What is the next step for bioplastics?

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

DOI: 10.3144/expresspolymlett.2024.81

GRAPHICAL ABSTRACT

RELATED ARTICLES

Elumalai Vengadesan, Swaminathan Muralidharan, Dhanjit Das, Thirugnanasambandam Arunkumar

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

Vol. 19., No.8., Pages 822-842, 2025

DOI: 10.3144/expresspolymlett.2025.63

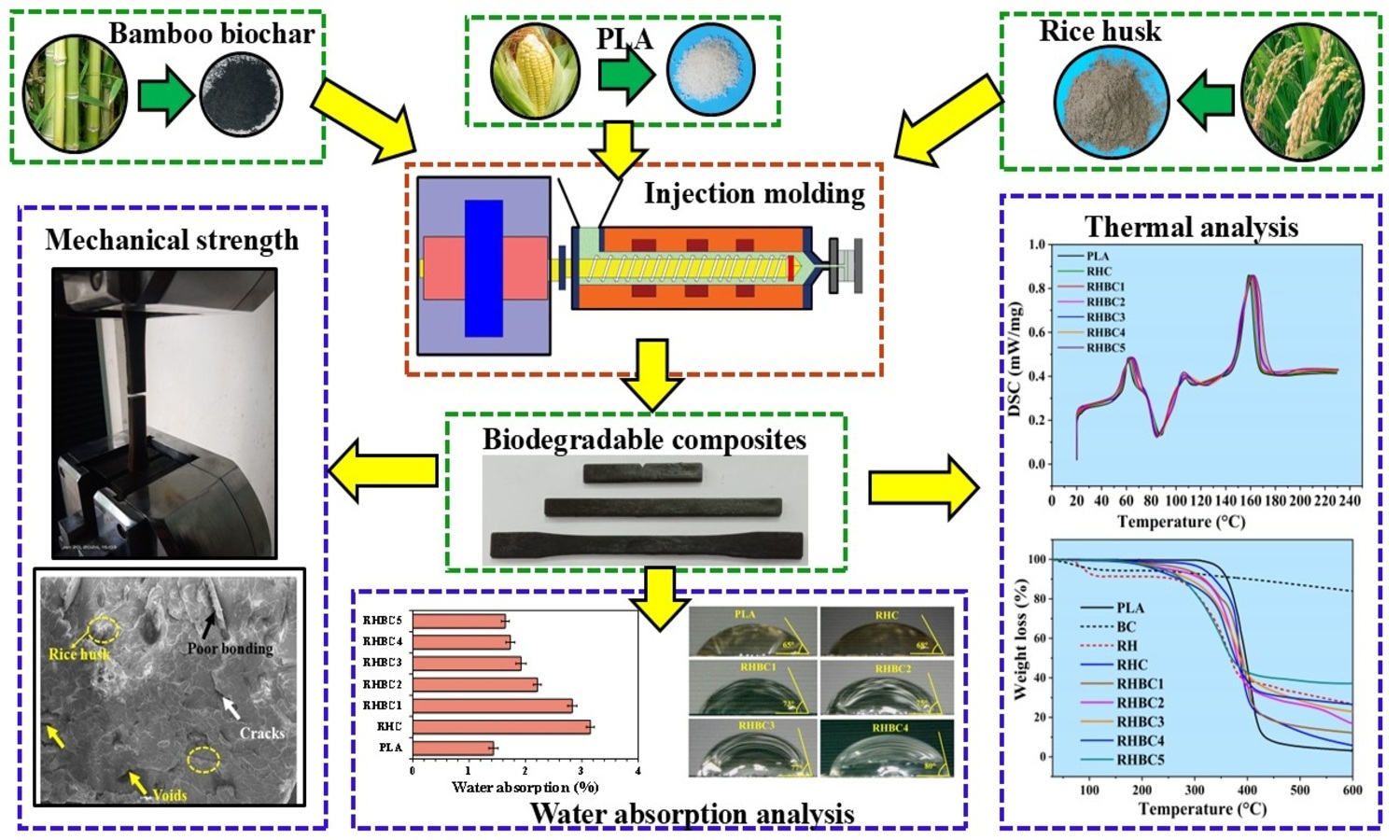

The growing need for sustainable materials has stimulated research into eco-friendly composites, with biochar emerging as an important reinforcement in polymer matrices. Biochar is a carbon-rich material produced by pyrolyzing organic biomass, offering various benefits over traditional fillers, including sustainability, waste reduction, and carbon sequestration. This study explores the effects of bamboo biochar as a hybrid reinforcement on the properties of polylactic acid (PLA)-rice husk composites. The present hybrid composites are prepared by varying the bamboo biochar from 5–25% and have better mechanical properties than PLA and its composite reinforced with a rice husk filler. The tensile, flexural, and compressive strengths of 51.5, 166.0, and 77.5 MPa are measured for the biochar percentage of 10%, representing increases of 73.1, 150.0, and 58.2% compared to PLA, and 158.2, 98.6, and 31% compared to the PLA composite with rice husk. Higher tensile and flexural moduli of 1.46 and 7.34 GPa are observed for 10 and 15%, respectively. However, the impact strength decreases with higher biochar content due to increased rigidity. The material’s hardness increases at higher biochar content due to enhanced stiffness. Thermal transition and degradation points rise due to increased crystallinity from the biochar reinforcement’s nucleation effect. Additionally, the hydrophobic biochar reinforcement reduces water absorption of PLA composite from 3.2 to 1.6%.

Guilherme Ribeiro de Carvalho, Rafael Affonso Netto, Camila Delarmelina, Marta Cristina Teixeira Duarte, Liliane Maria Ferrareso Lona

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

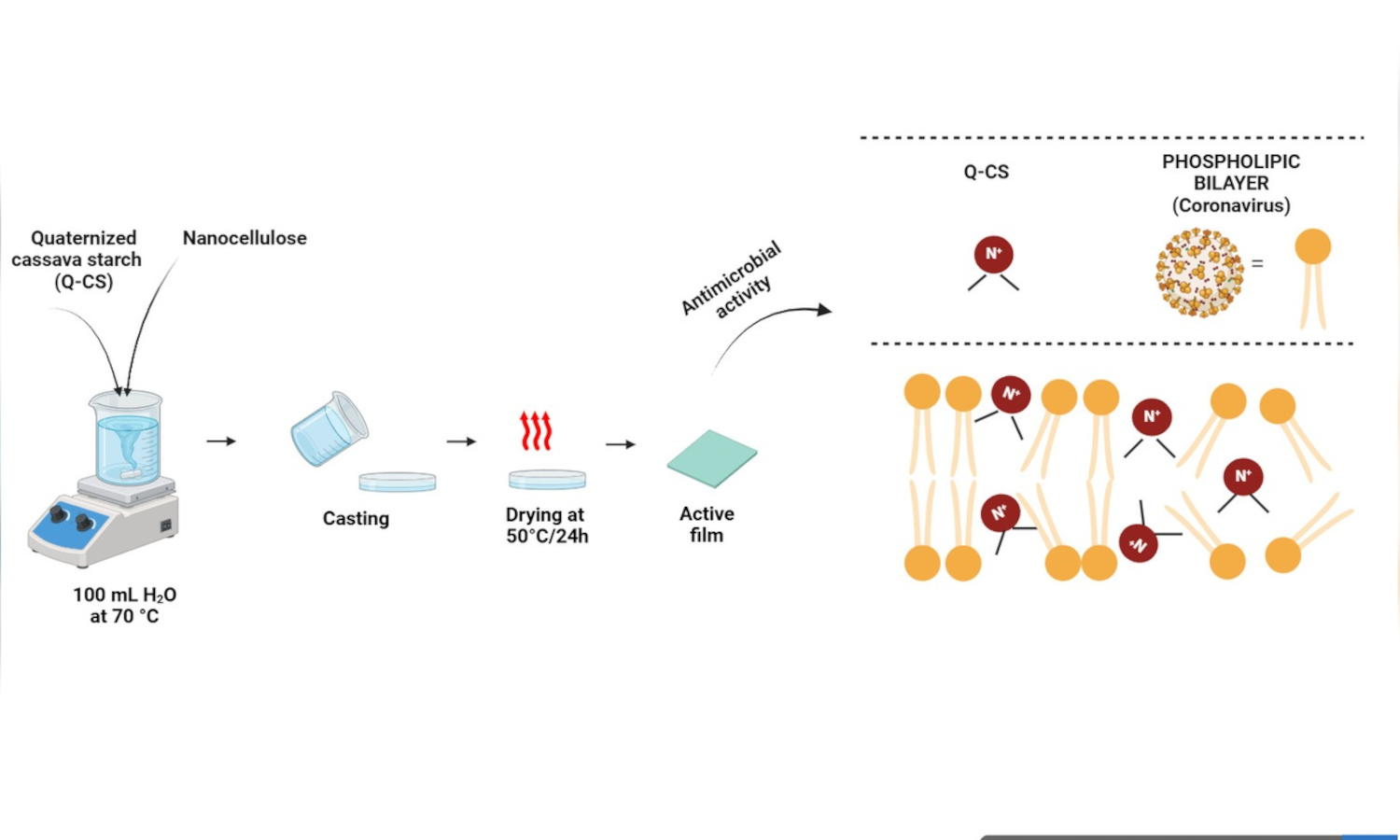

In this study, a new plastic film with antiviral and antibacterial properties was developed using modified cassava starch with glycidyltrimethylammonium chloride (GTMAC) and reinforced by crystalline nanocellulose (CNC), called Q-CS/CNC. For comparison, a control film (Q-CS) was produced without the addition of CNC. Elemental analysis revealed a degree of substitution (DS) of 0.552, indicating the replacement of the OH groups of starch by the NR4+ groups of GTMAC during the quaternization reaction. The addition of CNC resulted in significant increases (p < 0.05) of 38.9, 38.2, and 43.1% in thickness, opacity, and water vapor permeability measurements, respectively, compared to Q-CS. Incorporating CNC also contributed to an increase of 43.6% in tensile strength and 109% in stiffness but slightly decreased thermal stability. The Q-CS/CNC film demonstrated efficacy by inactivating 99% of the coronavirus in 1 min and inhibiting the growth of Staphylococcus aureus and Escherichia coli. This action is attributed to the electrostatic interaction of quaternary amino groups, grafted onto starch, with the phospholipid membrane of microorganisms, resulting in the inactivation of these microorganisms. Therefore, these results highlight the potential use of Q-CS/CNC film as antimicrobial packaging, especially against coronavirus.

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

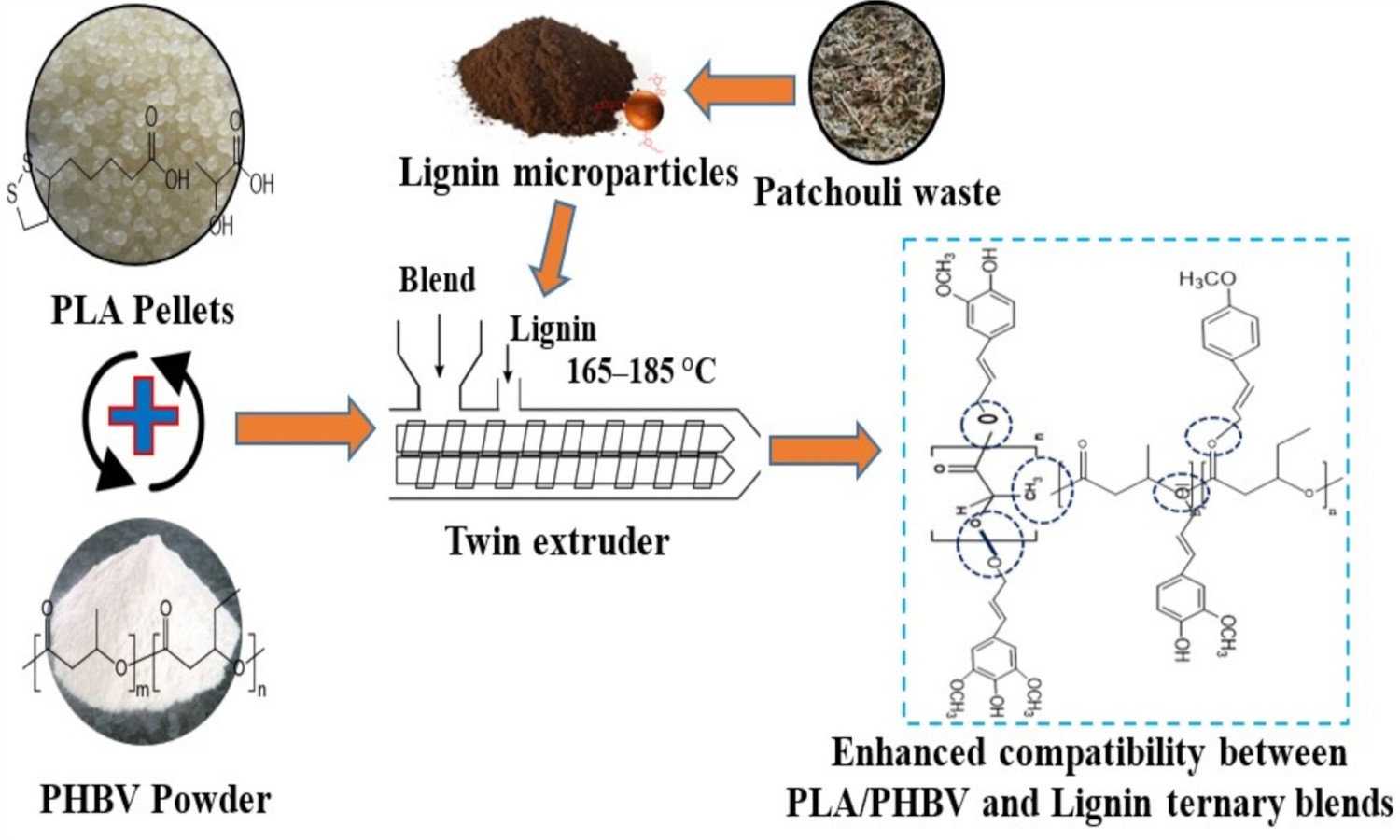

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

Alice da Conceição Alves de Lima, Andréa Monteiro Santana Silva Brito, Viviane Fonseca Caetano, Glória Maria Vinhas

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

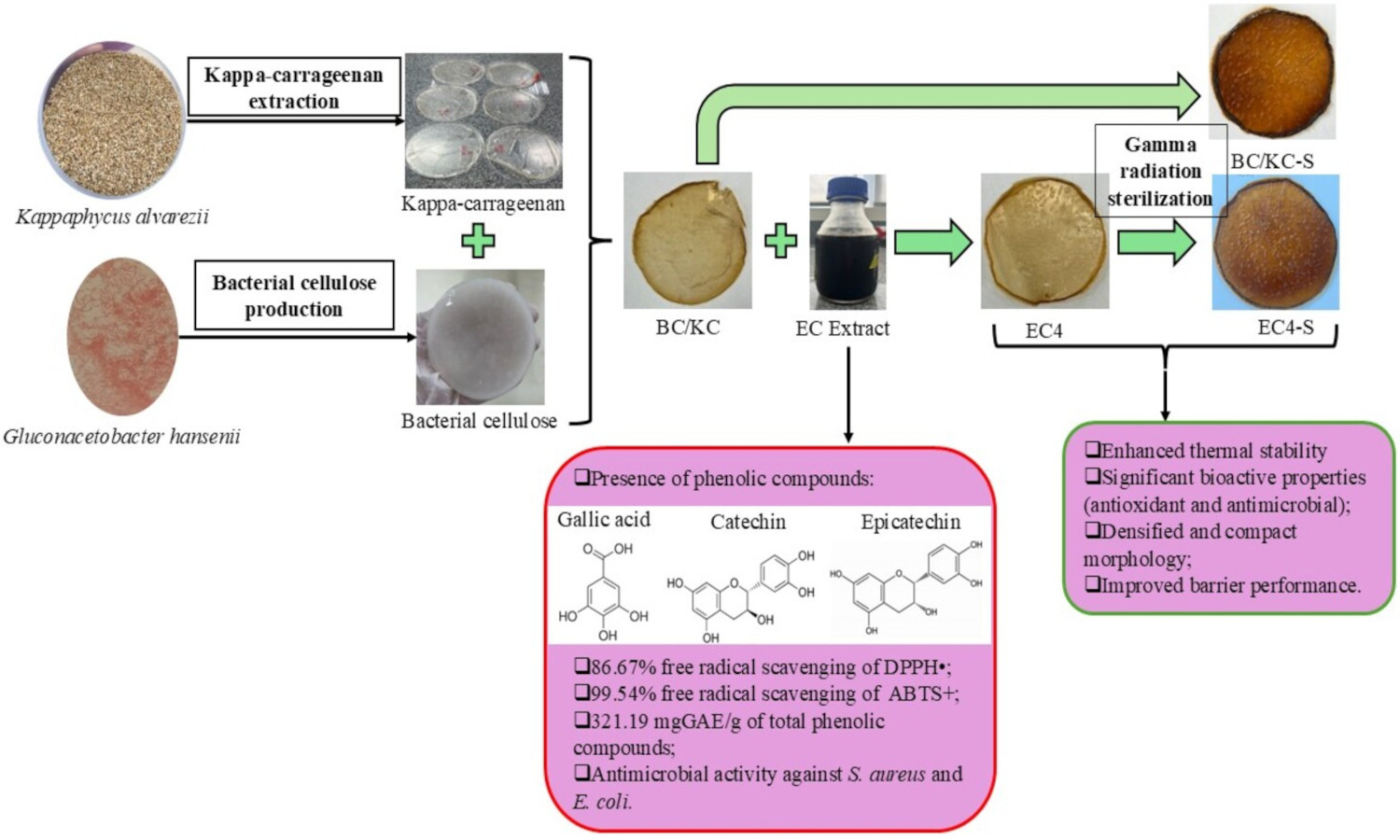

Biopolymer-based packaging, such as bacterial cellulose (BC) and kappa-carrageenan (KC), offers a sustainable solution to environmental challenges. The incorporation of bioactive extracts enhances antioxidant and antimicrobial properties, while gamma radiation sterilization ensures microbiological safety, improving functionality for food preservation and promoting sustainability in the packaging industry. The objective of this work was to develop a BC film incorporated with KC solution (1%, v/v) and cashew bark extract (EC) at concentrations of 1, 2, and 4% (v/v) for use as active food packaging. EC exhibited a total phenolic content of 321.19 mgGAE/g and showed 86.67 and 99.54% radical scavenging activity for 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2″-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), respectively. EC also displayed antimicrobial activity against S. aureus and E. coli, confirming its antimicrobial potential. BC/KC films incorporated with EC and irradiated with gamma radiation exhibited a thermal degradation in the range of 275–287 °C, maintaining good thermal stability. The water vapor permeability decreased by 55.12%, indicating improved barrier properties and the film’s morphology became more compact after EC incorporation and irradiation. BC/KC films show promises for extending the food shelf life as active packaging.

Seisuke Ata, Takumi Ono, Motonari Shibakami

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

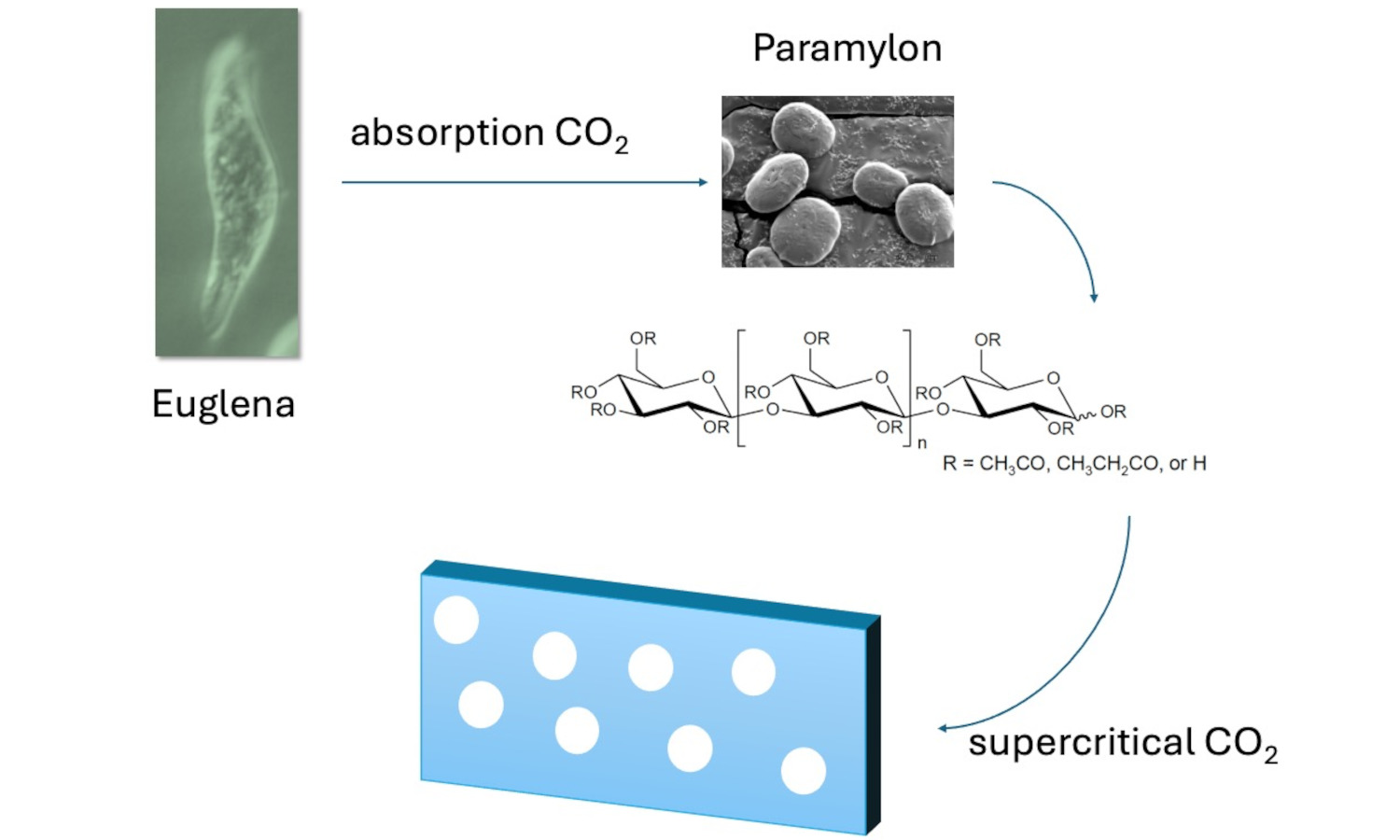

This study demonstrated, for the first time, the successful formation of porous paramylon esters, which were made from euglenoid polysaccharide known as paramylon and short-chain fatty acids, through supercritical CO2 processing. By maintaining a constant ester functional group attached to the paramylon and varying its proportion, distinct porous structures were selectively produced. Solubility parameter estimations indicated that changes in esterification had no significant effect on the solubility of the paramylon esters used in the experiment. Thus, these structural differences are likely attributed to variations in the viscoelastic properties of paramylon esters under supercritical CO2 conditions. Furthermore, thermal conductivity measurements revealed reductions of up to 20%. Intriguingly, substantial decreases in thermal conductivity were observed even at low foaming ratios, achieved through precise control of the porous structure.