Elucidating the synergistic interactions of macroalgae and cellulose nanofibers on the 3D structure of composite bioaerogel properties

Rayan Y. Mushtaq, Azfaralariff Ahmad , Abdul Khalil H.P.S.

, Abdul Khalil H.P.S. , Rana Baker Bakhaidar, Waleed Y. Rizg, Shazlina Abd Hamid, Abdulmohsin J. Alamoudi, Che Ku Abdullah

, Rana Baker Bakhaidar, Waleed Y. Rizg, Shazlina Abd Hamid, Abdulmohsin J. Alamoudi, Che Ku Abdullah , Tata Alfatah

, Tata Alfatah

, Abdul Khalil H.P.S.

, Abdul Khalil H.P.S. , Rana Baker Bakhaidar, Waleed Y. Rizg, Shazlina Abd Hamid, Abdulmohsin J. Alamoudi, Che Ku Abdullah

, Rana Baker Bakhaidar, Waleed Y. Rizg, Shazlina Abd Hamid, Abdulmohsin J. Alamoudi, Che Ku Abdullah , Tata Alfatah

, Tata AlfatahVol. 18., No.7., Pages 760-777, 2024

DOI: 10.3144/expresspolymlett.2024.56

DOI: 10.3144/expresspolymlett.2024.56

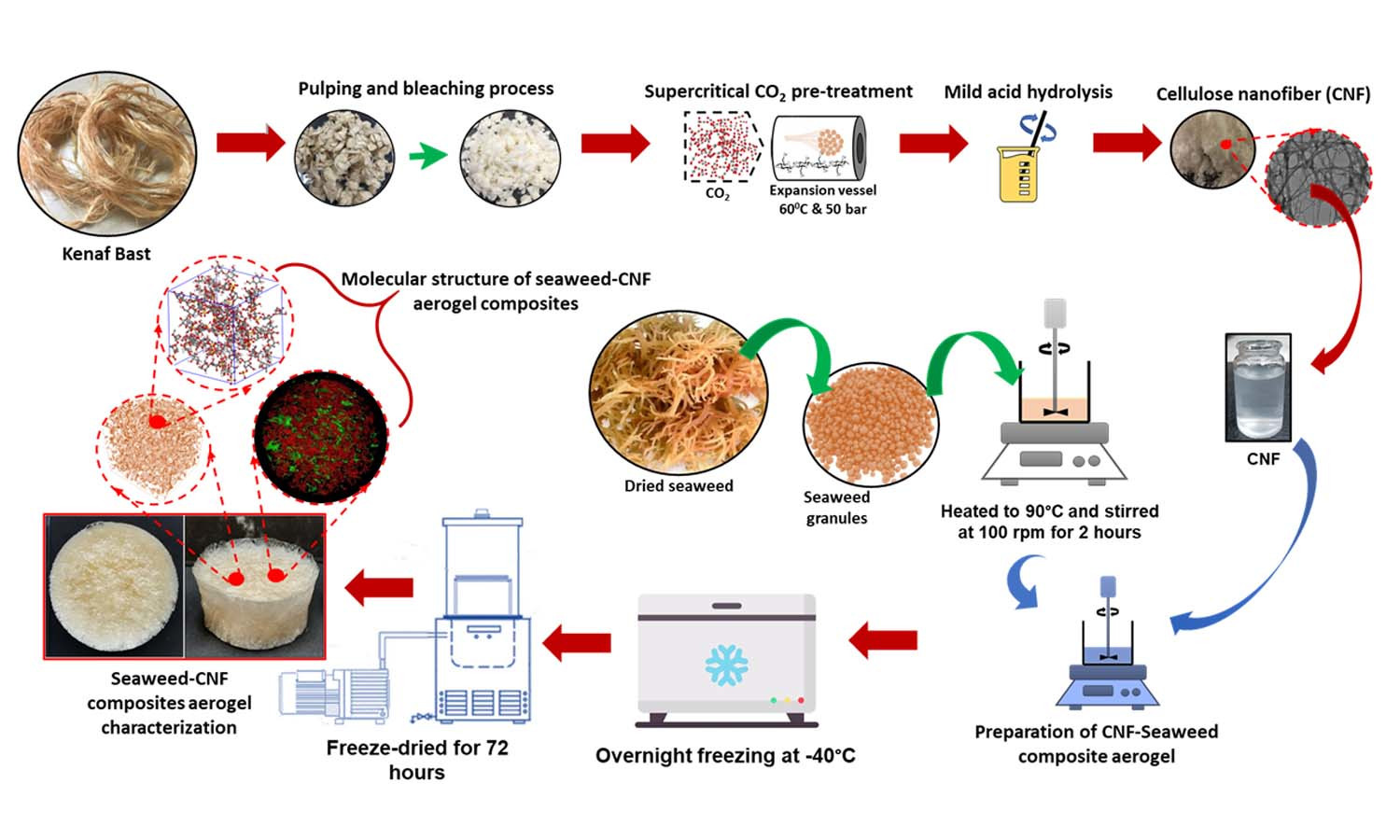

GRAPHICAL ABSTRACT

ABSTRACT

Seaweed

from macroalgae and cellulose from nonwood materials have gained attention in

various fields. This study explores how seaweed and cellulose nanofibers (CNF)

interact to form 3D networks in composite bioaerogels. The ratio of CNF and

seaweed was varied to see how it affects the aerogel’s inside and its

properties. The observations show that the biocomposite aerogel is more rigid

and shrinks less than using a single biopolymer. The CNF aerogel has a fine,

thin network structure, and the seaweed aerogel has a thin sheet structure. The

biocomposite aerogel combines both a fine network and a thin sheet structure.

The composite aerogel’s mechanical properties are significantly influenced by

seaweed composition. The introduction of CNF increases elasticity, while

seaweed enhances firmness. Generated computer modelling revealed that the

abundant hydroxyl groups in CNF facilitated the formation of intermolecular

bonds with seaweed. The bonding led to increased adhesion and entanglement

between biopolymers, consequently enhancing elasticity and establishing a

stable intermolecular interaction. The 3D X-ray imaging model shows that the

skeletal framework primarily consists of seaweed biopolymer, with CNF serving

to reinforce this structure thus enhancing the mechanical properties and

robustness of the composite bioaerogels.

RELATED ARTICLES

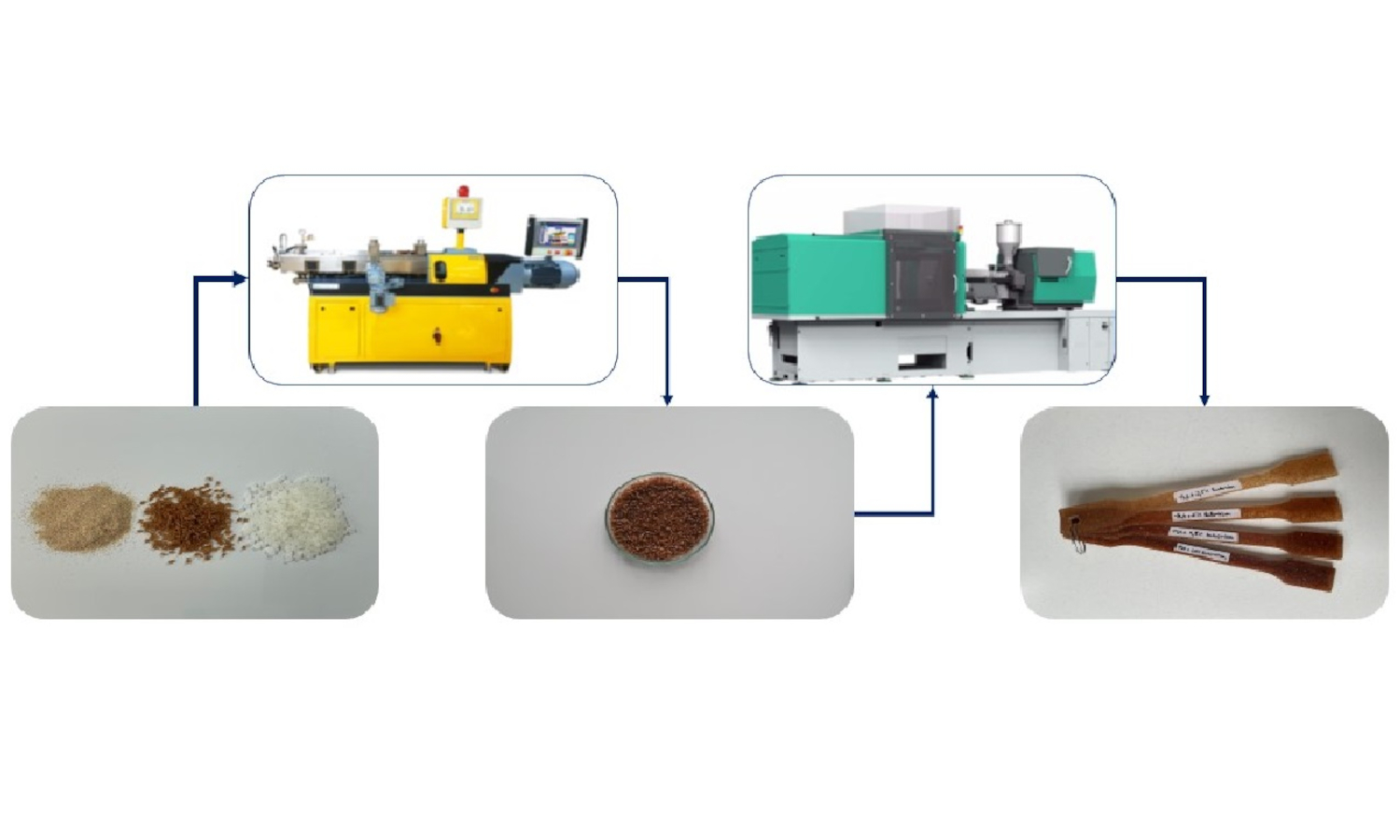

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

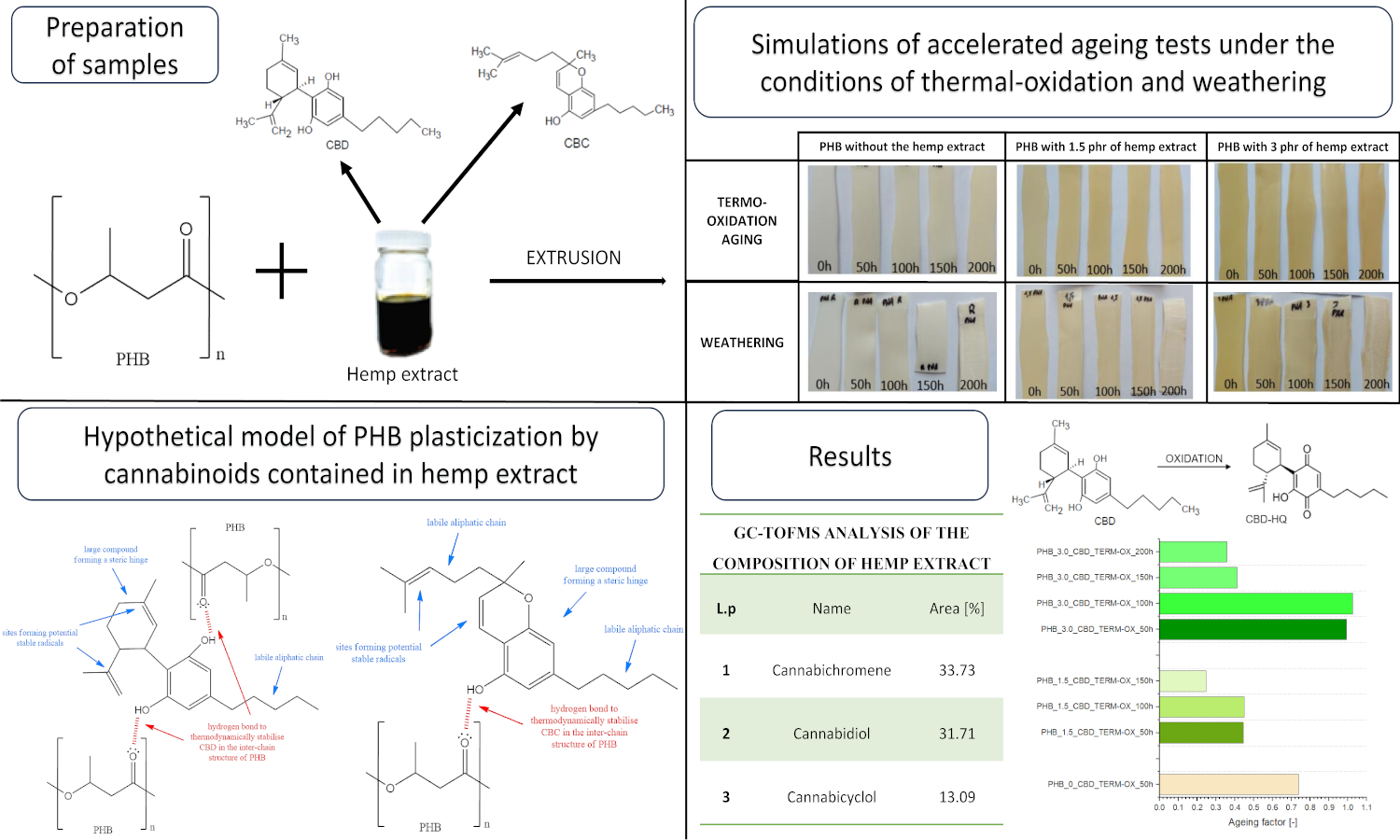

Karol Tutek, Anna Masek

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Biodegradable biopolymers like polyhydroxybutyrate (PHB) hold promise for sustainable packaging, but their inherent degradability reduces material stability. Synthetic stabilizers, though effective, raise environmental and potential toxicity concerns. This study explores a multifunctional natural anti-aging agent: a hemp extract rich in cannabidiol (CBD) and cannabichromene (CBC). PHB composites with varying hemp extract concentrations were prepared and subjected to thermooxidative and weathering aging. Characterization employed FTIR-ATR, carbonyl index, and spectrophotometry. Static mechanical properties, DSC, and surface free energy (SFE) were also assessed. Notably, the hemp extract exhibited stability under ambient conditions but showed migration with time and aging. The results suggest a plasticizing effect on PHB and highlight the contrasting roles of the extract: inhibiting thermooxidative aging while potentially accelerating aging under atmospheric conditions. This opens avenues for tailoring material durability, further evaluated by life cycle analysis (LCA). This work represents one of the first investigations into hemp extract as an anti-aging agent for eco-friendly polymers, expanding the knowledge base of natural multifunctional additives.

Sanjay Mavinkere Rangappa, Suchart Siengchin

Vol. 18., No.12., Pages 1176-1177, 2024

DOI: 10.3144/expresspolymlett.2024.89

Vol. 18., No.12., Pages 1176-1177, 2024

DOI: 10.3144/expresspolymlett.2024.89

This is an editorial article. It has no abstract.

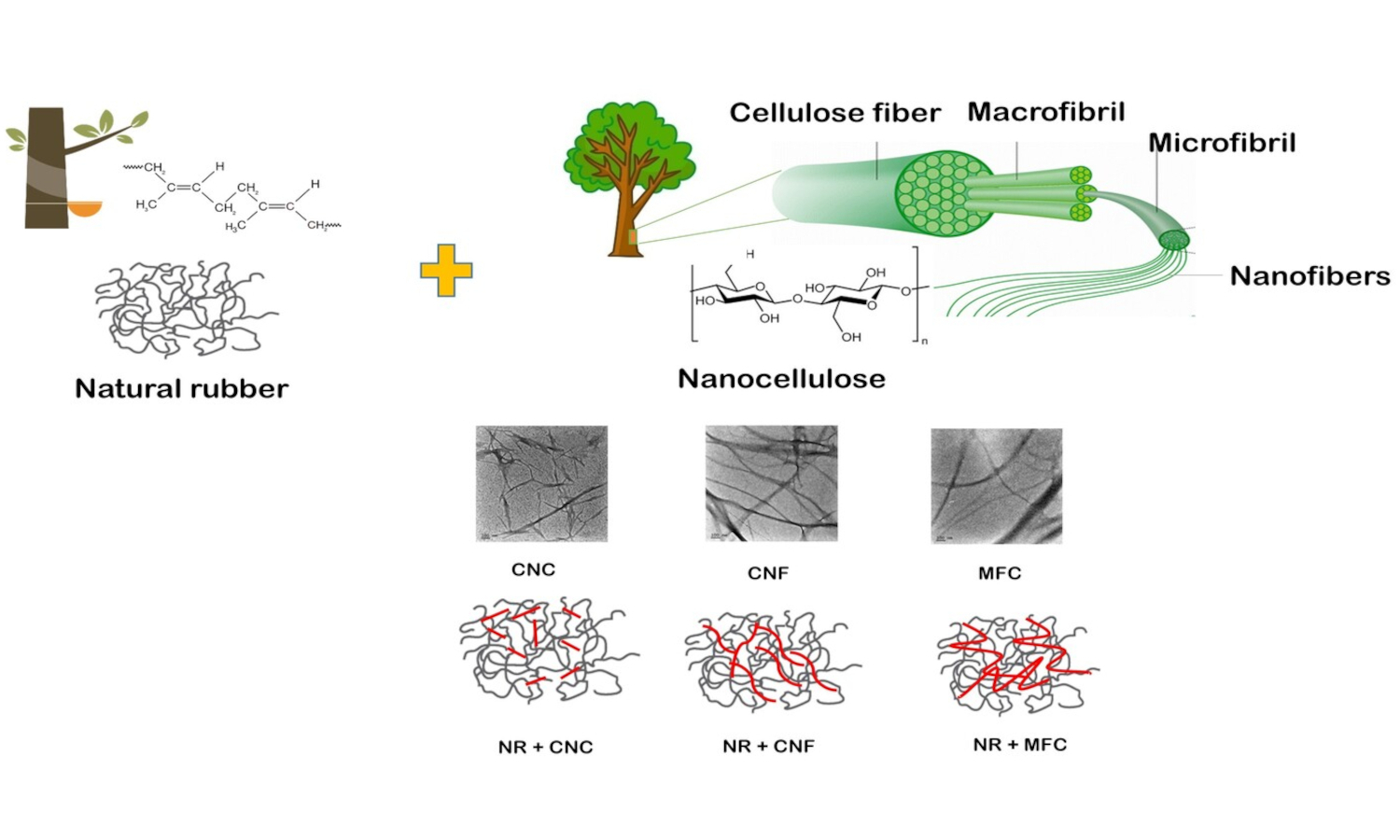

Milanta Tom, Sabu Thomas, Bastien Seantier, Yves Grohens, Mohamed Pulikaparambil Kochaidrew, Ramakrishnan Subramanian, Tapas Ranjan Mohanty, Henri Vahabi, Hanna Joseph Maria, Jibin Keloth Paduvilan, Martin George Thomas

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

The augmented demand for

sustainable nanocomposites has paved the way to explore naturally derived

materials. Nanocellulose, with its bountiful sources and inherent properties,

ranks top in the list of biofillers with a perspective of reducing the carbon

footprint. A systematic study is required to understand the reinforcing effect

of various types of nanocellulose. In the present work, we selected three types

of nanocellulose, i.e.,

cellulose nanocrystal (CNC), cellulose nanofiber (CNF) and microfibrillated

cellulose (MFC), to investigate the effect of geometrical structure on the

properties of unvulcanized natural rubber (NR). Incorporating these fillers

improved the tensile strength and modulus of natural rubber films significantly

through reinforcement via filler network structure. The reinforcing effect of

CNF was found to be higher compared to CNC and MFC, where an increase of 3.85

MPa in tensile strength from the neat sample was obtained. More uniform

dispersion was evident through transmission electron microscopy, atomic force

microscopy and Raman imaging for CNF in the rubber matrix. The structural

properties were determined using Raman spectra and X-ray diffraction. The rheological

studies revealed a good interaction between filler and NR. The work presented

comprehensively compares different types of nanocellulose as reinforcing filler

in NR matrix, which will help the researchers select an ideal type for their

specific application and, thus, the proper usage of renewable resources,

leading to sustainability and a circular economy.

Warda Masoom, Ayesha Khan, Amna Sarwar, Sara Musaddiq, Zahoor Hussain Farooqi, Sadia Iqbal

Vol. 18., No.3., Pages 260-281, 2024

DOI: 10.3144/expresspolymlett.2024.19

Vol. 18., No.3., Pages 260-281, 2024

DOI: 10.3144/expresspolymlett.2024.19

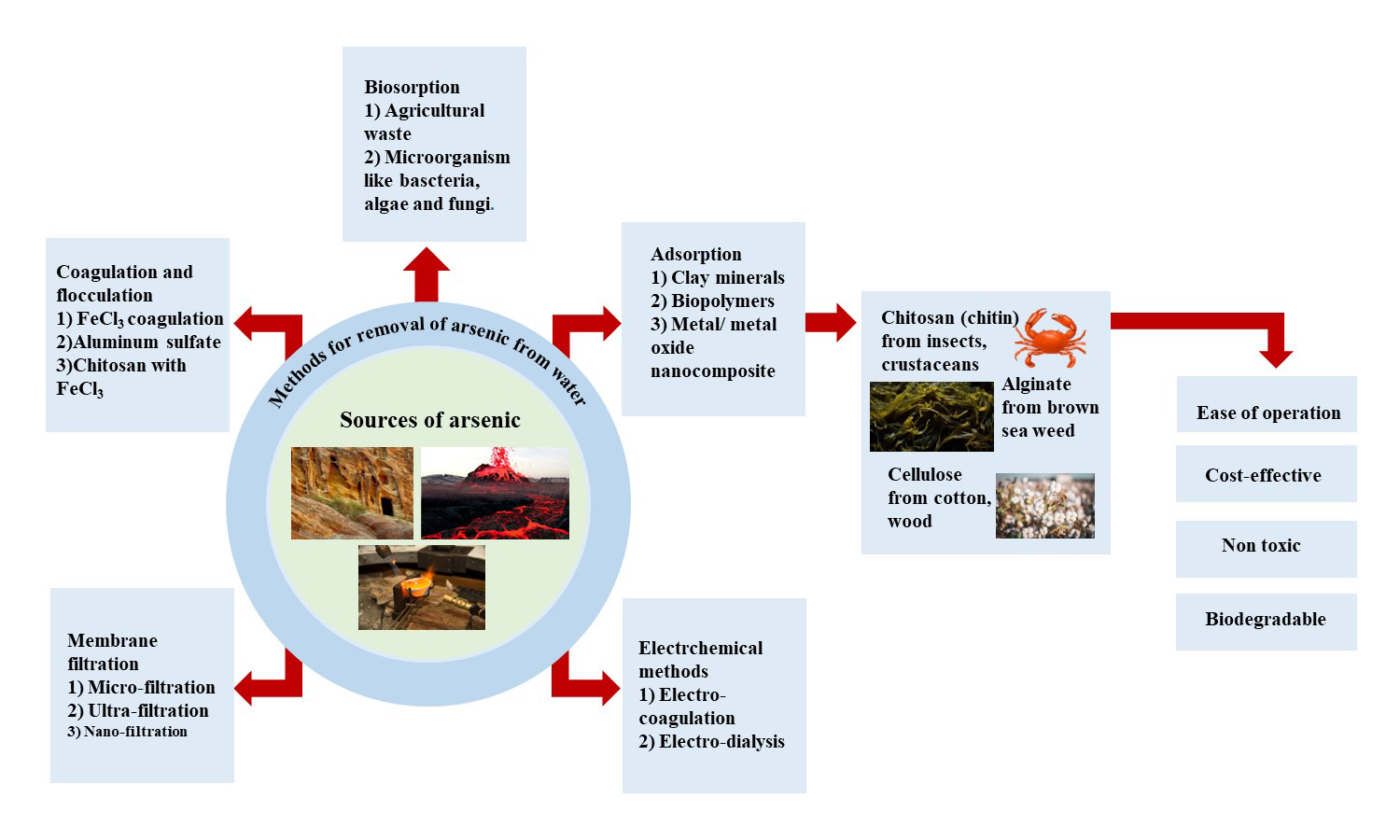

Arsenic, an element found in the Earth’s mantle, can be highly toxic, especially in its As (III) form. It enters our food chain through human activities like melting metals, using arsenic-based pesticides, and natural processes like volcanoes and rock breakdown. Consuming too much arsenic is extremely dangerous, impacting many countries worldwide. To tackle this issue, various methods like filtering, adding chemicals, and using electricity have been developed to clean arsenic-contaminated water. Among these, adsorption is a standout approach due to its simplicity and effectiveness. Biopolymers from living sources offer a natural solution, easily tweaked for arsenic removal. These biopolymers contain functionalities that can strongly latch onto toxic materials, acting like magnets. By customizing them with compounds like titanium dioxide (TiO2), magnetite (Fe3O4), and others, they become even better at capturing arsenic, shaped into tiny particles or beads. This adaptation makes biopolymers a promising choice for cleaning arsenic from water. This review focuses on ways to clean water, specifically exploring how materials like chitosan, alginate, and modified cellulose can be used to remove arsenic by adsorption. It investigates how these materials work under different conditions, highlighting important details. By sharing these insights, this article contributes to the ongoing efforts to ensure cleaner water resources.