Eco-friendly approach for nanocellulose isolation from agricultural wastes and the fabrication of bioaerogel scaffolds

Rahadian Zainul , Yonss Mbrook Albadn, Esam Bashir Yahya

, Yonss Mbrook Albadn, Esam Bashir Yahya , Salim Manoharadas

, Salim Manoharadas , Nur Izzaati Saharudin

, Nur Izzaati Saharudin , Abdul Khalil H. P. S.

, Abdul Khalil H. P. S. , Mohammad Rizwan Khan

, Mohammad Rizwan Khan , Mohamed Jaber

, Mohamed Jaber

, Yonss Mbrook Albadn, Esam Bashir Yahya

, Yonss Mbrook Albadn, Esam Bashir Yahya , Salim Manoharadas

, Salim Manoharadas , Nur Izzaati Saharudin

, Nur Izzaati Saharudin , Abdul Khalil H. P. S.

, Abdul Khalil H. P. S. , Mohammad Rizwan Khan

, Mohammad Rizwan Khan , Mohamed Jaber

, Mohamed JaberVol. 18., No.4., Pages 359-370, 2024

DOI: 10.3144/expresspolymlett.2024.27

DOI: 10.3144/expresspolymlett.2024.27

GRAPHICAL ABSTRACT

ABSTRACT

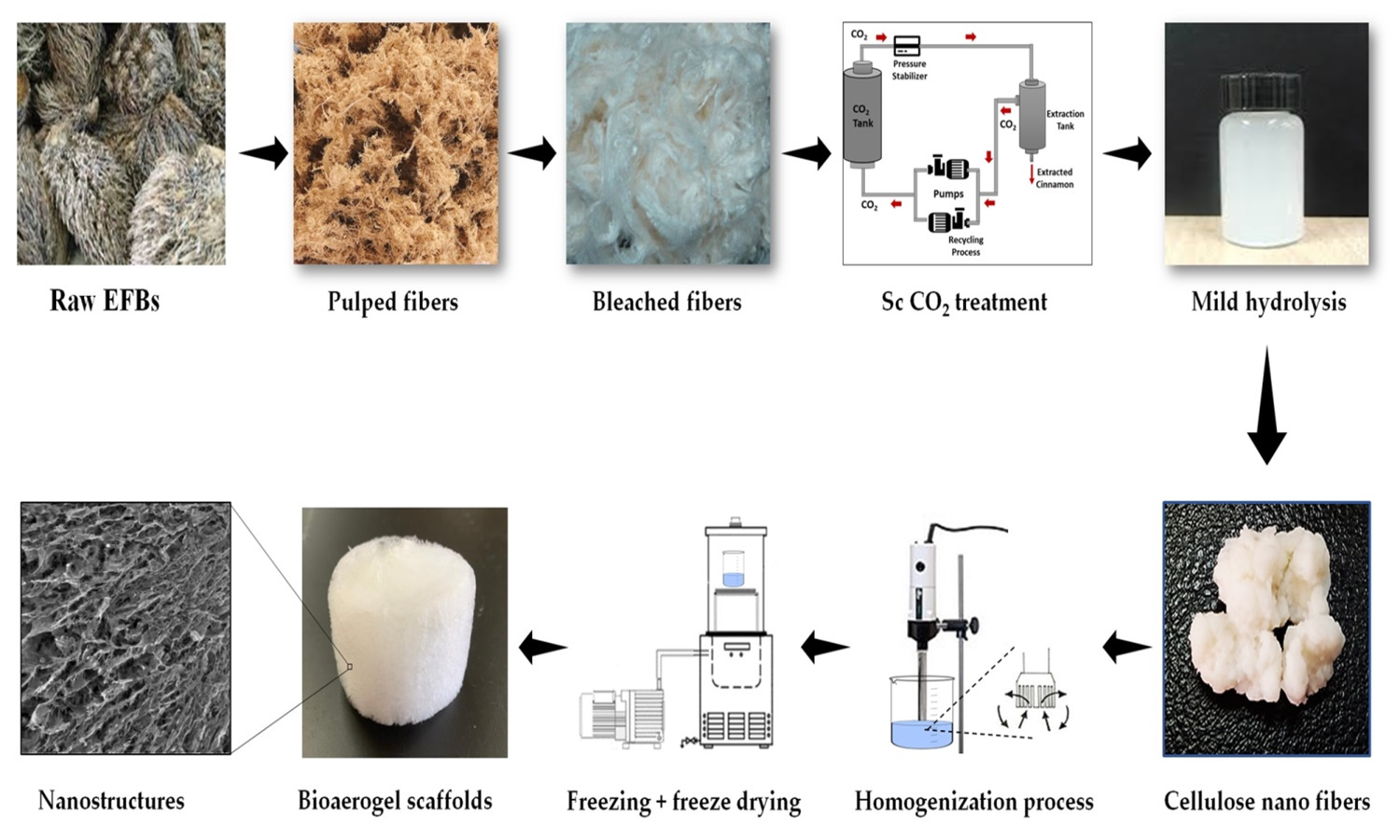

In this study, we employed supercritical carbon dioxide (scCO2) treatment under varying conditions: low-pressure treatment at 30 MPa and high temperature at 80°C (LPHT group) and high-pressure treatment at 60 MPa and low temperature at 50°C (HPLT group) for nanocellulose isolation. The scCO2 treatment resulted in smaller particle sizes and enhanced crystallinity. Notably, HPLT exhibited superior efficiency compared to LPHT treatment. Utilizing temperatures and pressures above the critical point effectively penetrated natural fibers, reducing nanocellulose particle sizes. Moreover, high-pressure and low-temperature nanocellulose demonstrated the highest crystallinity and negative zeta potential values (78.2% and –32.4±4.01 mV), surpassing those of the low-pressure and high-temperature group (77.9% and 26.0±2.34 mV) and control (77.3% and 25.9±3.13 mV). The concentration of nanocellulose significantly impacted the porosity, pore size, and water absorption of the bioaerogel scaffolds, indicating the potential for sustainable and environmentally friendly approaches in material fabrication for diverse applications.

RELATED ARTICLES

Wafa Mustafa Saleh, Esam Bashir Yahya, Mardiana Idayu Ahmad, Abdul Khalil H. P. S.

Vol. 19., No.5., Pages 457-469, 2025

DOI: 10.3144/expresspolymlett.2025.34

Vol. 19., No.5., Pages 457-469, 2025

DOI: 10.3144/expresspolymlett.2025.34

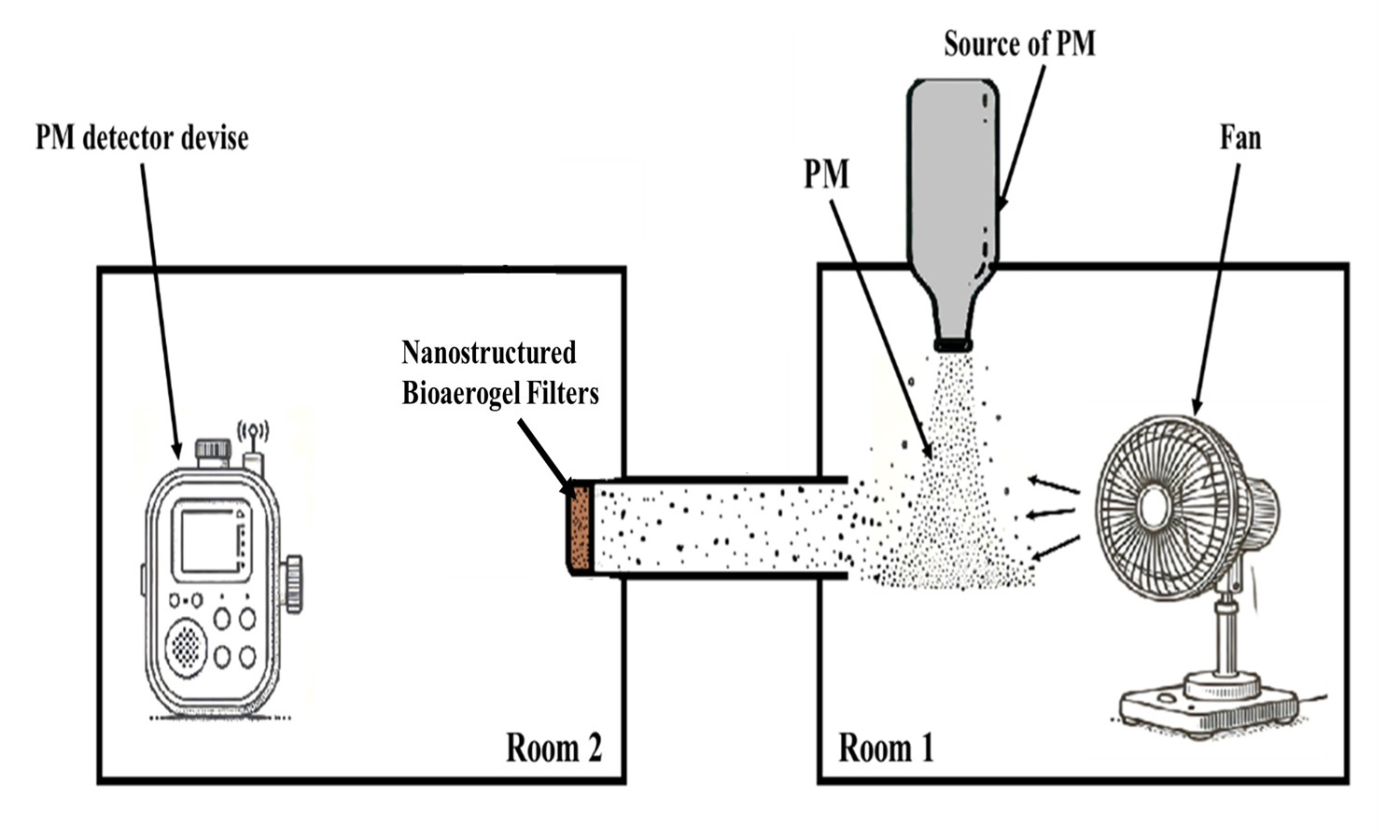

Particulate matter (PM) has been always a significant environmental and public health concern due to its adverse effects on air quality and respiratory health. This study evaluates the efficiency of hydrophobic nanostructured bioaerogels as PM filters under both normal and high-humidity conditions. Bioaerogels were prepared using nanocellulose and chitosan and modified with varying concentrations of tetraethyl orthosilicate (TEMS). At normal humidity, the 3% TEMS-modified bioaerogel demonstrated the highest average PM removal efficiency of 91.6%, attributed to its optimized balance of hydrophobicity, porosity, and mechanical strength. Under high-humidity conditions, the unmodified 0% TEMS bioaerogel exhibited a significant decline in performance due to water absorption, reducing its efficiency by over 15% after prolonged exposure. Conversely, the hydrophobic 3% TEMS bioaerogel maintained its efficiency at 91.4%, highlighting its ability to resist water-induced degradation. This study provide valuable insights into the design of bioaerogel-based filters for realworld applications where variable humidity poses a challenge.

Waleed Y. Rizg, Yonss Mbrook Albadn, Abdul Khalil H.P.S., Majed A Alghamdi, Osama A. Madkhali, Mohammed Baradwan, Fayroz Medhat Shazly, Marwan Marwan, Esam Bashir Yahya

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

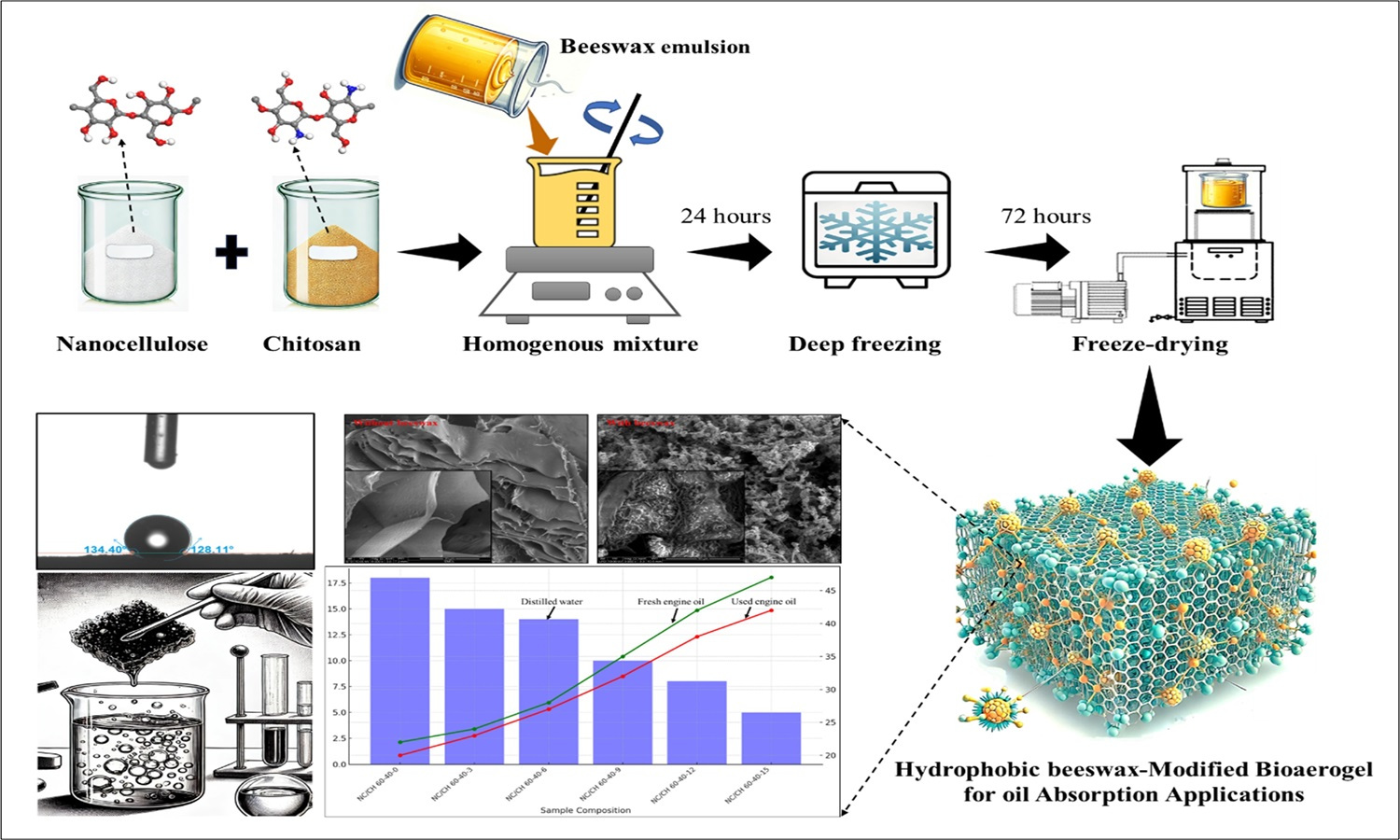

This study presents for the first time a sustainable approach to hydrophobic modification of nanocellulose/chitosan bioaerogels using beeswax emulsion. The incorporation of beeswax into the aerogel matrix resulted in increasing the density from 35.1 to 298 mg/cm3, while the porosity decreased from 96.4 to 62%. Fourier transform infrared spectroscopy (FT-IR) analysis confirmed the successful integration of beeswax into the nanocellulose/chitosan matrix, with distinct peaks corresponding to the characteristic functional groups of beeswax, such as C–H stretching vibrations, further validating the hydro - phobic modification. The mechanical properties showed increased hardness, from 0.24 to 0.95 N/mm2, indicating that higher beeswax content enhanced the rigidity of the aerogels. Contact angle measurements confirmed a dramatic improvement in hydrophobicity, with angles increasing from 47.68 to 134.40 and 128.11° for NC/CH 60-40-15. Water absorption capacity decreased from 17.5 g/g in the control sample to 8 g/g at the highest beeswax concentration, while oil absorption increased significantly, with fresh engine oil absorption rising from 3 to 45 g/g and used engine oil absorption from 2.5 to 40 g/g respectively. These results confirm the successful green modification of bioaerogels using beeswax, providing a sustainable and eco-friendly approach that enhances hydrophobicity, mechanical strength, and selective absorption properties.

Abdul Khalil H. P. S., Abdussalam Giuma, Esam Bashir Yahya, Indra Surya, Arif Nuryawan, Tata Alfatah, Mardiana Idayu Ahmad

Vol. 18., No.8., Pages 796-806, 2024

DOI: 10.3144/expresspolymlett.2024.59

Vol. 18., No.8., Pages 796-806, 2024

DOI: 10.3144/expresspolymlett.2024.59

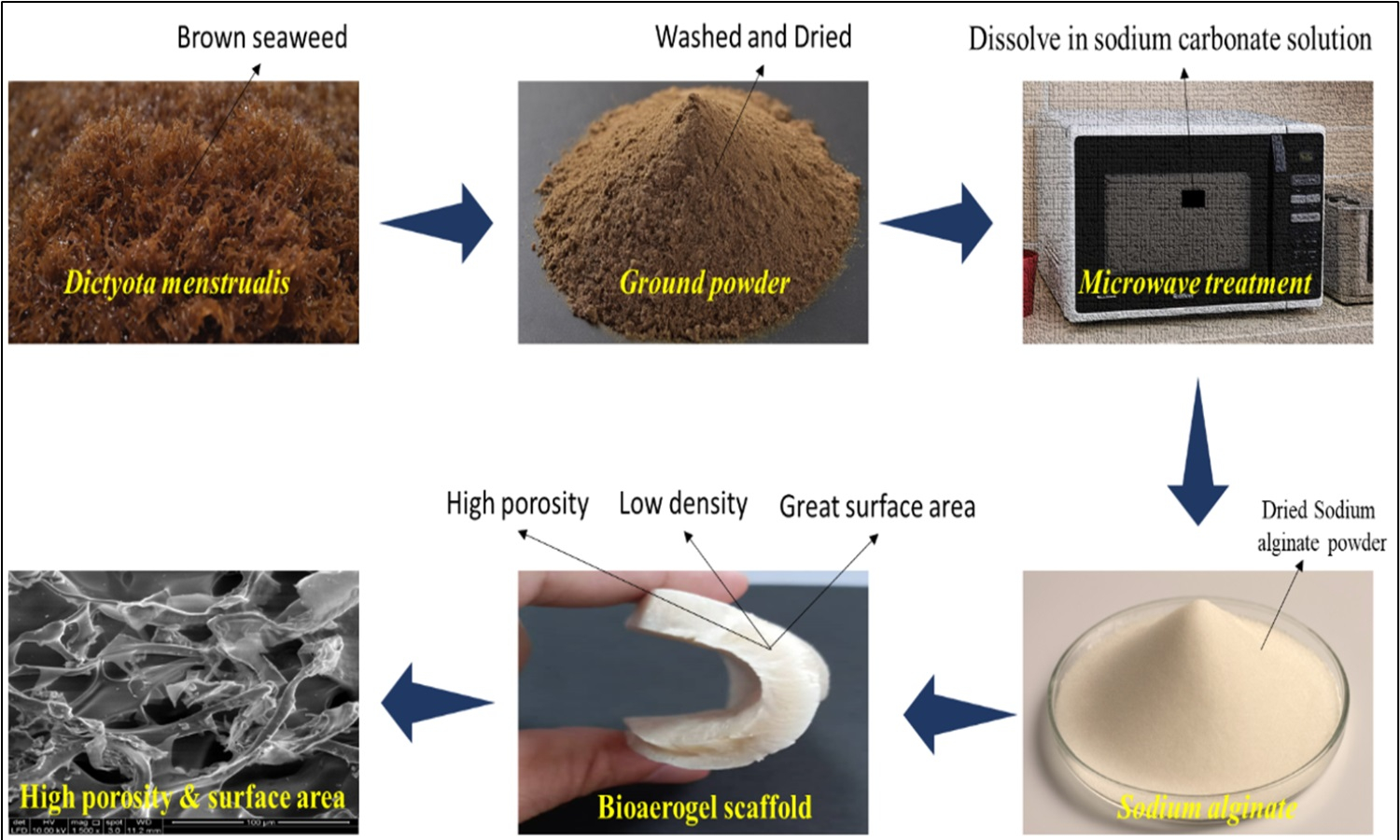

This study investigates the enhanced extraction of sodium alginate (SA) from Dictyota menstrualis using microwave-assisted techniques and its subsequent application in fabricating green thermal insulators. Utilizing optimized microwave parameters, we achieved a notable increase in SA yield, peaking at 18.5%, significantly higher than the 14.2% obtained through conventional methods. This process not only underscores the efficiency of microwave-assisted extraction by improving yield by approximately 30% but also highlights its environmental sustainability due to reduced solvent use and shorter processing times. The study demonstrates that increasing sodium alginate concentration from 1 to 5% enhances the mechanical strength and thermal insulation properties of bioaerogel scaffolds, evidenced by an increase in density from 0.171 to 0.234 g/cm3 and a decrease in porosity from 93.6 to 89.6%. Additionally, the thermal conductivity and diffusivity measurements of 0.065 W/(m·K) and 0.294 mm2/s, respectively, affirm the excellent thermal insulation stability of these scaffolds. The study demonstrates the potential of microwave-assisted extraction as a scalable and eco-friendly approach for biopolymer recovery, and the feasibility of using the extracted SA in creating effective, green thermal insulators, marking a significant step towards sustainable material development.