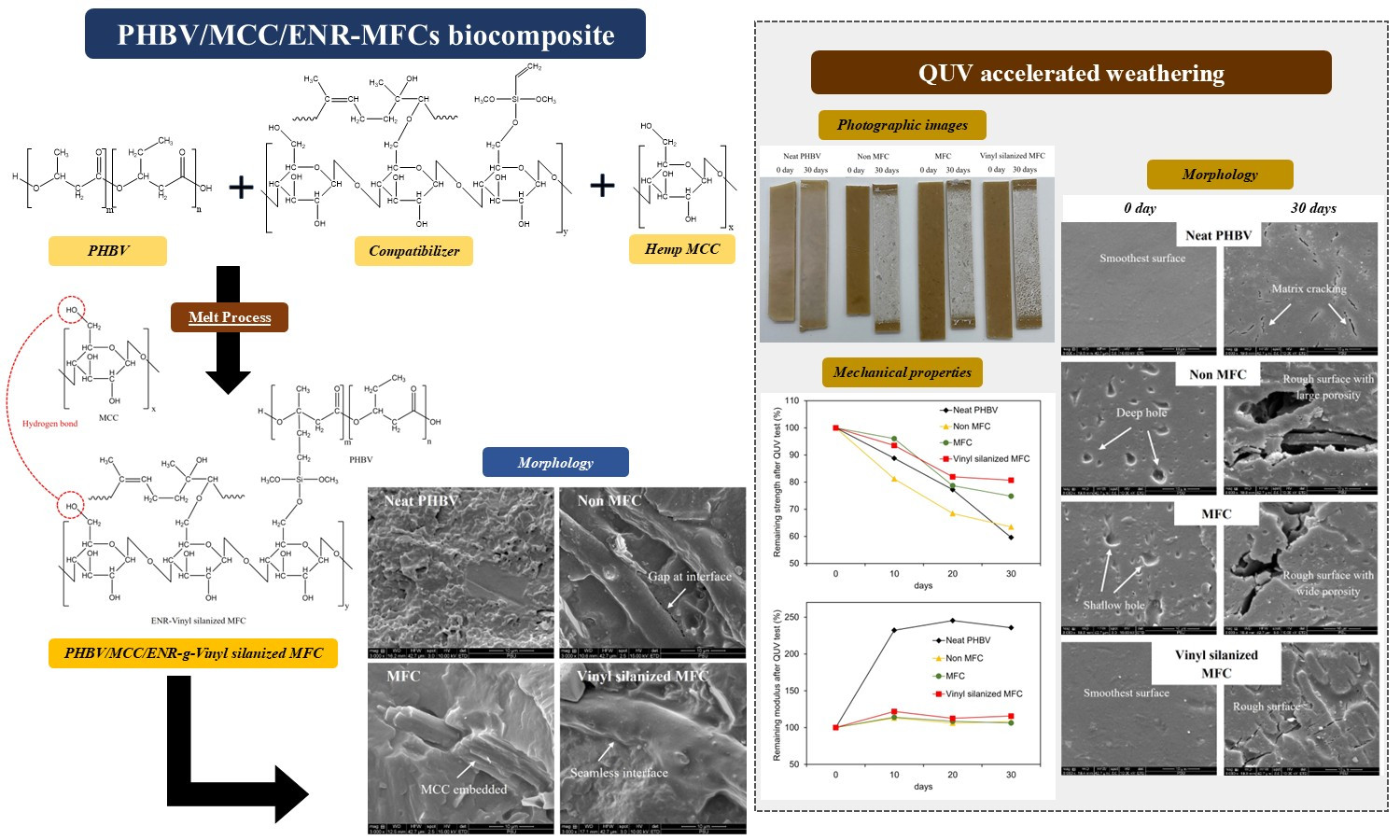

Rattanawadee Hedthong, Thorsak Kittikorn, Suding Kadea, Phuthanet Bamrungsiri

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

This research aimed to enhance the properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) biocomposites by incorporating hemp microcrystalline cellulose (MCC). Additionally, to improve interfacial adhesion between PHBV and MCC phases, a compatibilizer consisting of epoxidized natural rubber (ENR) grafted with microfibrillated cellulose (MFC) modified by vinyltrimethoxysilane (ENR-vinyl silanized MFC) was introduced. The addition of 5 wt% MCC increases the flexural modulus by approximately 65%. The use of ENR-vinyl silanized MFC as a compatibilizer demonstrated improved compatibility, as observed in scanning electron microscope (SEM) images. After 30 days of accelerated weathering (QUV) exposure, the flexural strength of the PHBV-based biocomposite with ENR-vinyl silanized MFC and MCC (vinyl silanized MFC biocomposite) was superior to that of the other samples. The remaining flexural strength can be sequentially categorized as follows: vinyl silanized MFC > MFC > non-MFC > PHBV. The Tg of PHBV-based biocomposites showed no significant change. Interestingly, the crystallinity of the vinyl silanized MFC biocomposite was the highest among all materials and demonstrated higher hydrophobicity. This makes the vinyl silanized MFC biocomposite a suitable material for construction, furniture, and both exterior and interior decoration.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.