Comparative evaluation of vascular bundle and parenchyma fillers from oil palm trunk in polypropylene wood-plastic composites

Vol. 19., No.10., Pages 994-1011, 2025

DOI: 10.3144/expresspolymlett.2025.75

DOI: 10.3144/expresspolymlett.2025.75

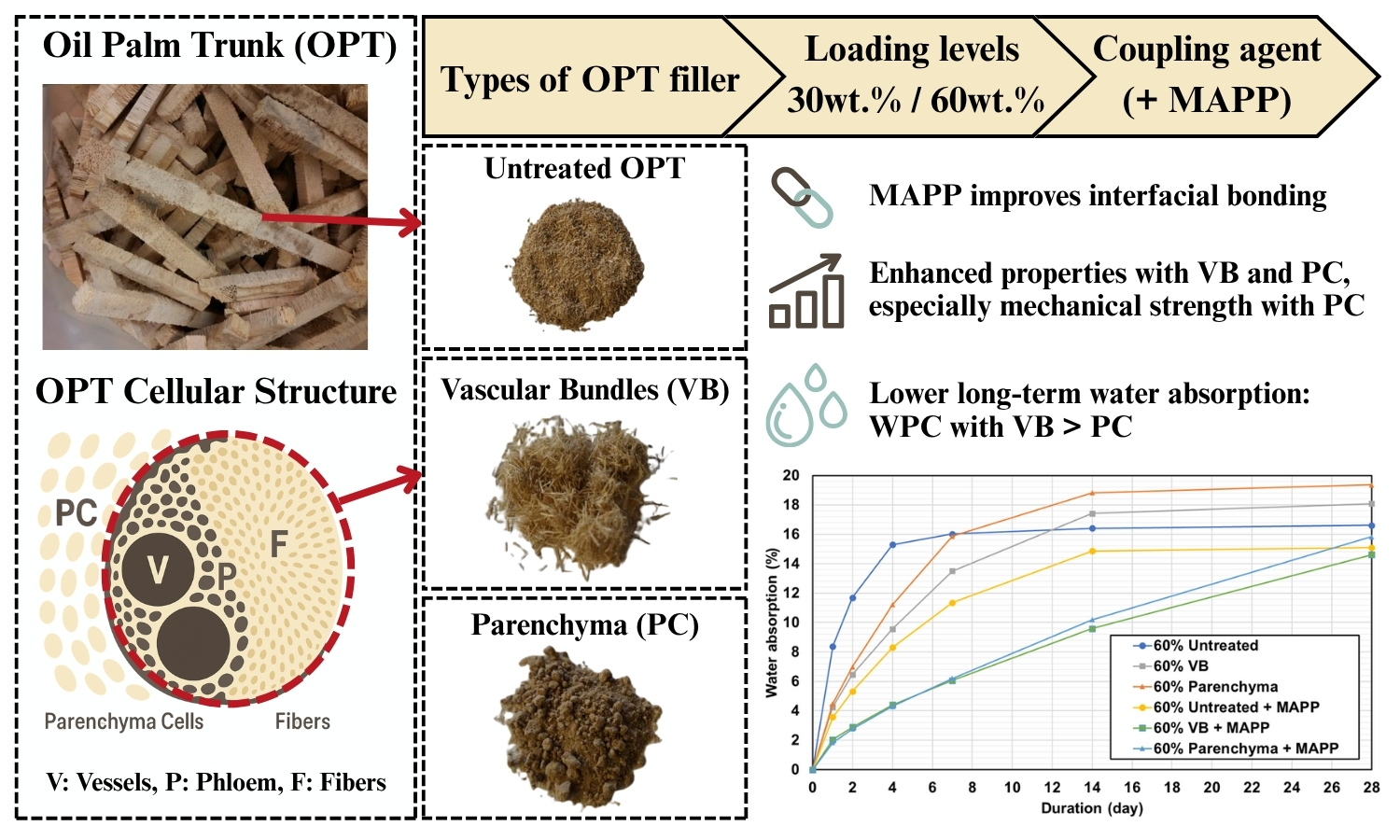

GRAPHICAL ABSTRACT

ABSTRACT

This study explores the mechanical properties and water resistance of polypropylene (PP) composites reinforced with oil palm trunk (OPT) components, specifically vascular bundles (VB) and parenchyma cells (PC) particles, at 30 and 60 wt% content levels. The research addresses challenges posed by the inherent variability in density and moisture sensitivity of OPT in composite formulation. Utilizing a hot-pressing technique, we examined the effects of OPT type, filler content, and the addition of a maleic anhydride-grafted polypropylene (MAPP) coupling agent. The findings reveal that VB- and PC-reinforced PP composites show enhanced density, moisture resistance, and overall mechanical performance relative to untreated OPT. Notably, while increasing OPT content improves modulus and density, it negatively impacts tensile and flexural strengths due to poor interfacial bonding. The incorporation of MAPP significantly enhances interfacial adhesion between the PP matrix and OPT fillers, leading to reduced moisture uptake and dimensional swelling, particularly at higher filler loadings. These results highlight the potential of VB and PC as sustainable reinforcement materials for wood-plastic composites (WPC), providing critical insights for optimizing composite designs aimed at improving durability and water resistance.

RELATED ARTICLES

Rebeka Lorber, József Gábor Kovács, Andreas Hausberger, Polona Umek, Miroslav Huskić, Aleš Hančič

Vol. 19., No.11., Pages 1133-1143, 2025

DOI: 10.3144/expresspolymlett.2025.83

Vol. 19., No.11., Pages 1133-1143, 2025

DOI: 10.3144/expresspolymlett.2025.83

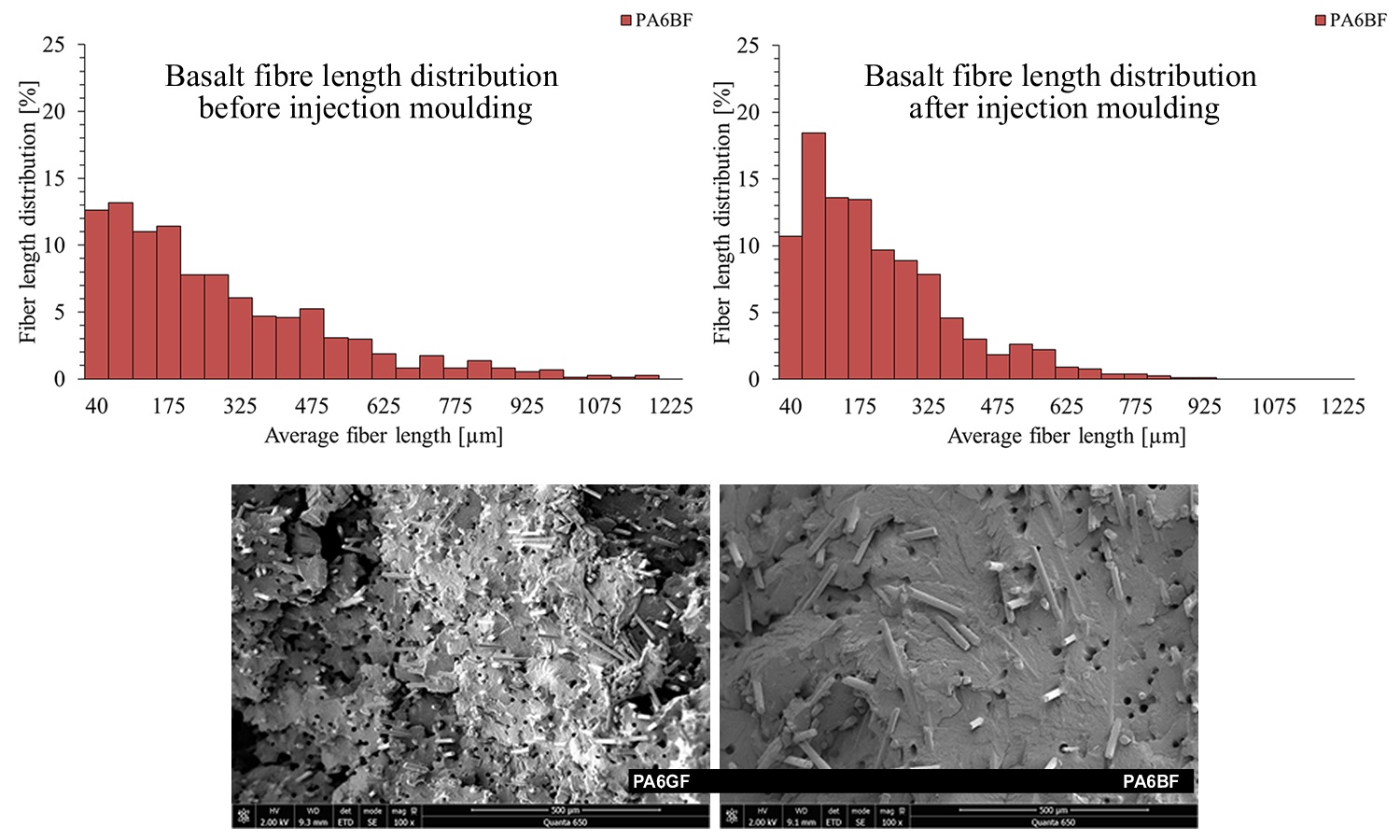

With the increasing use of e-mobility, the demand for high-quality materials to produce polymer gears is growing. Due to the tendency towards using natural materials and reducing carbon footprint, basalt fibers (BF) are tested as a substitute for glass fibers (GF). For this purpose, composites of polyamide 6 (PA6) with GF and BF, with and without compatibilizer and polytetrafluoroethylene (PTFE) are produced, tested, and properties compared. The mechanical, thermomechanical, thermal, and tribological properties of the composites, as well as the size of the fibers after the production of the composites and after injection molding, are determined. The compatibilizer improves the impact strength, while the glass fibers have a better reinforcing effect. The fibers increase crystallinity, but the effect is minimal. The thermal conductivity increases approximately the same for both fibers and is highest at composites that, in addition to 30% fibers, also contain PTFE. The tribological properties are comparable but slightly better for glass fibers. The fiber length is greatly reduced during the production of the composites and is around 200–300 μm in both cases. SEM imaging and mapping analysis show good dispersion of the fibers in the polymer and relatively poor compatibility with PA6.

Jiazheng Sun, Zhengyu Liao, You-Yong Wang, Yushan Zou, Jinhong Li, Zesheng Xu, Yongming Song

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

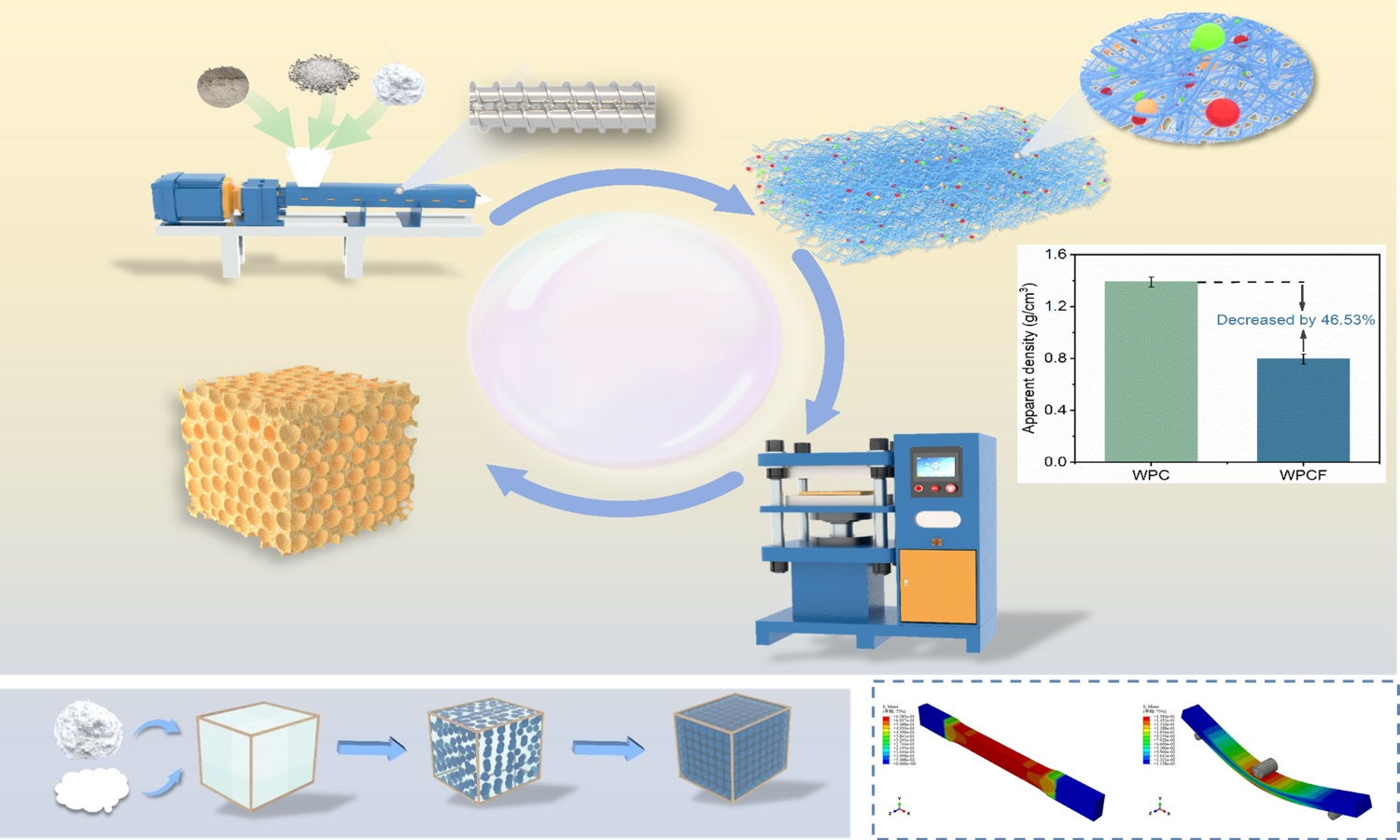

Wood–plastic composite (WPC) is an environmentally friendly and cost-effective materials, while the high density and suboptimal mechanical properties of traditional WPC limit their broader applications. In this study, a wood fiber/polypropylene composite foam (WPCF) is fabricated via chemical foaming enabled by Nano-polytetrafluoroethylene (PTFE). Compared with the unmodified wood fiber/polypropylene composite foam, our developed WPCF demonstrates a 37.69% increase in cell density and a 29.45% decrease in cell size with uniform cell distribution. The fine cell structure of WPCF is attributed to the improved crystallization and suitable viscoelastic behavior due to the addition of nano-PTFE. As a result, WPCF demonstrates superior mechnical performance. When the PTFE content was 1 wt%, WPCF shows a tensile strength of 9.41 MPa, a flexural strength of 22.63 MPa, and a improved impact strength of 5.27 kJ/m2, which is 47.65, 33.12, and 76.23% higher than those of unmodified WPCF. Given to the mechanical robustness and low density of WPCF, the as-prepared high-performance wood fiber/polypropylene composite foam is a promising alternative as a green and sustainable material to traditional wood in construction, furniture, and packaging sectors.

Waleed Y. Rizg, Amerh Aiad Alahmadi, Mohammed Baradwan, Rahul Dev Bairwan, Marwan M, Ahmed K. Mohamed, Sherif El Saadany, CK Abdullah, H.P.S. Abdul Khalil

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

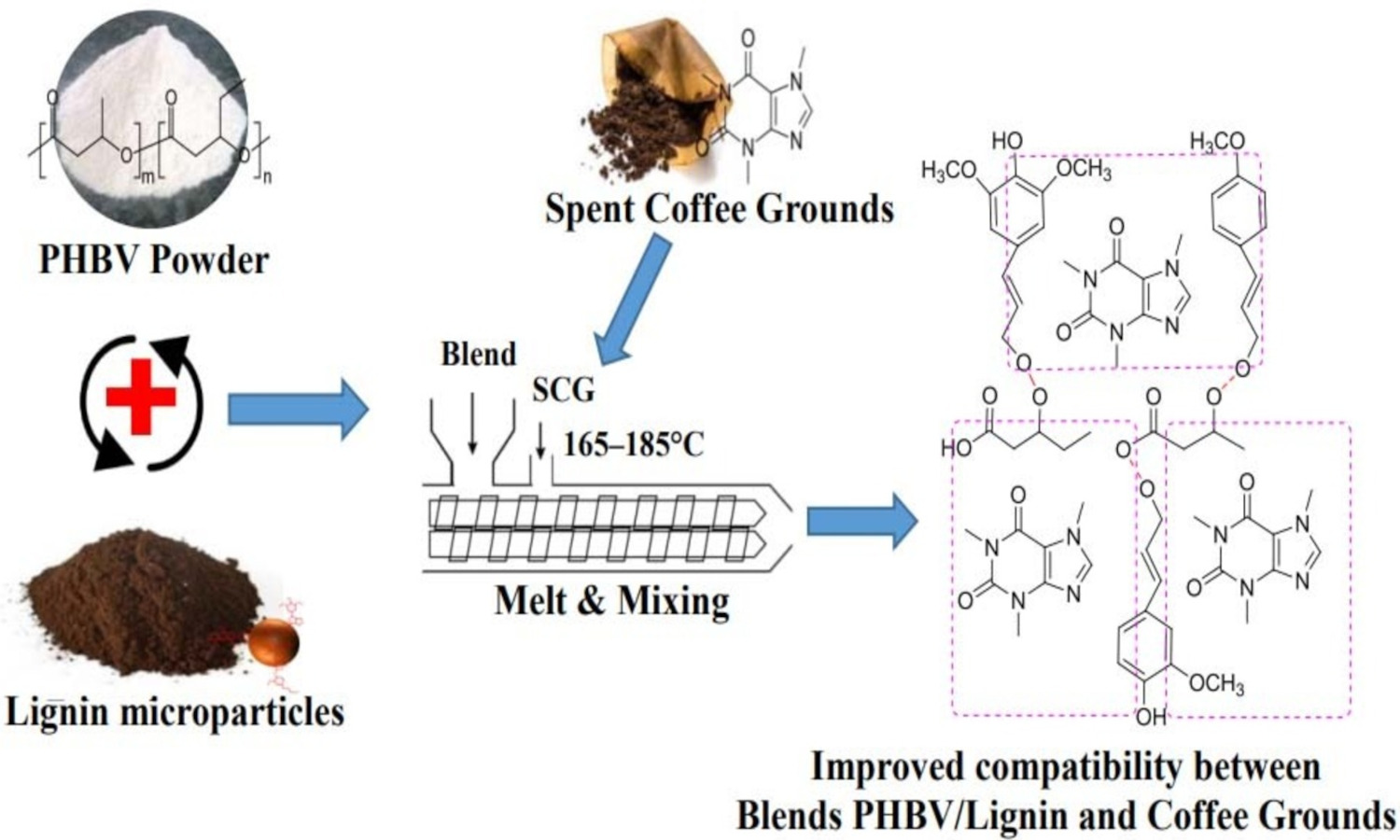

This study investigated the development of thermoplastic composites by incorporating crude lignin extracted from coir fiber waste, into poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a biodegradable polymer. The extracted crude lignin was blended with PHBV as a matrix, and spent coffee grounds (SCG) were used as biofillers. SCG were chemically modified through sodium hydroxide (NaOH) treatment and maleic anhydride (MA) grafting to enhance their compatibility with the PHBV/lignin blend. Raw and modified SCG were characterized for their functional, morphological, and thermal properties before being incorporated. Thermoplastic biocomposites were prepared via melt compounding and compression molding and evaluated for water barrier, morphological, mechanical, and thermal properties. Results showed that MA-grafted SCG significantly enhanced PHBV-lignin properties, increasing tensile strength by 23.7% and thermal stability by 11.9% compared to the control matrix. Optimal performance was observed at 5% MA-grafted SCG filler loading. However, higher SCG concentrations (7%) led to filler agglomeration, negatively affecting the material properties. This research demonstrated the potential of utilizing agricultural and food waste to create high-performance thermoplastic composites for future applications in biodegradable packaging, contributing to the advancement of a circular economy and environmental sustainability.

Lumirca Del Valle Espinoza León, Viviane Alves Escócio, Leila Lea Yuan Visconte, Ana Maria Furtado de Sousa, Ana Lúcia Nazareth da Silva, Elen Beatriz Acordi Vasques Pacheco

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

This study uses a rotomolding procedure to produce hollow cubes made of linear low-density polyethylene (LLDPE) and coconut fibers (CF). The purpose is to investigate the effect of different CF content (0, 5, 12.5, and 20 wt%) and size (100 and 50 mesh) on composite properties. As the CF content rises, the density of all composites decreases due to an increase in material porosity, a result of poor adhesion between the fiber and LLDPE. Impact strength reduced as the content of CF increased, except for the composite with 5 wt% of CF and 50 mesh size. The ineffective adhesion between coir fibers and LLDPE, along with the presence of voids in the matrix, caused the mechanical properties to deteriorate as the CF content increased. The flammability test revealed that all samples dripped. The neat LLDPE sample deformed, whereas the LLDPE/CF composites maintained their shape. This behavior suggests that CF plays a structural role in burning composites. Maleic anhydride-grafted polyethylene (MAPE), calcium stearate, and magnesium stearate additives did not contribute to reducing the composite’s porosity. MAPE was the only additive that did not reduce the elastic modulus of composites.