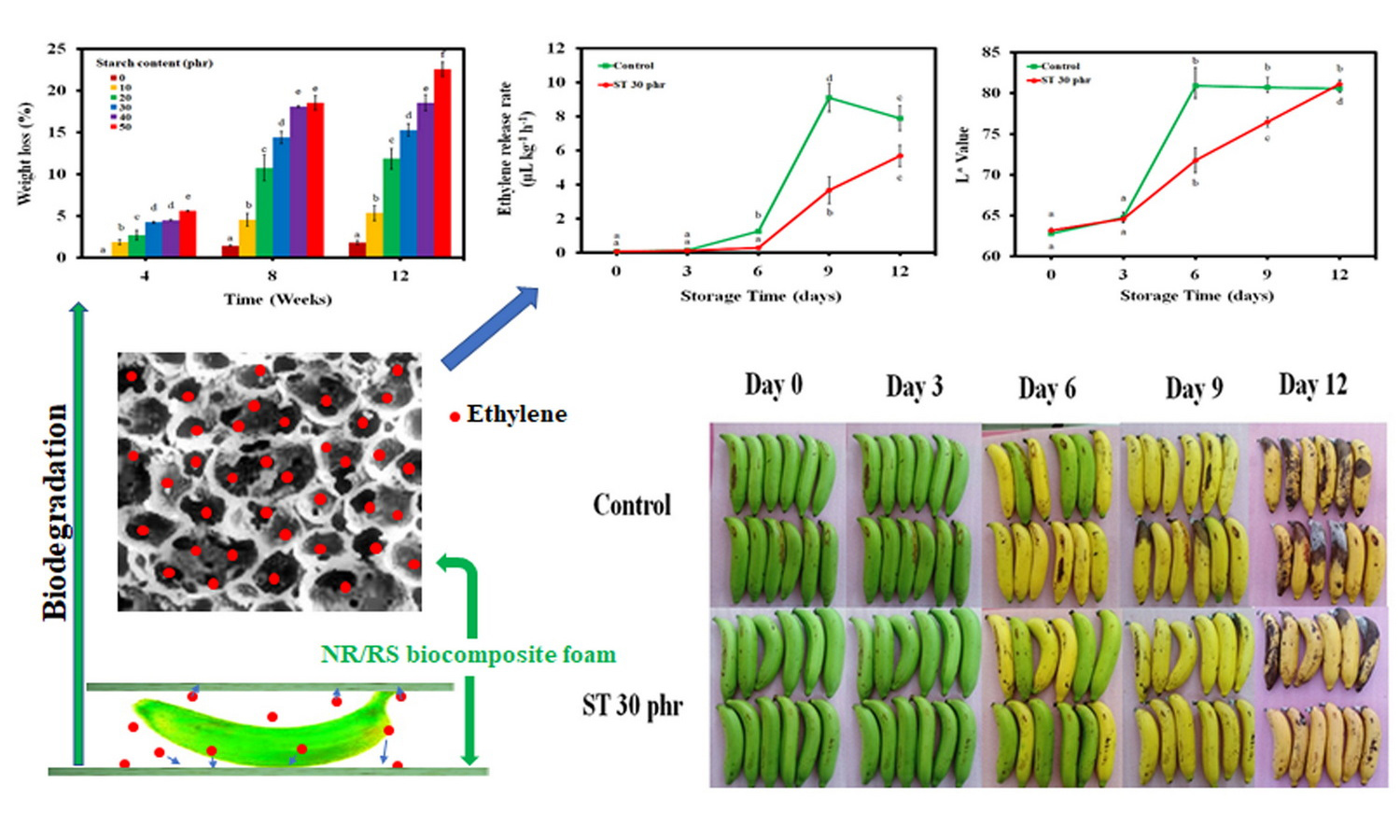

Eco-friendly biocomposite foam from natural rubber latex and rice starch for sustainable packaging applications

Vol. 18., No.1., Pages 27-40, 2024

DOI: 10.3144/expresspolymlett.2024.3

DOI: 10.3144/expresspolymlett.2024.3

GRAPHICAL ABSTRACT

ABSTRACT

An environmental pollution problem is caused in part by packaging materials made from non-biodegradable synthetic polymers derived from petroleum. In this study, eco-friendly biofoams derived from natural rubber (NR) latex and rice starch (RS) were manufactured on a laboratory scale using the Dunlop process. Rice starch content was varied from 0 to 50 phr. The morphological, thermal, physical, mechanical, and biodegradability properties of the NR/RS biocomposite foams were characterized. Scanning electron microscopy (SEM) was used to assess the morphology of the foam cells. Dynamic mechanical thermal analysis (DMTA) and Thermogravimetric analysis (TGA) were used to investigate the thermal characteristics. When RS was present, it was discovered that the biocomposite foams had decreased thermal stability and enhanced biodegradability. Introducing RS into the NR/RS biocomposite foams also decreased tensile strength, elongation at break, and rebound resilience but increased the 100% modulus, hardness, compression force deflection (CFD), and compression set. The NR/RS biocomposite foams better preserved the banana fruit than the absence of foam, with lower ethylene accumulation, lower total soluble solids (TSS), higher pulp firmness, and good color preservation. This demonstrated that these NR/RS biocomposite foams helped to preserve banana fruit quality during storage and could be used in sustainable packaging applications.

RELATED ARTICLES

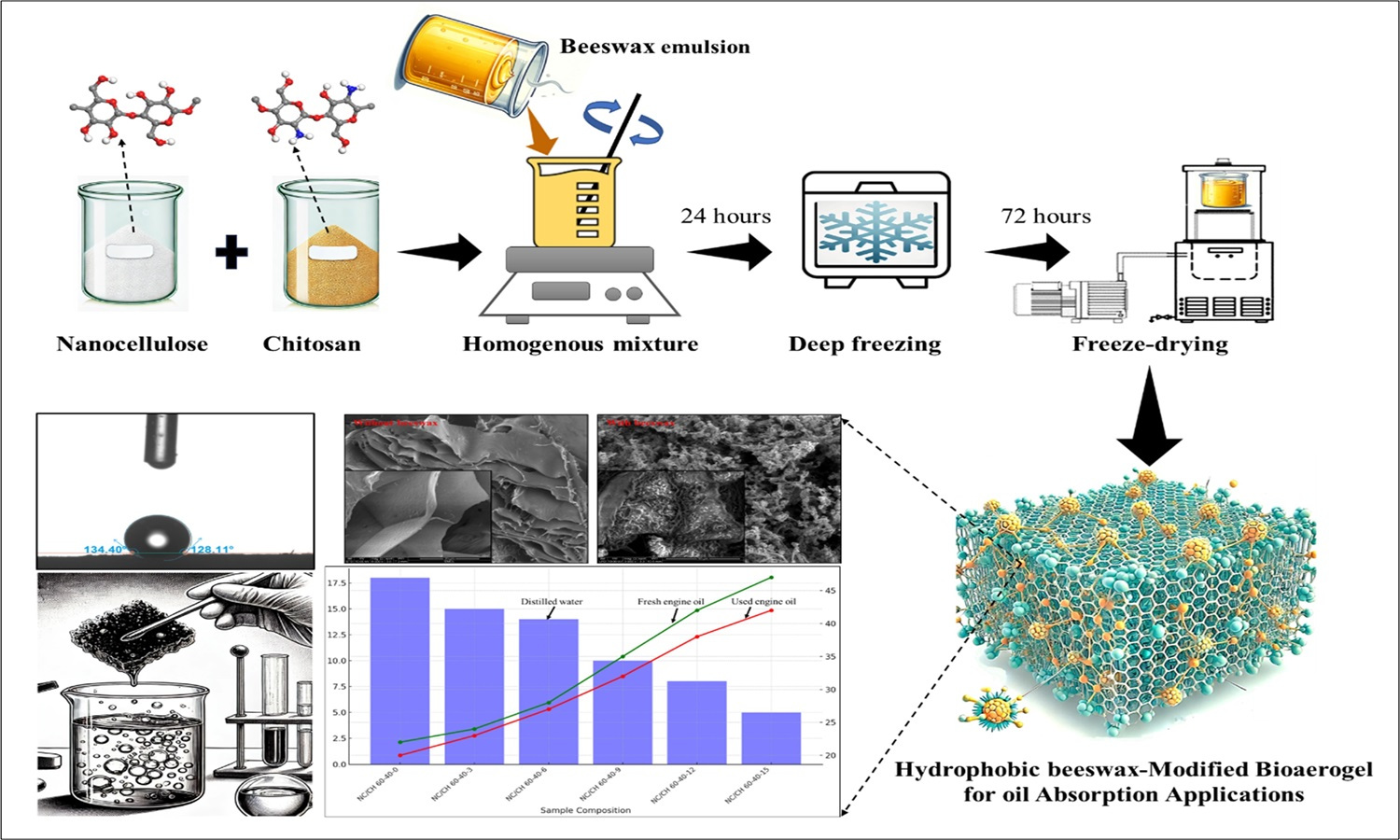

Waleed Y. Rizg, Yonss Mbrook Albadn, Abdul Khalil H.P.S., Majed A Alghamdi, Osama A. Madkhali, Mohammed Baradwan, Fayroz Medhat Shazly, Marwan Marwan, Esam Bashir Yahya

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

This study presents for the first time a sustainable approach to hydrophobic modification of nanocellulose/chitosan bioaerogels using beeswax emulsion. The incorporation of beeswax into the aerogel matrix resulted in increasing the density from 35.1 to 298 mg/cm3, while the porosity decreased from 96.4 to 62%. Fourier transform infrared spectroscopy (FT-IR) analysis confirmed the successful integration of beeswax into the nanocellulose/chitosan matrix, with distinct peaks corresponding to the characteristic functional groups of beeswax, such as C–H stretching vibrations, further validating the hydro - phobic modification. The mechanical properties showed increased hardness, from 0.24 to 0.95 N/mm2, indicating that higher beeswax content enhanced the rigidity of the aerogels. Contact angle measurements confirmed a dramatic improvement in hydrophobicity, with angles increasing from 47.68 to 134.40 and 128.11° for NC/CH 60-40-15. Water absorption capacity decreased from 17.5 g/g in the control sample to 8 g/g at the highest beeswax concentration, while oil absorption increased significantly, with fresh engine oil absorption rising from 3 to 45 g/g and used engine oil absorption from 2.5 to 40 g/g respectively. These results confirm the successful green modification of bioaerogels using beeswax, providing a sustainable and eco-friendly approach that enhances hydrophobicity, mechanical strength, and selective absorption properties.

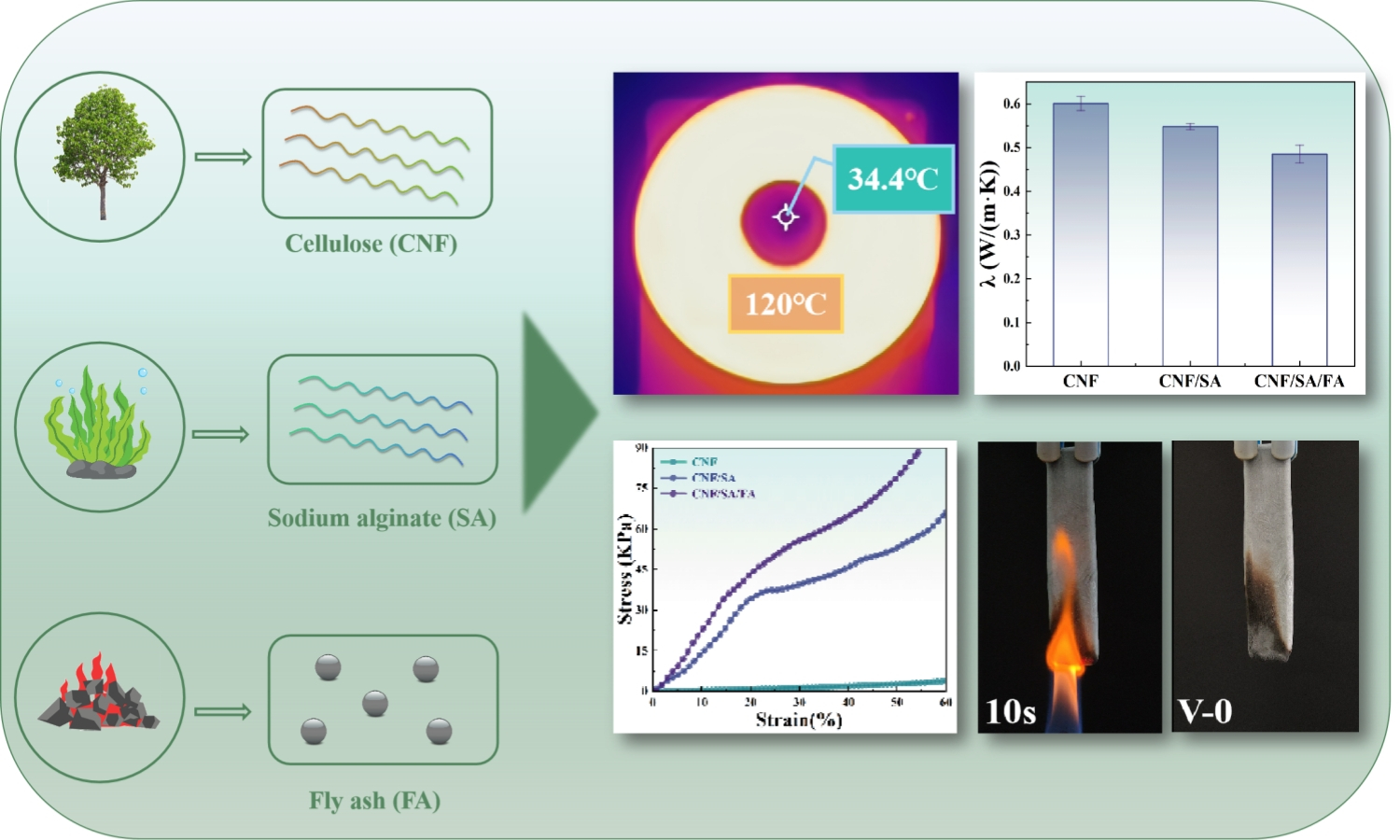

Ju Li, Lize Yang, Shuo Chen, Guotao Sun

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

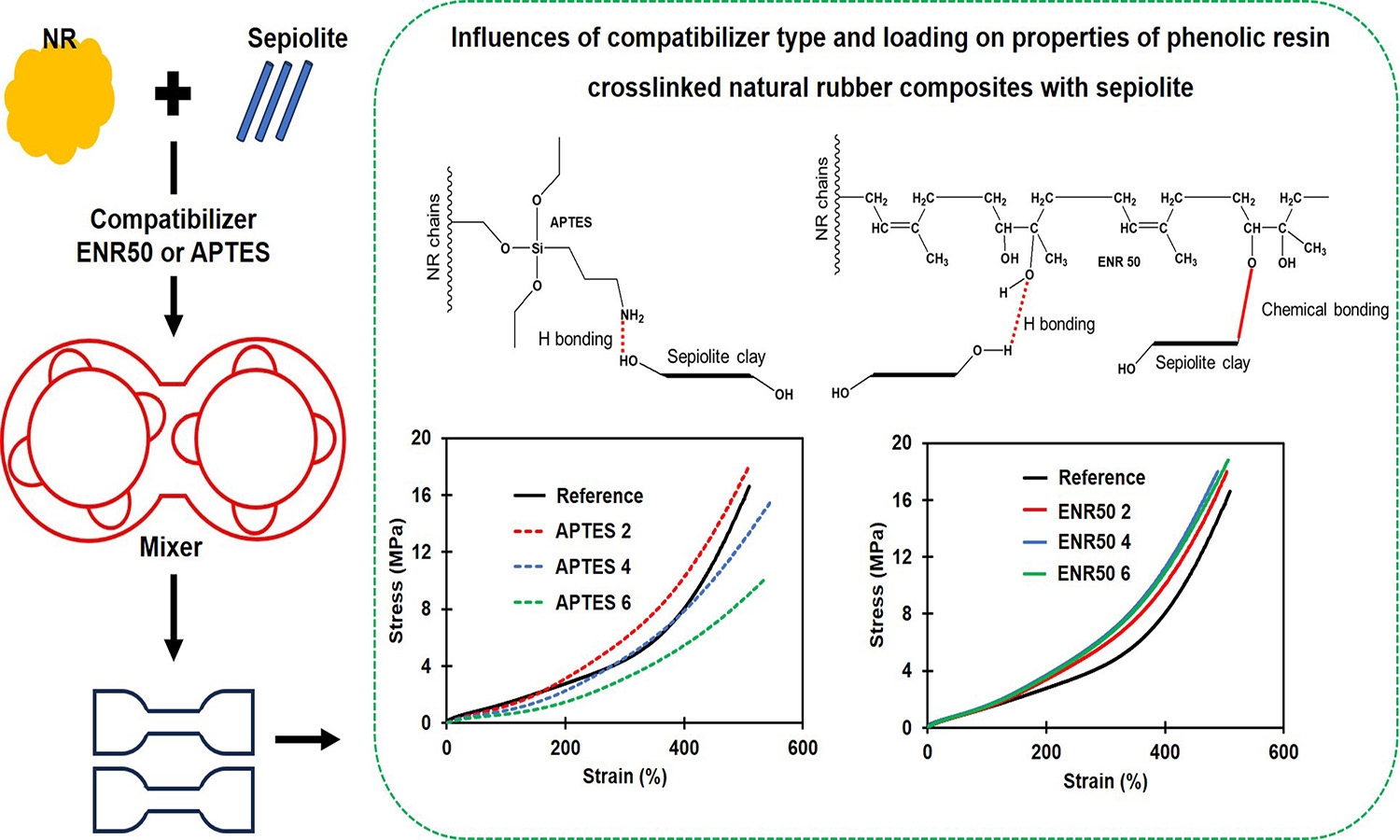

Nabil Hayeemasae, Siriwat Soontaranon, Abdulhakim Masa

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

Natural rubber (NR) composites reinforced with sepiolite and crosslinked with phenolic resin were prepared. Effects of compatibilizer types and contents, namely 3-aminopropyl triethoxysilane (APTES) or epoxidized NR (ENR50), on curing, tensile, strain-induced crystallization, and stress relaxation were investigated. Compared to APTES, ENR50 provided a greater compatibilizing effect in the NR composites. The ENR50 introduced strong physical and chemical interactions between sepiolite and NR, while only physical interaction was present in the APTES compatibilized composites. Stronger interaction between rubber and sepiolite improved filler dispersion, swelling resistance, and tensile strength; and delayed stress relaxation of the composite. Increased addition of ENR50 improved the modulus and tensile strength, and the greatest tensile strength was achieved at 2 phr ENR50 with a 15% improvement over composite without compatibilizer. In the case of APTES, 2 phr level enhanced tensile strength, but a further increase in APTES content degraded tensile, swelling resistance, and stress relaxation responses, due to its plasticizing effect. Moreover, ENR50 enhanced the strain-induced crystallization and delayed stress relaxation of the composites more than APTES. Weaker interaction between rubber and filler in APTES filled composites was due to having only hydrogen bonds formed between rubber and filler, in addition to crosslinks.

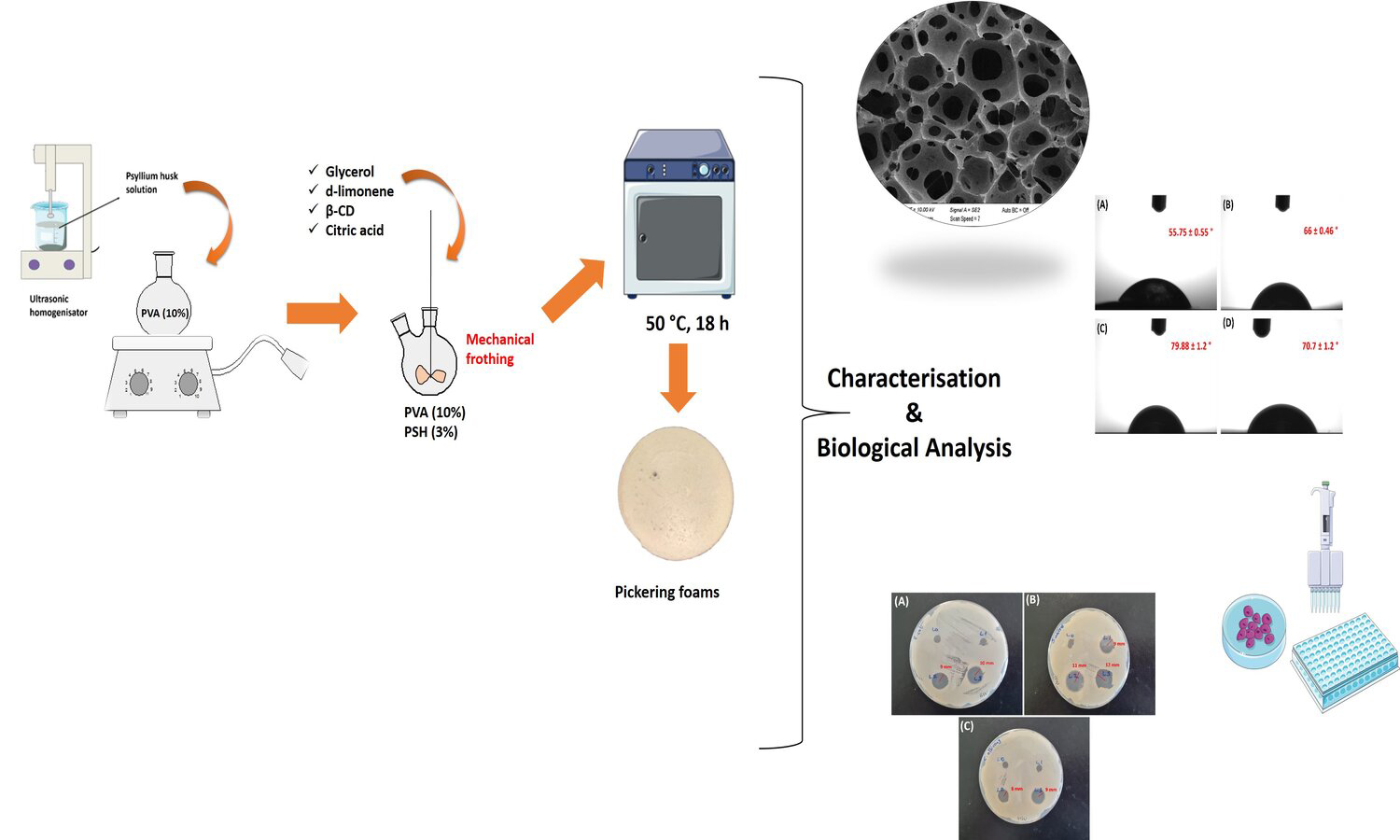

Fatma Nur Parın, Hatice Dinç, Uğur Parın, Elife Kıldalı, Gökçe Taner

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

In this study, Pickering foamed emulsions have been prepared using β-cyclodextrin (β-CD), and d-limonene as a surfactant and an oil phase, respectively. The incorporation of β-CD/d-limonene inclusion complexes (ICs) in specific proportions (1:1, 1:3, and 1:5) to water phase, which is a polymer matrix composed of a mixture of polyvinyl alcohol (PVA) and psyllium husk (PSH) by mechanical frothing at high speed, and air bubbles have been formed in oil in water (o/w) emulsions. Ecofriendly bio-based foams have been developed in this method. Scanning Electron Microscope (SEM) analysis showed PVA/PSH Pickering foams usually open porous morphologies and the addition of d-limonene increases the amount of porosity from 43 to 49%. Although the resulting foams indicated similar thermal degradation profile, the presence of d-limonene in foams increased thermal stability. The surfaces of foams have a hydrophilic property with contact angles values lower than 80°. The tensile strength of foams decreased from 170 to 100 kPa due to the increased porosity. All foams indicated antibacterial activity to Staphylococcus aureus (S. aureus) with 9–12 mm zone inhibition. The incorporation of d-limonene into foams surprisingly decreased the cell viability. In brief, our findings show that the Pickering foams can be beneficial for wound healing applications.

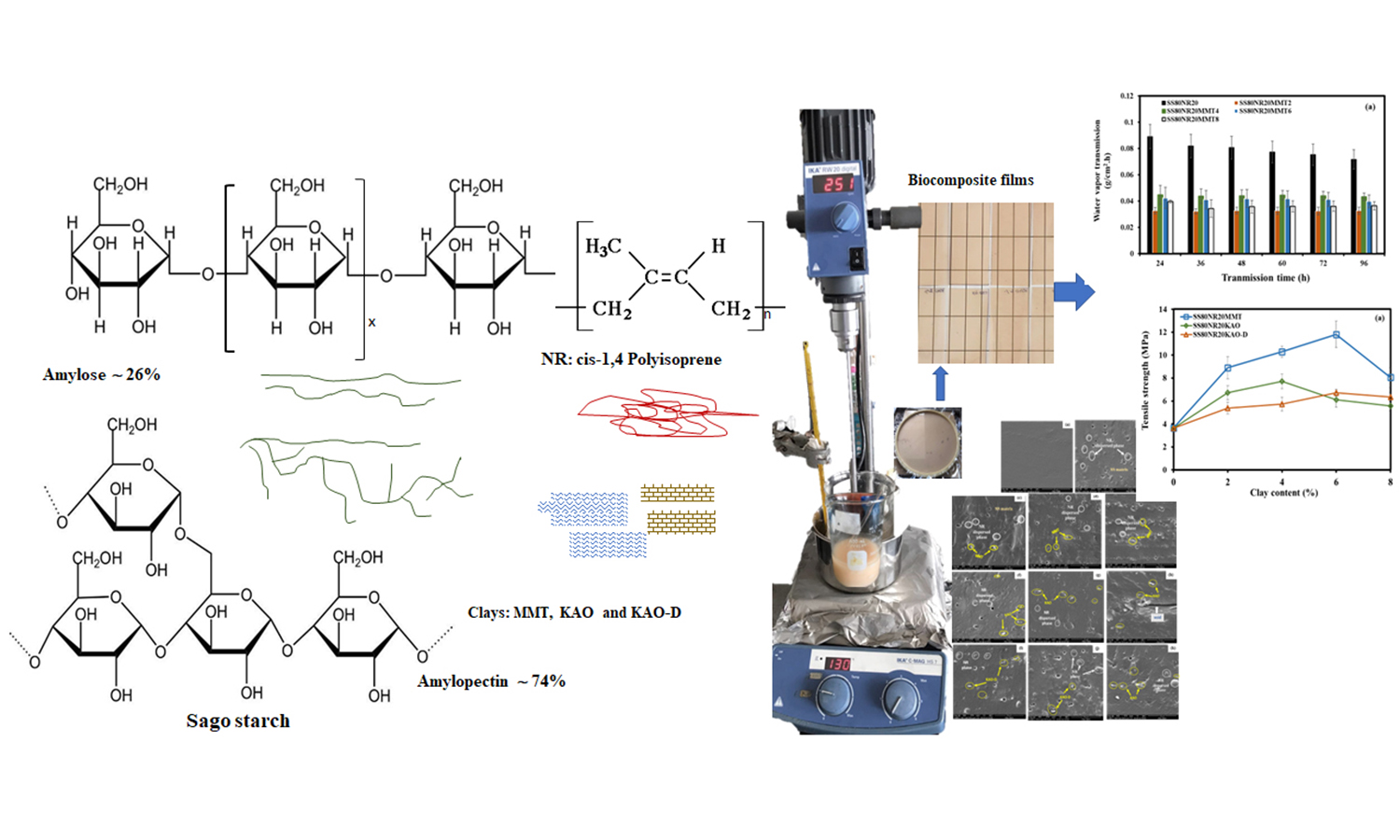

Jareerat Ruamcharoen, Ruszana Munlee, Lapporn Vayachuta, Polphat Ruamcharoen

Vol. 17., No.11., Pages 1096-1109, 2023

DOI: 10.3144/expresspolymlett.2023.83

Vol. 17., No.11., Pages 1096-1109, 2023

DOI: 10.3144/expresspolymlett.2023.83

Sago

starch (SS) was blended with natural rubber (NR) using nanoclays, namely

montmorillonite (MMT), kaolinite (KAO), and kaolinite modified by dimethyl

sulfoxide (KAO-D) to enhance its physical and mechanical properties. Each nanoclay

was incorporated at 2, 4, 6, and 8 wt%, respectively. The SS80NR20 (80 wt% of

sago starch and 20 wt% of natural rubber) biocomposites were characterized by

solubility of water, water vapor transmission, mechanical and thermal

properties. The constituent interaction and morphology of the SS80NR20

biocomposites were also presented by using X-ray diffraction (XRD) technique

and scanning electron microscope (SEM). The findings demonstrated that the

inclusion of clays significantly improved both the water resistance and tensile

properties when compared to the SS80NR20 blend. In the SS80NR20 biocomposites,

MMT at 6 wt% exhibited the lowest moisture content, solubility in water, and

water vapor transmission. As the amount of nanoclay in the biocomposites

increased, their tensile strength dramatically increased whilst their strain at

break had a tendency to diminish. Strong interaction by establishing the

intercalated structure of MMT, and KAO within SS80NR20 biocomposites were

attributed to both physical and mechanical properties, while the weak

interaction at the interface of SS and NR was attributed to KAO-D.