Biodegradable scaffold: integration of polylactic acid, hydroxyapatite, and graphene oxide via FDM 3D printing

André da Silva Siqueira, Natália Ferreira Braga, Pablo Andrés Riveros Muñoz, Lucas Freitas de Freitas, Aryel Heitor Ferreira , Guilhermino Jose Macêdo Fechine

, Guilhermino Jose Macêdo Fechine

, Guilhermino Jose Macêdo Fechine

, Guilhermino Jose Macêdo FechineVol. 18., No.6., Pages 656-672, 2024

DOI: 10.3144/expresspolymlett.2024.48

DOI: 10.3144/expresspolymlett.2024.48

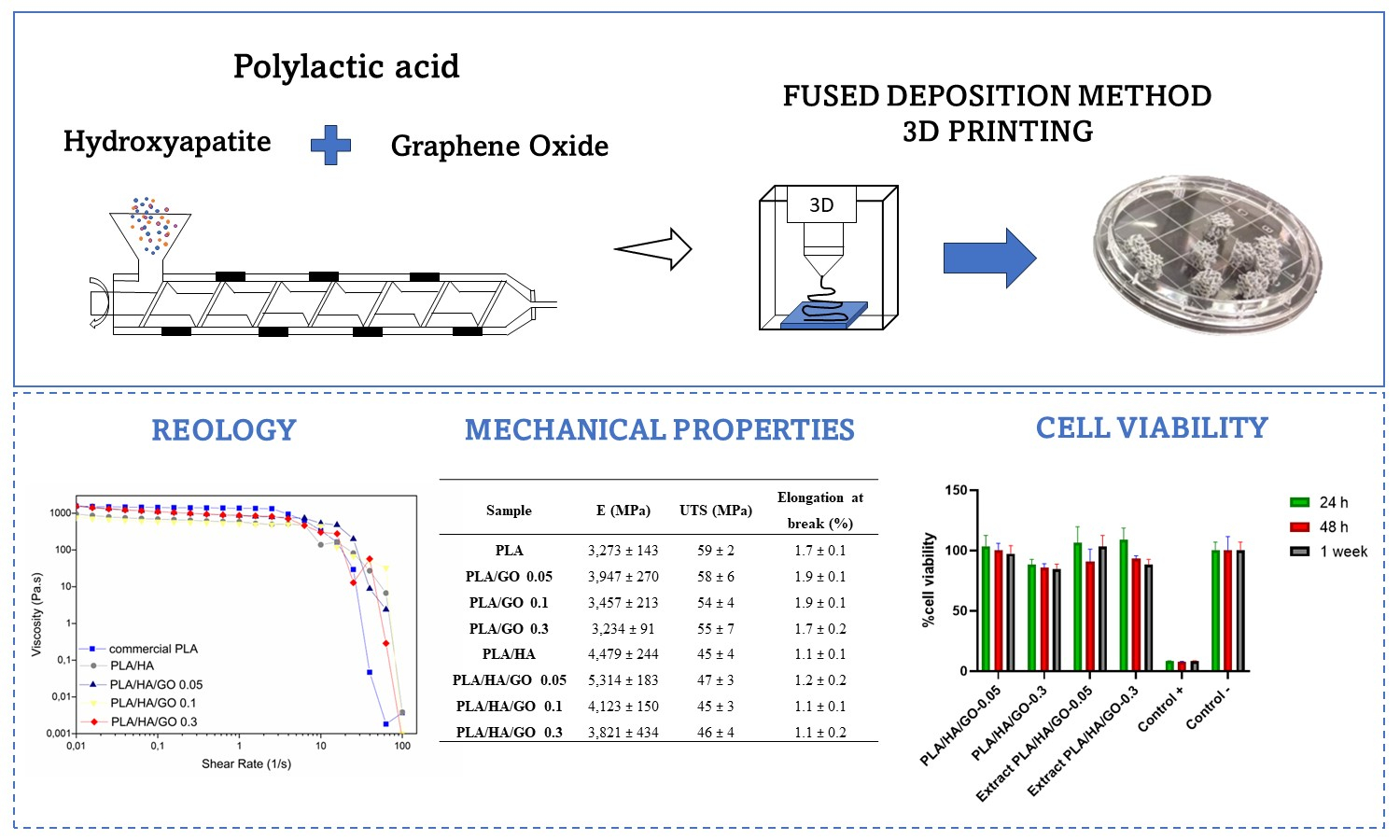

GRAPHICAL ABSTRACT

ABSTRACT

Extensive research and practical applications have been conducted within the biomaterials domain, focusing on polylactic acid (PLA) based composite. These composites have been explored for their favorable attributes, such as excellent processability, biodegradability, and bioactivity properties, but still lack mechanical properties. In this work, PLA-based nanocomposites were prepared by incorporating hydroxyapatite (HA) and graphene oxide (GO) via melt mixing (extruder). Filaments were obtained to develop scaffolds through 3D printing, utilizing the fused deposition method (FDM). The GO was produced using Hummer’s method and characterized by X-ray diffraction (XRD), thermogravimetric analysis (TGA), and Raman Spectroscopy. The composites were analyzed using Fourier-transform infrared spectroscopy (FTIR), molecular weight, contact angle measurements, and thermal, mechanical, and rheological analysis. Adding only 0.05 wt% of GO to both PLA and PLA/HA resulted in enhancements in mechanical properties, particularly tensile strength, and significantly modified the surface properties of the materials studied. Specifically, formulation involving PLA/HA/GO was the only one to exhibit rheological properties compatible with the scaffold production process via FDM. These specific formulations were also investigated regarding cytotoxicity, and the presence of GO induces good cytocompatibility in mouse osteoblast cells (MC3T3). These results suggest that FDM technology can be used to fabricate higher-performance (mechanical and biological) scaffolds for tissue engineering.

RELATED ARTICLES

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

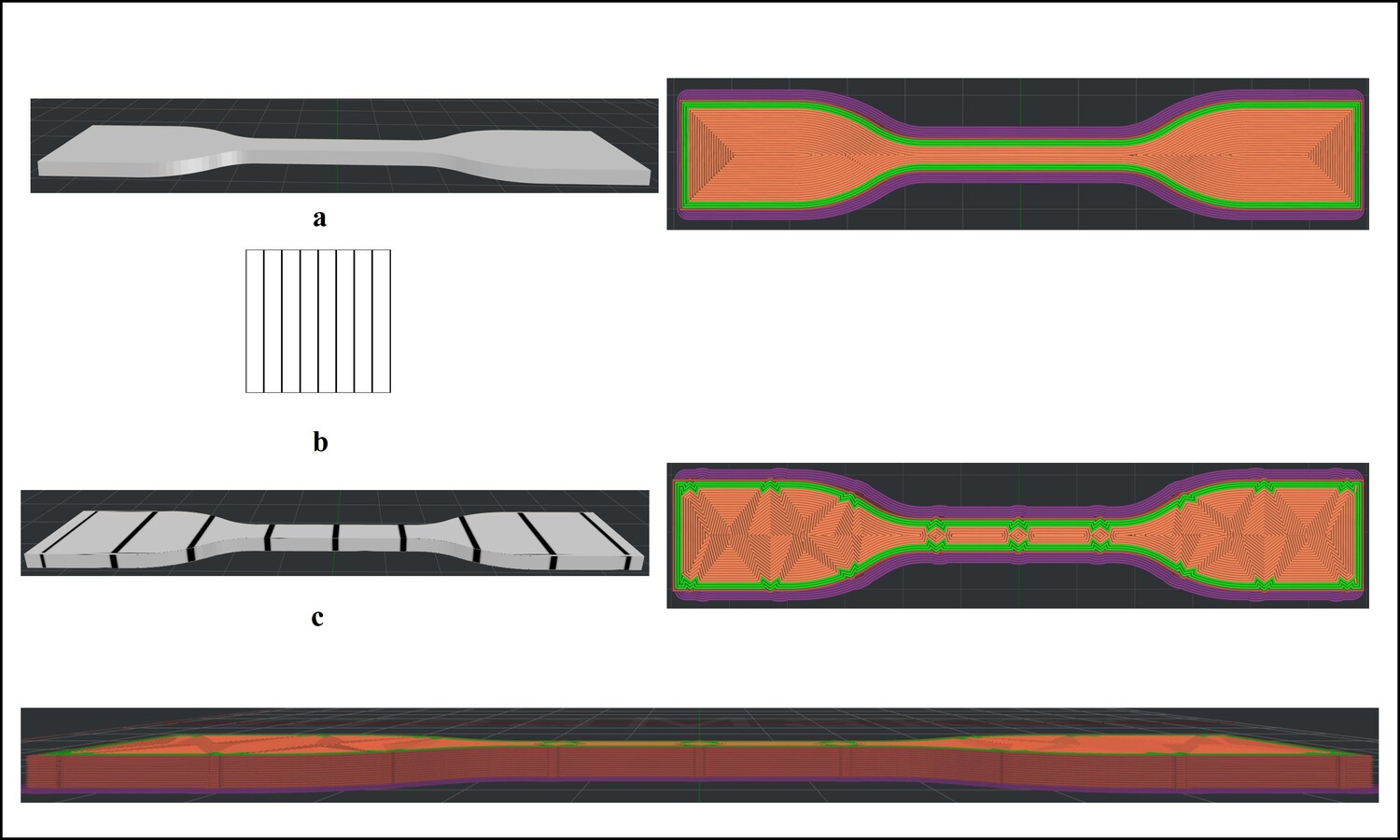

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

Aysun Güney, Lena Kernebeck, Dirk W. Grijpma

Vol. 18., No.4., Pages 349-358, 2024

DOI: 10.3144/expresspolymlett.2024.26

Vol. 18., No.4., Pages 349-358, 2024

DOI: 10.3144/expresspolymlett.2024.26

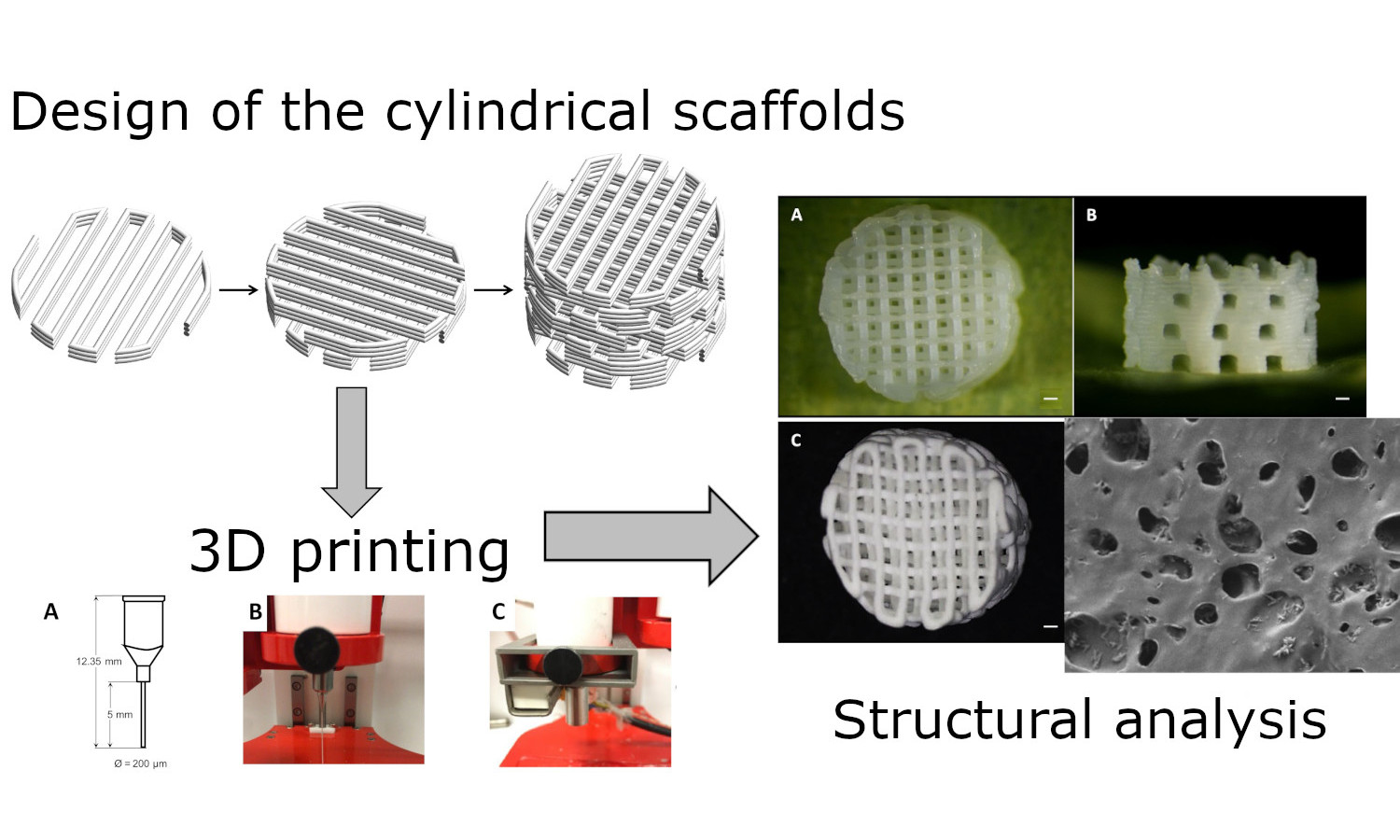

Biodegradable porous poly(ε-caprolactone)-poly(trimethylene carbonate)-poly(ε-caprolactone) triblock copolymers (PCL-b-PTMC-b-PCL) were synthesized by sequentεial polymerization of trimethylene carbonate (TMC) and ε-caprolactone (CL), and novel composites of PCL-b-PTMC-b-PCL with different amounts of nano-apatite (nAp) were prepared. This PTMC-based polymer matrix, which does not degrade into acidic compounds, together with the nanometer-sized apatite, which influences cell behavior, is an ideal bone regenerative material. Solvent casting these composites from chloroform solutions yielded solid films with excellent handling properties. The E-modulus of the nano-composite materials increases with nAp content, while toughness, tensile strength and elongation at break decrease. Using EC as solvent, porous composite films of PCL-b-PTMC-b-PCL and nAp could readily be prepared. The composites in EC were processed into form-stable designed tissue engineering scaffolds by 3D printing at relatively mild conditions. Besides the pore network structure with pores of 530 to 620 μm which corresponded to the design, smaller pores of 5–30 μm (due to EC crystallization) and even smaller ones of 200–500 nm (resulting from liquid-liquid exchange upon extraction of the solvent in the polymer rich phase) were observed in the printed composite scaffolds.