The competition between self-seeding and specific nucleation in crystallization of long-chain branched polypropylene

Sona Zenzingerova , Michal Kudlacek

, Michal Kudlacek , Jana Navratilova

, Jana Navratilova , Lenka Gajzlerova

, Lenka Gajzlerova , David Jaska

, David Jaska , Lubomir Benicek

, Lubomir Benicek , Roman Cermak

, Roman Cermak

, Michal Kudlacek

, Michal Kudlacek , Jana Navratilova

, Jana Navratilova , Lenka Gajzlerova

, Lenka Gajzlerova , David Jaska

, David Jaska , Lubomir Benicek

, Lubomir Benicek , Roman Cermak

, Roman Cermak

Vol. 17., No.11., Pages 1110-1120, 2023

DOI: 10.3144/expresspolymlett.2023.84

DOI: 10.3144/expresspolymlett.2023.84

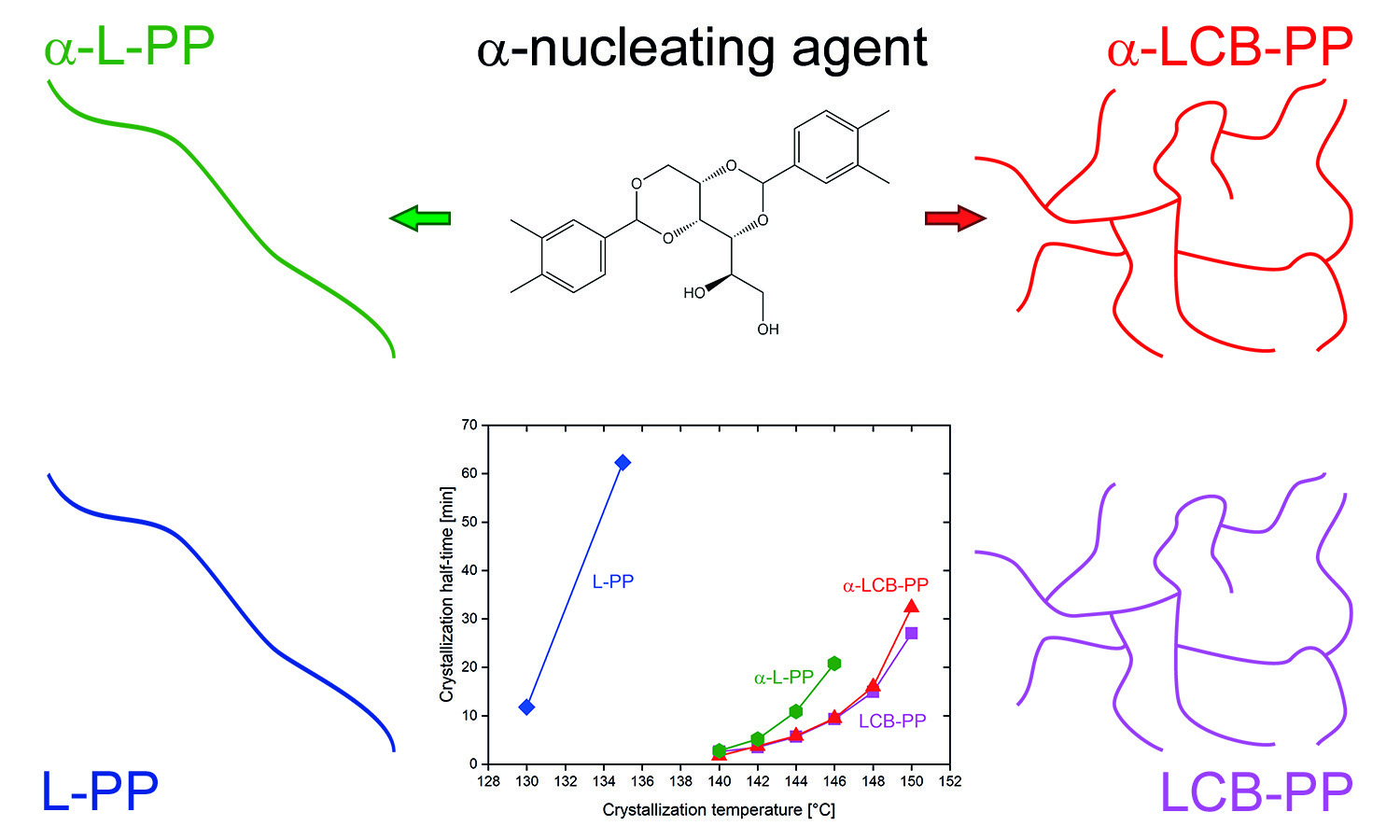

GRAPHICAL ABSTRACT

ABSTRACT

The

main purpose of this work is to present the effect of long-chain branching and

specific α-nucleation on the optical properties, crystallization and

supermolecular structure of polypropylene (PP). Commercially available α-nucleating/clarifying

agent 1,3;2,4-bis(3,4-dimethylbenzylidene)sorbitol (Millad 3988) was mixed into

linear PP and long-chain branched PP (LCB-PP) in the concentration of 0.2 wt%.

For the study of polymorphic composition, crystallinity, and crystallization process

under isothermal conditions in the temperature range of 130–150 °C,

differential scanning calorimetry and wide-angle X-ray scattering were used.

Although the used nucleating/clarifying agent appears to have a slight effect

on the optical properties of long-chain branched polypropylene, it does not

appear to affect the crystallization kinetics significantly. LCB-PP exhibited

self-nucleation, favored over nucleation by a specific nucleating agent.

RELATED ARTICLES

Dazhi Zhu, Junhao Wang, Yongheng Sun, Jianqiang Chu, Zhaobo Wang

Vol. 19., No.4., Pages 361-371, 2025

DOI: 10.3144/expresspolymlett.2025.27

Vol. 19., No.4., Pages 361-371, 2025

DOI: 10.3144/expresspolymlett.2025.27

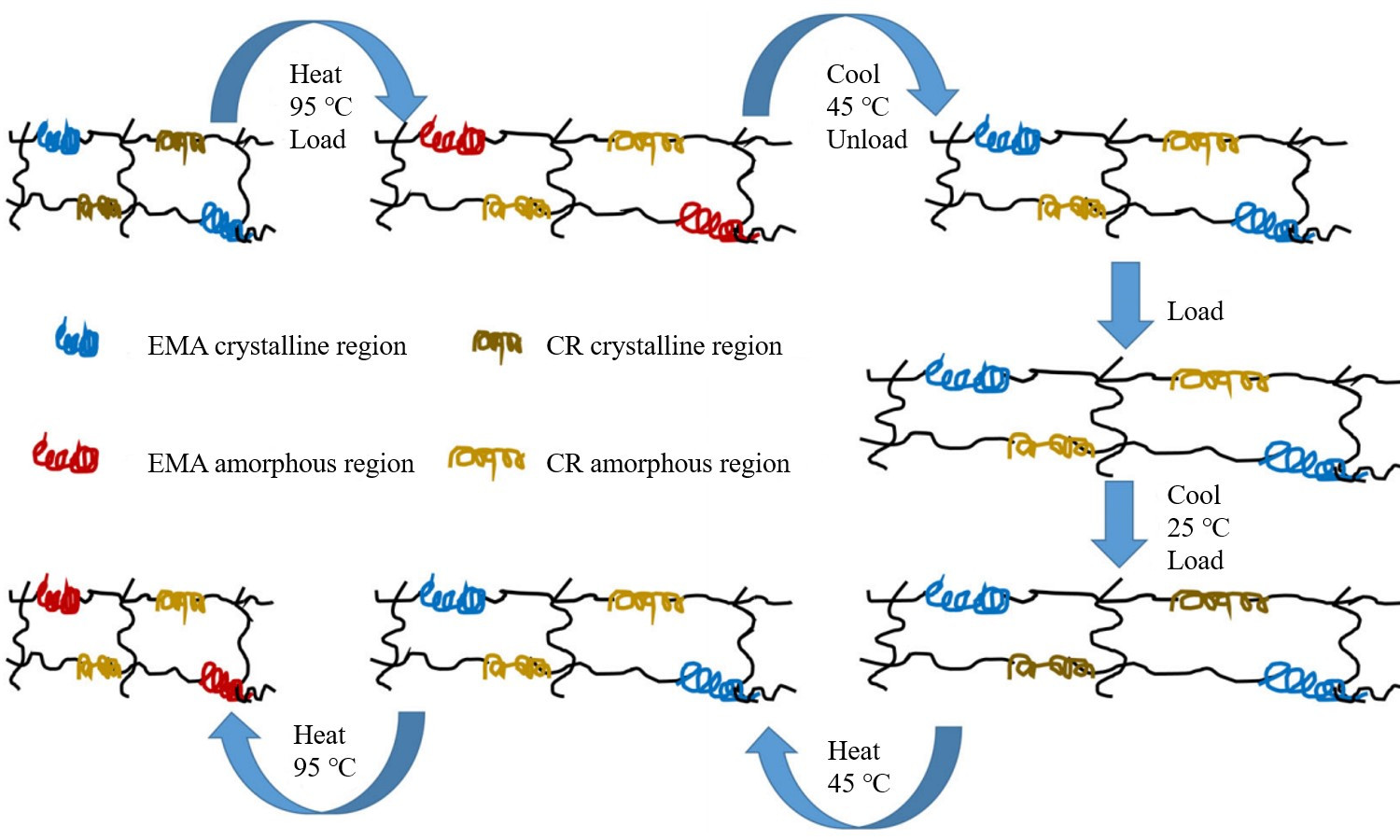

In this research, heat-triggered triple-shape memory polymers (TSMPs) based on the ethylene-methyl acrylate copolymer (EMA)/chloroprene rubber (CR) thermoplastic vulcanizates (TPVs) were prepared by dynamic vulcanization successfully; meanwhile, an effective and facile triple-shape memory strategy was designed to realize the efficient and stable shape fixity and recovery of two temporary shapes. The field-emission scanning electron microscope images showed that EMA/CR TPV surface was a sea-island structure with the CR particle size ranging from 3 to 6 μm. Differential scanning calorimeters and X-ray diffraction were used to investigate the crystallization behavior of both EMA and CR. These served as a significant basis for the two temporary shapes: fixity and recovery. The results of triple-shape memory tests showed that the EMA/CR TPV had excellent triple-shape memory properties, where the first shape fixity ratio was higher than 89% and both the first shape recovery ratio and second shape recovery ratio could be higher than 95%. It can be observed that the EMA/CR TPV exhibited rapid shape recovery speed with the first shape recovery time of 10 s and the second shape recovery time of 20 s, respectively. This research presents a novel approach to extending the application of TPV in the field of smart devices, endowing them with excellent mechanical and triple-shape memory properties.

Soňa Zenzingerová, Jana Navratilova, Lenka Gajzlerová, Michal Kudláček, David Jaška, Lubomir Benicek, Roman Čermák

Vol. 18., No.9., Pages 921-930, 2024

DOI: 10.3144/expresspolymlett.2024.69

Vol. 18., No.9., Pages 921-930, 2024

DOI: 10.3144/expresspolymlett.2024.69

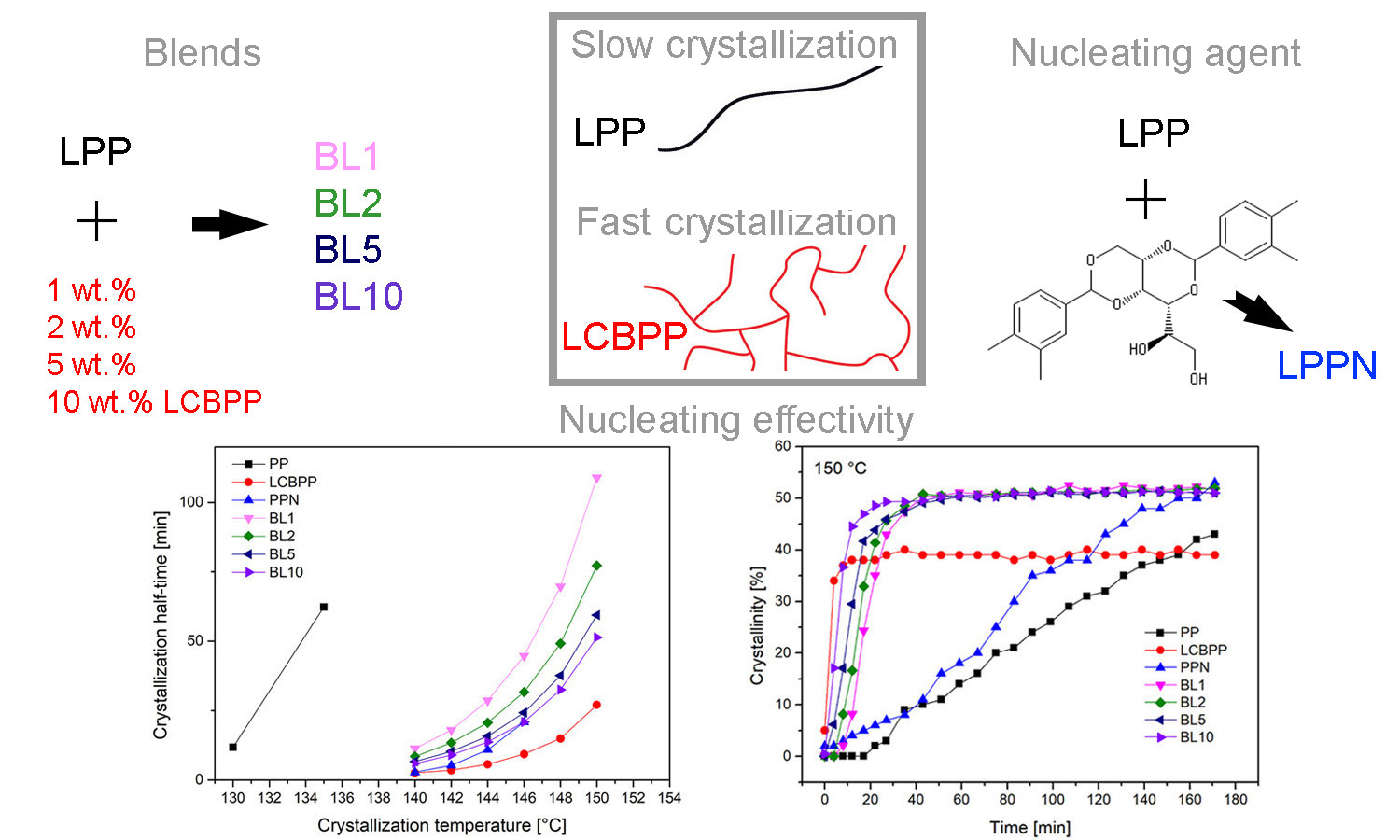

This study compares the efficiency of commercially available sorbitol-based clarifying agent (NA) and varying amounts of long chain-branched polypropylene (LCBPP) acting as a specific α-nucleating agent for linear polypropylene (PP). The sorbitol-based clarifying agent, 1,3;2,4-bis(3,4-dimethyl benzylidene)sorbitol (Millad 3988), in concentration 0.2 wt%, and LCBPP in the concentration of 1, 2, 5 and 10 wt% were mixed into PP. The comparison of the effect of NA and long branches under isothermal conditions on the crystallization process, crystallinity and polymorphic composition was realized by differential scanning calorimetry and wide-angle X-ray scattering. The addition of long chain-branched polypropylene, even at the lowest concentration, performs better at higher crystallization temperatures and has a superior effect on the crystallization process, crystallization rate and overall crystallization than the addition of NA.

Toughness enhancement of polyamide 1012 with intermolecular hydrogen bonding with 3-pentadecylphenol

Jing Lu, Qin Ma, Jianqi Yao, Jiajie Yin, Ruiyan Zhang, Faliang Luo

Vol. 18., No.7., Pages 705-714, 2024

DOI: 10.3144/expresspolymlett.2024.52

Vol. 18., No.7., Pages 705-714, 2024

DOI: 10.3144/expresspolymlett.2024.52

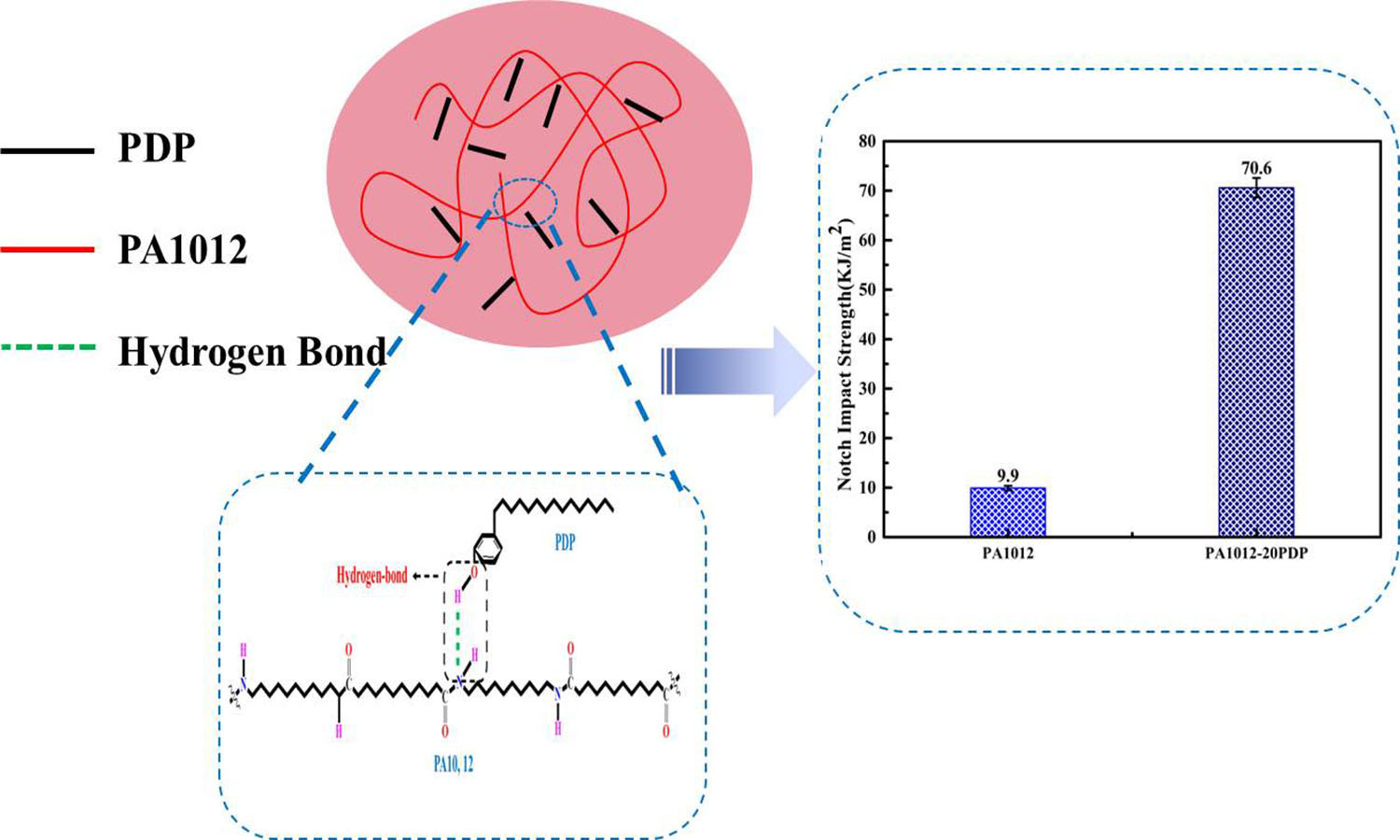

In order to improve the impact toughness of polyamide 1012 (PA1012) by reducing the amount of hydrogen bonding resulting from PA1012 itself, 3-pentadecylphenol (PDP) was considered to be added into PA1012 using melting extrusion. The hydrogen bonding interaction between PA1012 and PDP was characterized by Fourier transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR). The effects of PDP on the crystallization, melting process, and mechanical behavior of PA1012 were tested in detail. The results show that the PDP can reduce the temperature of PA1012 crystallization and melting but it can significantly improve elongation at break and impact toughness. The notched impact strength of the PA1012/PDP composites containing 20 wt% PDP reached to 70.6 kJ·m–2, which is about seven times that of the neat PA1012. The effects of PDP on PA1012 properties is ascribed to hydrogen bonding interaction between hydrogen bonding between phenol hydroxyl groups and amino groups on PA1012 chains. The deduction was also verified by adding acetylated 3-pentadecylphenol (APDP) to modify PA1012. It is believed the research will open up new prospects for the wide application of PA1012 toughening.

Markus Zach, Davide Tranchida, Enrico Carmeli, Jingbo Wang, Markus Gahleitner, Bernhard Hofko, Elena Pomakhina, Minna Aarnio-Winterhof

Vol. 18., No.7., Pages 715-727, 2024

DOI: 10.3144/expresspolymlett.2024.53

Vol. 18., No.7., Pages 715-727, 2024

DOI: 10.3144/expresspolymlett.2024.53

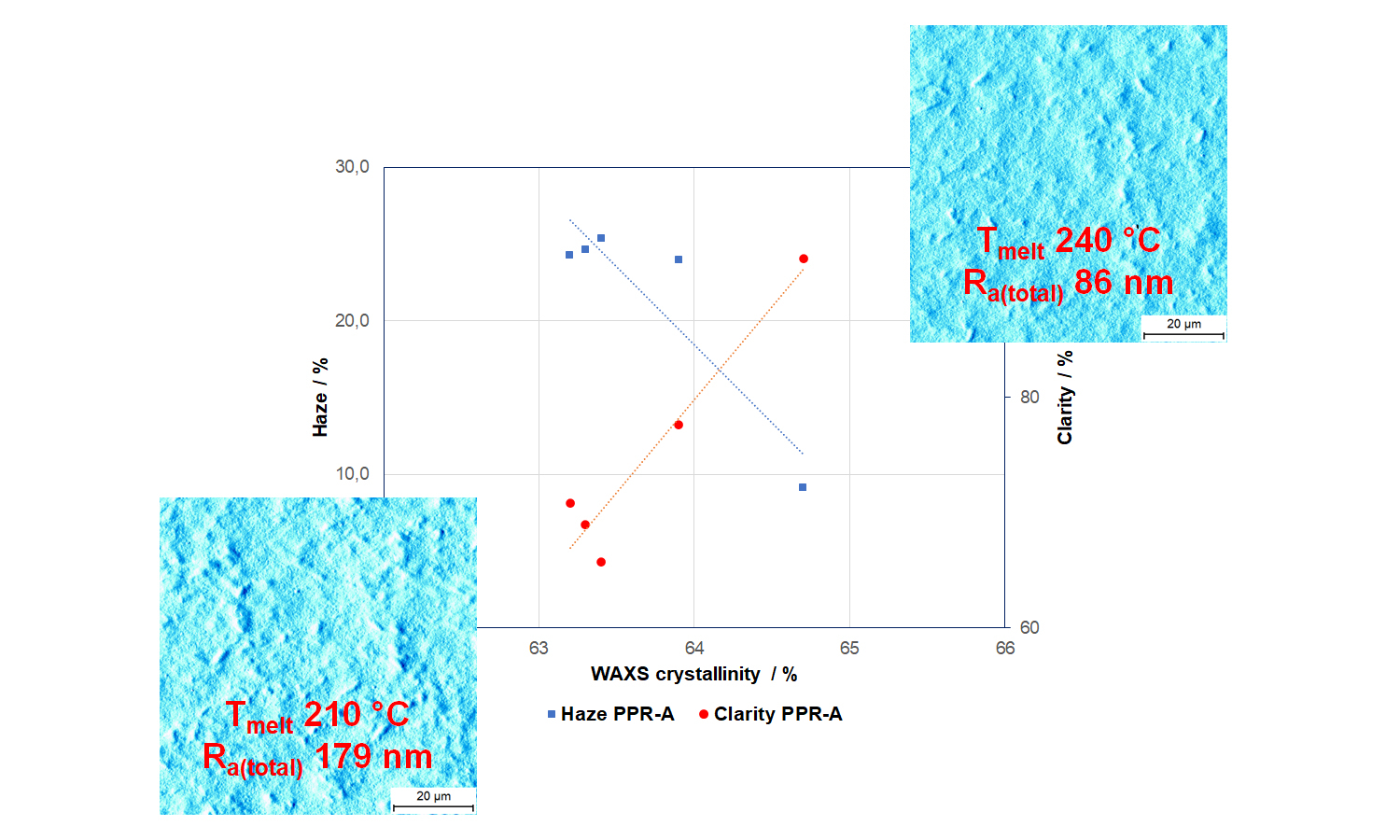

Blown films from ethylene-propylene random copolymers (C2C3-RACOs) are used in many packaging applications today, constituting a major fraction of both mono- and multilayer packaging film constructions. Combining high processing speed and output with good mechanical and optical performance, mostly high toughness and low haze, requires understanding the structure-property-processing relations. To improve said understanding for C2C3-RACO blown films, two commercial grades with a nearly identical C2 content of ~4.4 wt% and identical melt flow rate (MFR) but different nucleation were selected. These were tested in a processing study, varying melt temperature, blow-up ratio (BUR) and neck length. The film structure was analysed by wide angle X-ray scattering (WAXS) and atomic force microscopy (AFM), and the performance by standard mechanical and optical tests. Variation of film crystallinity was found to be in the range of 62 to 65%, much smaller than in earlier cast film studies on comparable polymers. The tensile modulus is the only performance parameter for which a general positive correlation to crystallinity can be found, blown films being about 50% stiffer than the softest cast films of a comparable polymer. Ductility and toughness are enhanced by higher orientation, resulting from higher BUR and/or higher neck length. For transparency and haze, low surface roughness is decisive at comparable crystallinity, which can be achieved by increasing melt temperature.