Continuous polydimethylsiloxane filament fabrication and characterizations

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

DOI: 10.3144/expresspolymlett.2025.36

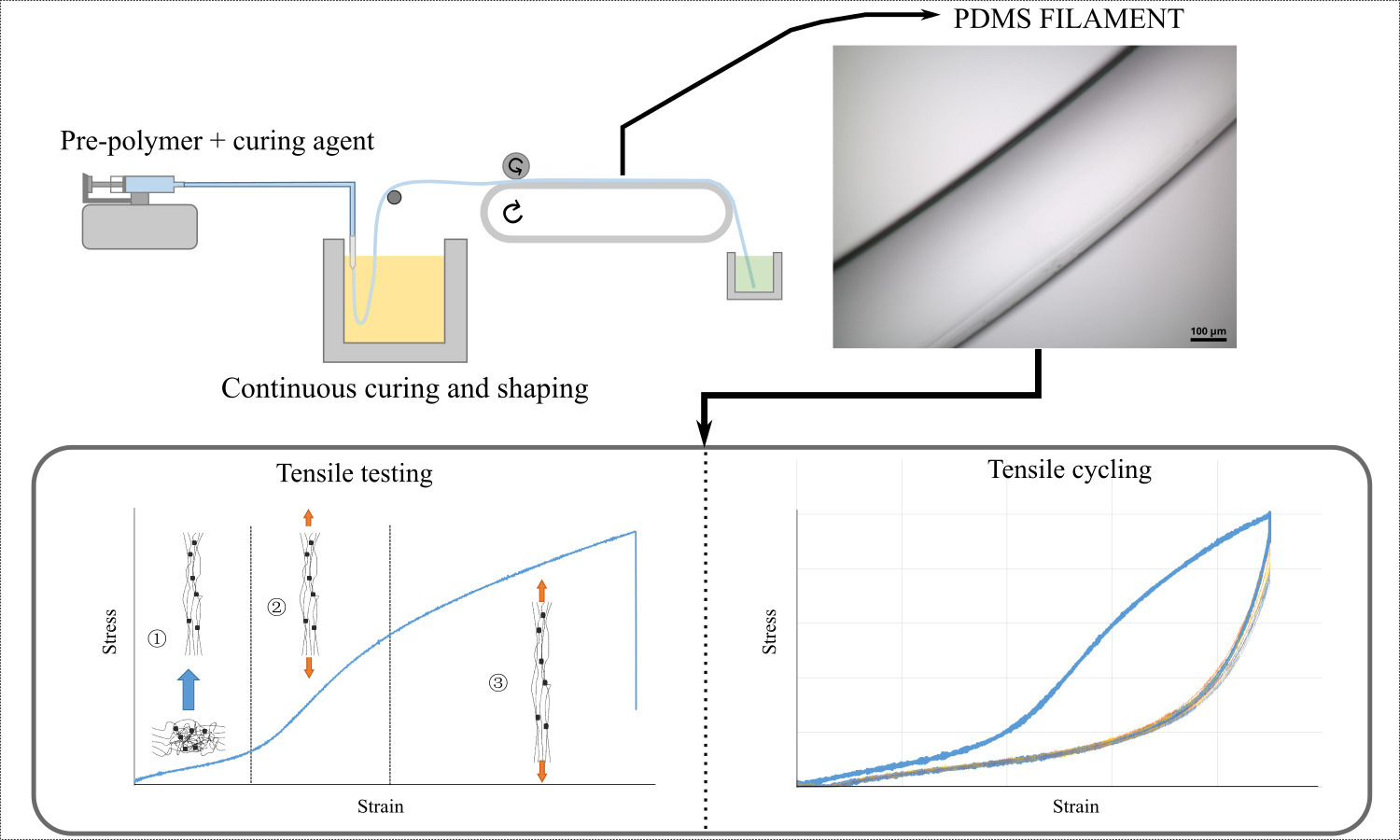

GRAPHICAL ABSTRACT

ABSTRACT

In this work, a PDMS spinning technique is developed and enables the continuous production of a filament with a circular cross-section (~500 μm diameter). The production of continuous silicone polymer filaments can be useful in the textile field to provide new properties in applications such as weaving, knitting or composite reinforcement. The method involves injecting the pre-polymer and curing agent mixture into a heated oil bath (202–215 °C) to simultaneously shape and cure the PDMS. The morphological and mechanical properties of the filament are studied regarding the production parameters (formulation, needle diameter, bath temperature, conveyor belt speed). The most homogeneous filament is produced at the highest temperature (215°C) and conveyor belt speed (13.6 m∙min–1). When subjected to cyclic mechanical stress, the PDMS filament produced exhibits stable mechanical behavior, making it suitable for a wide range of applications.

RELATED ARTICLES

Jordi Puiggalí

Vol. 19., No.12., Pages 1214-1215, 2025

DOI: 10.3144/expresspolymlett.2025.89

Vol. 19., No.12., Pages 1214-1215, 2025

DOI: 10.3144/expresspolymlett.2025.89

This is an editorial article. It has no abstract.

Mark Shneider, Xiaomeng Sui, Iddo Pinkas, Ulyana Shimanovich, Israel Greenfeld, Daniel Wagner

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

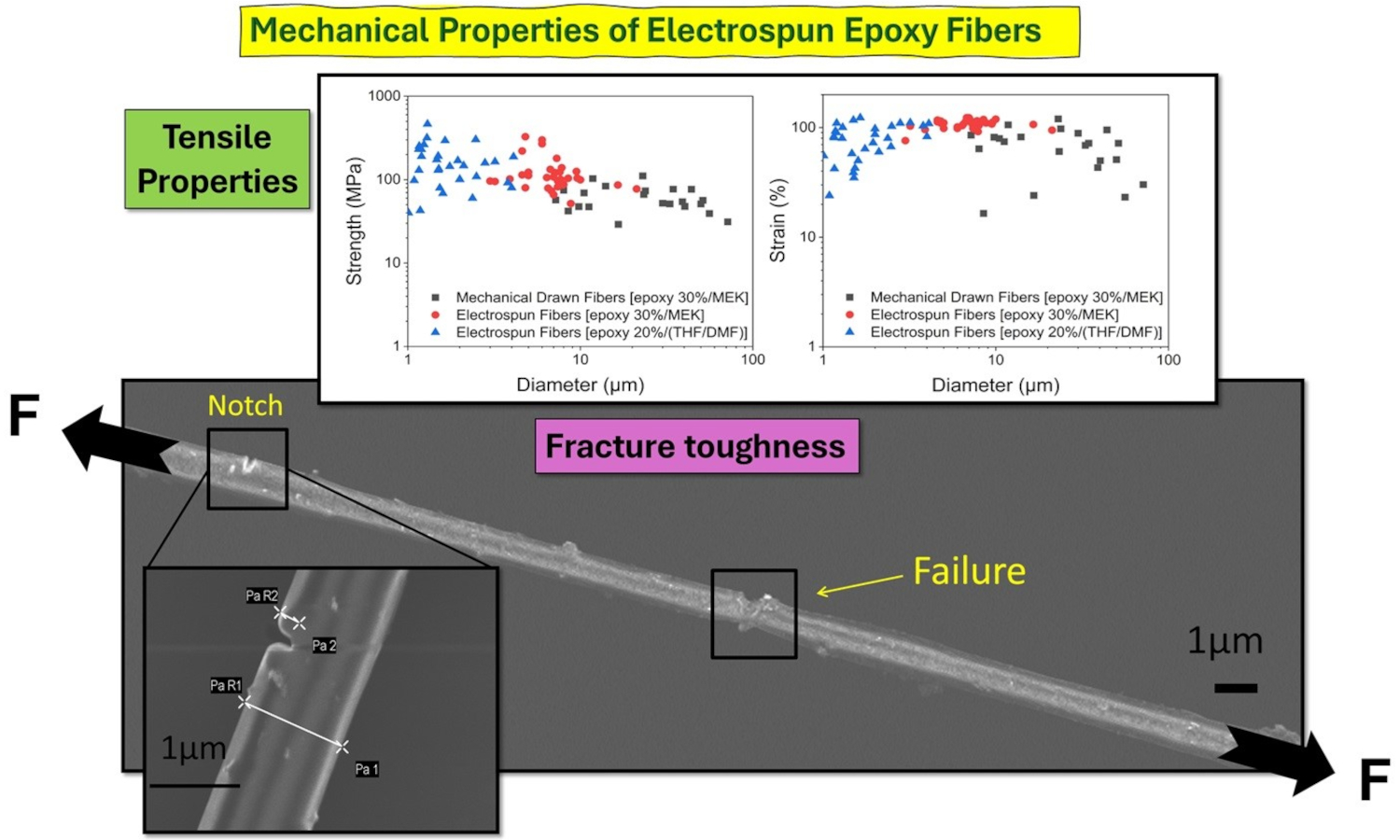

Electrospinning is a widely used technique for manufacturing nanofibers from polymers. The formation of continuous fibers during the drawing of a viscous solution typically depends on entanglements between polymer chains, making thermoplastics the preferred choice. In this study, we have shown that thermosetting polymers such as epoxy, which have crosslinked covalent bonds, can also be electrospun. The resulting fibers have diameters ranging from 150 nm to 6 μm. Tensile mechanical properties of fibers with diameters varying between 410 nm and 4 μm are compared with those of molded epoxy bulk. The electrospun fibers exhibit approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to the equivalent properties of bulk epoxy. When compared with brittle molded bulk, these fibers showed ductile properties. We also observed a correlation between the fiber diameter and the mechanical properties. The molecular morphology of the fibers was monitored and analyzed using polarized micro-Raman spectroscopy to detect molecular orientation. A comparison with epoxy fibers of different diameters from previous studies was conducted to better understand the size effect. This study shows, explains and models the evolution of epoxy molecular morphology from the solution (soft matter) to fiber (solid-state), explaining the transition from brittle to ductile in epoxy fibers, and clarifying the molecular mechanisms that lead to improved mechanical properties.

Jian Zhao, Xun Meng, Hongwei Piao, Hao Zhang, Zhibo Ren, Qi Han, Qinglin Huang, Hanli Wang

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

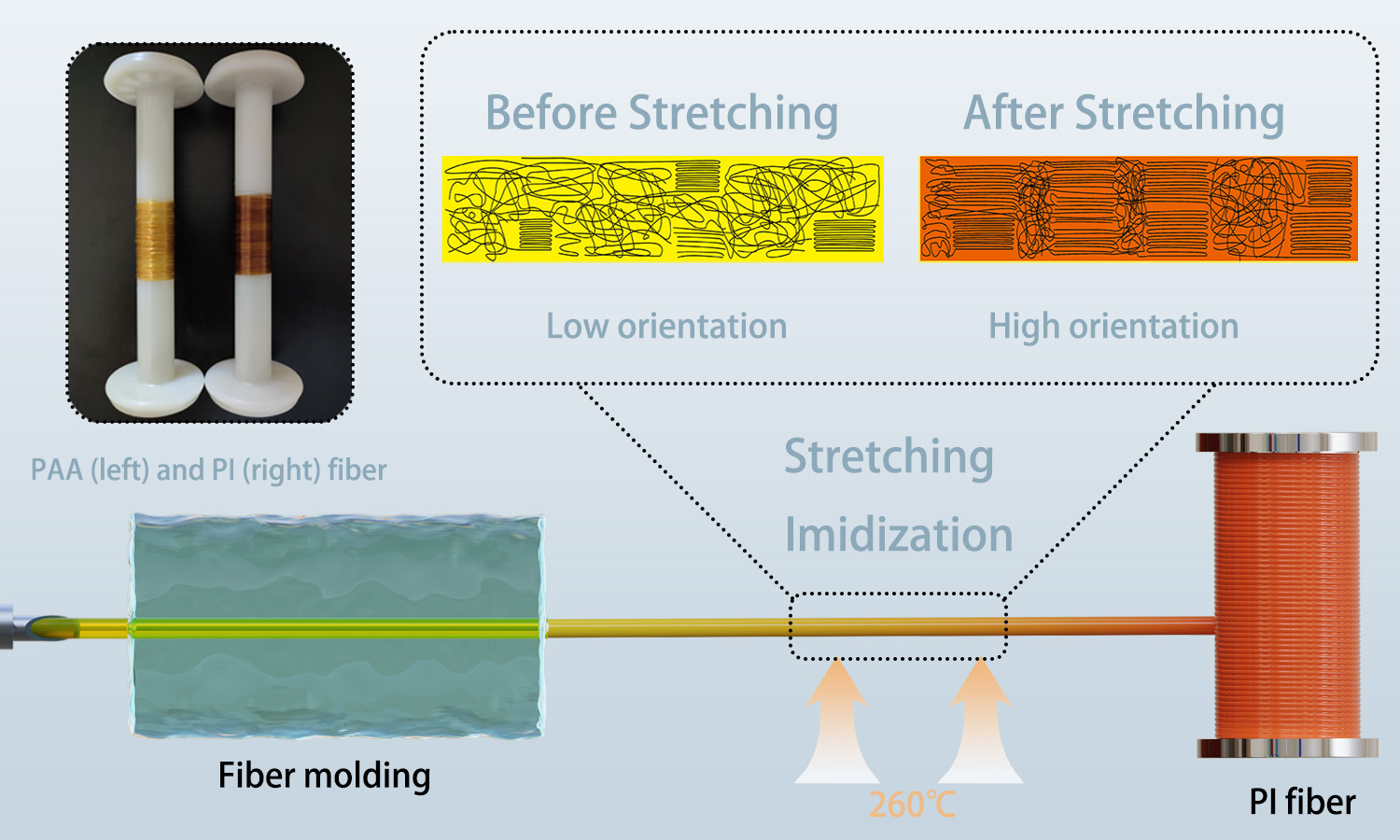

Polyimide (PI) fiber is a promising and high-performance polymer fiber with high temperature resistance and low density; however, much energy is needed during the thermal imidization process. Here, PI fiber with excellent mechanical properties and high-temperature resistance was fabricated via the dry-jet wet spinning method for polyamic acid (PAA) precursor fiber, followed by stretching and thermal imidization reaction at a lower temperature. With the increase of the stretching ratio, the mechanical properties of the PI fiber increase significantly. When the stretching was twice as long, the tensile strength and initial modulus of the fiber were as high as 6.23 and 114.13 cN·dtex–1, respectively. Fourier transform infrared results revealed that all samples were completely imidized at 260 °C. The resulting PI fibers exhibit only 5% weight loss at 539.53 °C, and its limiting oxygen index (LOI) can reach up to 32.6%, showing excellent high temperature resistance and flame-retardant properties as well as commendable mechanical performance, which compare favorably with those of other imidization methods.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

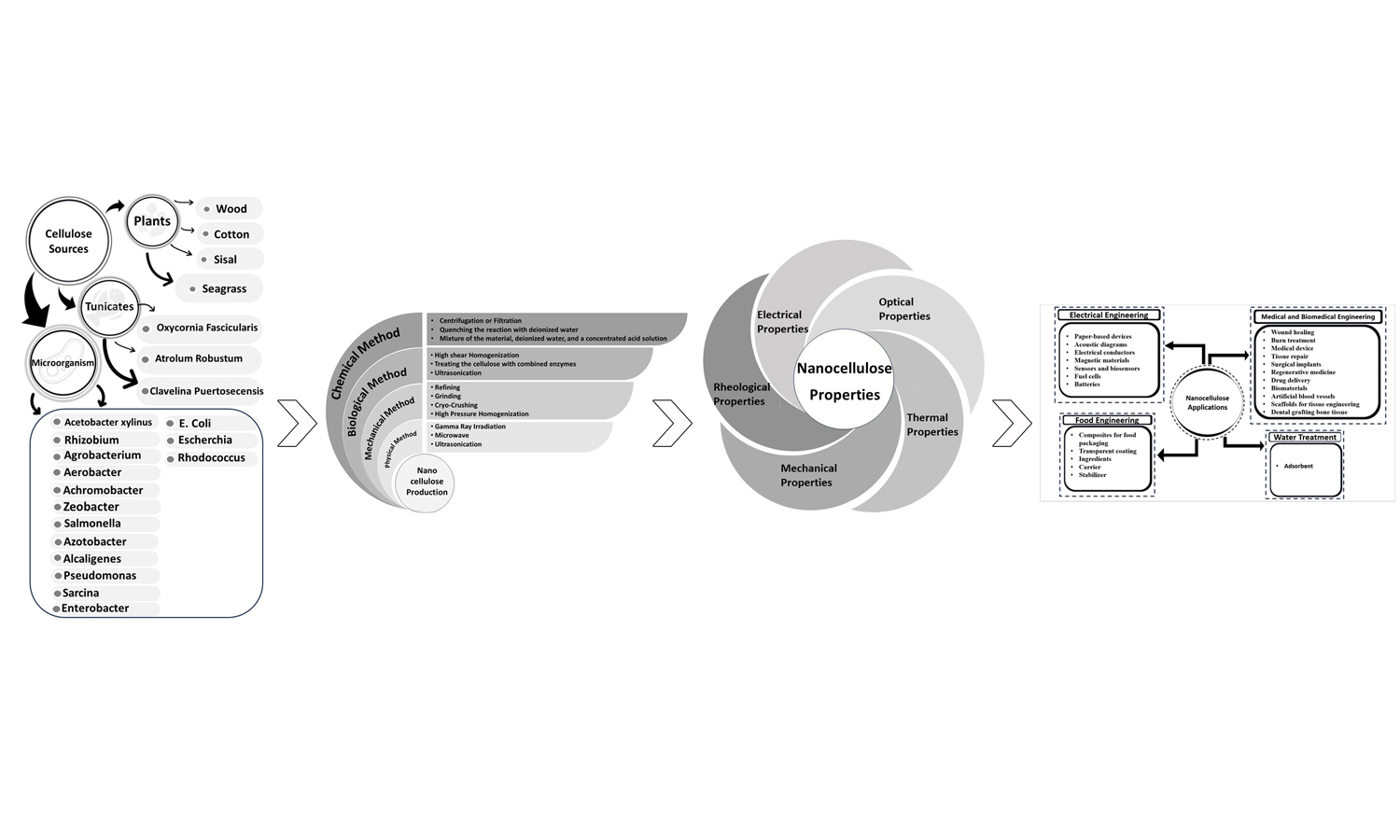

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.

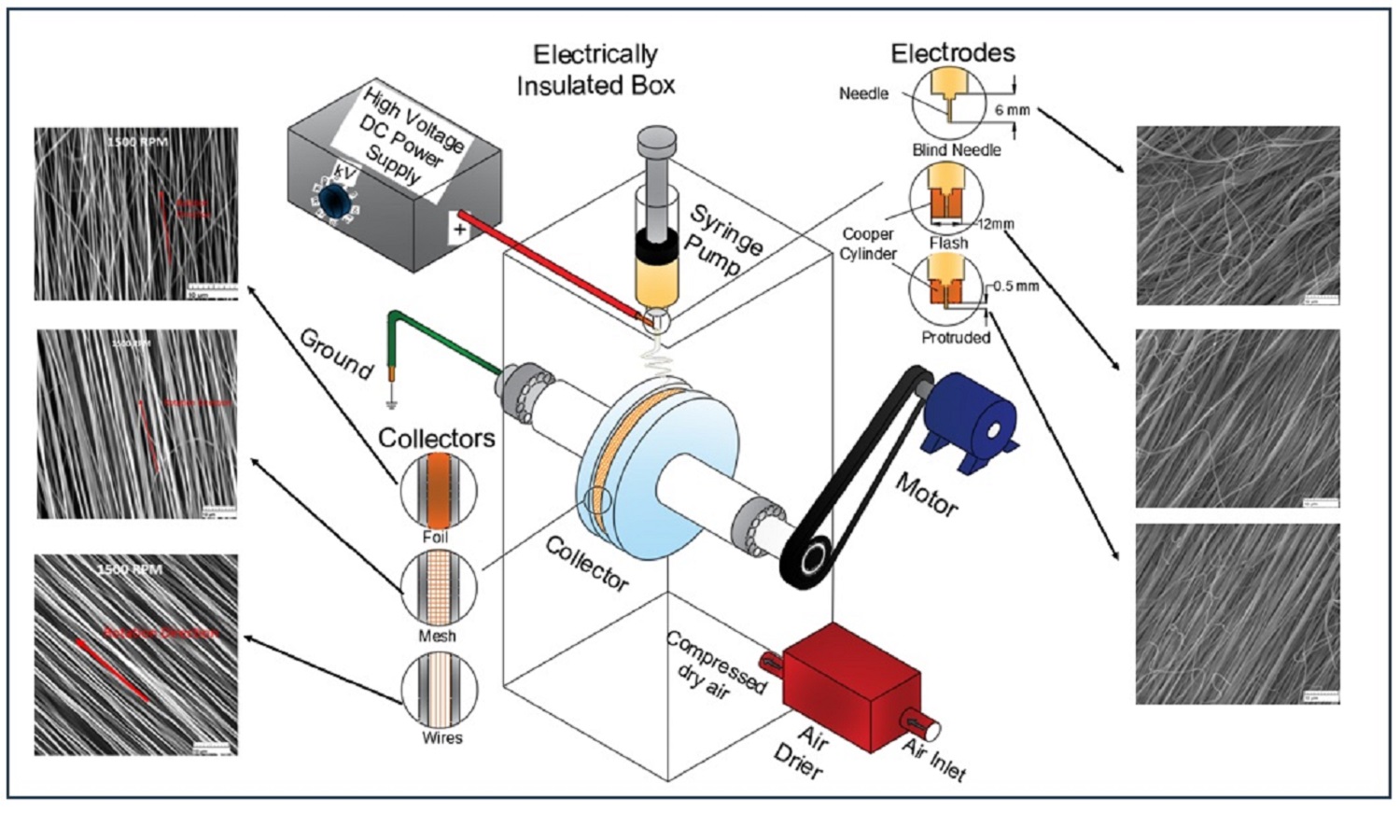

Mehmet Selim Demirtaş, Mrinal C. Saha

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

Nanomaterials, particularly nanofibers produced through electrospinning, have garnered significant attention due to their unique properties and diverse applications. This research explores the influence of collector design, electrode geometry, and collector speed on the properties of electrospun polyacrylonitrile (PAN) nanofibers. Finite element analysis (FEA) was employed to simulate electric fields, revealing the impact of collector geometry on field intensity. The experimental setup, enclosed in an isolated chamber, employed various collector types and electrode configurations. Scanning electron microscope (SEM) analysis showcased the effect of collector speed on fiber alignment and diameter. Furthermore, FEA simulations elucidated the role of electrode geometry and voltage in shaping the electric field, impacting fiber properties. The study introduces a novel, in-house method for producing highly aligned nanofibers and provides insights into optimizing electrospinning parameters for enhanced fiber properties. A testing protocol is devised to minimize surface damage when conducting mechanical tests on nanofiber films, employing a dynamic mechanical analyzer (DMA). Mechanical testing demonstrated the correlation between alignment and tensile strength. Overall, this research contributes valuable insights for tailoring electrospinning processes for tissue engineering and energy storage.