Beeswax-modified biopolymer aerogel: A sustainable approach to hydrophobic oil absorbing materials

Waleed Y. Rizg , Yonss Mbrook Albadn, Abdul Khalil H.P.S.

, Yonss Mbrook Albadn, Abdul Khalil H.P.S. , Majed A Alghamdi

, Majed A Alghamdi , Osama A. Madkhali

, Osama A. Madkhali , Mohammed Baradwan

, Mohammed Baradwan , Fayroz Medhat Shazly

, Fayroz Medhat Shazly , Marwan Marwan

, Marwan Marwan , Esam Bashir Yahya

, Esam Bashir Yahya

, Yonss Mbrook Albadn, Abdul Khalil H.P.S.

, Yonss Mbrook Albadn, Abdul Khalil H.P.S. , Majed A Alghamdi

, Majed A Alghamdi , Osama A. Madkhali

, Osama A. Madkhali , Mohammed Baradwan

, Mohammed Baradwan , Fayroz Medhat Shazly

, Fayroz Medhat Shazly , Marwan Marwan

, Marwan Marwan , Esam Bashir Yahya

, Esam Bashir Yahya

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

DOI: 10.3144/expresspolymlett.2025.40

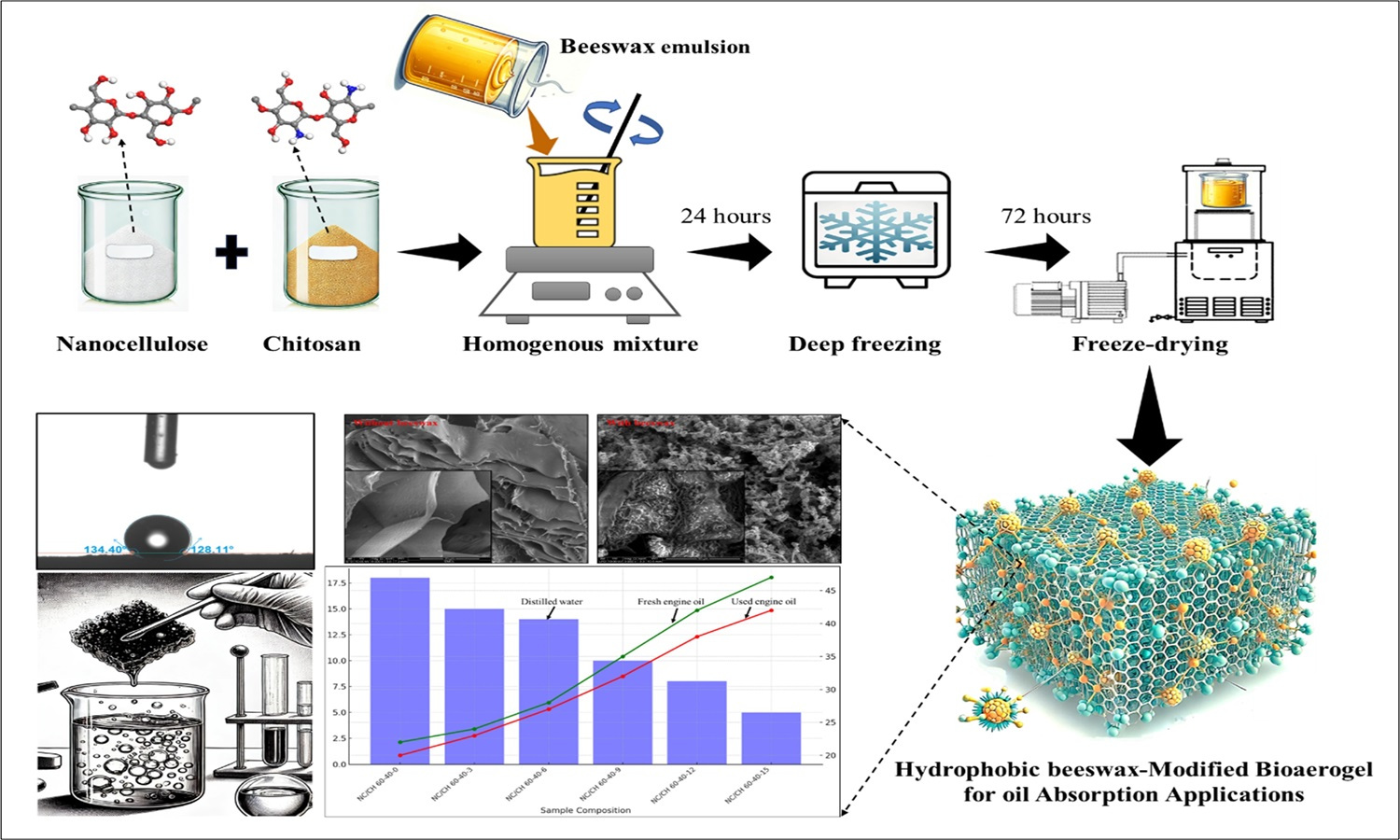

GRAPHICAL ABSTRACT

ABSTRACT

This study presents for the first time a sustainable approach to hydrophobic modification of nanocellulose/chitosan bioaerogels using beeswax emulsion. The incorporation of beeswax into the aerogel matrix resulted in increasing the density from 35.1 to 298 mg/cm3, while the porosity decreased from 96.4 to 62%. Fourier transform infrared spectroscopy (FT-IR) analysis confirmed the successful integration of beeswax into the nanocellulose/chitosan matrix, with distinct peaks corresponding to the characteristic functional groups of beeswax, such as C–H stretching vibrations, further validating the hydro - phobic modification. The mechanical properties showed increased hardness, from 0.24 to 0.95 N/mm2, indicating that higher beeswax content enhanced the rigidity of the aerogels. Contact angle measurements confirmed a dramatic improvement in hydrophobicity, with angles increasing from 47.68 to 134.40 and 128.11° for NC/CH 60-40-15. Water absorption capacity decreased from 17.5 g/g in the control sample to 8 g/g at the highest beeswax concentration, while oil absorption increased significantly, with fresh engine oil absorption rising from 3 to 45 g/g and used engine oil absorption from 2.5 to 40 g/g respectively. These results confirm the successful green modification of bioaerogels using beeswax, providing a sustainable and eco-friendly approach that enhances hydrophobicity, mechanical strength, and selective absorption properties.

RELATED ARTICLES

Jiazheng Sun, Zhengyu Liao, You-Yong Wang, Yushan Zou, Jinhong Li, Zesheng Xu, Yongming Song

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

Vol. 19., No.10., Pages 979-993, 2025

DOI: 10.3144/expresspolymlett.2025.74

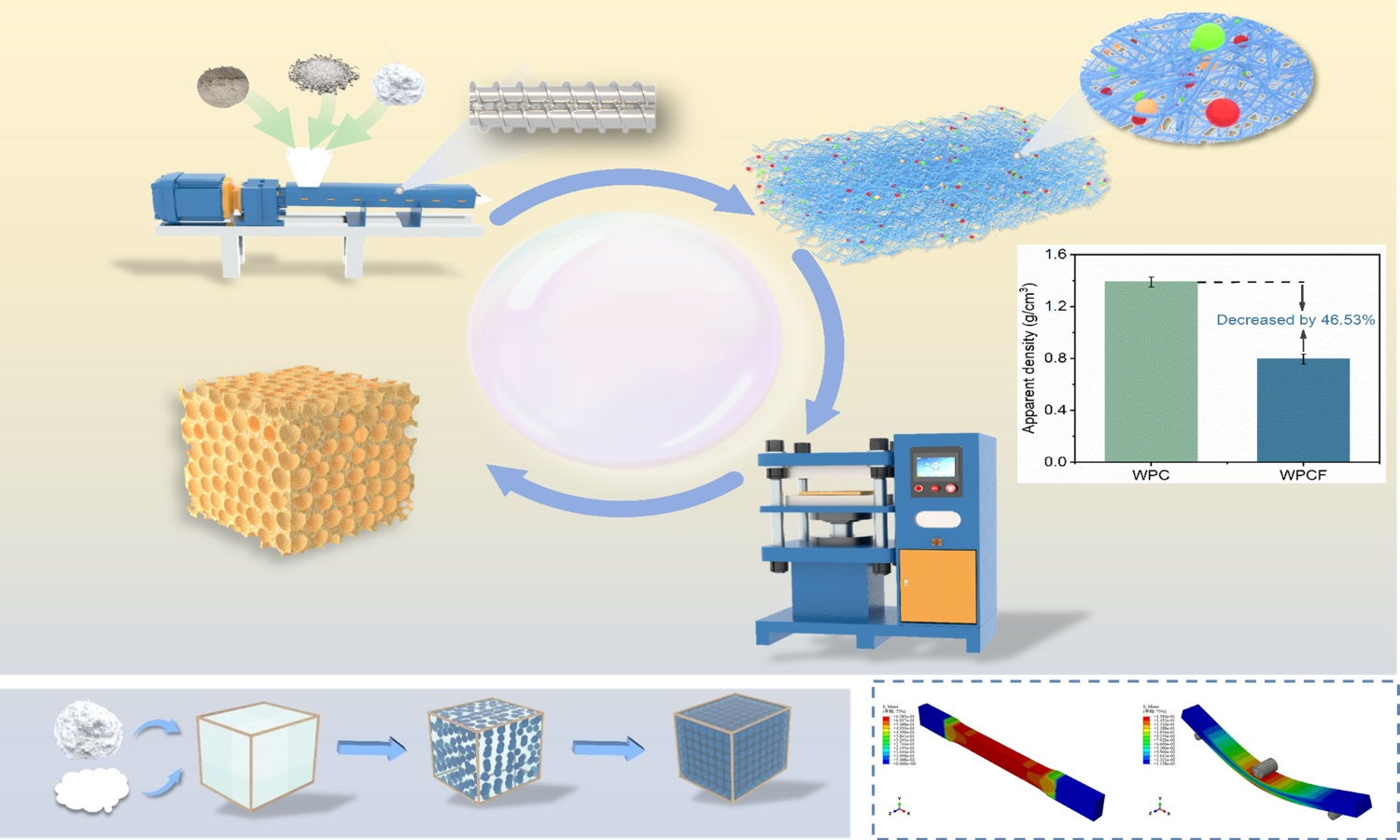

Wood–plastic composite (WPC) is an environmentally friendly and cost-effective materials, while the high density and suboptimal mechanical properties of traditional WPC limit their broader applications. In this study, a wood fiber/polypropylene composite foam (WPCF) is fabricated via chemical foaming enabled by Nano-polytetrafluoroethylene (PTFE). Compared with the unmodified wood fiber/polypropylene composite foam, our developed WPCF demonstrates a 37.69% increase in cell density and a 29.45% decrease in cell size with uniform cell distribution. The fine cell structure of WPCF is attributed to the improved crystallization and suitable viscoelastic behavior due to the addition of nano-PTFE. As a result, WPCF demonstrates superior mechnical performance. When the PTFE content was 1 wt%, WPCF shows a tensile strength of 9.41 MPa, a flexural strength of 22.63 MPa, and a improved impact strength of 5.27 kJ/m2, which is 47.65, 33.12, and 76.23% higher than those of unmodified WPCF. Given to the mechanical robustness and low density of WPCF, the as-prepared high-performance wood fiber/polypropylene composite foam is a promising alternative as a green and sustainable material to traditional wood in construction, furniture, and packaging sectors.

Viktória Kunsági, Péter Széplaki, Márton Tomin

Vol. 19., No.7., Pages 706-725, 2025

DOI: 10.3144/expresspolymlett.2025.54

Vol. 19., No.7., Pages 706-725, 2025

DOI: 10.3144/expresspolymlett.2025.54

In this study, we investigated the influence of processing parameters on the cellular structure and density of specimens fabricated using in-situ foam 3D printing. First, we conducted a comprehensive analysis to examine how the combined effects of printing temperature and speed influence the four key stages of the foaming process: gas dissolution, cell nucleation, cell growth, and stabilization. By evaluating the structural characteristics of the printed foams, we identified the dominant mechanisms governing each stage. Next, we explored the effect of nozzle diameter, an aspect previously unexamined in the literature. We found that smaller nozzle diameters promote higher cell density due to enhanced pressure drop and shear-induced nucleation, resulting in a 36.78% reduction in density and a 60.31% increase in cell density when using a 0.4 mm nozzle instead of 0.8 mm (at 240°C, 60 mm/sec). Finally, we fabricated functionally graded four-layer structures by adjusting the printing temperature for each layer to control porosity distribution. To evaluate the mechanical performance of these graded structures, we performed three-point bending and drop-weight impact tests, allowing us to assess how layer order influences mechanical properties. Our results showed that proper layer sequencing can increase flexural strength by up to 69.35% and improve perforation energy by more than 94.82% compared to homogeneous structures.

Seisuke Ata, Takumi Ono, Motonari Shibakami

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

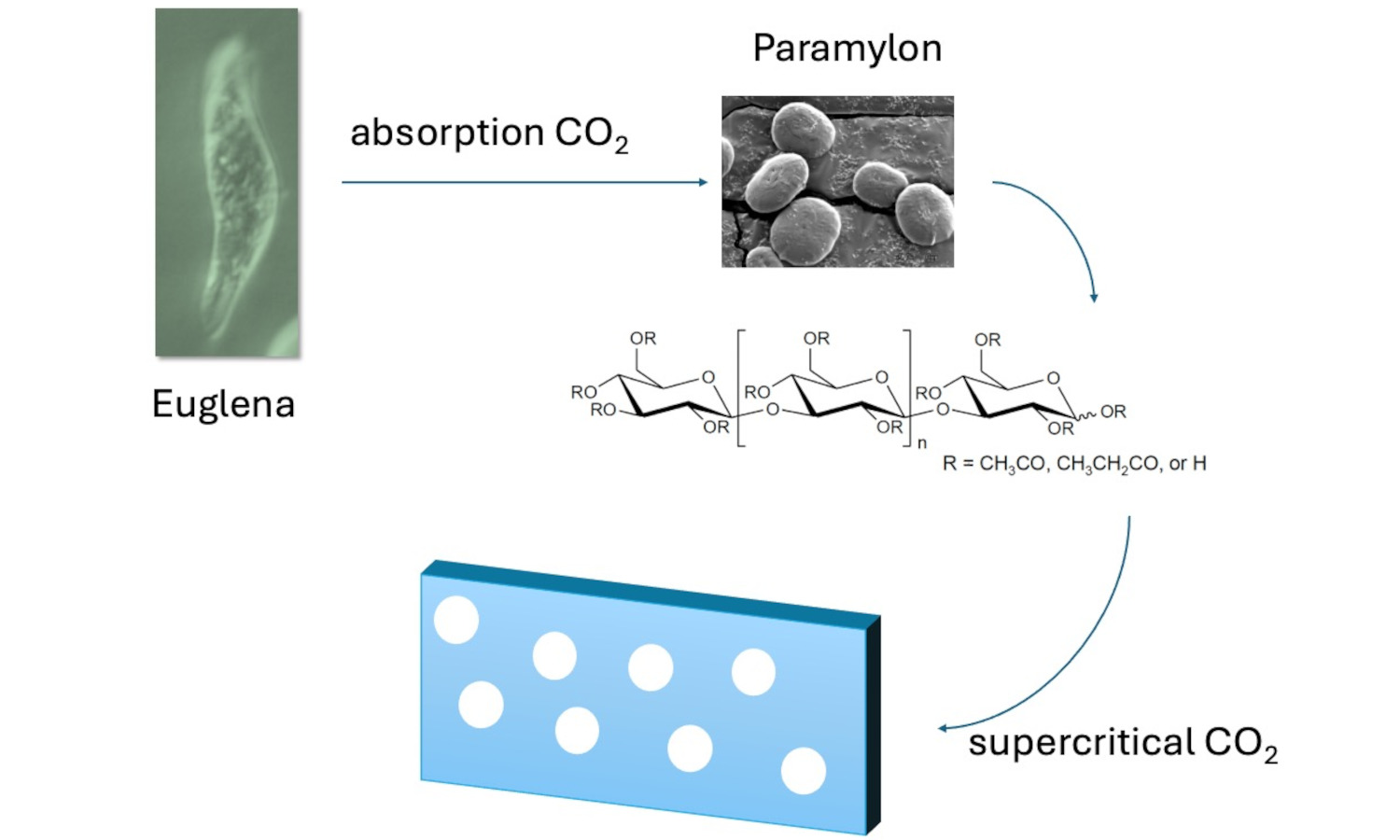

This study demonstrated, for the first time, the successful formation of porous paramylon esters, which were made from euglenoid polysaccharide known as paramylon and short-chain fatty acids, through supercritical CO2 processing. By maintaining a constant ester functional group attached to the paramylon and varying its proportion, distinct porous structures were selectively produced. Solubility parameter estimations indicated that changes in esterification had no significant effect on the solubility of the paramylon esters used in the experiment. Thus, these structural differences are likely attributed to variations in the viscoelastic properties of paramylon esters under supercritical CO2 conditions. Furthermore, thermal conductivity measurements revealed reductions of up to 20%. Intriguingly, substantial decreases in thermal conductivity were observed even at low foaming ratios, achieved through precise control of the porous structure.

Wafa Mustafa Saleh, Esam Bashir Yahya, Mardiana Idayu Ahmad, Abdul Khalil H. P. S.

Vol. 19., No.5., Pages 457-469, 2025

DOI: 10.3144/expresspolymlett.2025.34

Vol. 19., No.5., Pages 457-469, 2025

DOI: 10.3144/expresspolymlett.2025.34

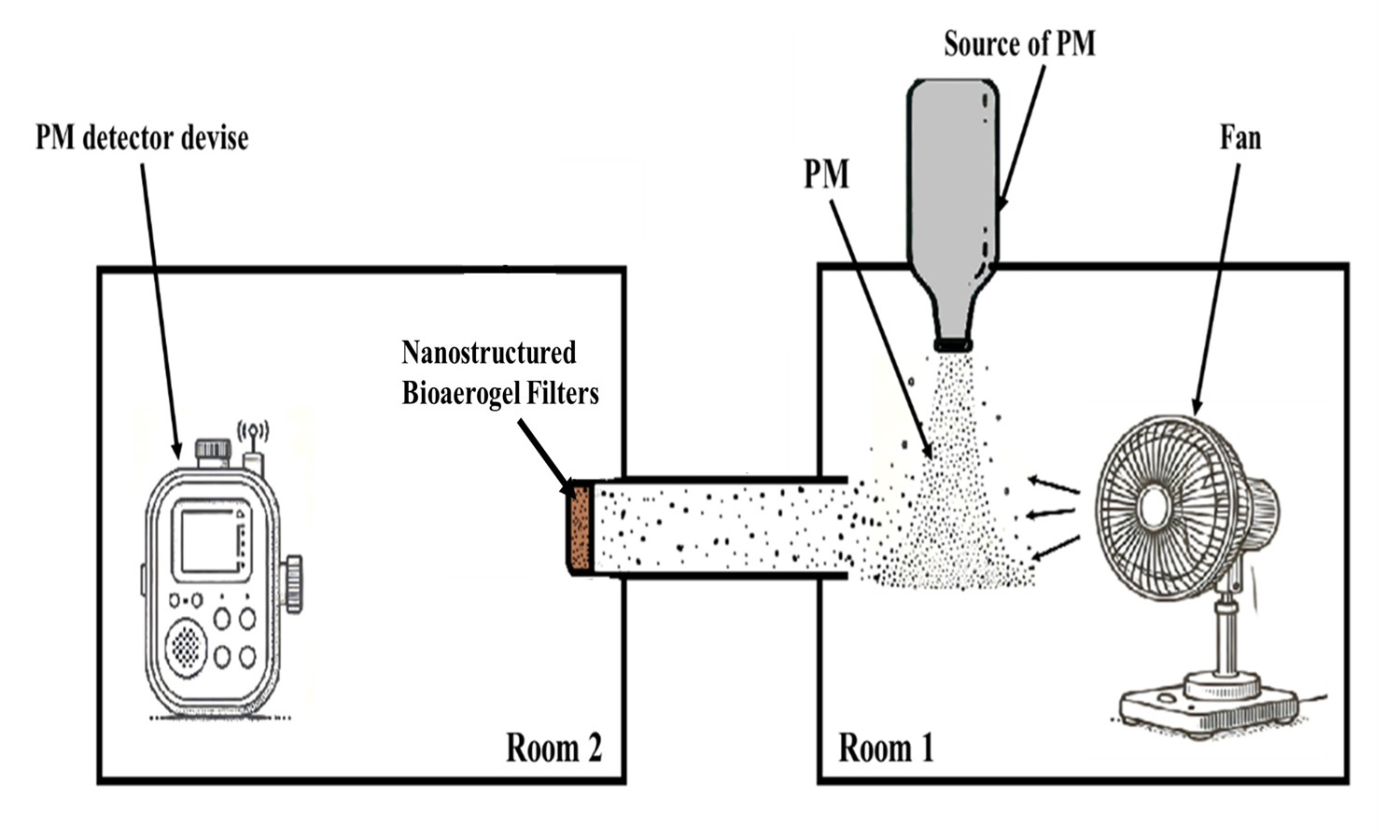

Particulate matter (PM) has been always a significant environmental and public health concern due to its adverse effects on air quality and respiratory health. This study evaluates the efficiency of hydrophobic nanostructured bioaerogels as PM filters under both normal and high-humidity conditions. Bioaerogels were prepared using nanocellulose and chitosan and modified with varying concentrations of tetraethyl orthosilicate (TEMS). At normal humidity, the 3% TEMS-modified bioaerogel demonstrated the highest average PM removal efficiency of 91.6%, attributed to its optimized balance of hydrophobicity, porosity, and mechanical strength. Under high-humidity conditions, the unmodified 0% TEMS bioaerogel exhibited a significant decline in performance due to water absorption, reducing its efficiency by over 15% after prolonged exposure. Conversely, the hydrophobic 3% TEMS bioaerogel maintained its efficiency at 91.4%, highlighting its ability to resist water-induced degradation. This study provide valuable insights into the design of bioaerogel-based filters for realworld applications where variable humidity poses a challenge.

Rahadian Zainul, Yonss Mbrook Albadn, Esam Bashir Yahya, Salim Manoharadas, Nur Izzaati Saharudin, Abdul Khalil H. P. S., Mohammad Rizwan Khan, Mohamed Jaber

Vol. 18., No.4., Pages 359-370, 2024

DOI: 10.3144/expresspolymlett.2024.27

Vol. 18., No.4., Pages 359-370, 2024

DOI: 10.3144/expresspolymlett.2024.27

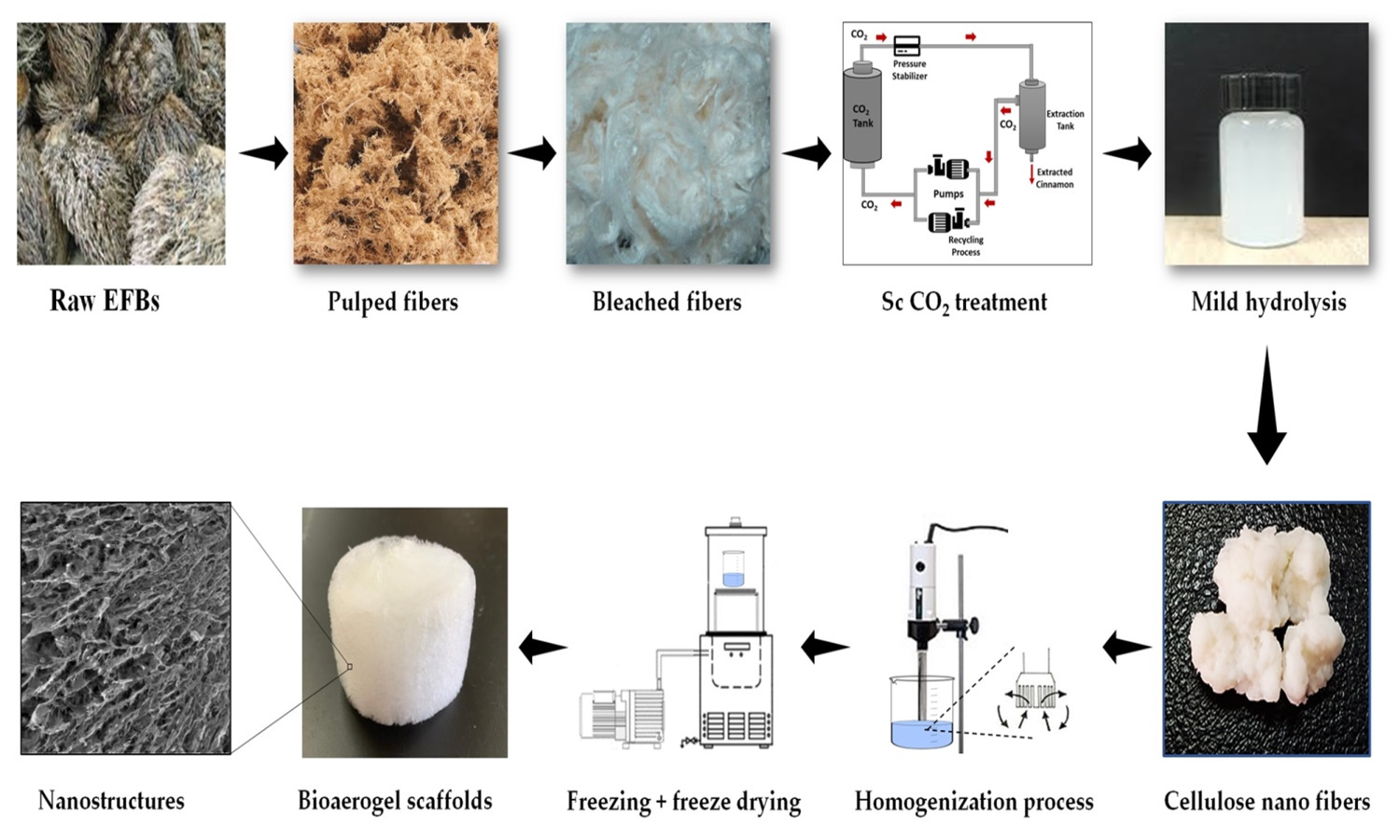

In this study, we employed supercritical carbon dioxide (scCO2) treatment under varying conditions: low-pressure treatment at 30 MPa and high temperature at 80°C (LPHT group) and high-pressure treatment at 60 MPa and low temperature at 50°C (HPLT group) for nanocellulose isolation. The scCO2 treatment resulted in smaller particle sizes and enhanced crystallinity. Notably, HPLT exhibited superior efficiency compared to LPHT treatment. Utilizing temperatures and pressures above the critical point effectively penetrated natural fibers, reducing nanocellulose particle sizes. Moreover, high-pressure and low-temperature nanocellulose demonstrated the highest crystallinity and negative zeta potential values (78.2% and –32.4±4.01 mV), surpassing those of the low-pressure and high-temperature group (77.9% and 26.0±2.34 mV) and control (77.3% and 25.9±3.13 mV). The concentration of nanocellulose significantly impacted the porosity, pore size, and water absorption of the bioaerogel scaffolds, indicating the potential for sustainable and environmentally friendly approaches in material fabrication for diverse applications.