Microstructural phenomena in ground tire rubber (GTR) devulcanized via combined thermochemomechanical and microwave processes monitored by FTIR and DTGA assisted by other techniques

Vol. 18., No.9., Pages 950-961, 2024

DOI: 10.3144/expresspolymlett.2024.72

DOI: 10.3144/expresspolymlett.2024.72

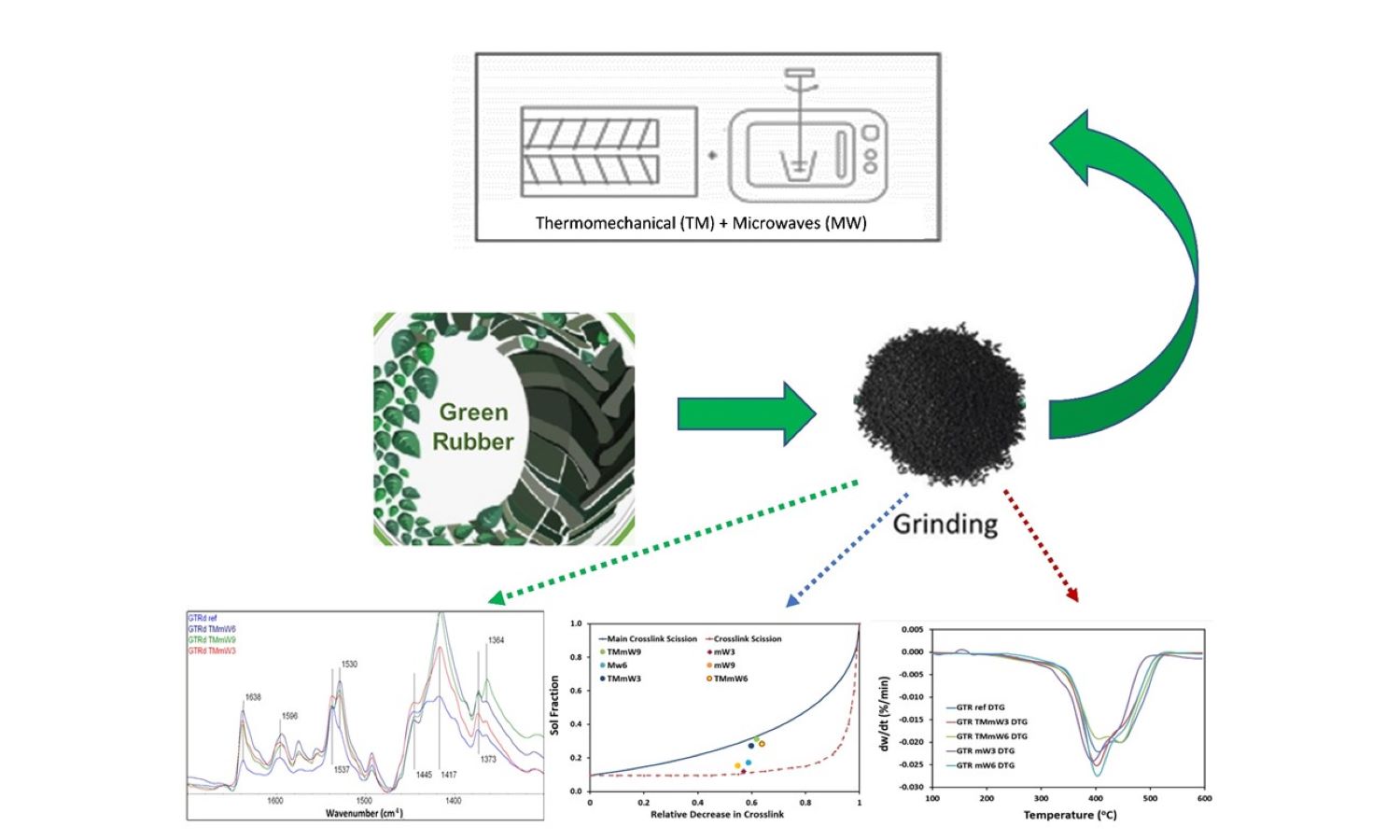

GRAPHICAL ABSTRACT

ABSTRACT

Analyzing rubber waste is crucial for value-added recycling, but the multitude of ingredients in vulcanized networks makes it challenging to characterize cross-linked rubbers. A combination of analytical techniques is usually required. In this study, two complementary characterization techniques, based on Fourier transform infrared (FTIR) spectroscopy and derivative thermogravimetric analysis (DTGA) were applied to analyze the structural, physical, and thermal behavior of ground tire rubber (GTR) samples devulcanized by two different processes. A set of samples was devulcanized by only microwaves (MW) while another set was treated with a combination of a thermochemomechanical (TM) process, which included the use of a devulcanization aid such as benzoyl peroxide, and microwaves. The combined technique proved to be more efficient in terms of the degree of devulcanization, significantly reducing the cross-linking density. However, the combined thermochemomechanical and microwave (TM/MW) devulcanization process resulted in greater degradation of the main rubber chains in the cross-linked network compared to the process using only microwaves.

RELATED ARTICLES

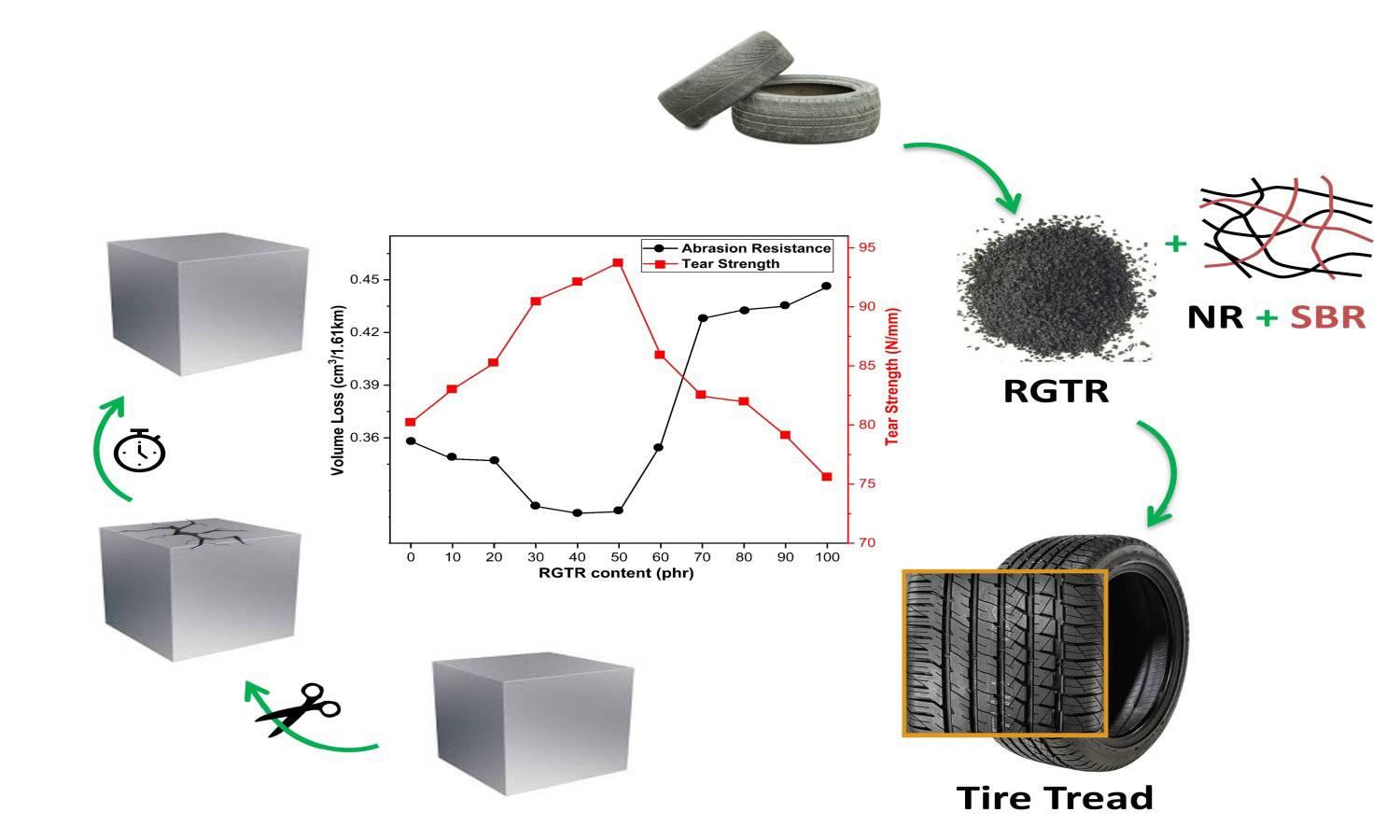

Reinforcing effect of thermo-oxidative reclaimed rubber on NR/SBR blends for tire tread applications

Yunhui Xu, Zaheer ul Haq, Junrong Li, Hui Tu, Zaixue Wang, Houluo Cong

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

This study explores the application of thermo-oxidative reclaimed ground tire rubber (RGTR) in natural rubber (NR)/styrene butadiene rubber (SBR) composite, focusing on its impact on morphology, mechanical properties, rheological behavior, vulcanization characteristics, aging resistance, tear strength and abrasion resistance. The findings revealed that RGTR enhances the tear strength and abrasion resistance of NR/SBR composites while maintaining comparable tensile strength, elongation at break, and modulus. The incorporation of RGTR reduced Mooney viscosity of the NR/SBR composites and improved flowability. It also shortened the vulcanization time and enhanced vulcanization efficiency. The NR/SBR composites with RGTR loadings below 60 phr exhibited optimal performance, achieved a maximum tear strength of 93.77 N/mm and improved abrasion resistance. However, higher RGTR content led to increased agglomeration, as evidenced by scanning electron microscopy (SEM), which showed finer dispersion at lower RGTR contents and larger aggregates at higher loadings. These findings demonstrate the potential of RGTR as a sustainable additive for enhancing specific properties in NR/SBR composites, contributing to both performance optimization and waste tire management.

Rattanawadee Ninjan, Bencha Thongnuanchan, Phakawat Tongnuanchan, Subhan Salaeh, Jutharat Intapun, Abdulhakim Masa, Natinee Lopattananon

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

Vol. 20., No.1., Pages 18-35, 2026

DOI: 10.3144/expresspolymlett.2026.3

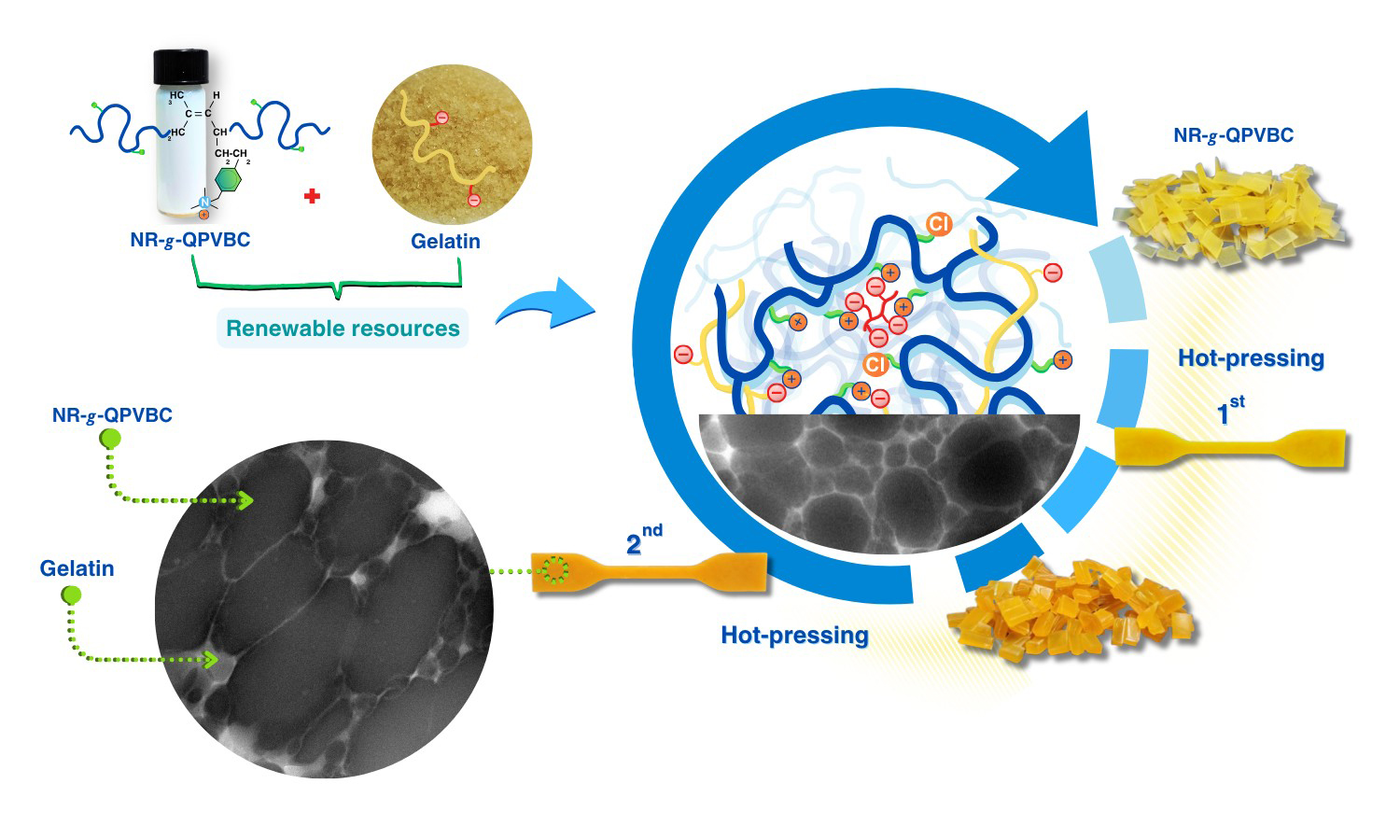

The present study has proposed a straightforward method to improve the reprocessability of modified natural rubber (NR) by blending it with gelatin (GT). The reprocessable characteristics of these blends were evaluated based on their remolding capabilities and mechanical recovery performance. In this method, poly(vinylbenzyl chloride) (PVBC) was first grafted onto NR chains to create graft copolymers known as NR-g-PVBC. The benzyl chloride groups in the graft copolymers were subsequently converted into quaternary ammonium groups, referred to as NR-g-QPVBC. This modification enabled ionic crosslinking when NR-g-QPVBC reacted with ethylenediamine tetraacetic acid. Blends were created by incorporating GT powder into the NR-g-QPVBC latex. The optimal loading level of GT was determined to be 30 wt%, as the resulting film exhibited the highest recovery of tensile properties. Initially, the film's tensile strength was measured at 15 MPa. After being remolded at 160 °C, the tensile strength decreased to 9.3 MPa, resulting in a recovery rate of 60.7% and withstanding a tensile strain of 144%. Although the NR-g-QPVBC/GT films could be remolded, their tensile properties declined with increasing remolding cycles. Therefore, this work demonstrated a practical method for producing NR-based films that could be reshaped through hot-pressing after being formed into products, increasing their reusability.

Azizon Kaesaman, Tassaneeya Khunrang, Charoen Nakason

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

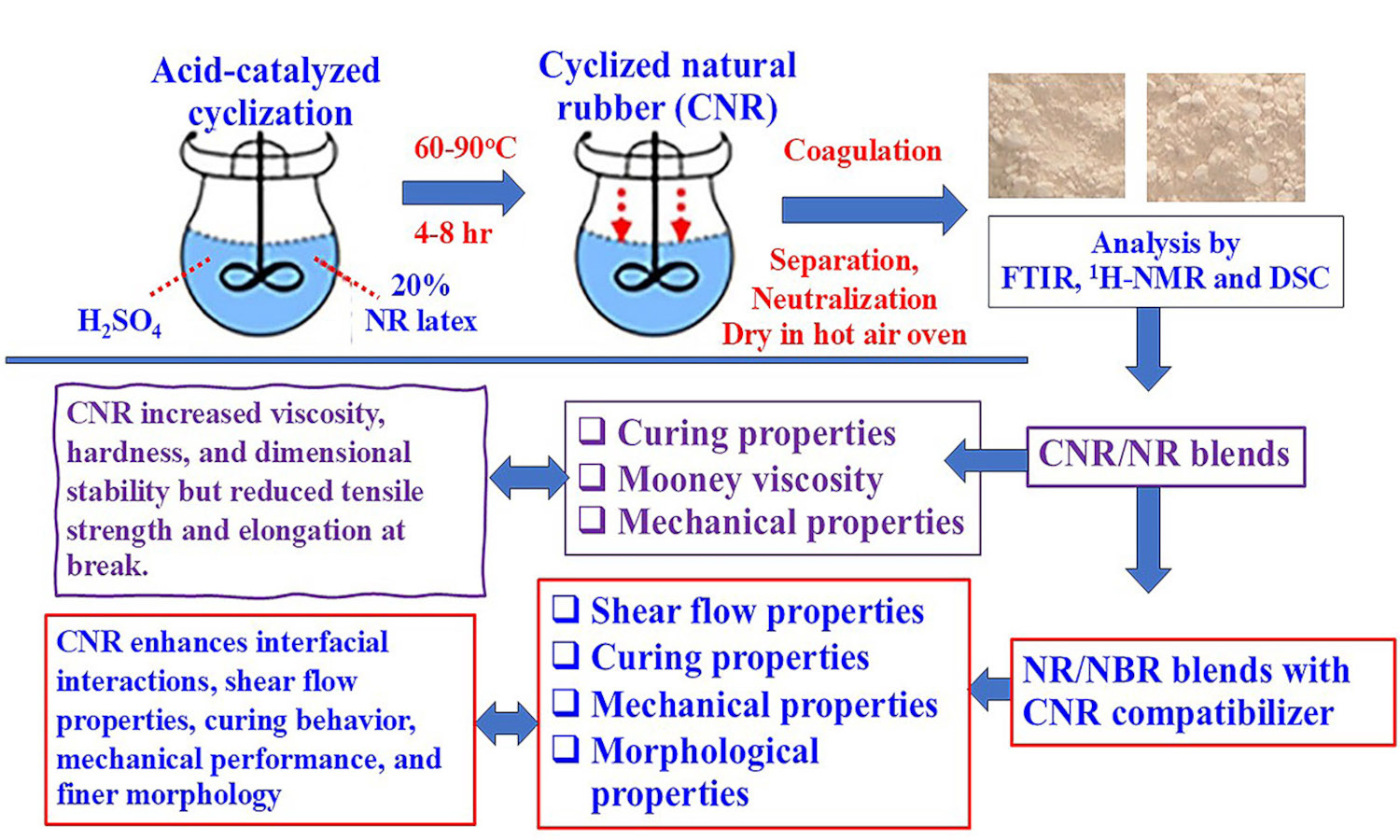

Cyclized natural rubber (CNR) was synthesized through the acid-catalyzed reaction of natural rubber (NR) latex using sulfuric acid as a catalyst and stabilized with a non-ionic surfactant. Cyclization was evaluated by iodine numbers under varying reaction times, temperatures, and NR-to-acid ratios. Fourier transform infrared spectroscopy (FTIR) and proton nuclear magnetic resonance spectroscopy (1H-NMR) confirmed the formation of cyclic structures in CNR molecules. Differential scanning calorimetry (DSC) showed that the glass transition temperature (Tg) of CNR increased with cyclization, indicating greater rigidity and less chain flexibility. CNR was then blended with NR and used as a compatibilizer in NR/acrylonitrile butadiene rubber (NBR)blends. It increased blend viscosity, hardness, and dimensional stability but reduced tensile strength and elongation due to its rigid cyclic domains. In NR/NBR blends, CNR outperformed a commercial homogenizer in enhancing interfacial interactions, leading to superior shear flow properties, curing behavior, and mechanical performance. This is attributed to the polar groups in CNR, which enhance intermolecular interactions and phase compatibility, resulting in finer phase morphology. This study highlights the potential of CNR as a versatile material for enhancing the performance of rubber compounds, with promising applications in advanced industrial formulations.

Liu Yang, Xuan Zhao, Sun Xinyu, Shuai Yuan, Lei Zhu

Vol. 19., No.8., Pages 783-795, 2025

DOI: 10.3144/expresspolymlett.2025.60

Vol. 19., No.8., Pages 783-795, 2025

DOI: 10.3144/expresspolymlett.2025.60

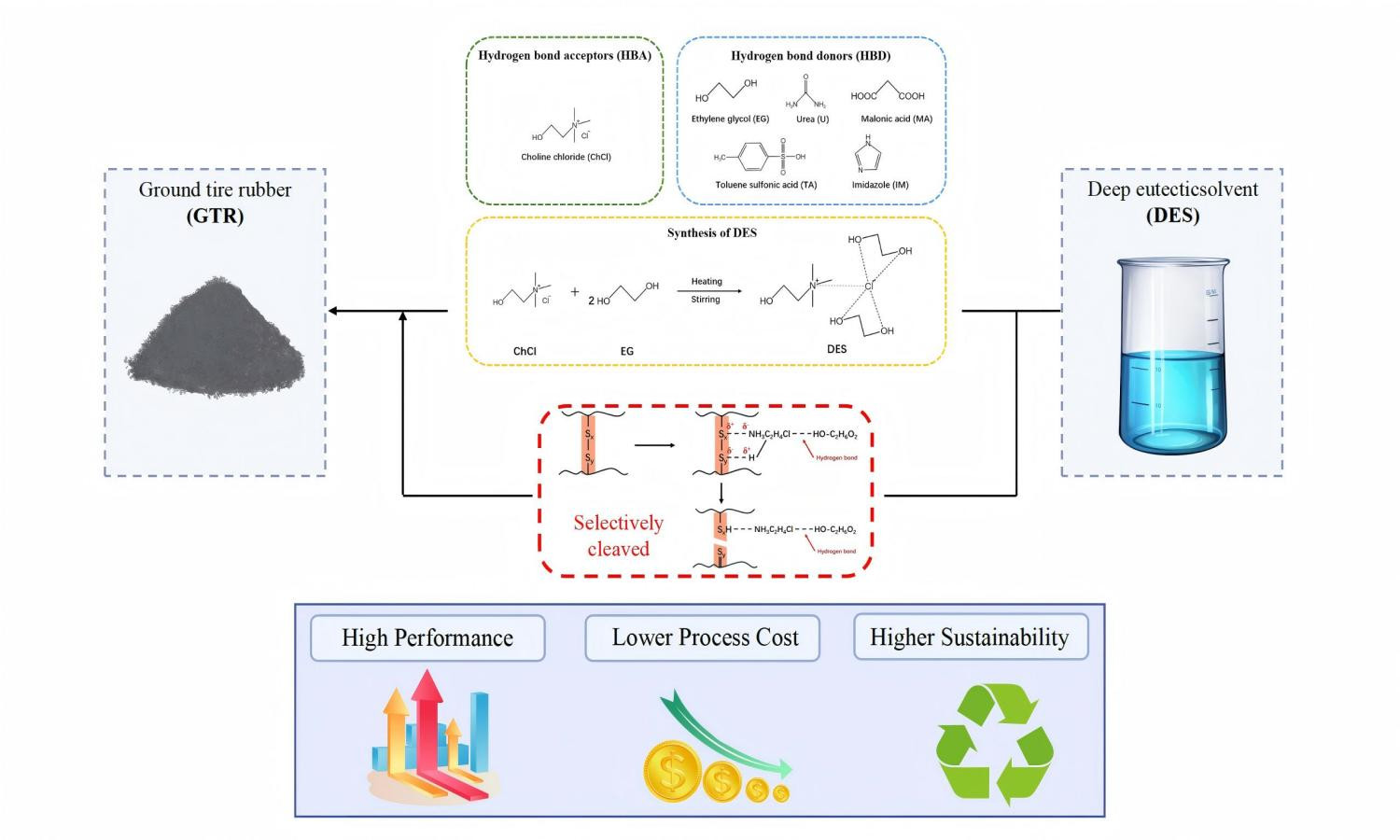

Waste tire rubber poses significant environmental challenges due to its non-biodegradability and complex crosslinkedvstructure. In this sense, this study aims to examine the utilization of deep eutectic solvents (DESs) in the desulfurizationvprocess of ground tire rubber (GTR). A range of hydrogen bond donors (HBDs), including ethylene glycol, malonic acid,vimidazole, toluene sulfonic acid, and urea, were combined with choline chloride, which serves as a hydrogen bond acceptorv(HBA), to synthesize deep eutectic solvents. Subsequently, these DESs are used in the modification of rubber devulcanizationvprocesses. Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and Horikx analysis werevused to confirm the occurrence of devulcanization. The studies confirmed that the devulcanization process was selective invnature, effectively reducing random chain scission while maintaining the integrity of the polymer. Furthermore, the vulcanizatesvobtained post-treatment demonstrated enhanced properties, including increased tensile strength, modulus, tear strength, hardness, and durability, with ethylene glycol-based DES (DES-E) exhibiting the most pronounced enhancements.

Agata Rodak, Józef Haponiuk, Shifeng Wang, Krzysztof Formela

Vol. 18., No.12., Pages 1191-1208, 2024

DOI: 10.3144/expresspolymlett.2024.91

Vol. 18., No.12., Pages 1191-1208, 2024

DOI: 10.3144/expresspolymlett.2024.91

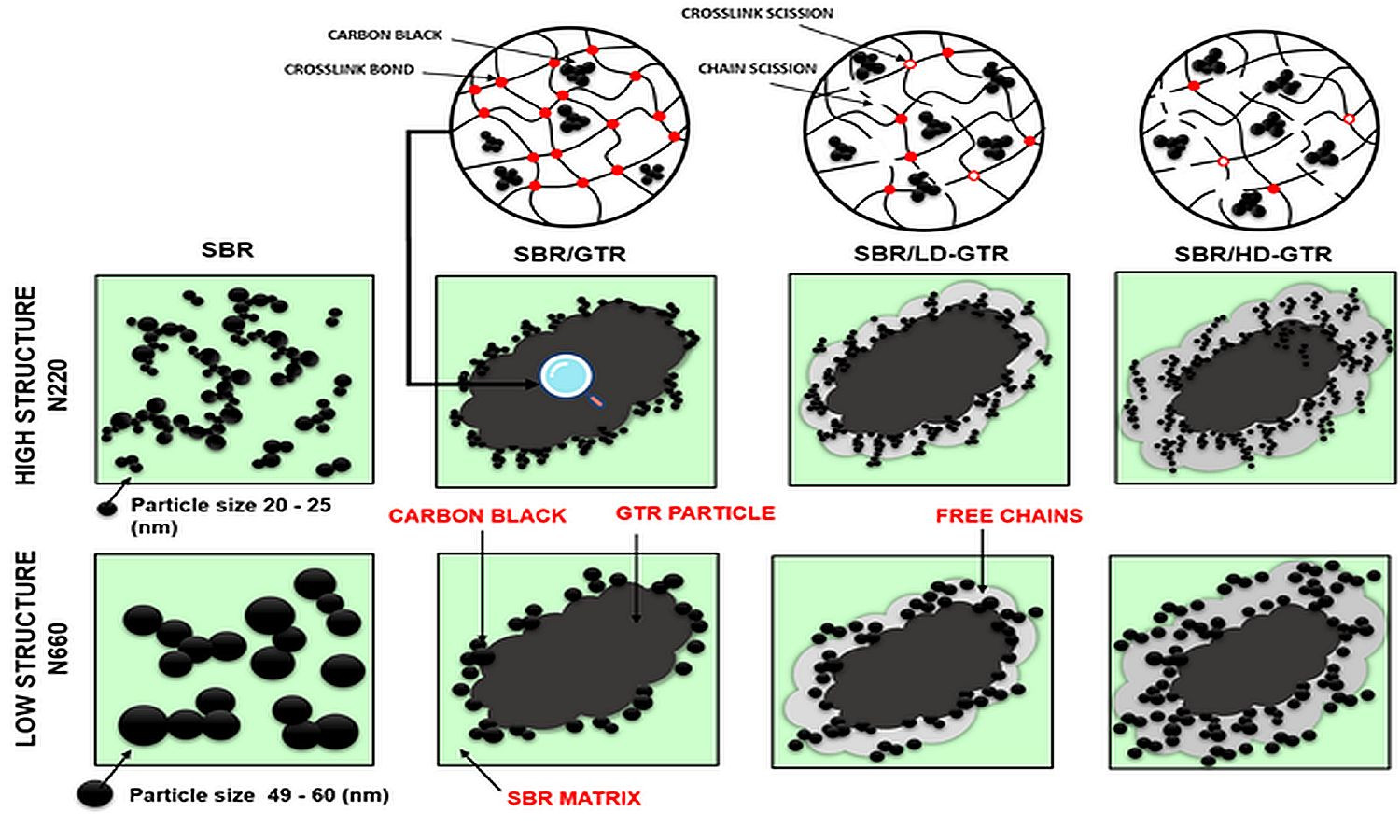

Carbon black migration between ground tire rubber (GTR) and rubber matrix is essential in developing high-performance rubber/GTR composites. In this work, carbon black N220 (surface area: 107.1 m2/g, particle size: 20–25 nm) and N660 (surface area: 33.1 m2/g, particle size: 49–60 nm) were used as the reinforcement fillers for styrene-butadiene rubber (SBR) blended with reclaimed GTR. The combined effects of GTR devulcanization level and carbon black grade on the properties of SBR/GTR composites were investigated considering curing characteristics, thermal stability, physico-mechanical properties, dynamic mechanical properties, swelling behavior, and morphology. The results showed that, regardless of GTR devulcanization level and carbon black grade, application of GTR resulted in deterioration of mechanical properties compared to a reference sample without GTR. It was observed the reinforcement effect of carbon black in SBR/GTR composites was more visible with higher devulcanization level of GTR and lower particle sizes of carbon black fillers. SBR/GTR composites reinforced with carbon black N220 were characterized by tensile strength in the range of 15.3–16.3 MPa and abrasion resistance in the range of 120–123 mm3, which justify their potential application in the manufacturing of technical rubber goods or footwear.