Mechanical and thermal properties of corn cob and lavender stem reinforced poly(lactic-acid)-based composites

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

DOI: 10.3144/expresspolymlett.2025.55

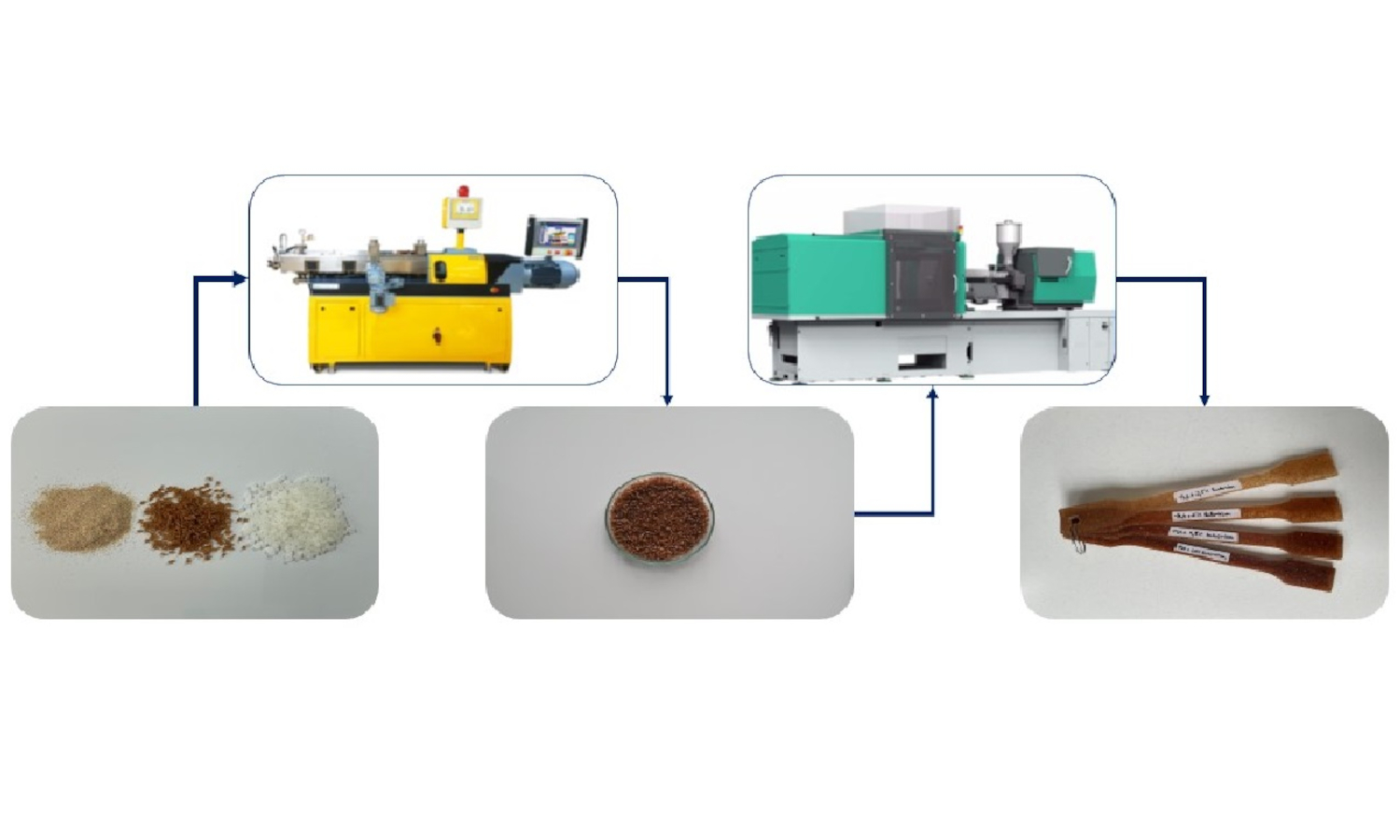

GRAPHICAL ABSTRACT

ABSTRACT

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

RELATED ARTICLES

Paulina Bednarczyk, Kamil Rożniakowski

Vol. 20., No.3., Pages 233-245, 2026

DOI: 10.3144/expresspolymlett.2026.19

Vol. 20., No.3., Pages 233-245, 2026

DOI: 10.3144/expresspolymlett.2026.19

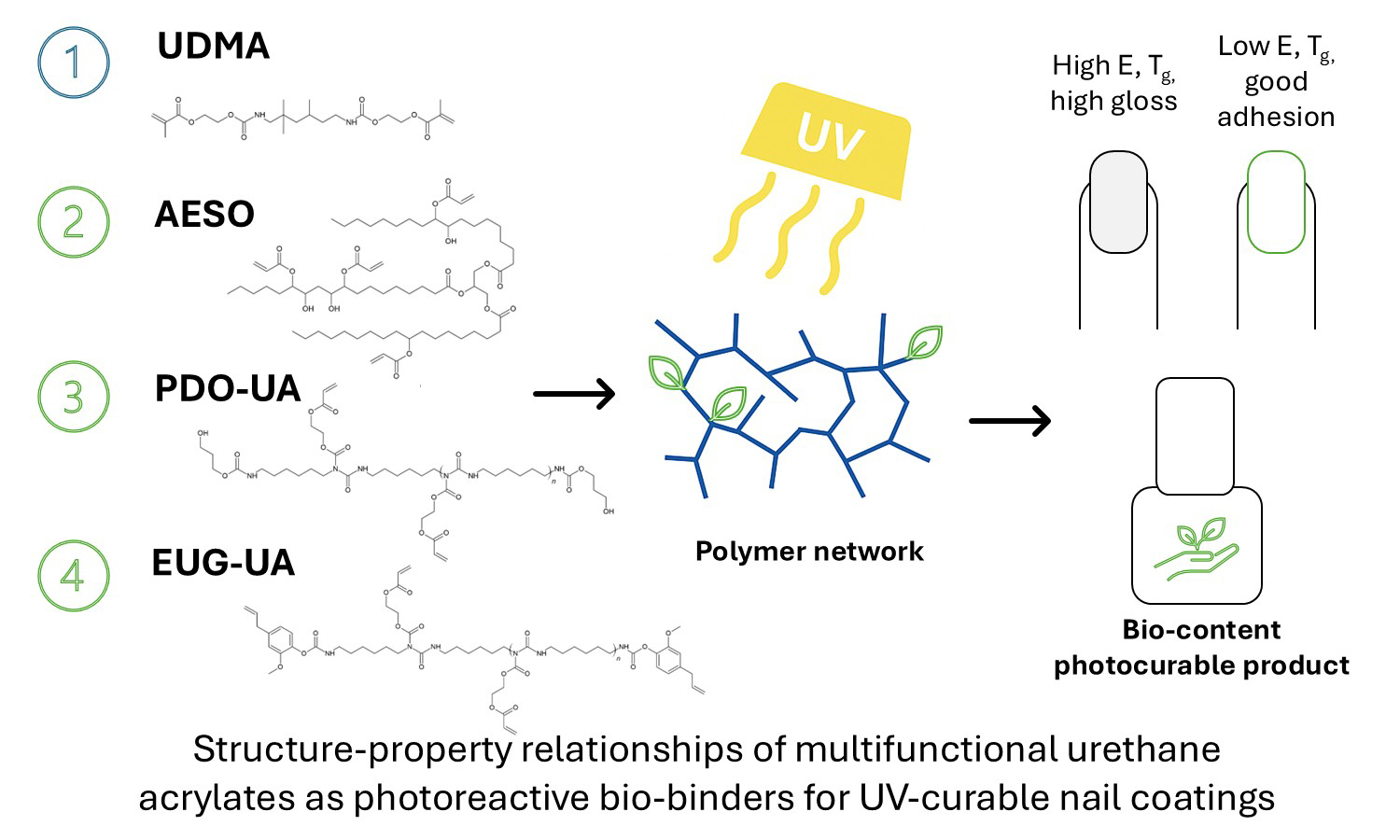

This study investigates the structure–property relationships of multi-functional urethane acrylate resins designed as photoreactive binders for UV-curable nail coatings. Four systems were examined: a commercial resin urethane dimethacrylate (UDMA), a bio-based acrylated epoxidized soybean oil (AESO), and two newly synthesized bio-based urethane acrylates derived from 1,3-propanediol (PDO–UA) and eugenol (EUG–UA). Photopolymerization kinetics were analyzed by realtime FTIR, while the properties of the cured coatings were also determined. The mechanical and thermal behavior of selfsupporting polymer films was evaluated by tensile testing and DSC analysis. The UDMA network exhibited the highest crosslink density, reflected in its high modulus (≈0.5 GPa), tensile strength (≈15 MPa), and Tg (≈60°C), making it suitable for use as a top coat. AESO showed moderate stiffness and flexibility, whereas PDO–UA and EUG–UA formed soft, low-Tg (–12 and –17°C) and highly deformable networks typical of elastomeric materials. The combined mechanical and thermal results confirmed that crosslink density strongly governs coating performance and applicability. This study demonstrates that blending UDMA with bio-based oligomers enables the design of sustainable, UV-curable nail lacquers with an optimal balance of hardness, flexibility, and adhesion to the natural nail plate.

Cláudia Andréa Batista dos Santos, Bartłomiej Kryszak, Rafał Malinowski, Aleksandra Ujćič, Konrad Szustakiewicz

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

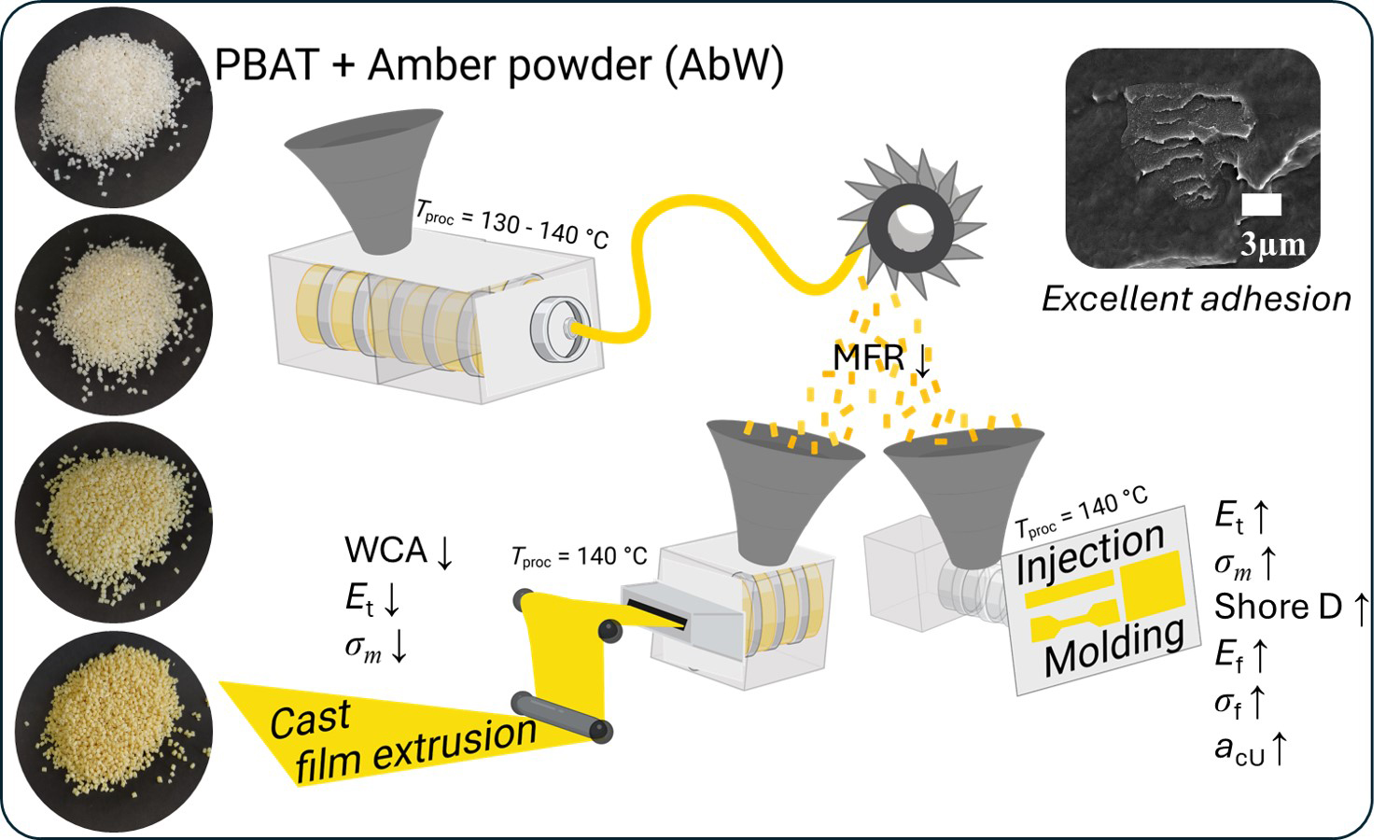

This study investigates the interaction between poly(butylene adipate-co-terephthalate) (PBAT) and amber powdered waste (AbW) from jewelry at different filler concentrations (0, 1, 2.5, and 5 wt%) obtained via melt mixing in a corotating twin screw extruder. The resulting materials were pelletized and processed using two techniques: 1) cast film extrusion and 2) injection molding. The shaped specimens exhibited excellent interfacial adhesion. Thermal behavior, as assessed by Vicat softening temperature (VST), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA), showed minimal variation among the composites. Despite similar melt flow rate (MFR) values among the samples, the incorporation of AbW affected the behavior of the polymer during cast film extrusion. Consequently, the composite films exhibited lower tensile mechanical parameters (tensile strength, Young’s modulus, stress and strain at break) compared to the neat PBAT film. In turn, the injection molded composites showed improved tensile, flexural, and impact parameters compared to their neat counterpart. Additionally, a slight decrease in water contact angle (WCA) suggested increased surface hydrophilicity of the extruded films. These findings demonstrate the potential of AbW as an additive for biopolymer composites with enhanced mechanical performance. The increased surface hydrophilicity is particularly relevant for applications targeting biocompatibility and biodegradability.

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

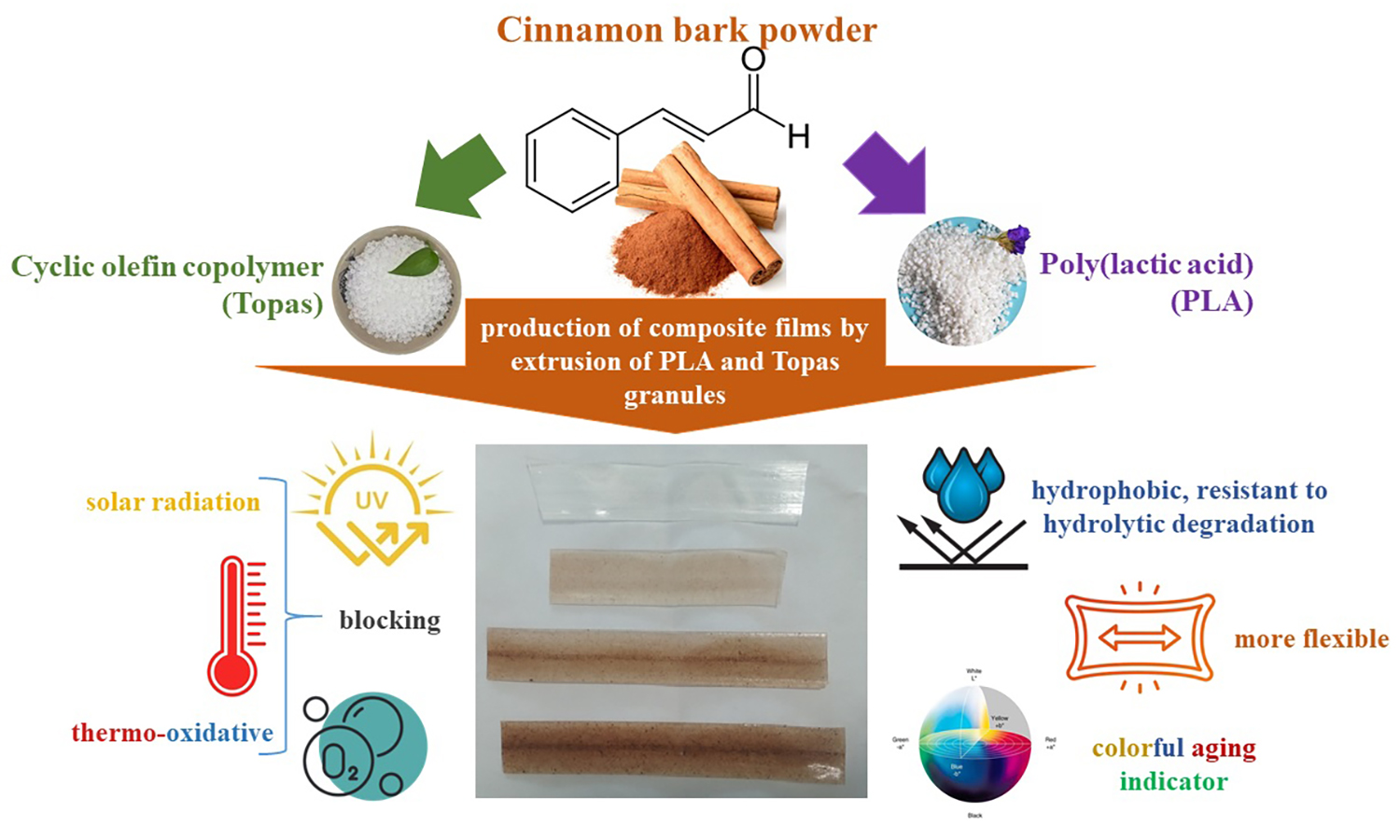

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

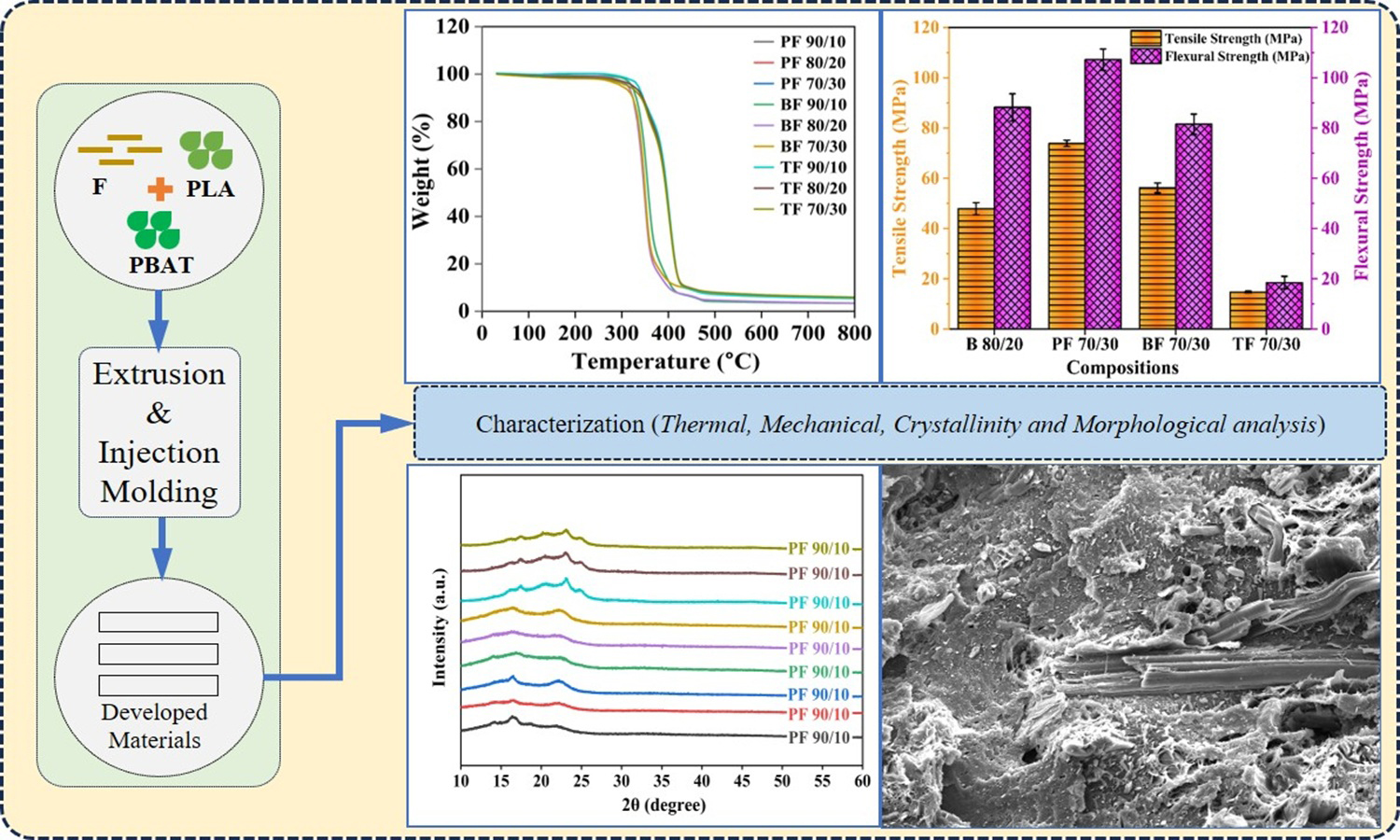

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

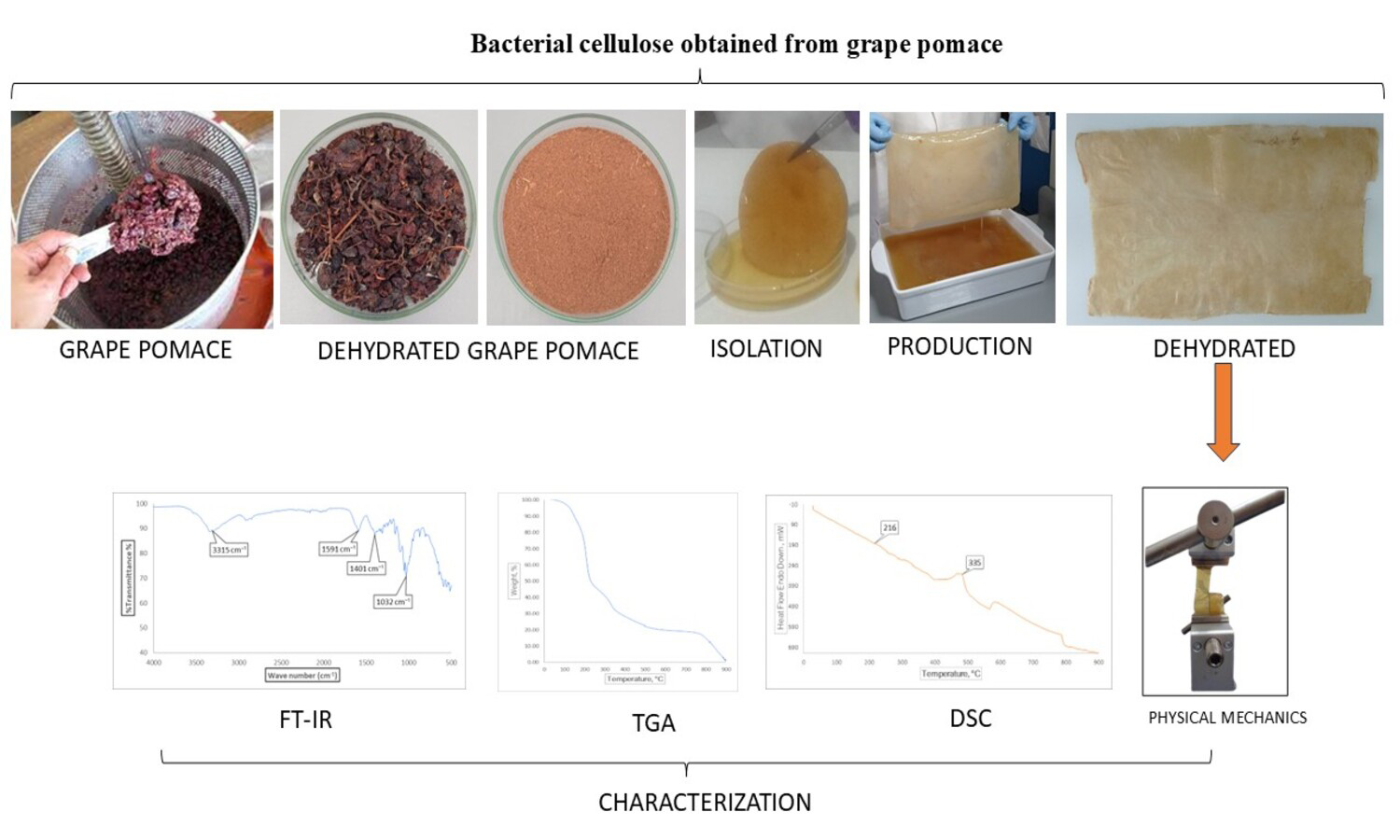

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.