Content

All issues / Volume 19 (2025) / Issue 8 (August)

Georgios C. Psarras

Vol. 19., No.8., Pages 751-752, 2025

DOI: 10.3144/expresspolymlett.2025.57

Vol. 19., No.8., Pages 751-752, 2025

DOI: 10.3144/expresspolymlett.2025.57

This is an editorial article. It has no abstract.

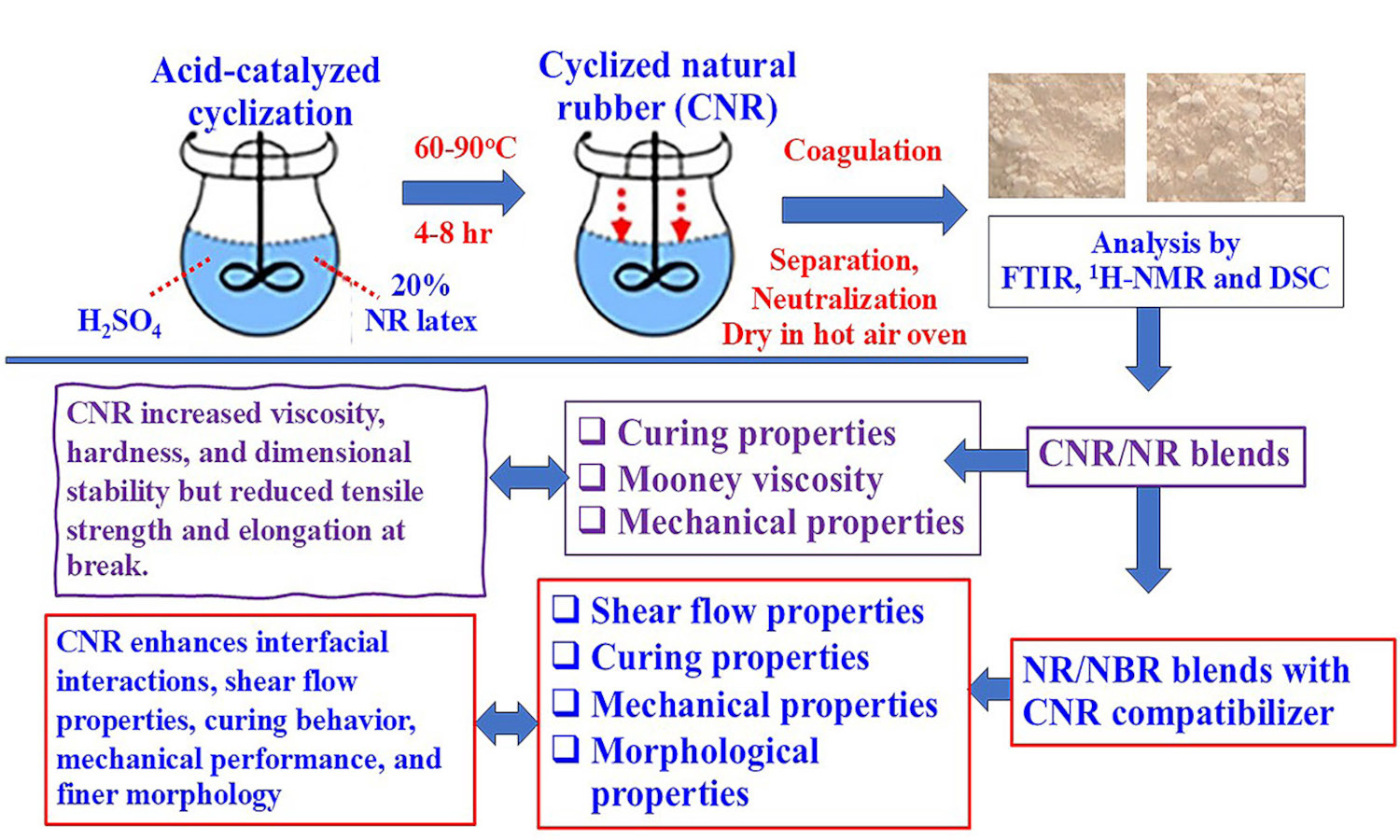

Azizon Kaesaman, Tassaneeya Khunrang, Charoen Nakason

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

Cyclized natural rubber (CNR) was synthesized through the acid-catalyzed reaction of natural rubber (NR) latex using sulfuric acid as a catalyst and stabilized with a non-ionic surfactant. Cyclization was evaluated by iodine numbers under varying reaction times, temperatures, and NR-to-acid ratios. Fourier transform infrared spectroscopy (FTIR) and proton nuclear magnetic resonance spectroscopy (1H-NMR) confirmed the formation of cyclic structures in CNR molecules. Differential scanning calorimetry (DSC) showed that the glass transition temperature (Tg) of CNR increased with cyclization, indicating greater rigidity and less chain flexibility. CNR was then blended with NR and used as a compatibilizer in NR/acrylonitrile butadiene rubber (NBR)blends. It increased blend viscosity, hardness, and dimensional stability but reduced tensile strength and elongation due to its rigid cyclic domains. In NR/NBR blends, CNR outperformed a commercial homogenizer in enhancing interfacial interactions, leading to superior shear flow properties, curing behavior, and mechanical performance. This is attributed to the polar groups in CNR, which enhance intermolecular interactions and phase compatibility, resulting in finer phase morphology. This study highlights the potential of CNR as a versatile material for enhancing the performance of rubber compounds, with promising applications in advanced industrial formulations.

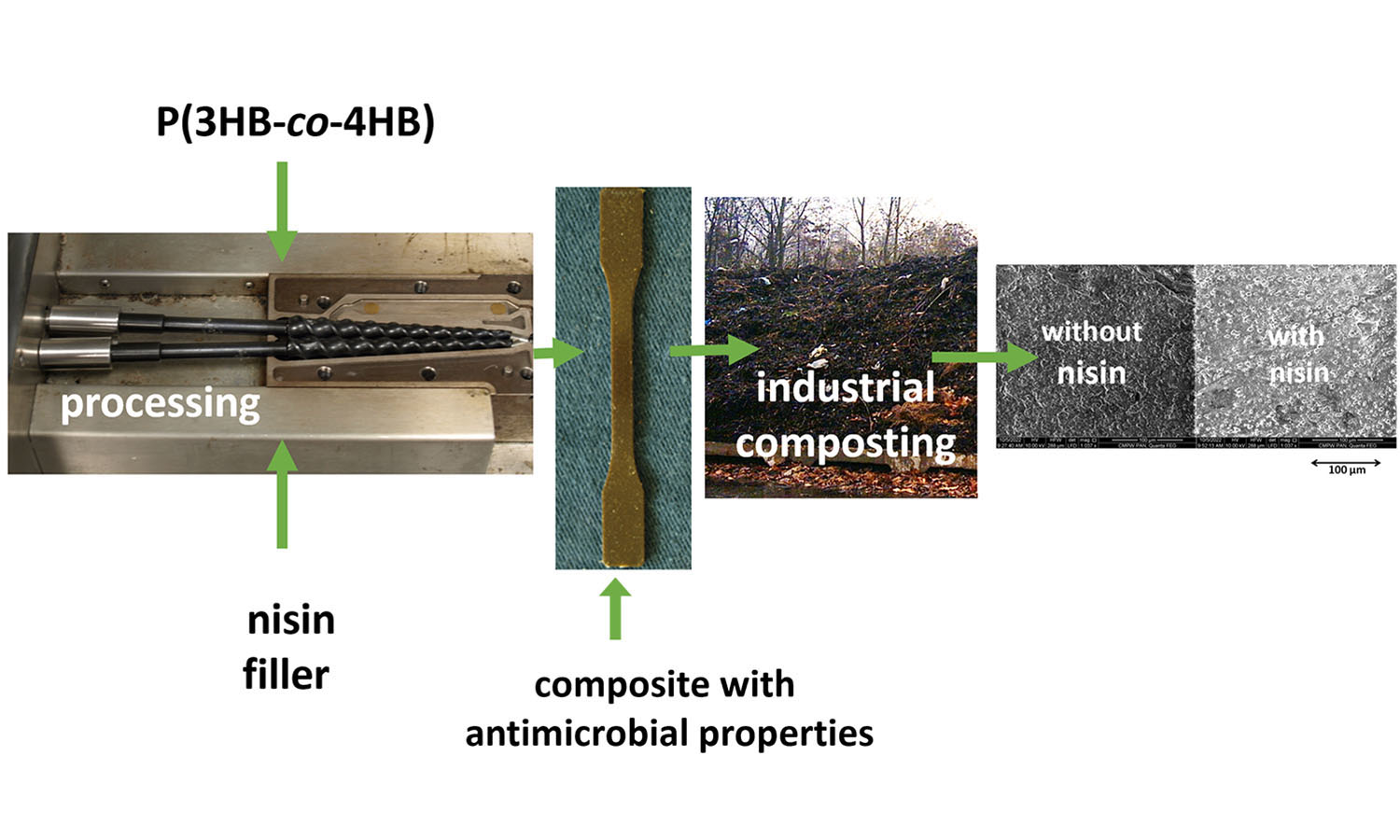

Marta Musioł, Michał Sobota, Henryk Janeczek, Anna Smola -Dmochowska, Brian Johnston, Iza Radecka

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

This study focused on developing compostable packaging materials possessing beneficial microbiological characteristics and evaluating their degradation process. We explore the use of nisin as a versatile antimicrobial additive in biodegradable materials. Our findings demonstrate nisin’s significant influence on the processing and degradation of composites. Nisin’s amphiphilic structure, characterized by both hydrophobic and hydrophilic components, enhances its interaction with the polymer matrix. This interaction affects smaller molar mass reduction during processing and leads to variations in degradation dynamics. The results suggest that nisin has minimal impact on the thermal stability of the matrix during processing, with less than a one-degree increase observed. Thermal stability improved for all materials during degradation, but nisin’s presence slowed this increase. Nisin’s influence on the matrix of jute fiber composites, was more pronounced, affecting the material during processing and subsequent degradation. The results indicate that samples containing nisin inhibit the growth of the gram-positive bacterium Staphylococcus aureus (S. aureus) after 24 h of incubation. The inclusion of fillers in composites elevates the microbiological activity by filler ‘antibacterial promotion’ effects in samples containing nisin. Connection with previous studies highlights the significance of polymer chain length on the composite’s antimicrobial properties.

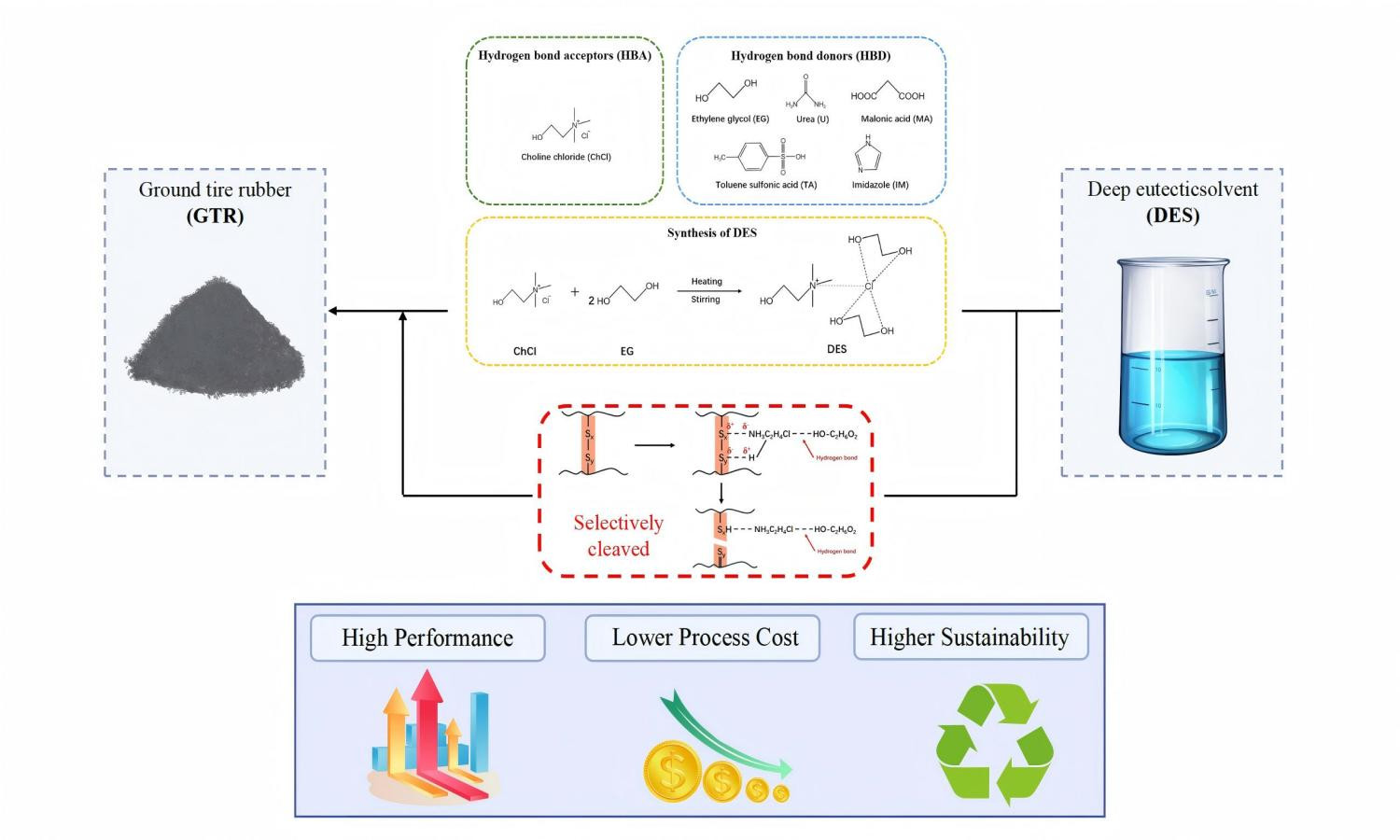

Liu Yang, Xuan Zhao, Sun Xinyu, Shuai Yuan, Lei Zhu

Vol. 19., No.8., Pages 783-795, 2025

DOI: 10.3144/expresspolymlett.2025.60

Vol. 19., No.8., Pages 783-795, 2025

DOI: 10.3144/expresspolymlett.2025.60

Waste tire rubber poses significant environmental challenges due to its non-biodegradability and complex crosslinkedvstructure. In this sense, this study aims to examine the utilization of deep eutectic solvents (DESs) in the desulfurizationvprocess of ground tire rubber (GTR). A range of hydrogen bond donors (HBDs), including ethylene glycol, malonic acid,vimidazole, toluene sulfonic acid, and urea, were combined with choline chloride, which serves as a hydrogen bond acceptorv(HBA), to synthesize deep eutectic solvents. Subsequently, these DESs are used in the modification of rubber devulcanizationvprocesses. Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and Horikx analysis werevused to confirm the occurrence of devulcanization. The studies confirmed that the devulcanization process was selective invnature, effectively reducing random chain scission while maintaining the integrity of the polymer. Furthermore, the vulcanizatesvobtained post-treatment demonstrated enhanced properties, including increased tensile strength, modulus, tear strength, hardness, and durability, with ethylene glycol-based DES (DES-E) exhibiting the most pronounced enhancements.

Kai Du, Qiang Ben, Xiaoqiang Wang

Vol. 19., No.8., Pages 796-808, 2025

DOI: 10.3144/expresspolymlett.2025.61

Vol. 19., No.8., Pages 796-808, 2025

DOI: 10.3144/expresspolymlett.2025.61

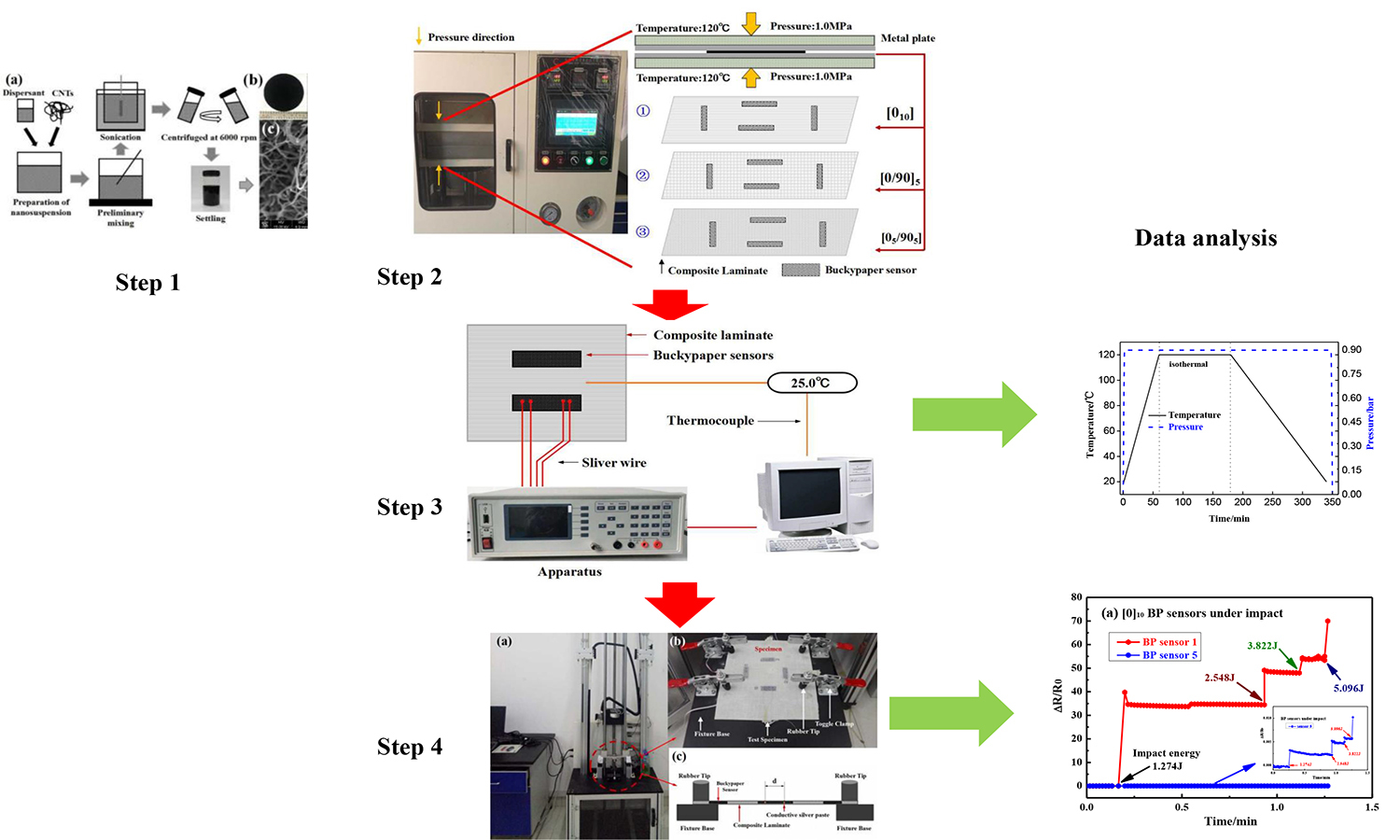

The main purpose of structural health monitoring (SHM) is to detect damage at its earliest possible stage to prevent severe deterioration and reduce subsequent repair costs. Carbon nanotubes (CNTs) buckypaper (BP) was embedded into different cross-ply glass fibre composites to monitor the curing process and impact damage as an in situ sensor in this research. BP sensor can capture the four stages of the curing process, the gel point of the resin and residual stresses of the composite structure can be achieved by analysing the change of the resistance curve. Numerical and experimental analyses were performed to predict the damage in composite structures subjected to low-velocity impact. BP sensors’ electrical resistance increases with repeated impact loading; composite structure elastic deformation and damage evolution can be identified from resistance change. Experiment results show that structure monitoring based on the BP sensors cannot only detect small, barely visible impact damage flaws and the damage evaluation of composite structures subjected to impact, but also provide a new method to monitor the curing process through the analysis of results. This work makes some constructive contributions to monitoring the manufacturing process of composites and long-term SHM to evaluate impact resistance and damage prediction of composite structures.

Gergő Zsolt Marton, Fanni Balogh, Gábor Szebényi

Vol. 19., No.8., Pages 809-821, 2025

DOI: 10.3144/expresspolymlett.2025.62

Vol. 19., No.8., Pages 809-821, 2025

DOI: 10.3144/expresspolymlett.2025.62

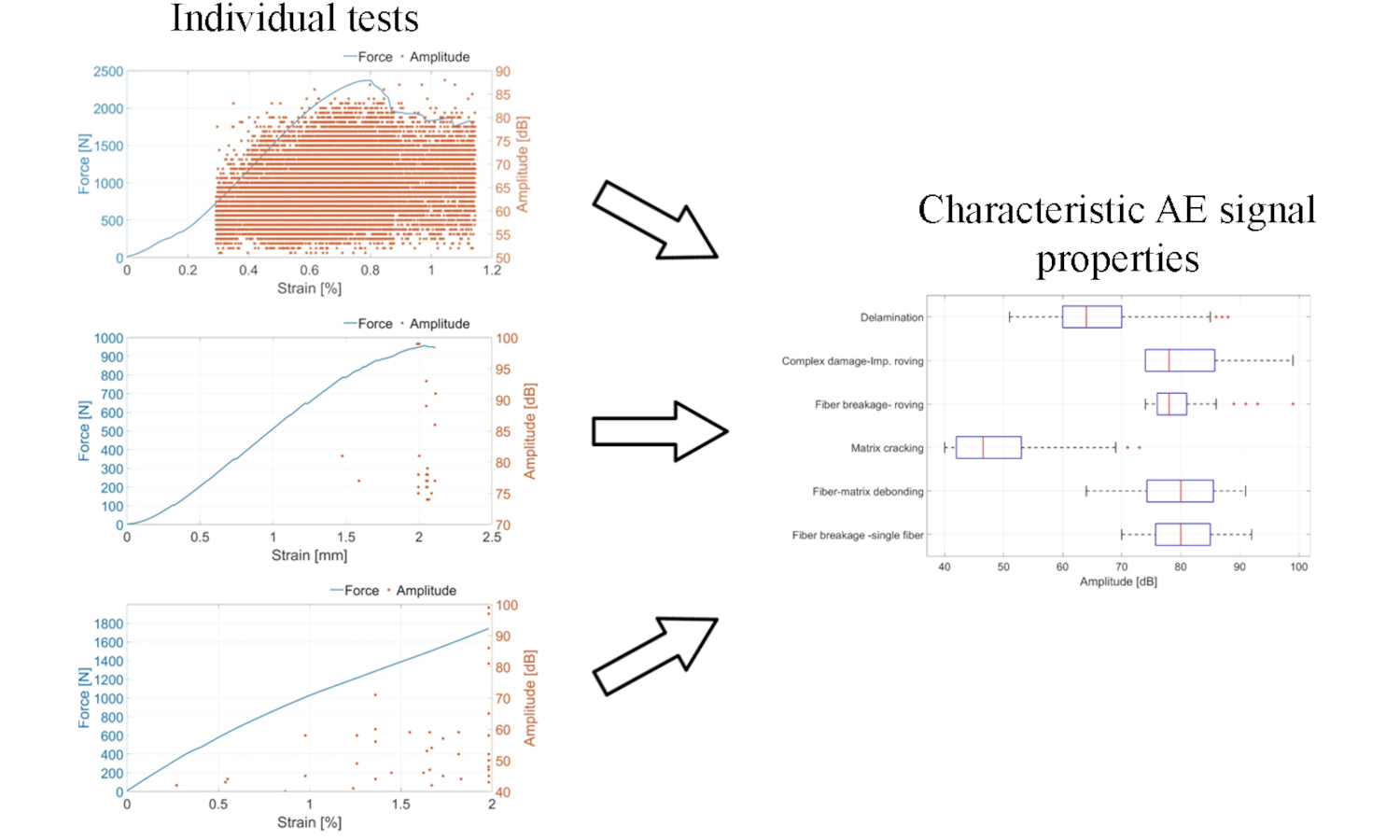

The failure of fiber-reinforced polymer composites is considered a complex process resulting from several concurrent damage mechanisms and their interactions. To better understand the damage modes of composites, which is necessary to ensure their structural health monitoring, increase their reliability, and validate different methods used for influencing their damage and failure process, it is crucial to detect, identify, and analyze different damage modes present in composite materials. The acoustic emission technique provides the opportunity to acquire damage-related data, which can be analyzed and associated with different modes of damage. In the current study, we conducted specific tests using the acoustic emission (AE) technique on the composite and its constituents, which can induce individual damage modes, thereby enabling the determination of their characteristic AE signal properties and their identification in complex composite structures.

Elumalai Vengadesan, Swaminathan Muralidharan, Dhanjit Das, Thirugnanasambandam Arunkumar

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

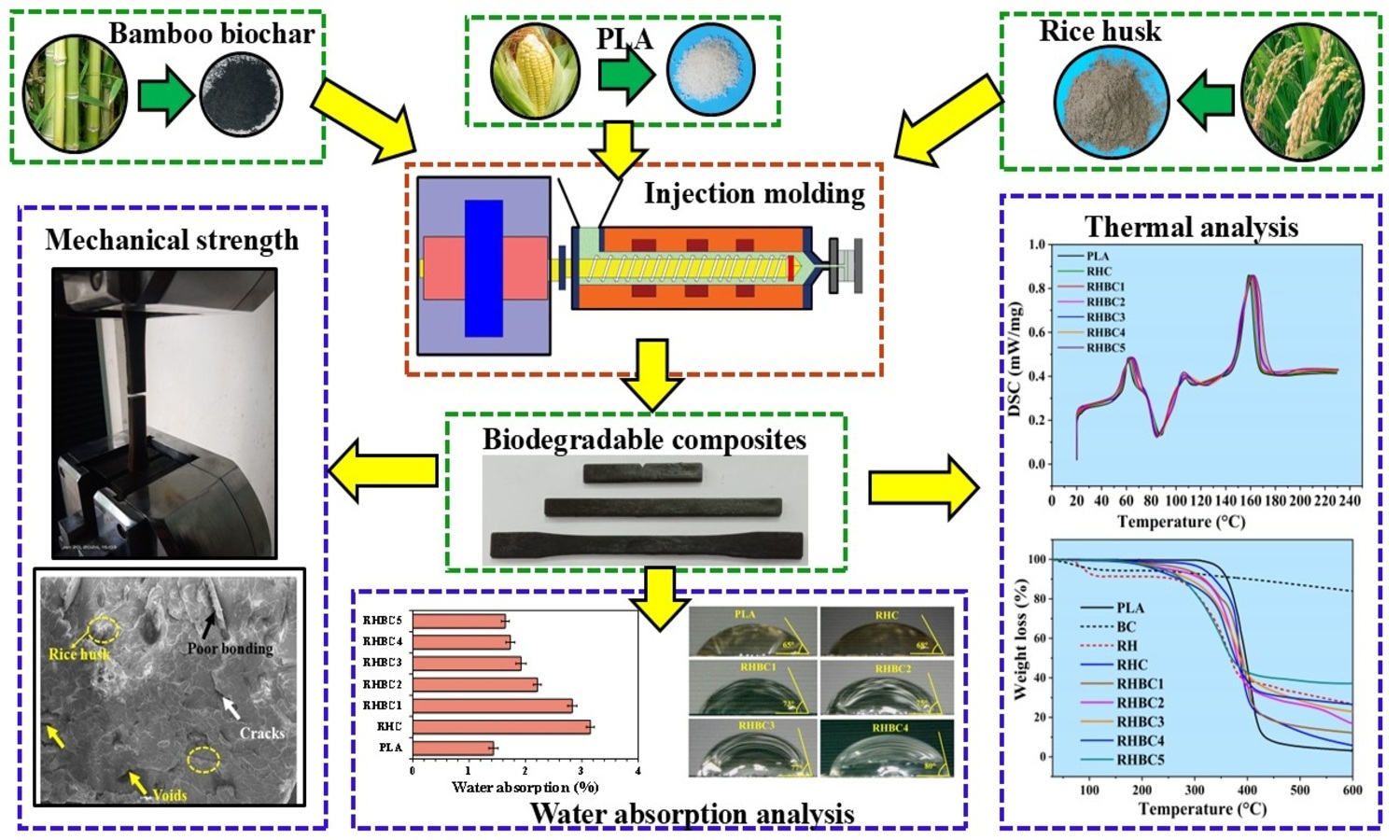

The growing need for sustainable materials has stimulated research into eco-friendly composites, with biochar emerging as an important reinforcement in polymer matrices. Biochar is a carbon-rich material produced by pyrolyzing organic biomass, offering various benefits over traditional fillers, including sustainability, waste reduction, and carbon sequestration. This study explores the effects of bamboo biochar as a hybrid reinforcement on the properties of polylactic acid (PLA)-rice husk composites. The present hybrid composites are prepared by varying the bamboo biochar from 5–25% and have better mechanical properties than PLA and its composite reinforced with a rice husk filler. The tensile, flexural, and compressive strengths of 51.5, 166.0, and 77.5 MPa are measured for the biochar percentage of 10%, representing increases of 73.1, 150.0, and 58.2% compared to PLA, and 158.2, 98.6, and 31% compared to the PLA composite with rice husk. Higher tensile and flexural moduli of 1.46 and 7.34 GPa are observed for 10 and 15%, respectively. However, the impact strength decreases with higher biochar content due to increased rigidity. The material’s hardness increases at higher biochar content due to enhanced stiffness. Thermal transition and degradation points rise due to increased crystallinity from the biochar reinforcement’s nucleation effect. Additionally, the hydrophobic biochar reinforcement reduces water absorption of PLA composite from 3.2 to 1.6%.

Kankanok Longkaew, Philippe Daniel, Taweechai Amornsakchai, Thanchanok Ratvijitvech, Pranee Phinyocheep

Vol. 19., No.8., Pages 843-859, 2025

DOI: 10.3144/expresspolymlett.2025.64

Vol. 19., No.8., Pages 843-859, 2025

DOI: 10.3144/expresspolymlett.2025.64

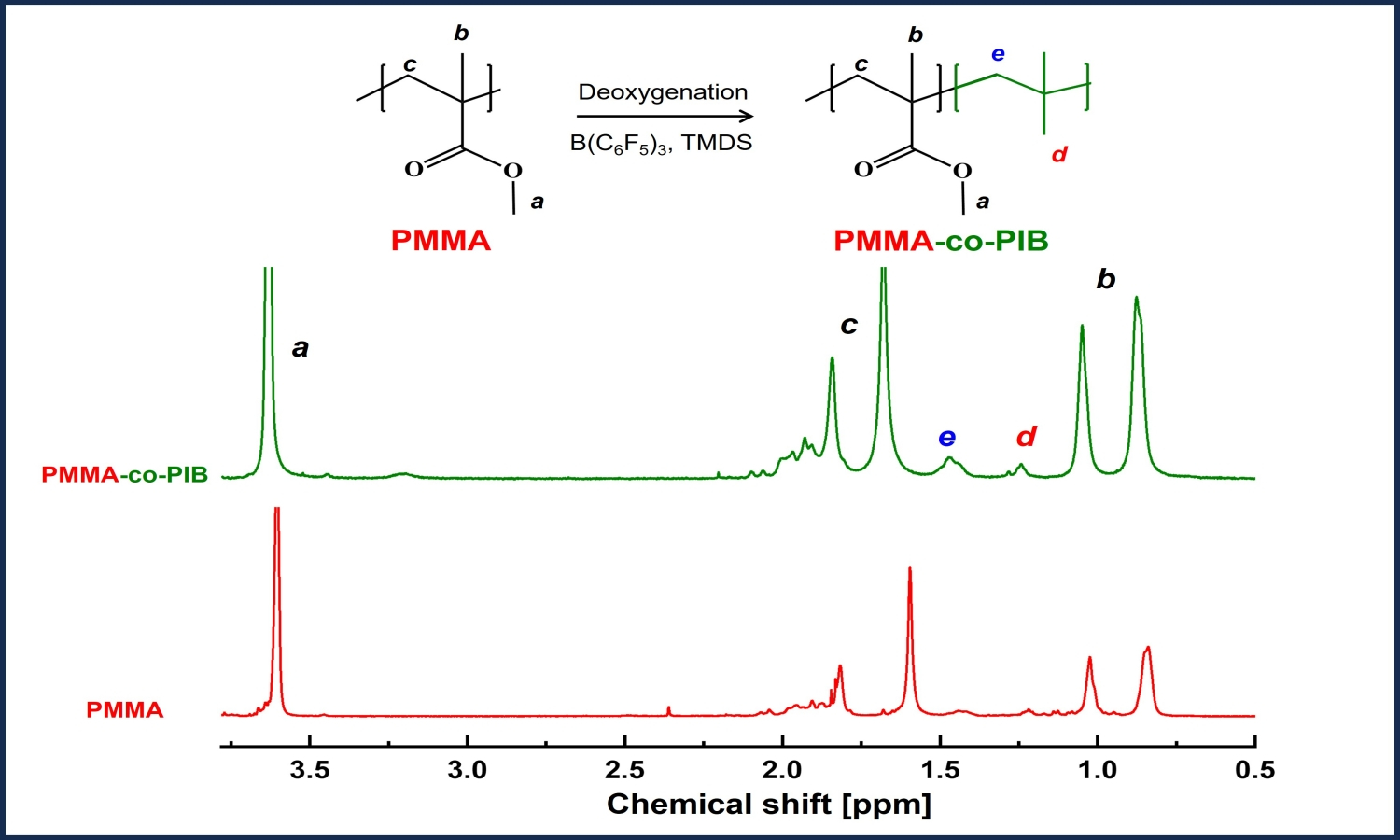

Poly(methyl methacrylate) or PMMA is a versatile material because of its ease of manipulation and biocompatibility. However, brittleness limits its applications; hence, copolymerization of PMMA with rubber such as polyisobutylene (PIB) is required. PMMA-co-PIB preparation by conventional copolymerization requires the purification of co-monomers under an inert atmosphere. In this study, the transformation of PMMA into PMMA-co-PIB was explored using a deoxygenation reaction. PMMA was treated with tris(pentafluorophenyl) borane and 1,1,3,3-tetramethyldisiloxane (TMDS) at room temperature, 50, and 70 °C for 1, 2, and 3 day reaction times. FTIR results revealed a reduction in the ester functional group of PMMA at 1724 cm–1. PMMA was partially converted into PIB moieties, forming PMMA-co-PIB. The highest degree of deoxygenation (48.2%) was obtained after a reaction for 1 day at room temperature. When the PIB structure was present in the PMMA backbone, the PMMA glass transition temperature (115.6 °C) was shifted to a lower temperature (83.7°C). A significant decrease in the modulus of PMMA from 3.40 to 1.29 GPa (PMMA-co-PIB) reveals improved toughness. This straightforward post-polymerization approach involving the deoxygenation of PMMA offers a promising, simple, and mild condition for synthesizing PMMA-co-PIB. This will enable new applications in medical appliances or high-value coating materials.