A comparison of the mechanical behaviour of natural rubber-based blends using waste rubber particles obtained by cryogrinding and high-shear mixing

Vol. 17., No.11., Pages 1135-1153, 2023

DOI: 10.3144/expresspolymlett.2023.86

DOI: 10.3144/expresspolymlett.2023.86

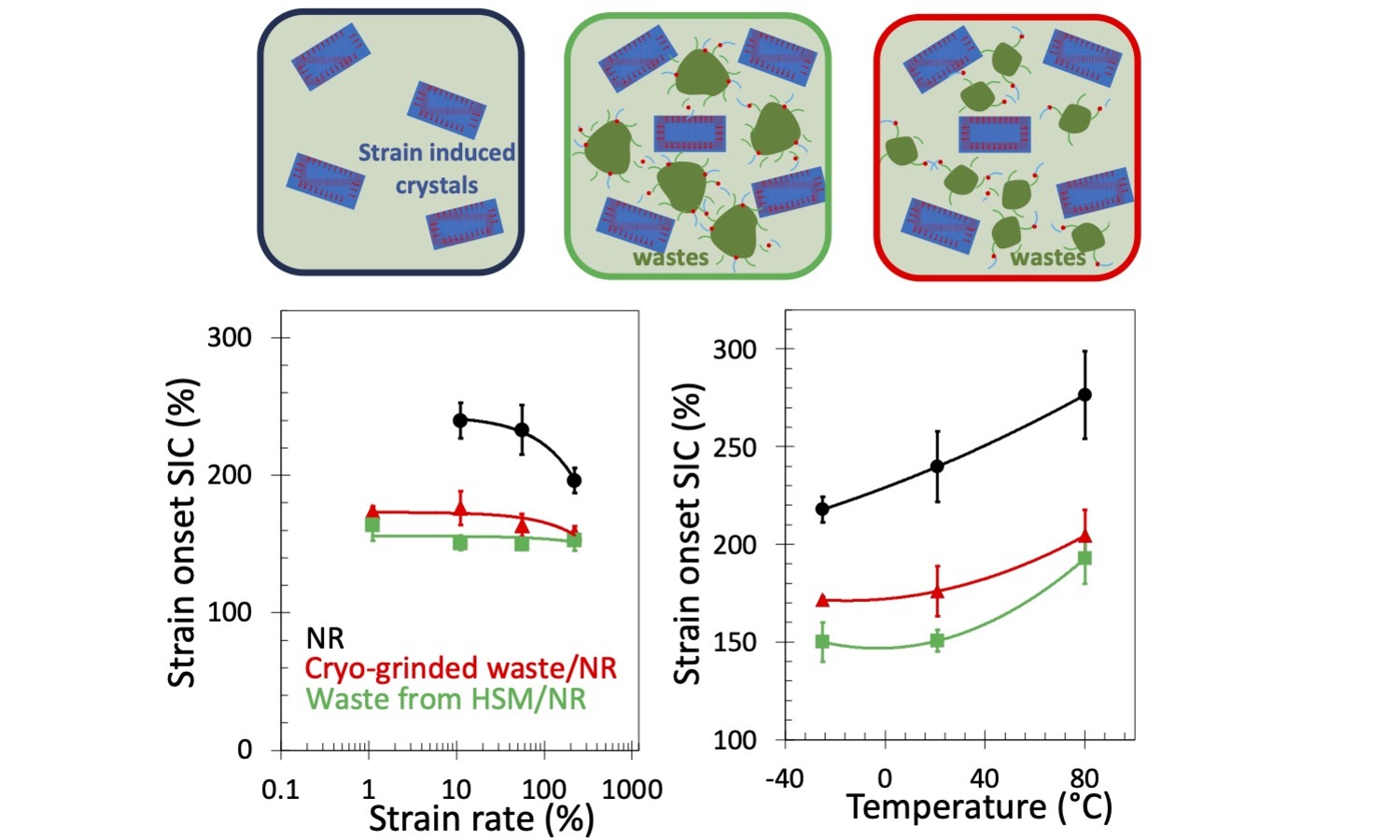

GRAPHICAL ABSTRACT

ABSTRACT

The

influence of the type of mechanical recycling of waste rubber particles on the

tensile properties of waste/natural rubber blends has been investigated. The

wastes originating from ground tyre rubber (GTR) had been treated by two

distinct processes: cryo-grinding and high shear mixing (HSM). For both

processes, the resulting composites show enhanced stiffness and strength for

all strain rates and temperatures tested. This is attributed to both the

reinforcing effect of the waste as well as the nucleation ability of the wastes

on strain induced crystallization (SIC) in the natural rubber (NR) matrix.

Cryo-grinding was shown to provide the finest particle size with an average

diameter of 34 μm, while the HSM process was found to show an elastic modulus

of aggregated GTR powder of 7 MPa at 1 Hz at room temperature. Within these

characteristics, the NR/GTR blends using the HSM process show the best tensile

performance under single loading, with the highest strength and highest ability

to crystallize under strain. Under cyclic loading, NR/GTR blends using

cryo-ground GTR particles show the best performance, which we ascribed to their

ability to better distribute and accommodate the stress from one cycle to another

owing to their finest size. Both explored recycling techniques provide the

natural/waste rubber blends interesting properties such as mechanical

reinforcement and strain-induced crystallization ability under various testing

conditions.

RELATED ARTICLES

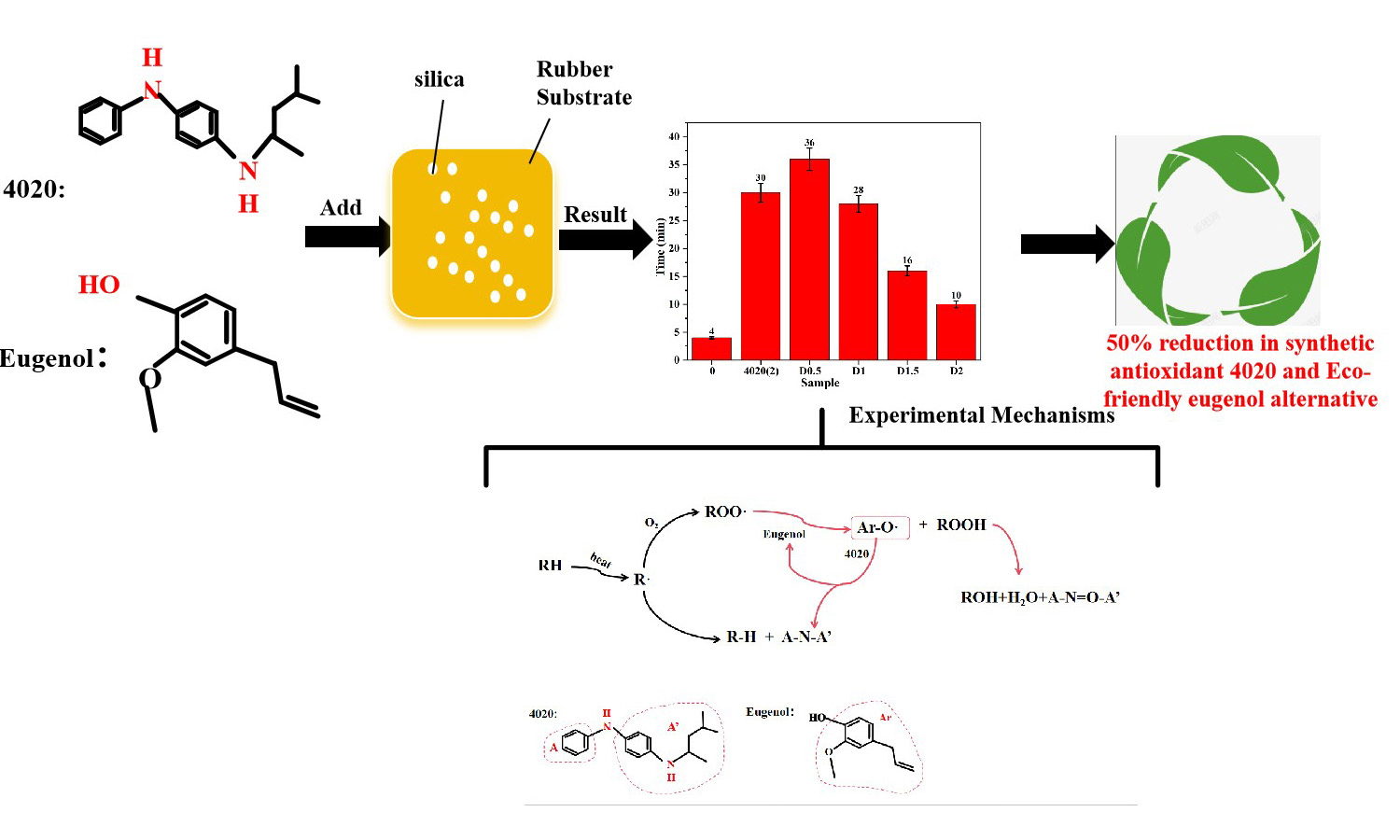

Wenhui Han, Yaqi Ge, Peng Wang, Haojun Zang, Shengqiang Xu, Huiguang Bian, Chuansheng Wang

Vol. 19., No.12., Pages 1274-1285, 2025

DOI: 10.3144/expresspolymlett.2025.94

Vol. 19., No.12., Pages 1274-1285, 2025

DOI: 10.3144/expresspolymlett.2025.94

This study investigates eugenol as an alternative to mitigate environmental pollution and worker hazards associated with antioxidant N-(1,3-dimethyl)butyl-N′-phenyl-p-phenylenediamine (4020) while aligning with trends toward sustainable additives. Silica/natural rubber (NR) composites with varying ratios of eugenol and 4020 were prepared to assess their aging resistance, mechanical properties, and the synergistic antioxidant effects. Thermogravimetric analysis, cross-linking density experiments, thermo-oxidative aging tests, and oxidation induction tests revealed the highest thermo-oxidative aging resistance when 0.5 phr of 4020 was substituted with eugenol. When 1.0 phr of 4020 was replaced by eugenol, the antioxidant properties of the composites matched those containing 2.0 phr of 4020. However, when eugenol exceeded 1 phr, the antioxidant properties gradually decreased. DIN wear tests showed optimal wear resistance when 1 phr of 4020 was replaced with eugenol. These findings suggest that 50% of conventional antioxidants can be substituted with eugenol without compromising material properties. The partial substitution of eugenol in silica/NR composites proves eugenol can act as a sustainable alternative, providing comparable antioxidant capacity while reducing environmental impact.

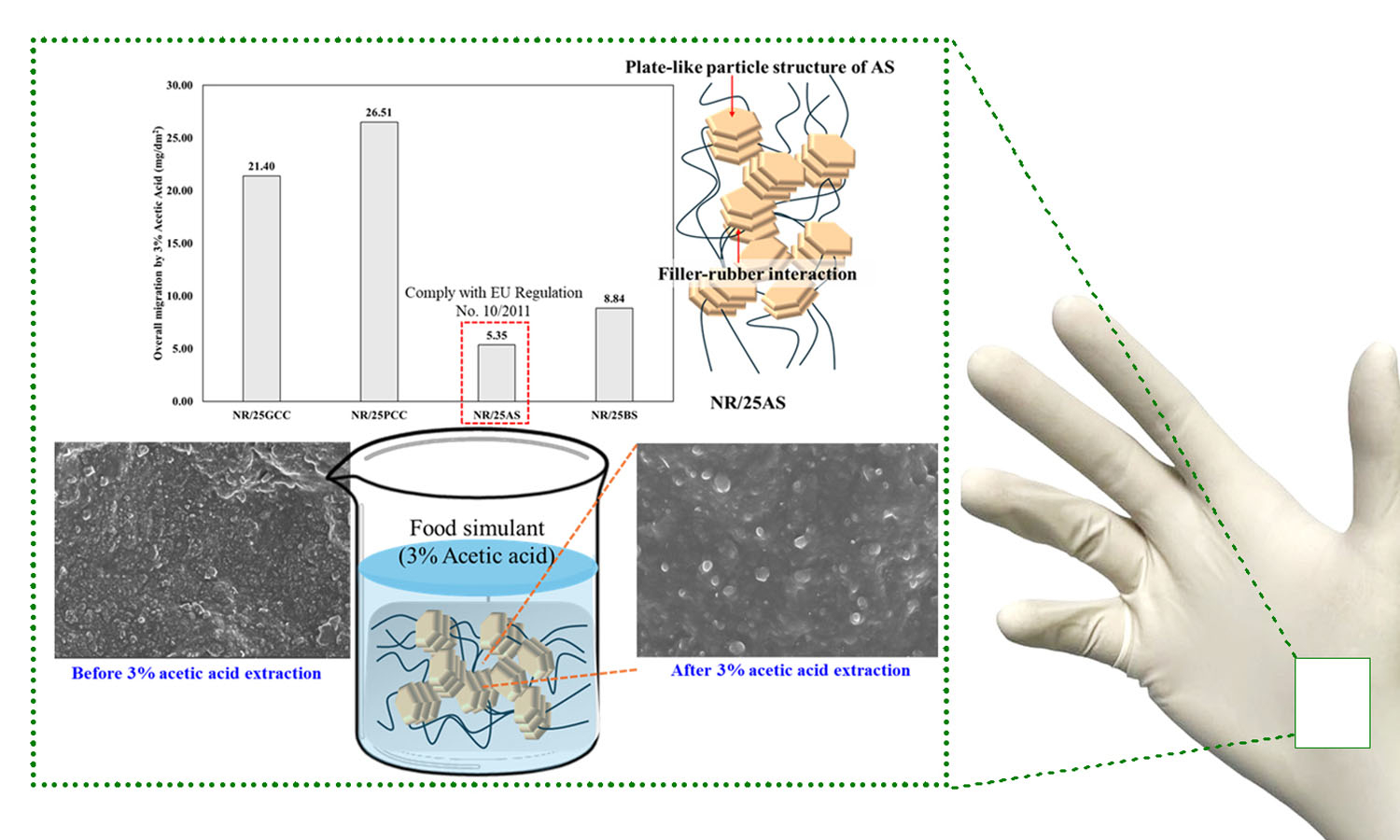

Sirithorn Kaewklum, Parisa Faibunchan, Apinya Krainoi, Banyat Cherdchim, Jutharat Intapun

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Vol. 19., No.9., Pages 929-945, 2025

DOI: 10.3144/expresspolymlett.2025.70

Powder-free natural rubber gloves for chemical migration resistance of food-contact grade are prepared using a variety of fillers, including ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), aluminum silicate (AS), and barium sulfate (BS)-filled natural rubber (NR), respectively. The properties of NR gloves, including mechanical, dynamic mechanical, and thermal properties, were investigated. Furthermore, the overall migration test of NR gloves was conducted according to the regulations for food contact gloves (EU Regulation No. 10/2011), using 3% acetic acid as the simulant. Among the fillers studied, the plate-like particles of AS facilitated the most effective filler-rubber interactions and reinforcement in AS-filled natural rubber (NR/AS). Consequently, the highest crosslink density, force at break, and damping properties of NR gloves were achieved by applying AS in the NR matrix. Moreover, the lowest overall migration level was observed for NR/AS with a value of 5.35 mg/dm2, which complies with EU Regulation (overall migration of food simulants shall not exceed 10 mg/dm2). Therefore, NR gloves filled with AS are suitable for food-contacting NR gloves.

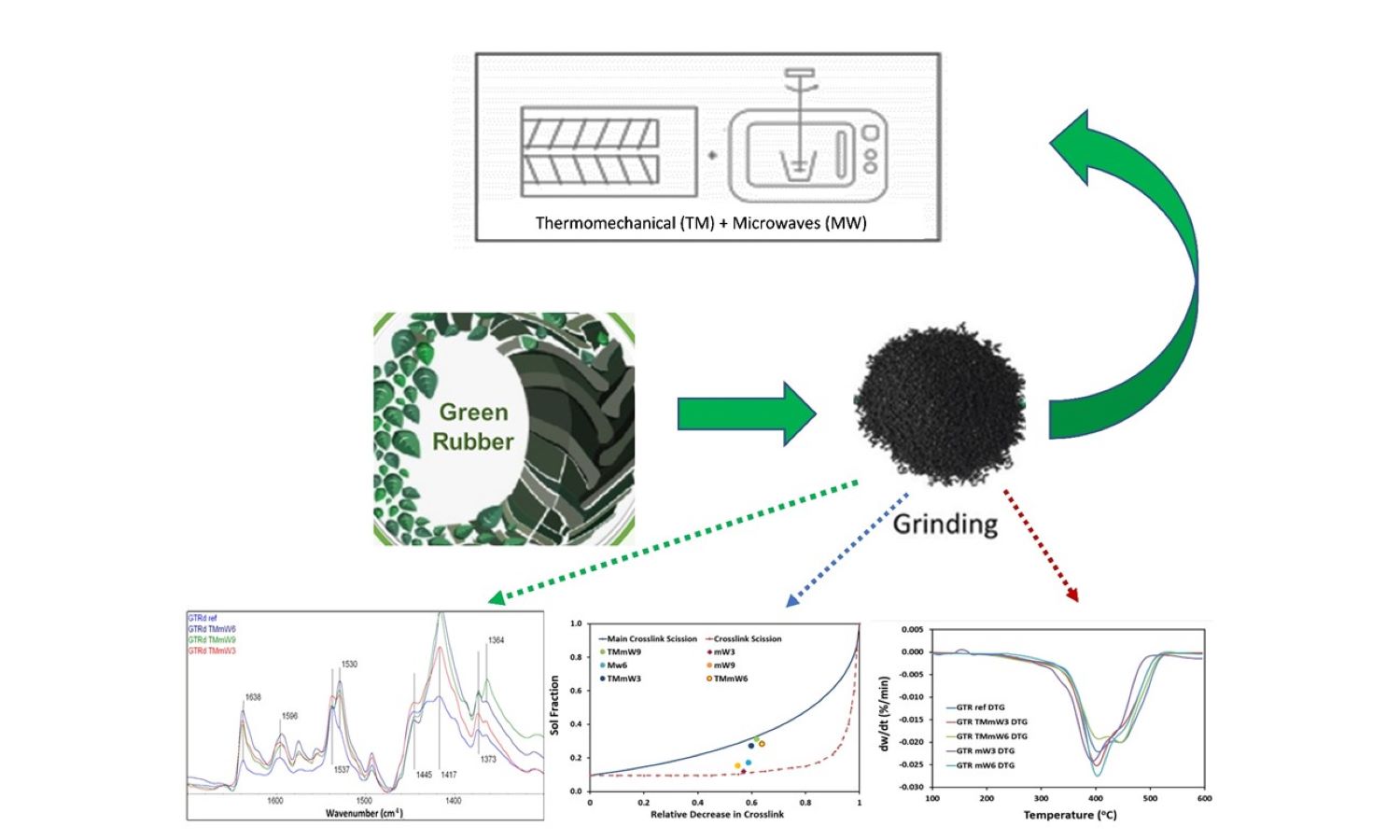

Xavier Colom, Mohammad Reza Saeb, Javier Cañavate

Vol. 18., No.9., Pages 950-961, 2024

DOI: 10.3144/expresspolymlett.2024.72

Vol. 18., No.9., Pages 950-961, 2024

DOI: 10.3144/expresspolymlett.2024.72

Analyzing rubber waste is crucial for value-added recycling, but the multitude of ingredients in vulcanized networks makes it challenging to characterize cross-linked rubbers. A combination of analytical techniques is usually required. In this study, two complementary characterization techniques, based on Fourier transform infrared (FTIR) spectroscopy and derivative thermogravimetric analysis (DTGA) were applied to analyze the structural, physical, and thermal behavior of ground tire rubber (GTR) samples devulcanized by two different processes. A set of samples was devulcanized by only microwaves (MW) while another set was treated with a combination of a thermochemomechanical (TM) process, which included the use of a devulcanization aid such as benzoyl peroxide, and microwaves. The combined technique proved to be more efficient in terms of the degree of devulcanization, significantly reducing the cross-linking density. However, the combined thermochemomechanical and microwave (TM/MW) devulcanization process resulted in greater degradation of the main rubber chains in the cross-linked network compared to the process using only microwaves.