Content

All issues / Volume 19 (2025) / Issue 10 (October)

Kinsuk Naskar

Vol. 19., No.10., Pages 977-978, 2025

DOI: 10.3144/expresspolymlett.2025.73

Vol. 19., No.10., Pages 977-978, 2025

DOI: 10.3144/expresspolymlett.2025.73

This is an editorial article. It has no abstract.

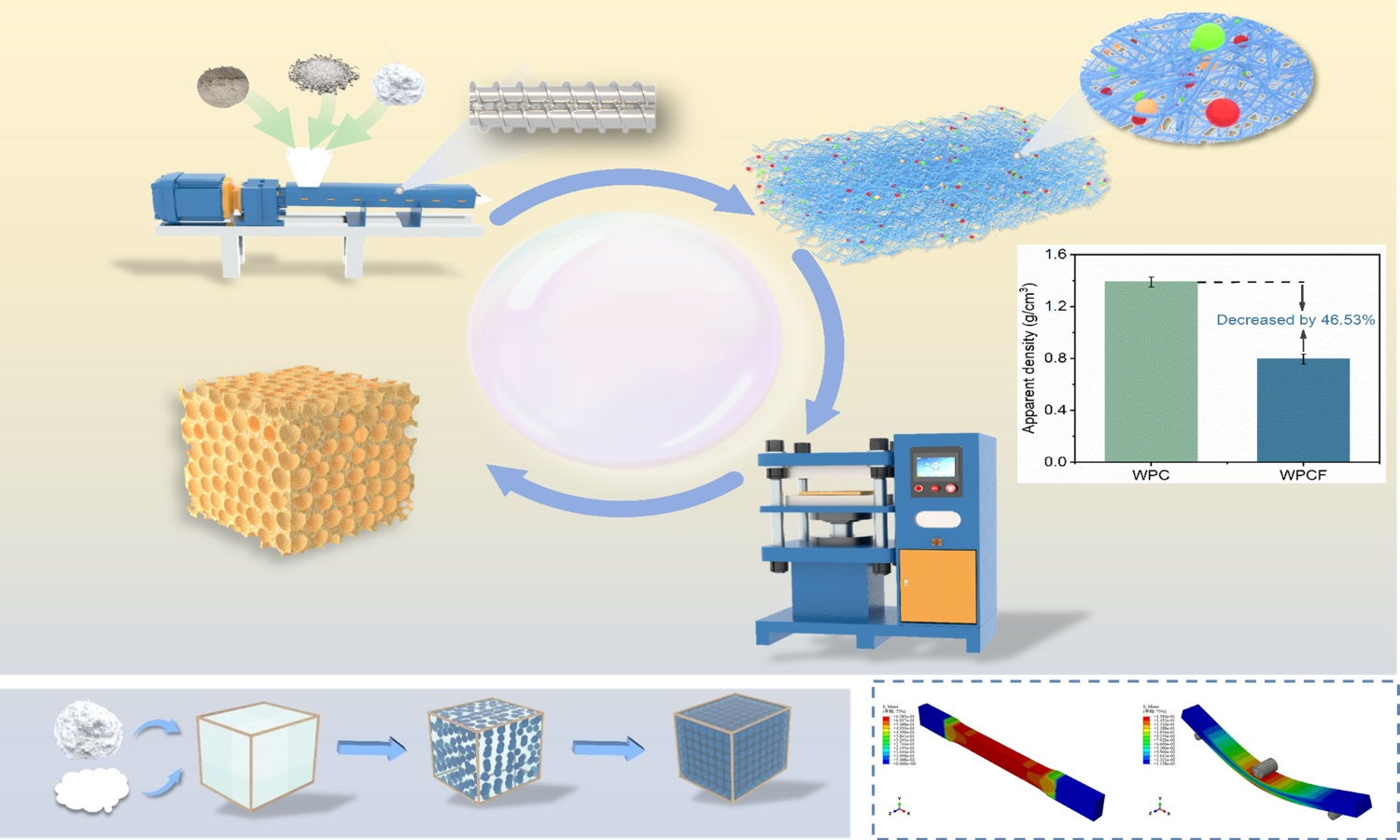

Jiazheng Sun, Zhengyu Liao, You-Yong Wang, Yushan Zou, Jinhong Li, Zesheng Xu, Yongming Song

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

Wood–plastic composite (WPC) is an environmentally friendly and cost-effective materials, while the high density and suboptimal mechanical properties of traditional WPC limit their broader applications. In this study, a wood fiber/polypropylene composite foam (WPCF) is fabricated via chemical foaming enabled by Nano-polytetrafluoroethylene (PTFE). Compared with the unmodified wood fiber/polypropylene composite foam, our developed WPCF demonstrates a 37.69% increase in cell density and a 29.45% decrease in cell size with uniform cell distribution. The fine cell structure of WPCF is attributed to the improved crystallization and suitable viscoelastic behavior due to the addition of nano-PTFE. As a result, WPCF demonstrates superior mechnical performance. When the PTFE content was 1 wt%, WPCF shows a tensile strength of 9.41 MPa, a flexural strength of 22.63 MPa, and a improved impact strength of 5.27 kJ/m2, which is 47.65, 33.12, and 76.23% higher than those of unmodified WPCF. Given to the mechanical robustness and low density of WPCF, the as-prepared high-performance wood fiber/polypropylene composite foam is a promising alternative as a green and sustainable material to traditional wood in construction, furniture, and packaging sectors.

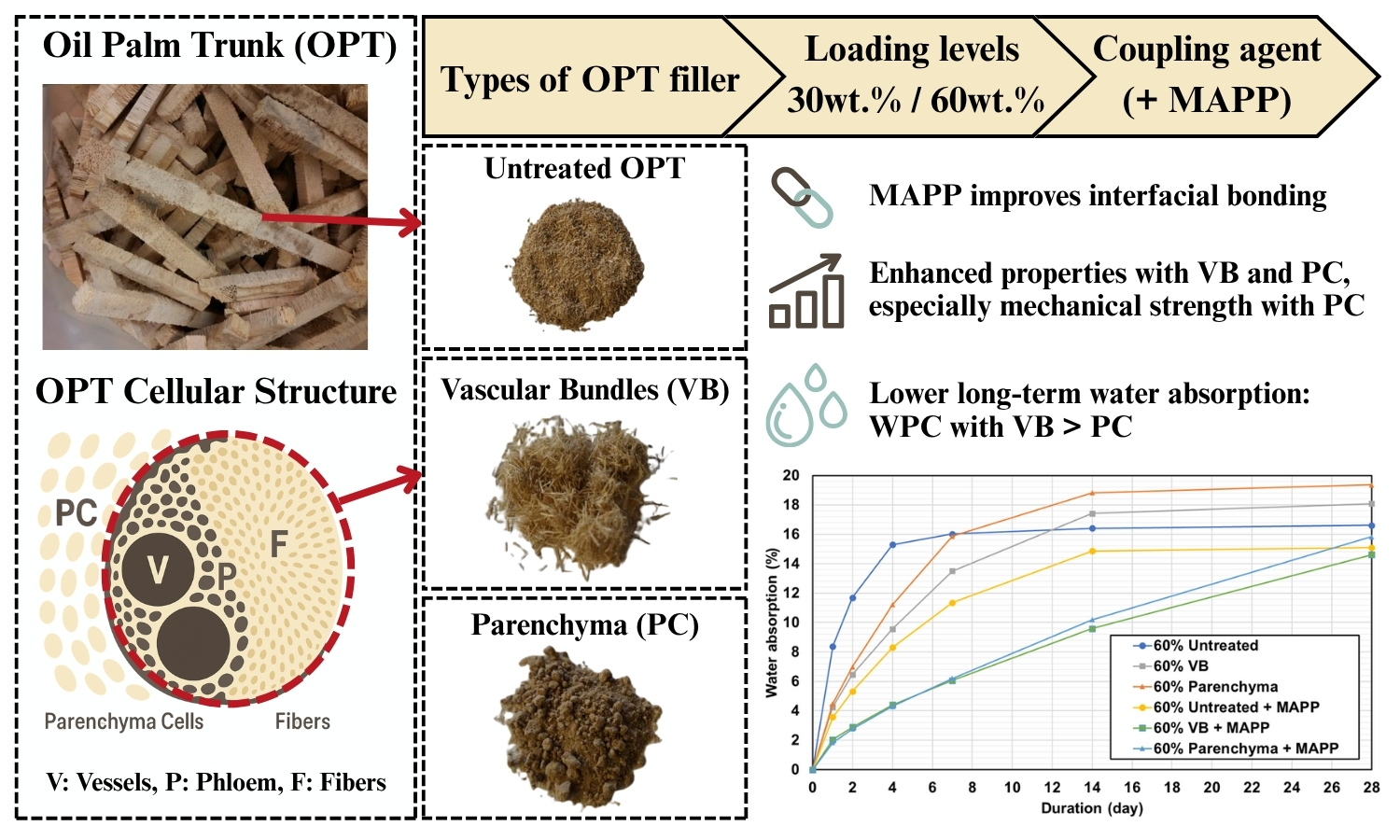

Kanokorn Sae-Ueng, Charoen Nakason, Andreas Krause

Vol. 19., No.10., Pages 994-1011, 2025

DOI: 10.3144/expresspolymlett.2025.75

Vol. 19., No.10., Pages 994-1011, 2025

DOI: 10.3144/expresspolymlett.2025.75

This study explores the mechanical properties and water resistance of polypropylene (PP) composites reinforced with oil palm trunk (OPT) components, specifically vascular bundles (VB) and parenchyma cells (PC) particles, at 30 and 60 wt% content levels. The research addresses challenges posed by the inherent variability in density and moisture sensitivity of OPT in composite formulation. Utilizing a hot-pressing technique, we examined the effects of OPT type, filler content, and the addition of a maleic anhydride-grafted polypropylene (MAPP) coupling agent. The findings reveal that VB- and PC-reinforced PP composites show enhanced density, moisture resistance, and overall mechanical performance relative to untreated OPT. Notably, while increasing OPT content improves modulus and density, it negatively impacts tensile and flexural strengths due to poor interfacial bonding. The incorporation of MAPP significantly enhances interfacial adhesion between the PP matrix and OPT fillers, leading to reduced moisture uptake and dimensional swelling, particularly at higher filler loadings. These results highlight the potential of VB and PC as sustainable reinforcement materials for wood-plastic composites (WPC), providing critical insights for optimizing composite designs aimed at improving durability and water resistance.

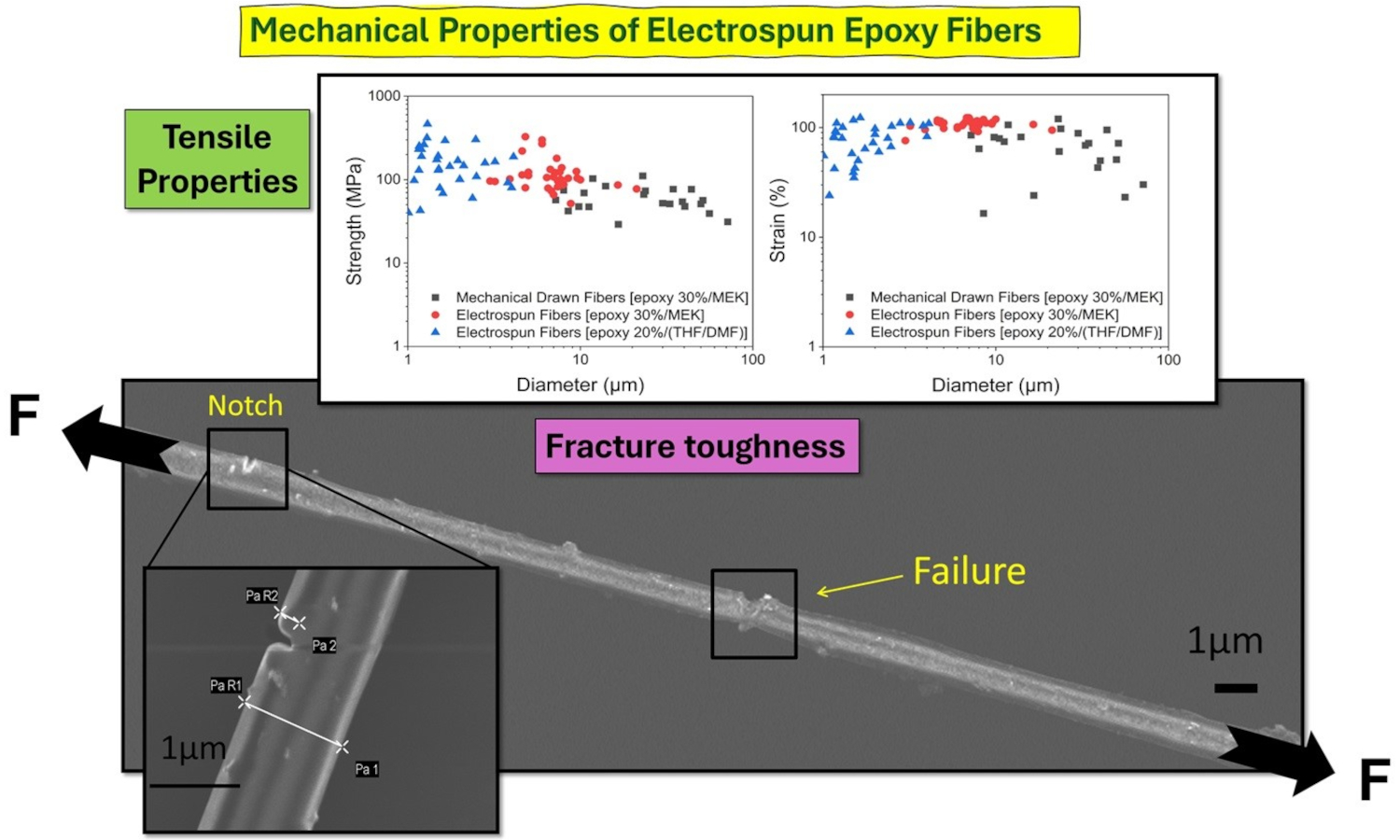

Mark Shneider, Xiaomeng Sui, Iddo Pinkas, Ulyana Shimanovich, Israel Greenfeld, Daniel Wagner

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Electrospinning is a widely used technique for manufacturing nanofibers from polymers. The formation of continuous fibers during the drawing of a viscous solution typically depends on entanglements between polymer chains, making thermoplastics the preferred choice. In this study, we have shown that thermosetting polymers such as epoxy, which have crosslinked covalent bonds, can also be electrospun. The resulting fibers have diameters ranging from 150 nm to 6 μm. Tensile mechanical properties of fibers with diameters varying between 410 nm and 4 μm are compared with those of molded epoxy bulk. The electrospun fibers exhibit approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to the equivalent properties of bulk epoxy. When compared with brittle molded bulk, these fibers showed ductile properties. We also observed a correlation between the fiber diameter and the mechanical properties. The molecular morphology of the fibers was monitored and analyzed using polarized micro-Raman spectroscopy to detect molecular orientation. A comparison with epoxy fibers of different diameters from previous studies was conducted to better understand the size effect. This study shows, explains and models the evolution of epoxy molecular morphology from the solution (soft matter) to fiber (solid-state), explaining the transition from brittle to ductile in epoxy fibers, and clarifying the molecular mechanisms that lead to improved mechanical properties.

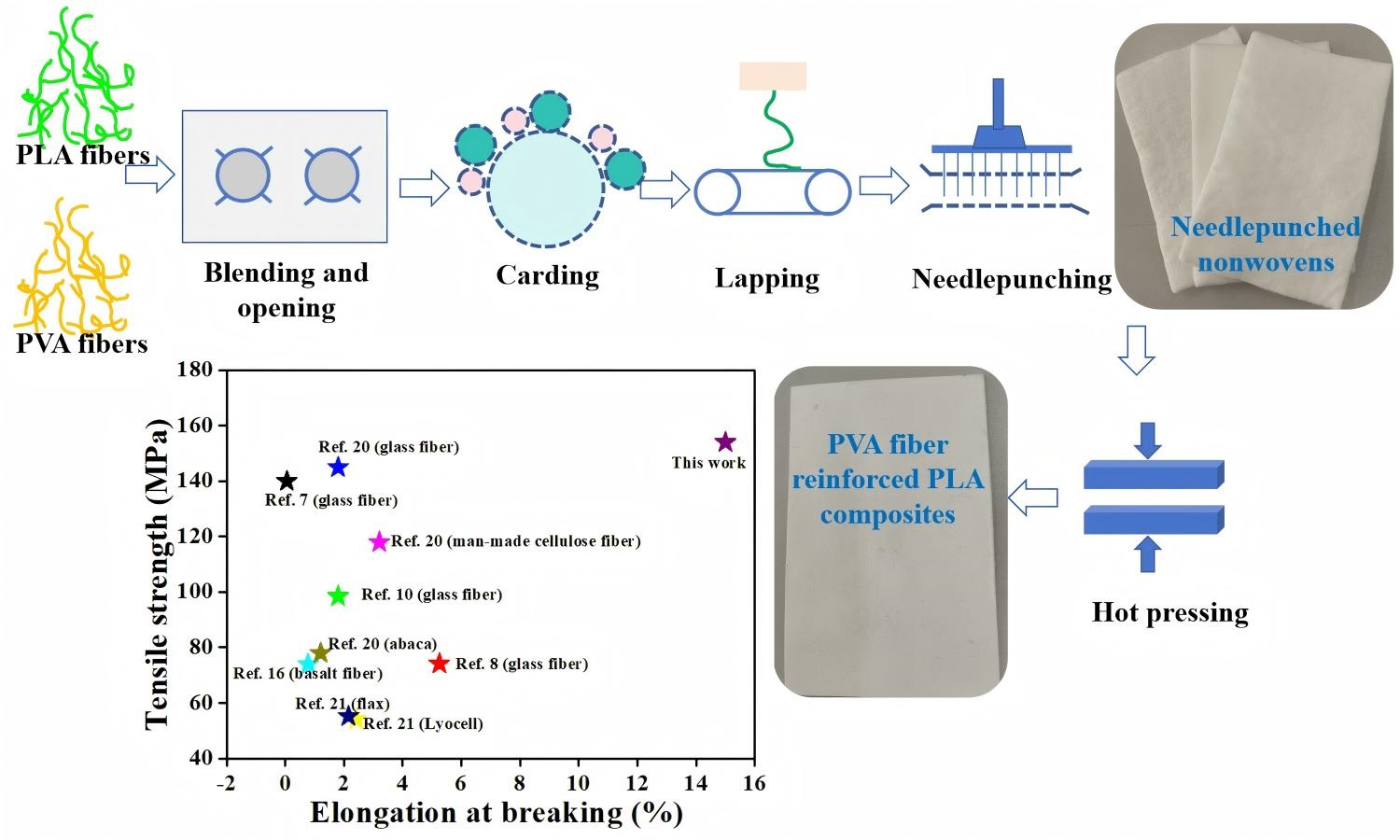

Qingsheng Liu, Yiqiang Yao, Shihua Qin, Zeping Duan, Qiaoxian Chen, Shiying Guo, Li Xing, Dawei Li, Helan Xu

Vol. 19., No.10., Pages 1027-1037, 2025

DOI: 10.3144/expresspolymlett.2025.77

Vol. 19., No.10., Pages 1027-1037, 2025

DOI: 10.3144/expresspolymlett.2025.77

High-strength and high-modulus polyvinyl alcohol fiber (PVAF) reinforced polylactide (PLA) composites (PVAF/PLA-FRPs) with different fiber content were prepared by needlepunching nonwoven process, followed by hot pressing using PVAFs and PLA fibers as raw materials. The obtained PVAF/PLA-FRPs had excellent mechanical properties and isotropic characteristics. The tensile strength and initial modulus of machine and cross-machine direction of PVAF/PLAFRP with 50% PVAF reached 154 MPa and 5.1 GPa, and 152 MPa and 5.2 GPa, respectively. The corresponding strain at break was 15.0 and 13.9%, respectively. PVAF/PLA-FRP with 50% PVAF presented higher tensile strength and strain at break than short fiber-reinforced PLA composites reported by other groups. The tensile destruction of PVAF/PLA-FRPs was attributed to both the pulling out of PVAF from the PLA matrix and the break of PVAF. In PVAF/PLA-FRPs, PVAF acted as an effective nucleating agent to promote the crystallization of PLA.

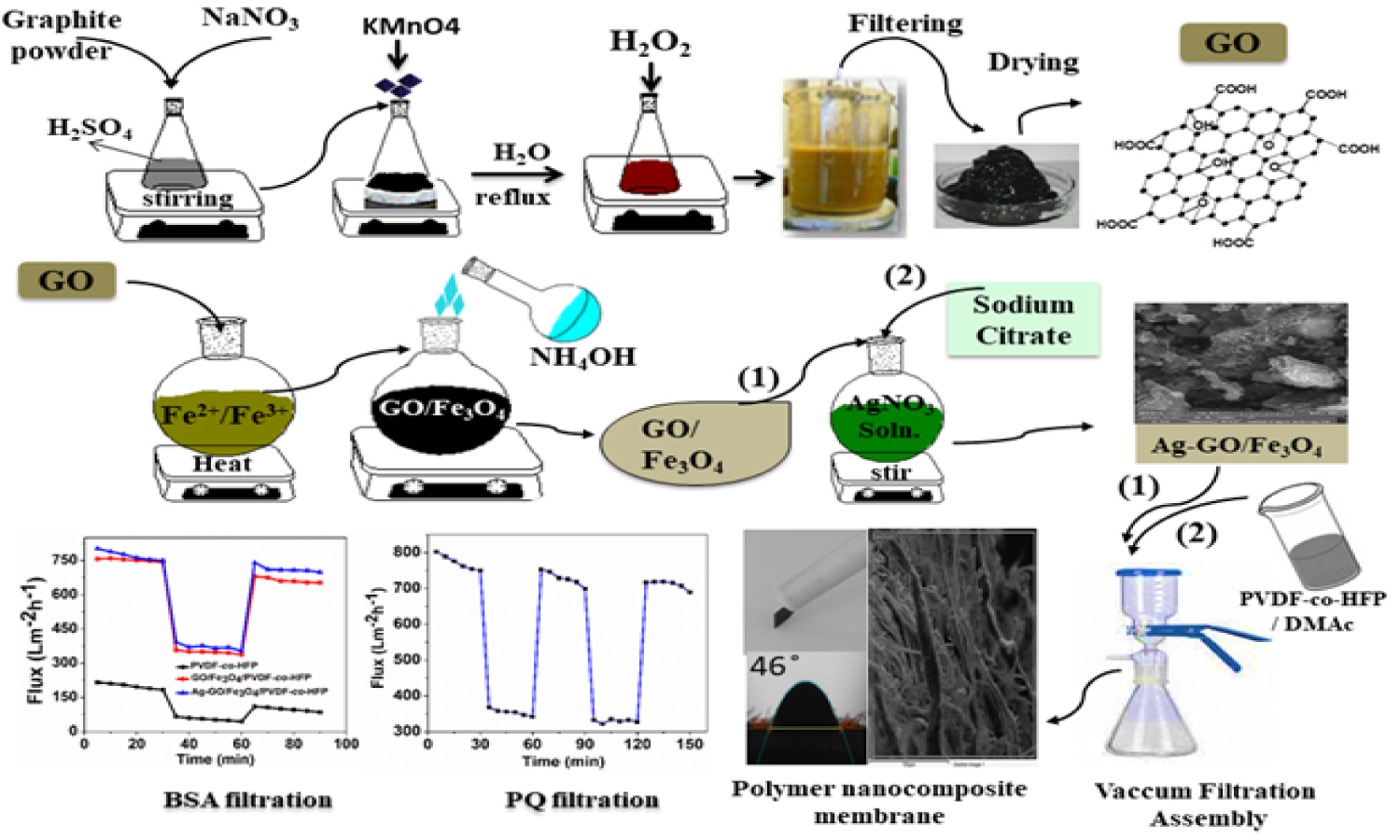

Hafsa Ilyas, Syeda Huma H. Zaidi, Salwa D. Al-Malwi, Muhammad Yasir, Muhammad Usman, Seemab Parvaiz, Muhammad Siddiq

Vol. 19., No.10., Pages 1038-1052, 2025

DOI: 10.3144/expresspolymlett.2025.78

Vol. 19., No.10., Pages 1038-1052, 2025

DOI: 10.3144/expresspolymlett.2025.78

Magnetically active membranes based on GO/Fe3O4and Ag-GO/Fe3O4have been synthesized via the resin-infiltration technique, achieving significant improvements in rejection and antifouling properties, followed by their characterization by X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), energy dispersive X-rays spectroscopy (EDX) and thermal gravimetric analysis (TGA). The increasing demand for efficient water purification technologies is challenged by low separation efficiency, poor resistance to fouling, and limited tunability in dynamic environments, as well as low rejection performance. This study addresses the research gap by developing and evaluating GO/Fe3O4and Ag-GO/Fe3O4membranes to enhance water treatment performance through improved rejection rates and antifouling capabilities. It exhibits separation efficiency, fouling resistance, and high thermomechanical stability with the added advantage of magnetic responsiveness – a combination that addresses multiple persistent issues in membrane-based water treatment. GO/Fe3O4 and Ag-GO/Fe3O4 improved the flux recovery ratio of pristine PVDF-co-HFP membrane from 50.8 to 89.9 and 92.3%, while the rejection % of paraquat (PQ) herbicide increased up to 92.7%. This research is important because magnetically active membranes do not need external magnetic fields to move the magnetic particles to the membrane’s surface.

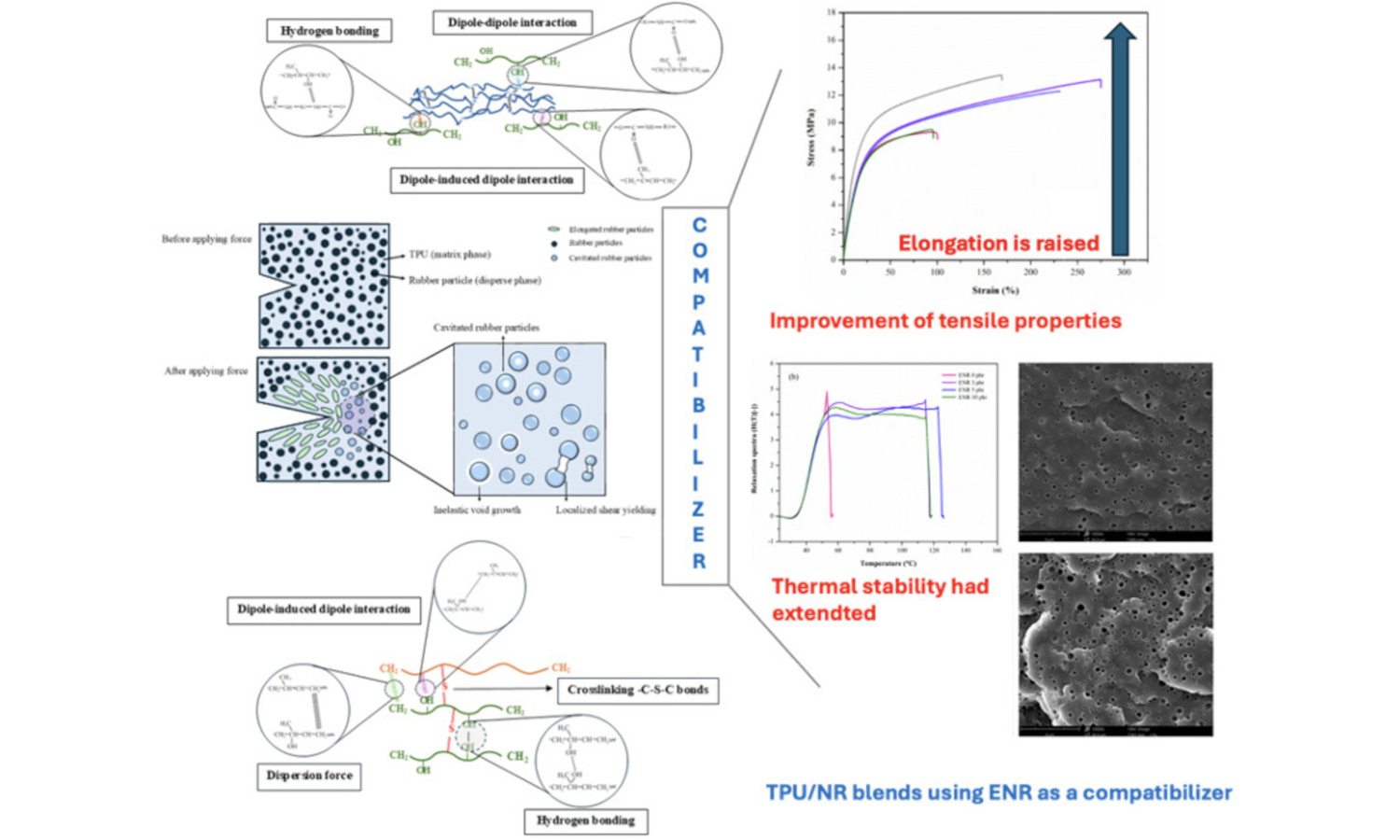

Torfan Srisuwanno, Jobish Johns, Christopher Bascucci, Frank Clemens, Yeampon Nakaramontri

Vol. 19., No.10., Pages 1053-1072, 2025

DOI: 10.3144/expresspolymlett.2025.79

Vol. 19., No.10., Pages 1053-1072, 2025

DOI: 10.3144/expresspolymlett.2025.79

Thermoplastic natural rubber (TPNR) is widely used across industries due to its unique blend of elasticity and processability. Thermoplastic vulcanizates (TPVs) based on thermoplastic polyurethane (TPU) offer excellent mechanical properties and flexibility, yet often require enhanced elasticity and durability. Blending TPU with natural rubber (NR) is promising; however, phase incompatibility reduces mechanical strength and thermal stability. To address this, epoxidized NR (ENR) was employed as a compatibilizer in TPU/NR blends. ENR’s hydrocarbon backbone interacts with crosslinked NR, while epoxy groups enhance adhesion with TPU. Incorporating 3 phr of ENR significantly improved crosslinking, increased tensile strength by 41.1%, enhanced stress relaxation, and lowered the glass transition temperatures of both TPU and NR phases in the TPU/NR blends. These effects are attributed to improved chemical bridging between TPU and NR. However, excess ENR disrupts phase compatibility, causing polymer entanglement and reduced strength. Optimizing ENR content is essential for developing high-performance TPU/NR blends. Printability was demonstrated using the material extrusion additive manufacturing (MEx-AM) fused deposition modeling (FDM), showing potential for flexible applications like splints and medical devices.

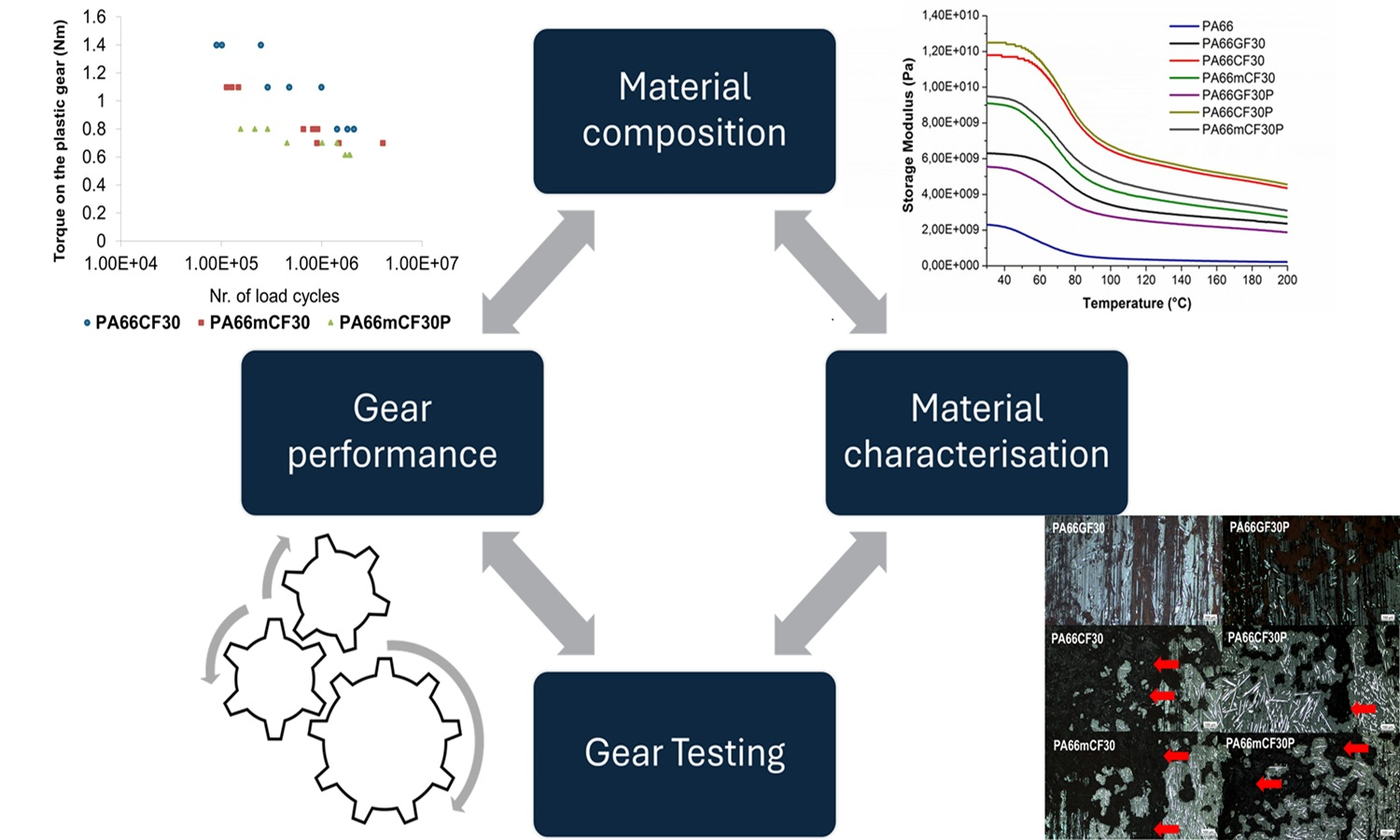

Rebeka Lorber, Janez Slapnik, Borut Černe, Andreas Hausberger, Jan Sumfleth

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

The study investigates the use of repurposed milled carbon fibre (mCF) as reinforcement for polyamide 66 (PA66) in gear applications, addressing environmental and cost concerns of virgin carbon fibres. Neat PA66 and PA66 composites reinforced with mCF, glass fibres (GF), and carbon fibres (CF), with and without polytetrafluoroethylene (PTFE), were injection moulded and evaluated for microstructure (fibre length), thermal, mechanical, surface, and tribological properties, as well as gear performance under VDI 2736 guidelines. CF reinforced composites showed the highest modulus and tensile strength, followed by mCF and GF. PTFE reduced modulus and strength in binary composites. All reinforced composites significantly lowered the coefficient of friction (COF) and wear rate compared to neat PA66, with mCF showing the most notable improvements. PTFE slightly improved tribological performance only for GF (wear) and CF (COF) composites. In gear testing, binary composites outperformed neat PA66, with CF performing best, followed by mCF and GF. Ternary composites had slightly lower performance than their binary equivalents. Correlation analysis showed that gear performance is closely linked to structural integrity. Failure analysis revealed higher crack susceptibility in mCF reinforced gears due to shorter fibre length. The findings highlight mCF reinforced PA66 as a sustainable, cost-effective material for durable polymer gears.