Environmentally friendly polyurethanes based on non-isocyanate synthesis

Vol. 18., No.1., Pages 88-101, 2024

DOI: 10.3144/expresspolymlett.2024.7

DOI: 10.3144/expresspolymlett.2024.7

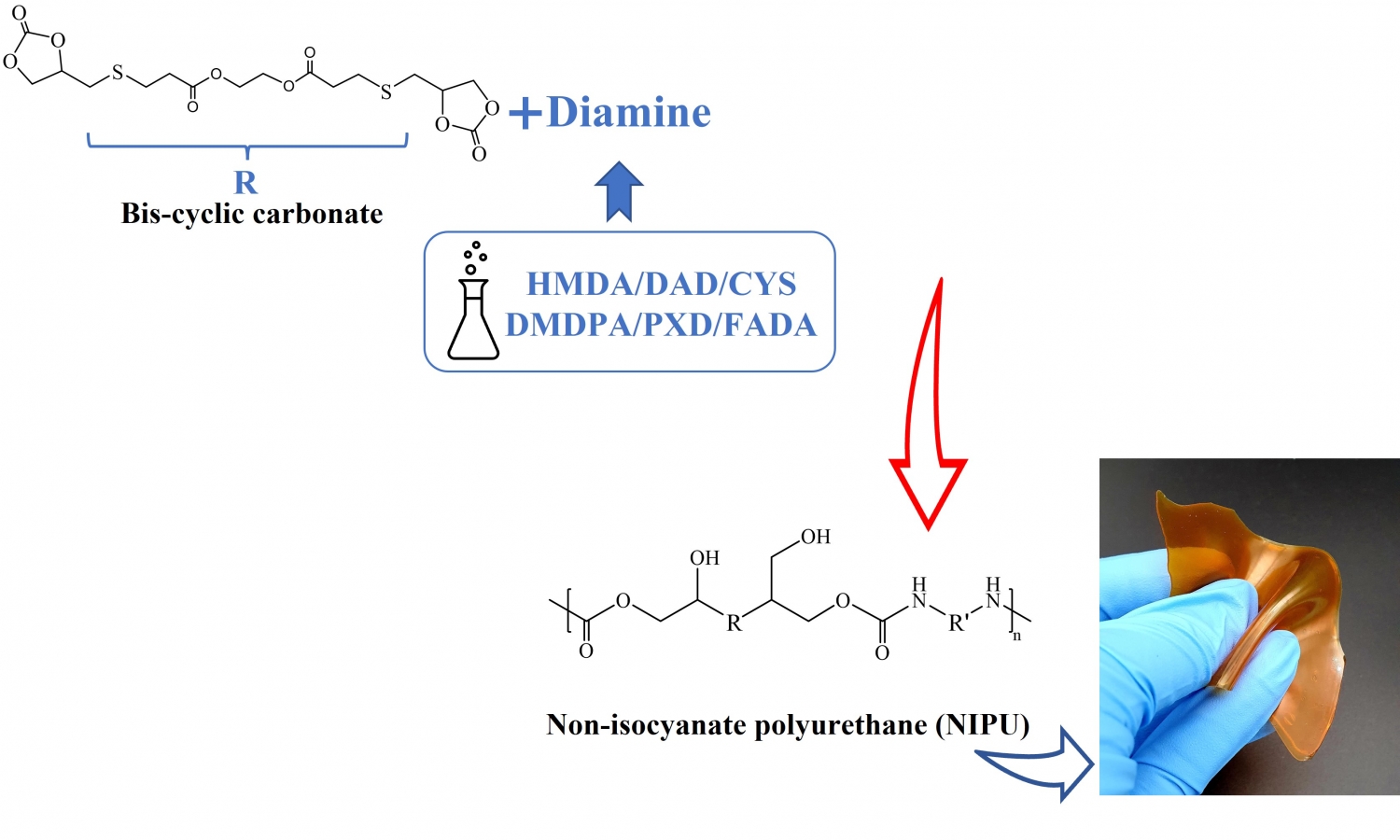

GRAPHICAL ABSTRACT

ABSTRACT

A series of environmentally friendly non-isocyanate polyurethanes (NIPUs) was synthesized through a polycondensation reaction of as-synthesized semi-bio-based bis-cyclic carbonate with diamine derivatives. The synthesis of biscyclic carbonate was realized, for the first time, from 1-thioglycerol and polyethylene glycol diacrylate via thiol-ene click and transcarbonation reaction, respectively. The impacts of using different diamine derivatives on the chemical structural, mechanical properties, thermal stability, and surface wettability of the NIPUs were determined. It was found that the NIPU containing fatty acid-based diamine decomposed at a lower temperature than that of other polymers. Besides, it demonstrated a lower Young’s modulus and a higher tensile strain at break, possibly due to its four-branched structure and greater flexibility. Meanwhile, the NIPU prepared with p-xylylenediamine provided the highest decomposition temperature, owing to an aromatic moiety in the polymer’s backbone, which improved its stiffness and thermal stability. Furthermore, it was understood that the NIPU containing diamino-N-methyldipropyl-amine exhibited a higher Young’s modulus and a lower tensile strain at break, as it had a nitrogen atom in its structure and a trigonal pyramidal configuration with the highest density of hydrogen bonds between polymer chains. Most of the developed NIPUs displayed hydrophobic surface properties, offering promising alternatives to isocyanate-based coating materials.

RELATED ARTICLES

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

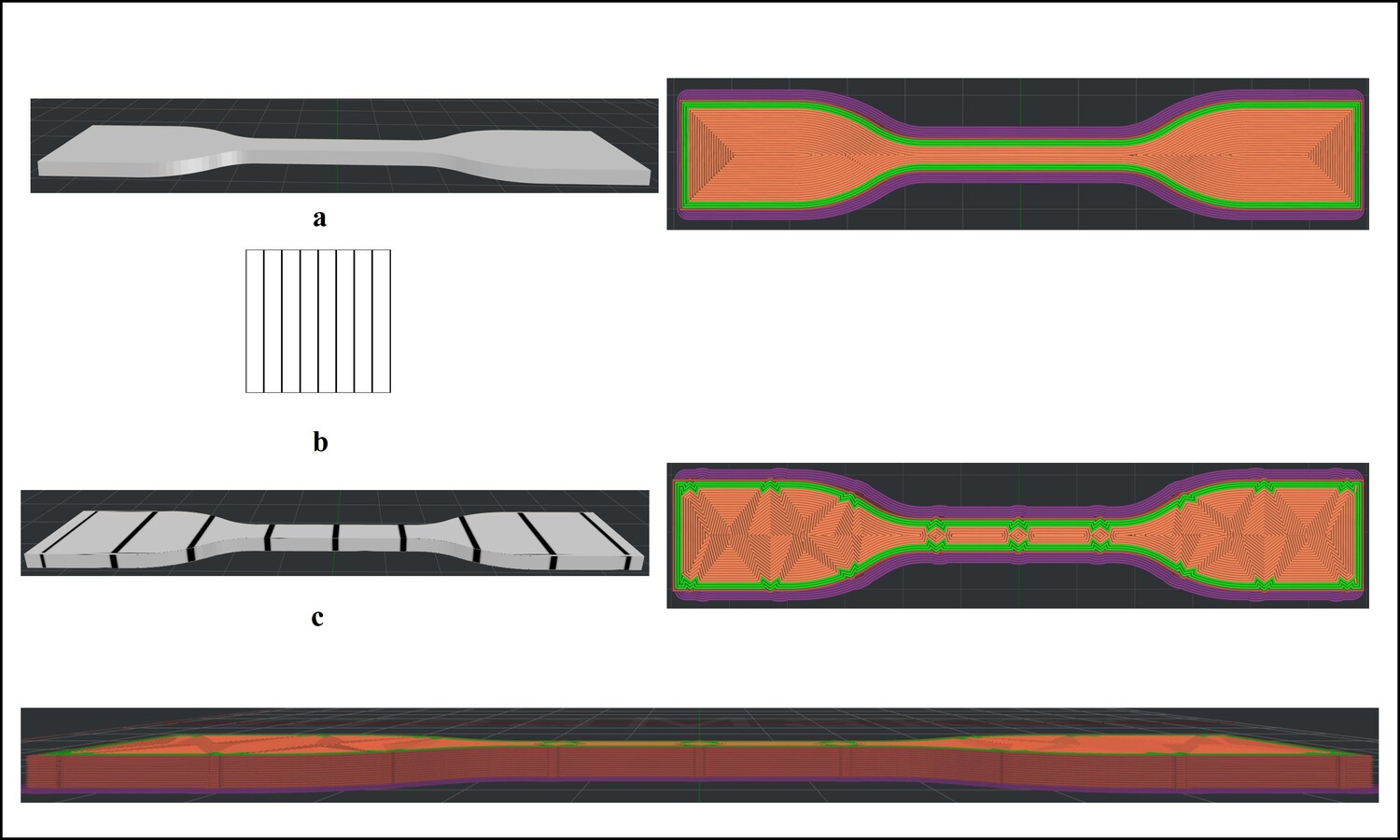

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.