Surface texture effects on mechanical properties of additively manufactured polylactic acid

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

DOI: 10.3144/expresspolymlett.2025.2

GRAPHICAL ABSTRACT

ABSTRACT

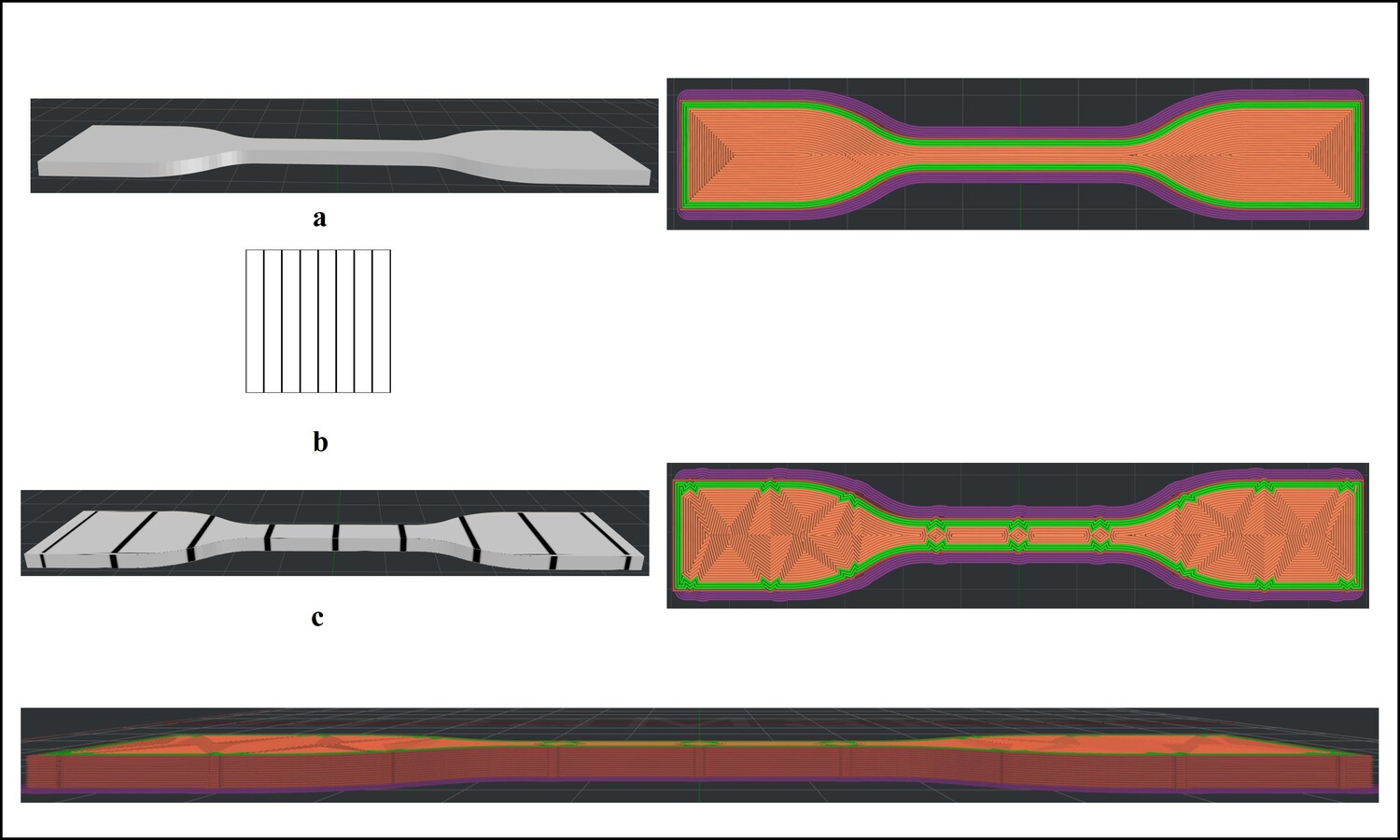

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

RELATED ARTICLES

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

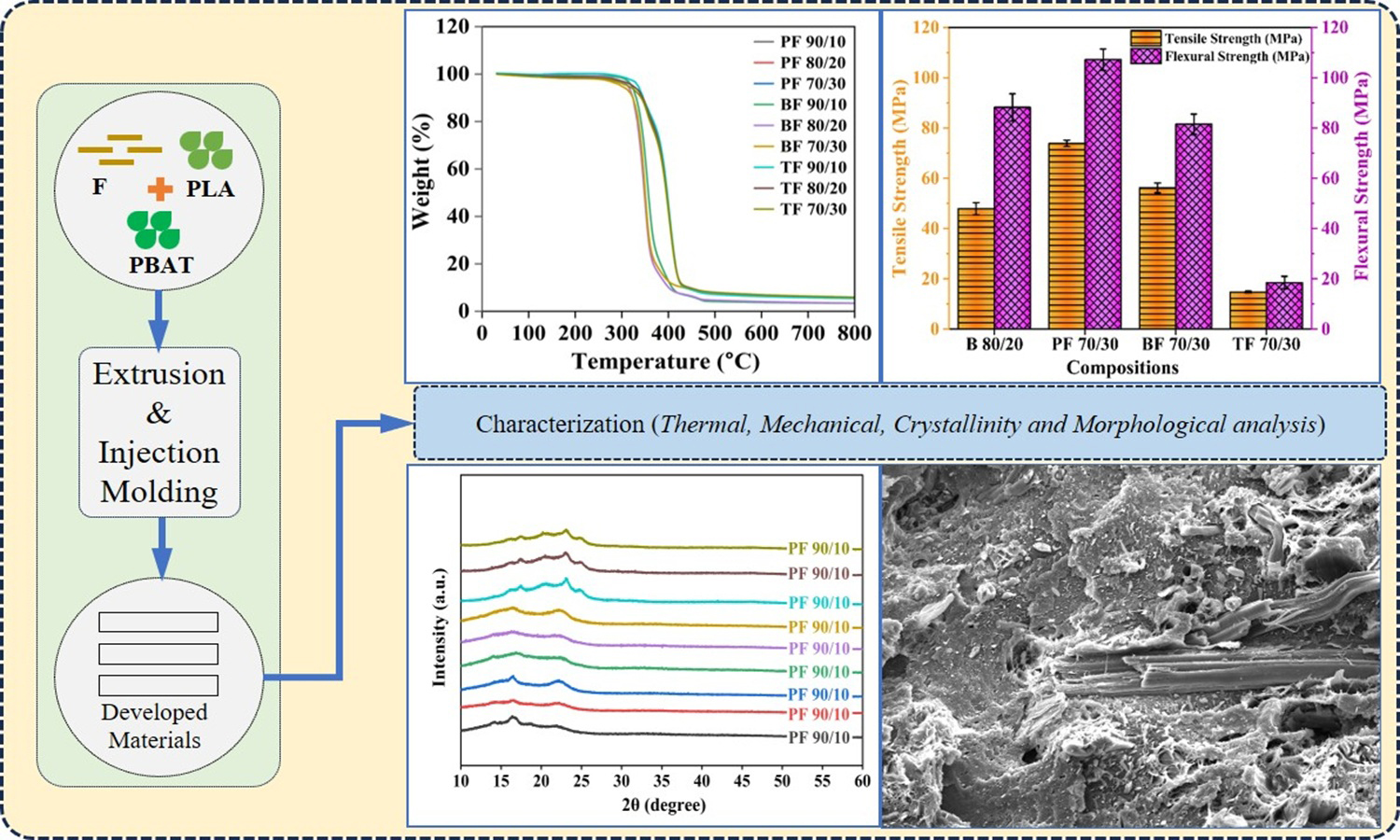

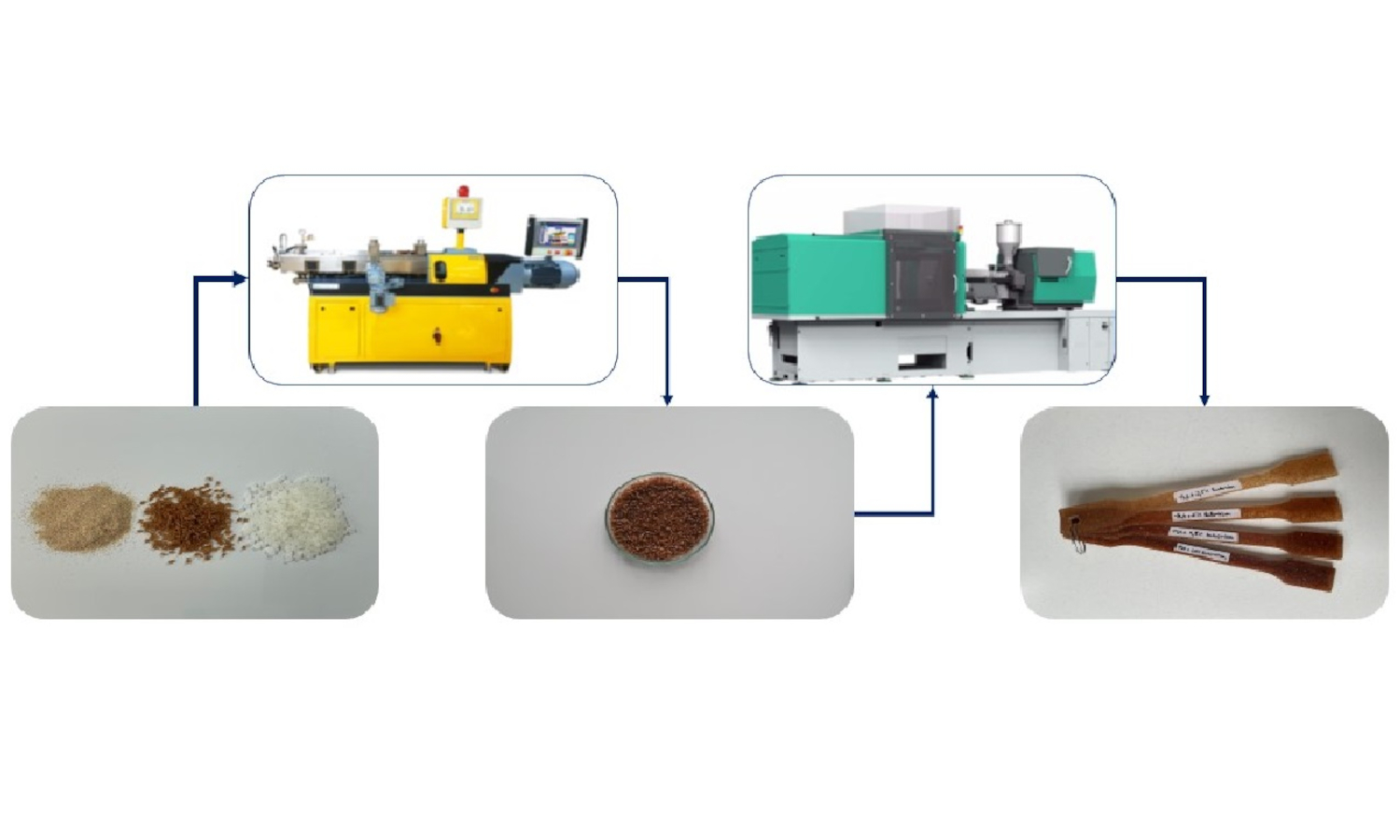

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

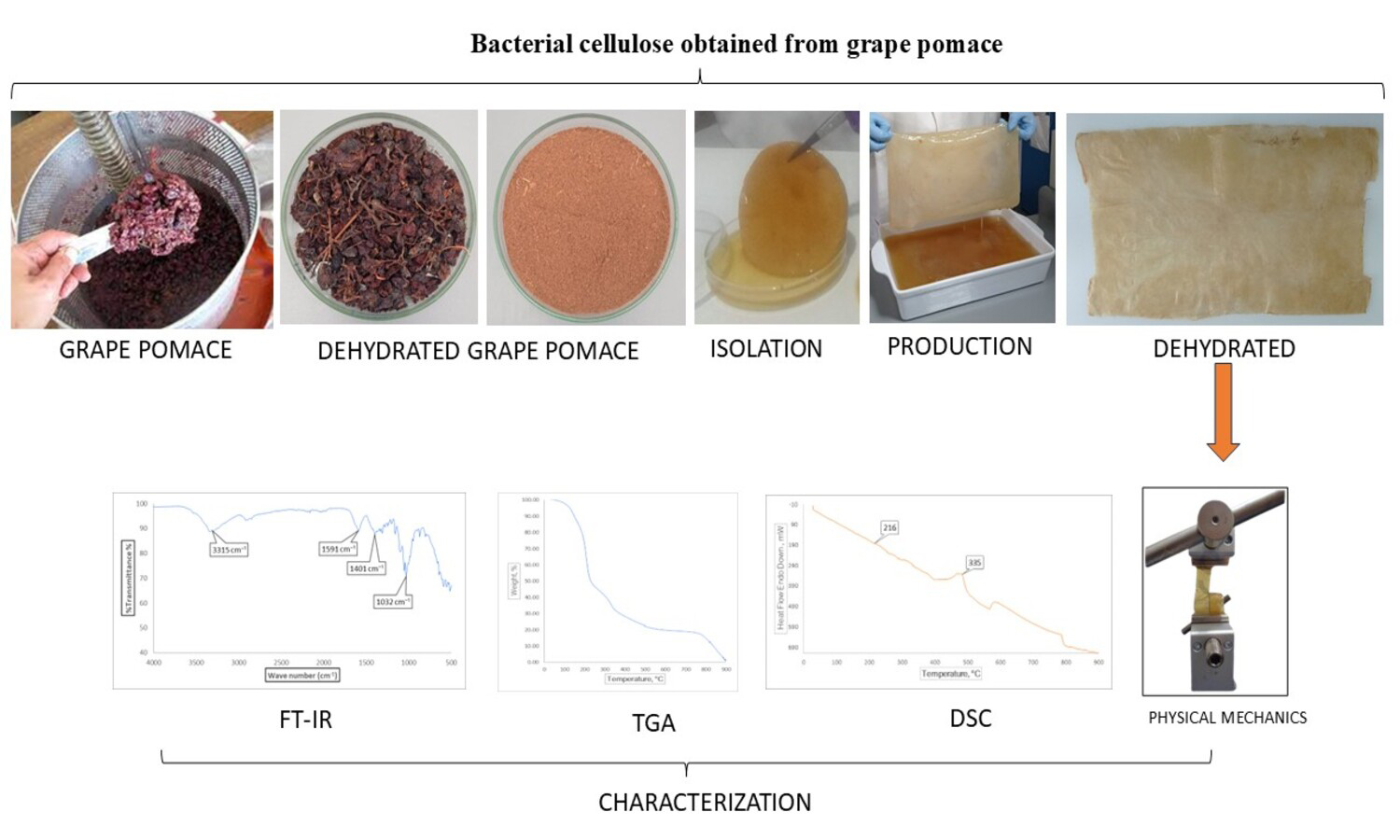

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.

Elumalai Vengadesan, Swaminathan Muralidharan, Dhanjit Das, Thirugnanasambandam Arunkumar

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

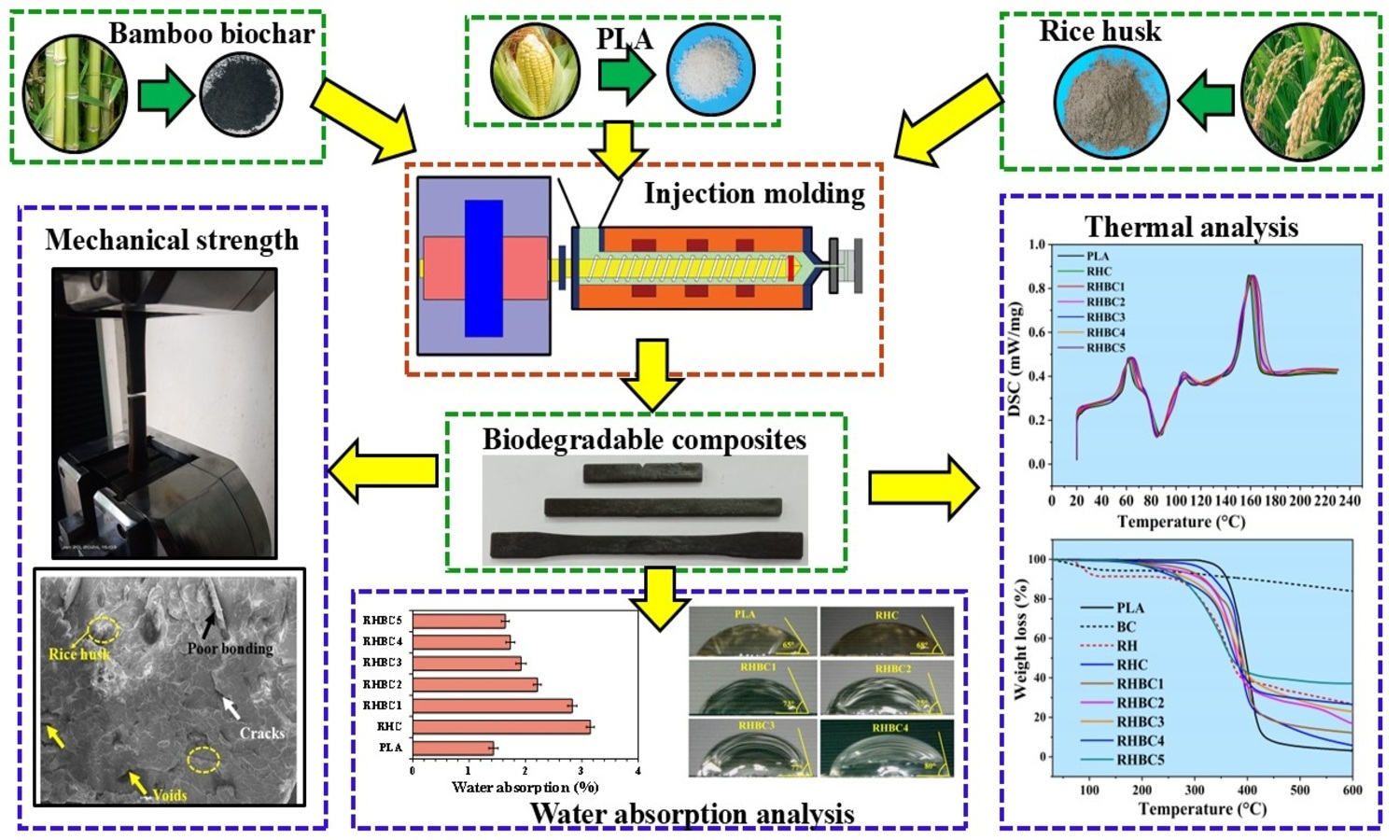

The growing need for sustainable materials has stimulated research into eco-friendly composites, with biochar emerging as an important reinforcement in polymer matrices. Biochar is a carbon-rich material produced by pyrolyzing organic biomass, offering various benefits over traditional fillers, including sustainability, waste reduction, and carbon sequestration. This study explores the effects of bamboo biochar as a hybrid reinforcement on the properties of polylactic acid (PLA)-rice husk composites. The present hybrid composites are prepared by varying the bamboo biochar from 5–25% and have better mechanical properties than PLA and its composite reinforced with a rice husk filler. The tensile, flexural, and compressive strengths of 51.5, 166.0, and 77.5 MPa are measured for the biochar percentage of 10%, representing increases of 73.1, 150.0, and 58.2% compared to PLA, and 158.2, 98.6, and 31% compared to the PLA composite with rice husk. Higher tensile and flexural moduli of 1.46 and 7.34 GPa are observed for 10 and 15%, respectively. However, the impact strength decreases with higher biochar content due to increased rigidity. The material’s hardness increases at higher biochar content due to enhanced stiffness. Thermal transition and degradation points rise due to increased crystallinity from the biochar reinforcement’s nucleation effect. Additionally, the hydrophobic biochar reinforcement reduces water absorption of PLA composite from 3.2 to 1.6%.

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

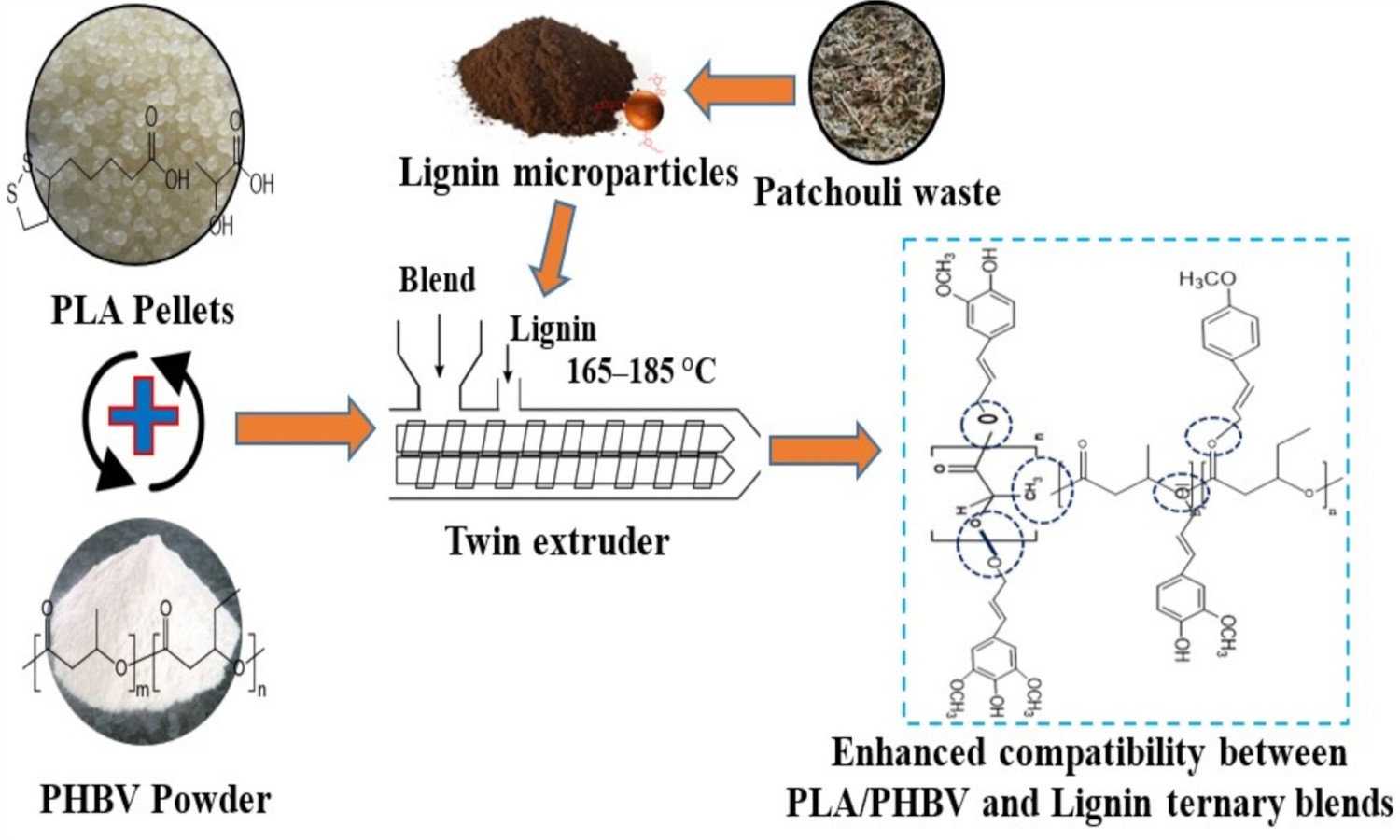

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.