Correlation between solution relative viscosity and the microstructural properties of the poly(3-hydroxybutyrate-co-3-hydroxyvalerate) – PHBV solution blow spun mats

Lucas Gomes Rabello , Maira Rievrs Nogueira Alvares

, Maira Rievrs Nogueira Alvares , Roberto Carlos da Conceição Ribeiro

, Roberto Carlos da Conceição Ribeiro , Paula Mendes Jardim

, Paula Mendes Jardim , Rossana Mara da Silva Moreira Thiré

, Rossana Mara da Silva Moreira Thiré

, Maira Rievrs Nogueira Alvares

, Maira Rievrs Nogueira Alvares , Roberto Carlos da Conceição Ribeiro

, Roberto Carlos da Conceição Ribeiro , Paula Mendes Jardim

, Paula Mendes Jardim , Rossana Mara da Silva Moreira Thiré

, Rossana Mara da Silva Moreira Thiré

Vol. 17., No.12., Pages 1239-1256, 2023

DOI: 10.3144/expresspolymlett.2023.94

DOI: 10.3144/expresspolymlett.2023.94

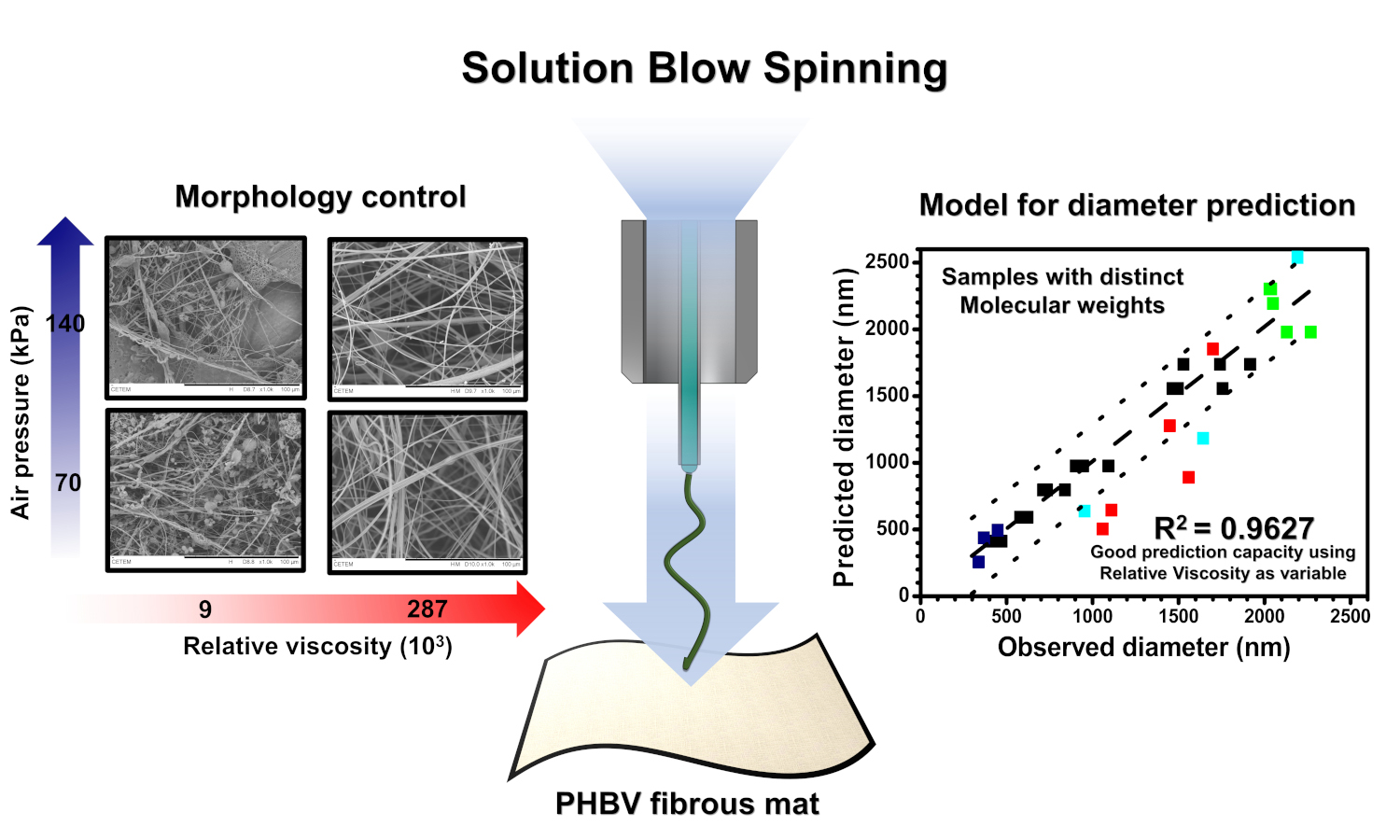

GRAPHICAL ABSTRACT

ABSTRACT

In this study, we produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) fibrous mats via solution blow spinning (SBS) and evaluated their microstructural properties. We propose here the utilization of the theoretical estimative of relative viscosity (RV) as an independent variable in a statistical design of experiments (DoE) to account for the polymer’s molecular weight (Mw) effect on the determination of the diameter and morphology of the fibers. The RV of the solution (42.3・103–287.4・103) and air pressure – AP (70–140 kPa) were varied. The analysis of variance (ANOVA) indicated that the increase in RV favored an increment in fiber size and resistance to alignment. Higher AP produced aligned and thinner fibers with higher crystallinity. The spinnability regions were determined based on the estimated RV of the PHBV solutions and the AP levels. Fibers were formed at 70 kPa from solutions with RV ranging from 10・103 to 106, while at 140 kPa, from 42・103 to 106. Nanofibers were produced from less viscous solutions (RV = 42.3・103–124.4・103), while microfibers were produced from solutions with RV = 287.4・103. The developed ANOVA model predicted with good accuracy (R2adj. = 0.96) the average diameter of the PHBV fibers produced from the SBS technique using polymers with distinct Mw values, including those available in the literature data.

RELATED ARTICLES

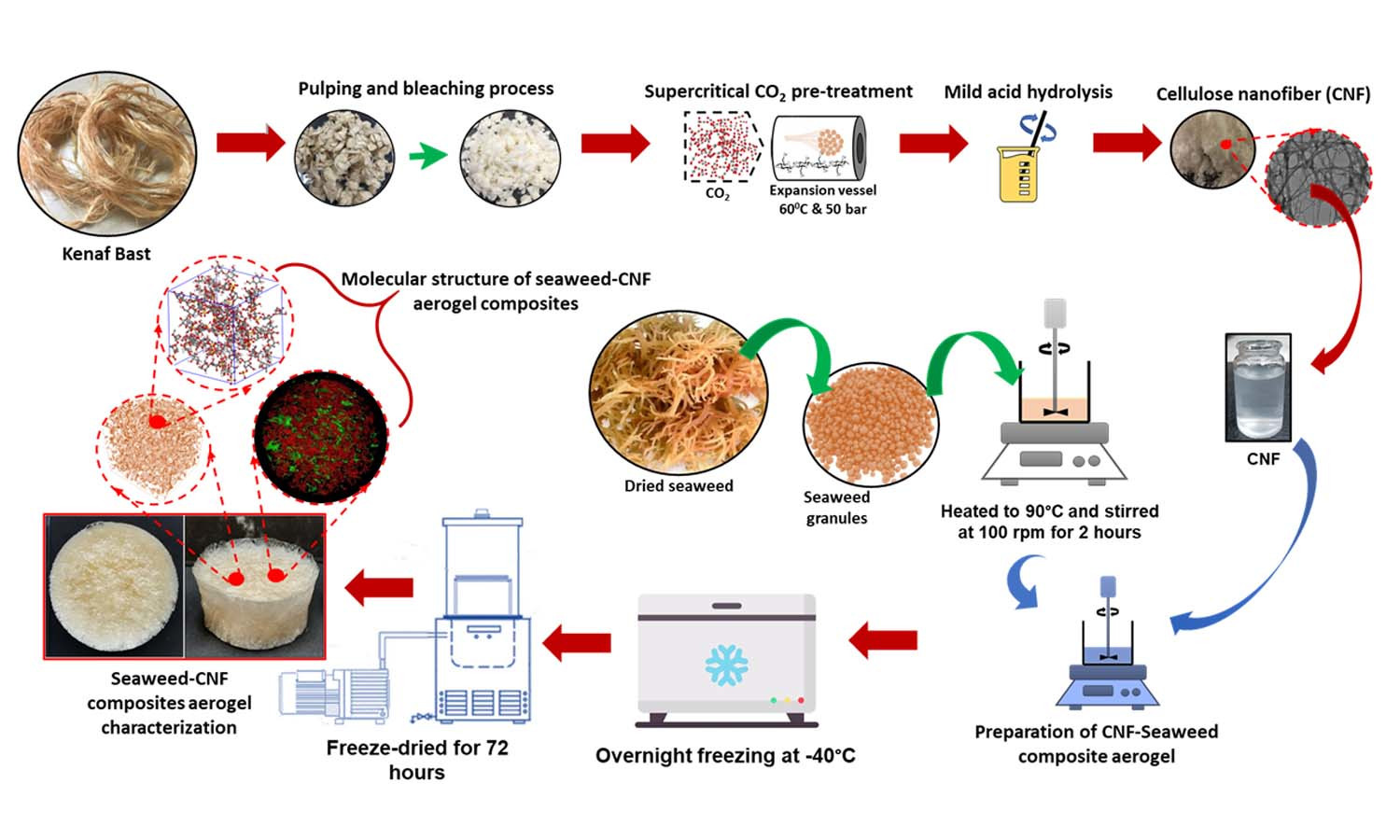

Rayan Y. Mushtaq, Azfaralariff Ahmad, Abdul Khalil H.P.S., Rana Baker Bakhaidar, Waleed Y. Rizg, Shazlina Abd Hamid, Abdulmohsin J. Alamoudi, Che Ku Abdullah, Tata Alfatah

Vol. 18., No.7., Pages 760-777, 2024

DOI: 10.3144/expresspolymlett.2024.56

Vol. 18., No.7., Pages 760-777, 2024

DOI: 10.3144/expresspolymlett.2024.56

Seaweed

from macroalgae and cellulose from nonwood materials have gained attention in

various fields. This study explores how seaweed and cellulose nanofibers (CNF)

interact to form 3D networks in composite bioaerogels. The ratio of CNF and

seaweed was varied to see how it affects the aerogel’s inside and its

properties. The observations show that the biocomposite aerogel is more rigid

and shrinks less than using a single biopolymer. The CNF aerogel has a fine,

thin network structure, and the seaweed aerogel has a thin sheet structure. The

biocomposite aerogel combines both a fine network and a thin sheet structure.

The composite aerogel’s mechanical properties are significantly influenced by

seaweed composition. The introduction of CNF increases elasticity, while

seaweed enhances firmness. Generated computer modelling revealed that the

abundant hydroxyl groups in CNF facilitated the formation of intermolecular

bonds with seaweed. The bonding led to increased adhesion and entanglement

between biopolymers, consequently enhancing elasticity and establishing a

stable intermolecular interaction. The 3D X-ray imaging model shows that the

skeletal framework primarily consists of seaweed biopolymer, with CNF serving

to reinforce this structure thus enhancing the mechanical properties and

robustness of the composite bioaerogels.