Processing effects on crystal morphology and application performance of blown films from propylene-ethylene random copolymers

Markus Zach, Davide Tranchida, Enrico Carmeli, Jingbo Wang, Markus Gahleitner, Bernhard Hofko, Elena Pomakhina, Minna Aarnio-Winterhof

Vol. 18., No.7., Pages 715-727, 2024

DOI: 10.3144/expresspolymlett.2024.53

DOI: 10.3144/expresspolymlett.2024.53

GRAPHICAL ABSTRACT

ABSTRACT

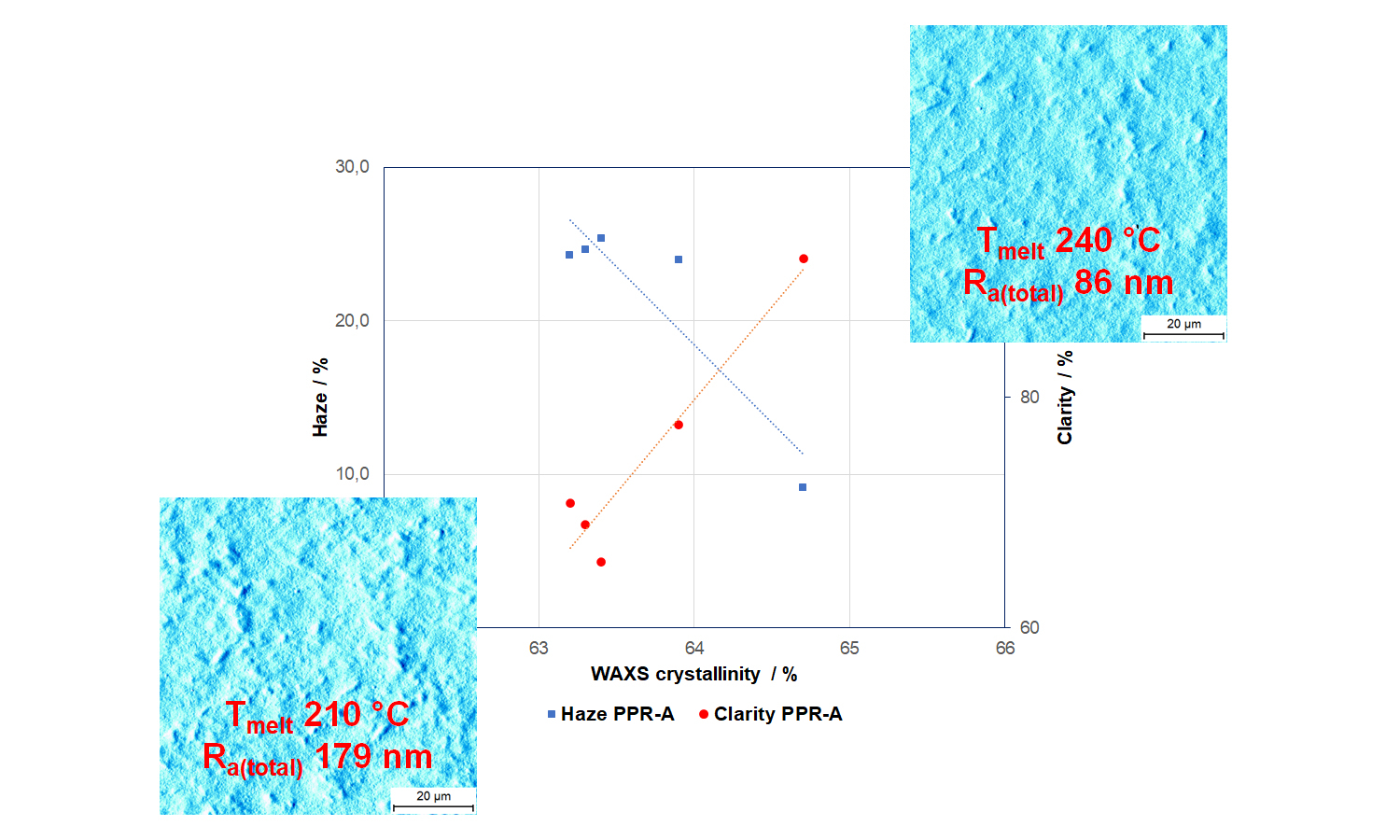

Blown films from ethylene-propylene random copolymers (C2C3-RACOs) are used in many packaging applications today, constituting a major fraction of both mono- and multilayer packaging film constructions. Combining high processing speed and output with good mechanical and optical performance, mostly high toughness and low haze, requires understanding the structure-property-processing relations. To improve said understanding for C2C3-RACO blown films, two commercial grades with a nearly identical C2 content of ~4.4 wt% and identical melt flow rate (MFR) but different nucleation were selected. These were tested in a processing study, varying melt temperature, blow-up ratio (BUR) and neck length. The film structure was analysed by wide angle X-ray scattering (WAXS) and atomic force microscopy (AFM), and the performance by standard mechanical and optical tests. Variation of film crystallinity was found to be in the range of 62 to 65%, much smaller than in earlier cast film studies on comparable polymers. The tensile modulus is the only performance parameter for which a general positive correlation to crystallinity can be found, blown films being about 50% stiffer than the softest cast films of a comparable polymer. Ductility and toughness are enhanced by higher orientation, resulting from higher BUR and/or higher neck length. For transparency and haze, low surface roughness is decisive at comparable crystallinity, which can be achieved by increasing melt temperature.

RELATED ARTICLES

Sona Zenzingerova, Michal Kudlacek, Jana Navratilova, Lenka Gajzlerova, David Jaska, Lubomir Benicek, Roman Cermak

Vol. 17., No.11., Pages 1110-1120, 2023

DOI: 10.3144/expresspolymlett.2023.84

Vol. 17., No.11., Pages 1110-1120, 2023

DOI: 10.3144/expresspolymlett.2023.84

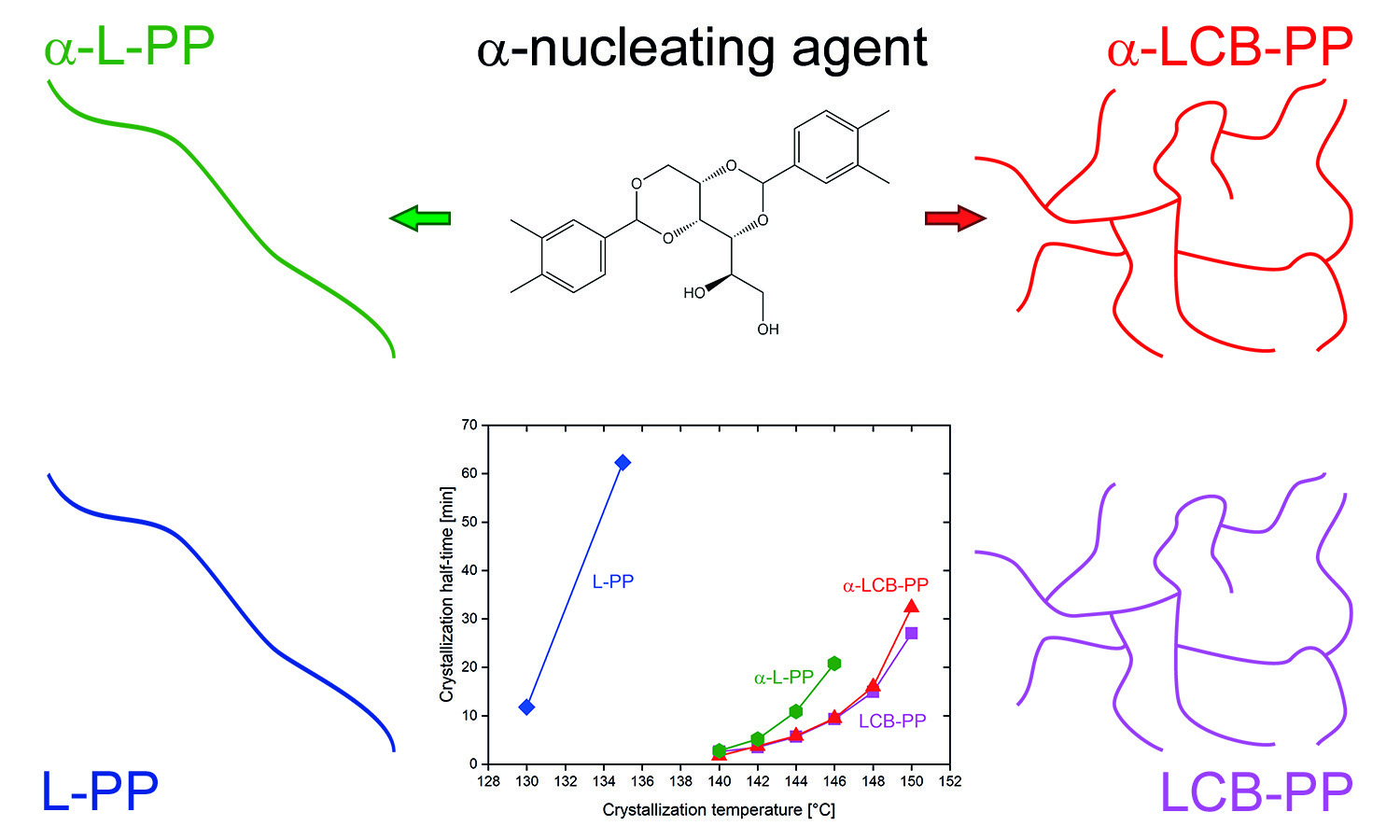

The

main purpose of this work is to present the effect of long-chain branching and

specific α-nucleation on the optical properties, crystallization and

supermolecular structure of polypropylene (PP). Commercially available α-nucleating/clarifying

agent 1,3;2,4-bis(3,4-dimethylbenzylidene)sorbitol (Millad 3988) was mixed into

linear PP and long-chain branched PP (LCB-PP) in the concentration of 0.2 wt%.

For the study of polymorphic composition, crystallinity, and crystallization process

under isothermal conditions in the temperature range of 130–150 °C,

differential scanning calorimetry and wide-angle X-ray scattering were used.

Although the used nucleating/clarifying agent appears to have a slight effect

on the optical properties of long-chain branched polypropylene, it does not

appear to affect the crystallization kinetics significantly. LCB-PP exhibited

self-nucleation, favored over nucleation by a specific nucleating agent.