Incorporation of cashew bark extract and gamma irradiation effects on biodegradable bacterial cellulose/kappa-carrageenan film

Alice da Conceição Alves de Lima , Andréa Monteiro Santana Silva Brito

, Andréa Monteiro Santana Silva Brito , Viviane Fonseca Caetano

, Viviane Fonseca Caetano , Glória Maria Vinhas

, Glória Maria Vinhas

, Andréa Monteiro Santana Silva Brito

, Andréa Monteiro Santana Silva Brito , Viviane Fonseca Caetano

, Viviane Fonseca Caetano , Glória Maria Vinhas

, Glória Maria Vinhas

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

DOI: 10.3144/expresspolymlett.2025.46

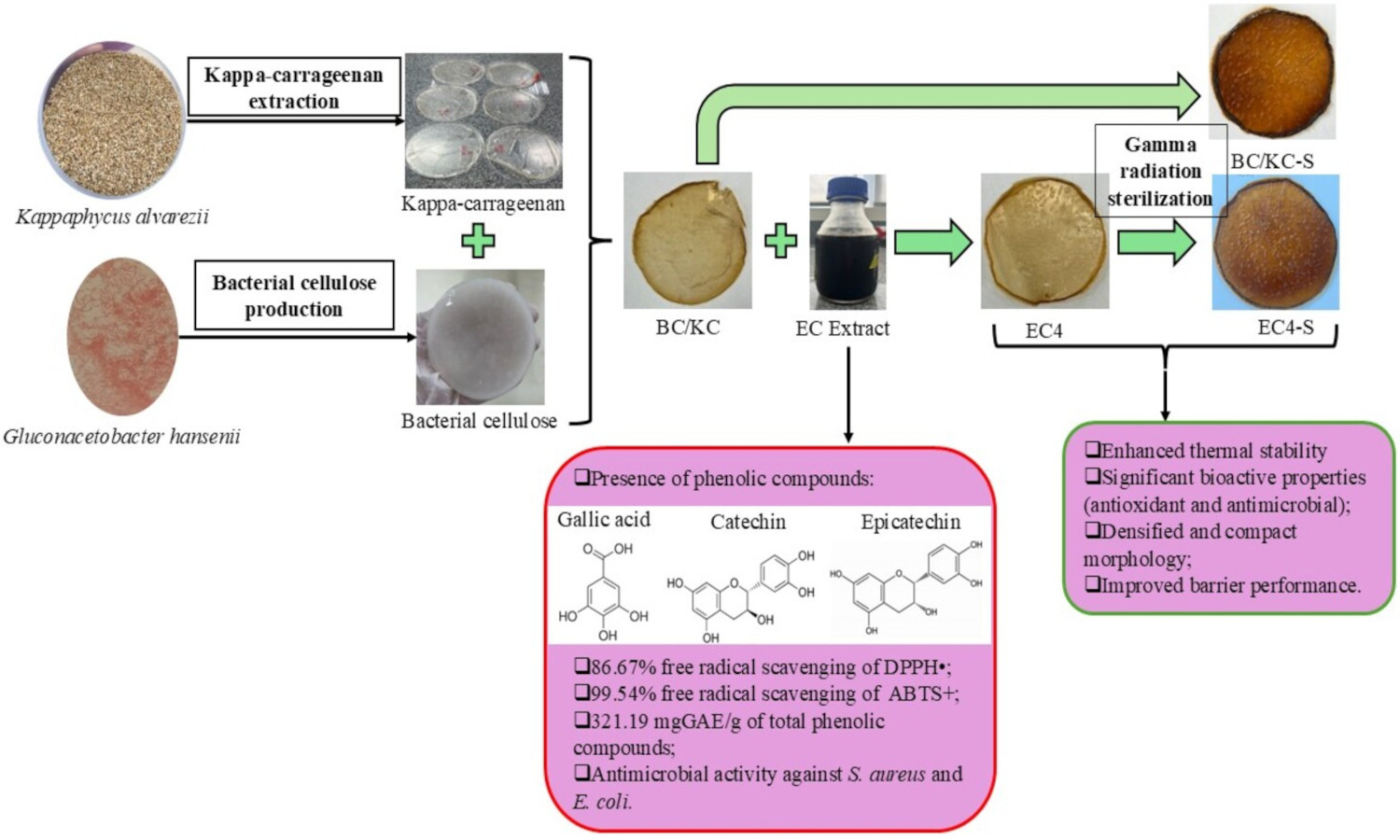

GRAPHICAL ABSTRACT

ABSTRACT

Biopolymer-based packaging, such as bacterial cellulose (BC) and kappa-carrageenan (KC), offers a sustainable solution to environmental challenges. The incorporation of bioactive extracts enhances antioxidant and antimicrobial properties, while gamma radiation sterilization ensures microbiological safety, improving functionality for food preservation and promoting sustainability in the packaging industry. The objective of this work was to develop a BC film incorporated with KC solution (1%, v/v) and cashew bark extract (EC) at concentrations of 1, 2, and 4% (v/v) for use as active food packaging. EC exhibited a total phenolic content of 321.19 mgGAE/g and showed 86.67 and 99.54% radical scavenging activity for 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2″-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), respectively. EC also displayed antimicrobial activity against S. aureus and E. coli, confirming its antimicrobial potential. BC/KC films incorporated with EC and irradiated with gamma radiation exhibited a thermal degradation in the range of 275–287 °C, maintaining good thermal stability. The water vapor permeability decreased by 55.12%, indicating improved barrier properties and the film’s morphology became more compact after EC incorporation and irradiation. BC/KC films show promises for extending the food shelf life as active packaging.

RELATED ARTICLES

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

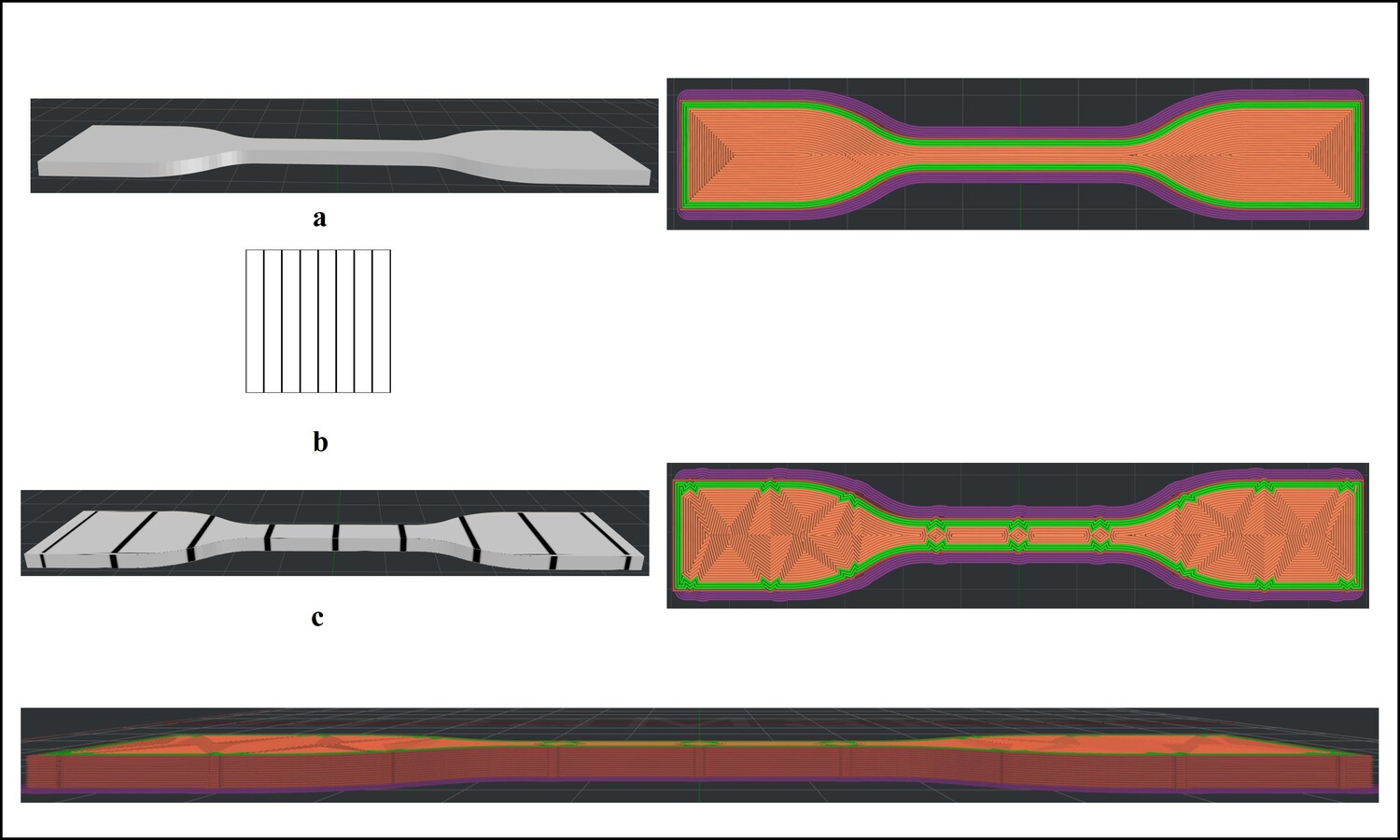

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

Karol Tutek, Anna Masek

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

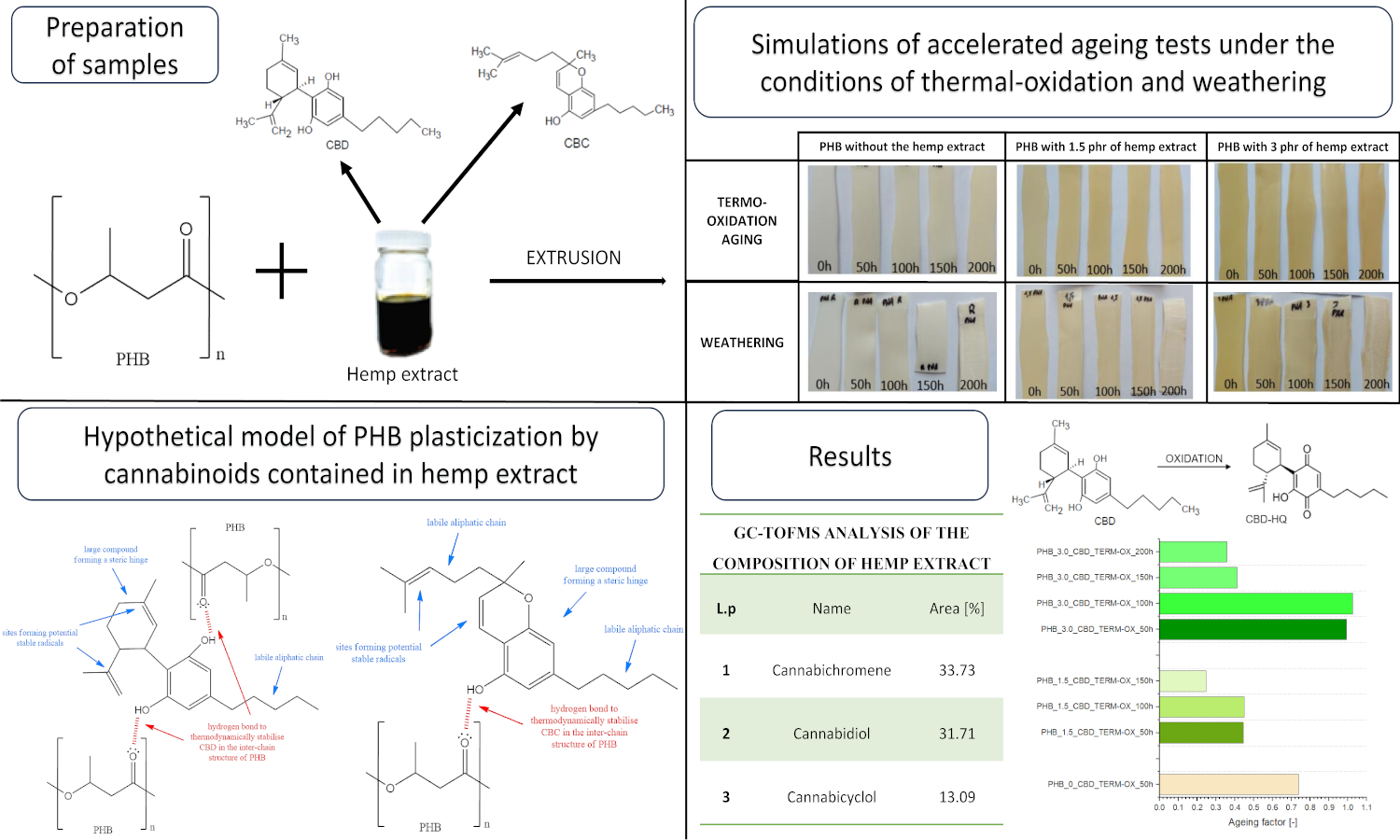

Biodegradable biopolymers like polyhydroxybutyrate (PHB) hold promise for sustainable packaging, but their inherent degradability reduces material stability. Synthetic stabilizers, though effective, raise environmental and potential toxicity concerns. This study explores a multifunctional natural anti-aging agent: a hemp extract rich in cannabidiol (CBD) and cannabichromene (CBC). PHB composites with varying hemp extract concentrations were prepared and subjected to thermooxidative and weathering aging. Characterization employed FTIR-ATR, carbonyl index, and spectrophotometry. Static mechanical properties, DSC, and surface free energy (SFE) were also assessed. Notably, the hemp extract exhibited stability under ambient conditions but showed migration with time and aging. The results suggest a plasticizing effect on PHB and highlight the contrasting roles of the extract: inhibiting thermooxidative aging while potentially accelerating aging under atmospheric conditions. This opens avenues for tailoring material durability, further evaluated by life cycle analysis (LCA). This work represents one of the first investigations into hemp extract as an anti-aging agent for eco-friendly polymers, expanding the knowledge base of natural multifunctional additives.

Tamás Tábi

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

This is an editorial article. It has no abstract.

Viktor Konstantin Dragan, Noémi Petrovics, Csaba Kirchkeszner, Tamás Tábi, Bálint Sámuel Szabó, Zsuzsanna Eke

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

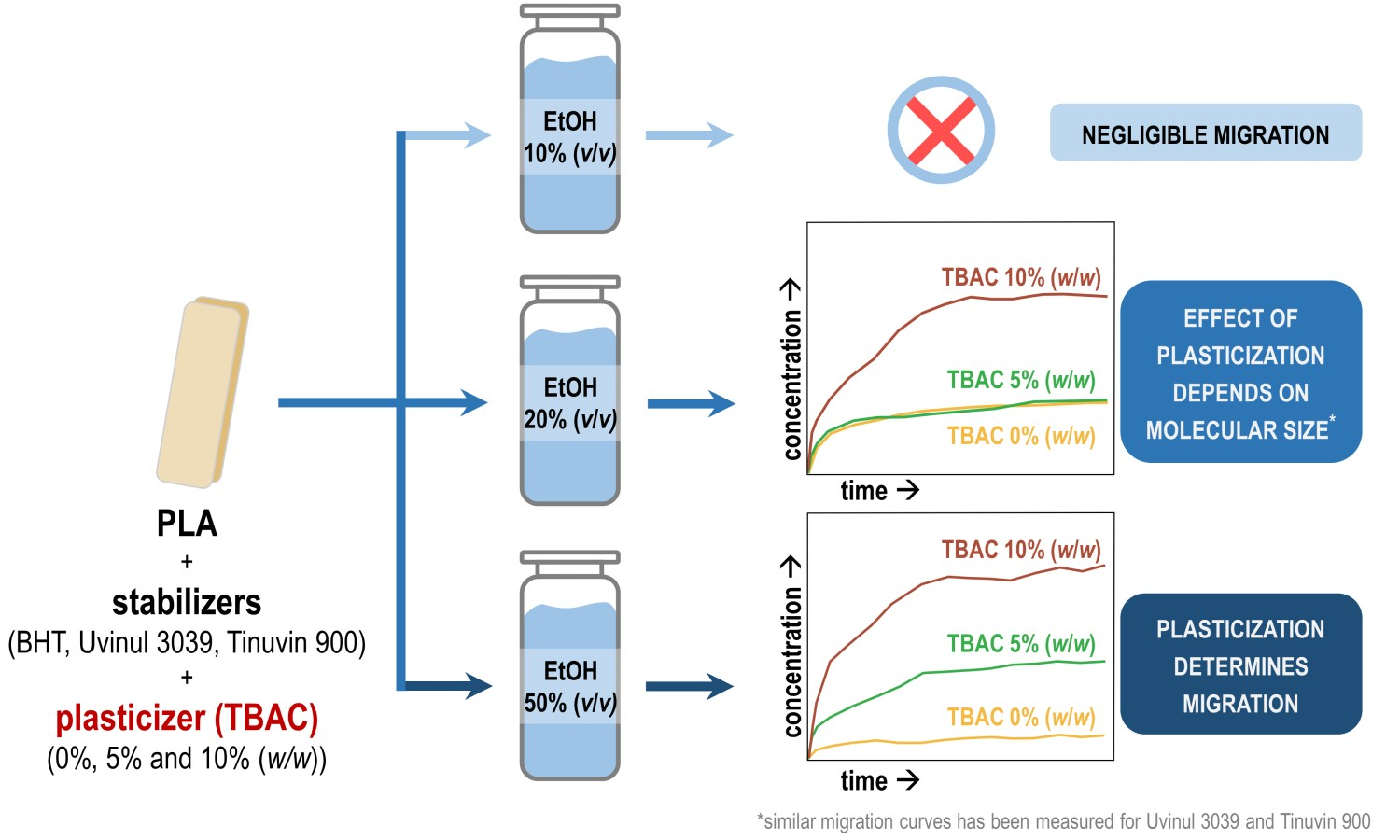

The

effect of swelling and plasticizer content of a plastic, as well as the ethanol

content of the food simulant on the migration kinetics of three stabilizer-type

additives from polylactic acid (PLA)-based food contact plastics has been

investigated. The results proved that the parameters that affect the diffusion

of substances inside the polymer matrix, i.e.,

swelling, plasticization, and the size of migrants, are the decisive factors in

the migration from PLA to ethanolic food simulants. Both swelling and migration

were negligible when ethanol 10% (v/v) was used. Contrarily, the specific

migration limits of Commission Regulation (European Union, EU) No. 10/2011 were

exceeded in ethanol 50% (v/v) for all investigated stabilizers. Migration was

promoted by plasticization, but this effect could only be observed when the

applied food simulant swelled the plastic (at least 20% (v/v) ethanol content).

The dependence of the plasticizer’s migration-enhancing effect on the swelling

has not been shown before. When the plasticization caused increased migration,

it also led to specific migration limit exceeding within a shorter period of

time. It happens even if PLA-based plastics are dedicated to the storage of

hydrophilic food, which is the most common application area of these products.

These results can support the improvement of both consumer safety and active

packaging development.

Praveen Kumar Sharma, Jae-Young Chung

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

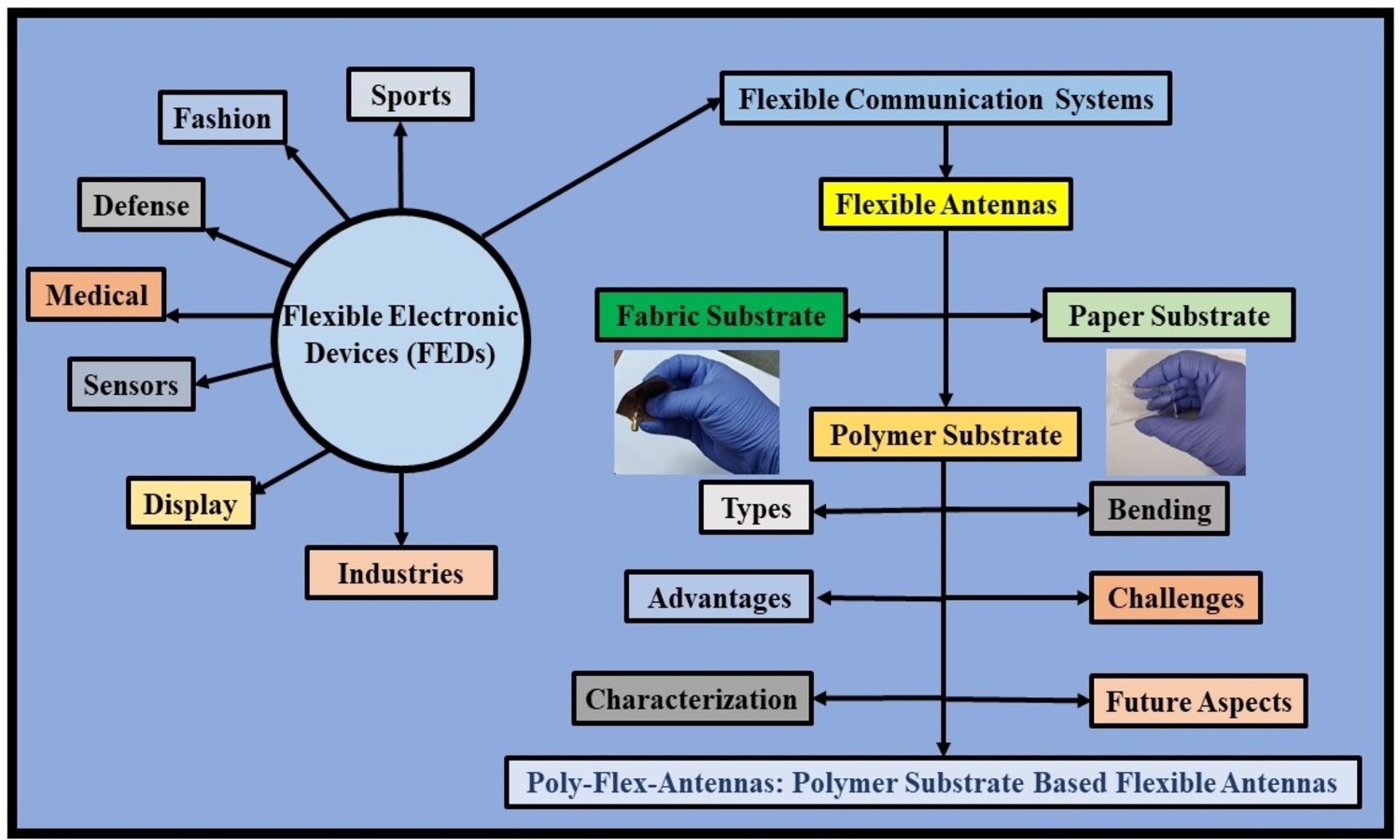

The

proliferation of flexible electronics has entirely transformed the field of

antenna design and paved the door for cutting-edge uses in communication,

sensing, and other areas. The present research lends a succinct overview of the

intriguing advancements in flexible antenna technology, with specific emphasis

on the implementation of polymer substrates. As we refer to poly-flex antennas in

this article, they stand for the incorporation of polymer substrates in antenna

design. Polymer substrates are the optimum candidate for flexible antenna

applications as they have specific advantages, including being lightweight,

conformable, and inexpensive. The main features of poly-flex antennas, such as

their design concepts, fabrication processes, and performance characteristics,

are being explored in this proposed article. We delve into the wide variety of

polymer substrates that are appropriate for antennas, taking into account their

dielectric characteristics, flexibility, and environmental resistance. Their

dielectric characterization, bending effects, challenges, and future prospects

of this burgeoning field are also addressed. We conclude by emphasizing the

immense potential of poly-flex-antennas to shape the future of wireless

communication and sensing systems, and how the adoption of polymer substrates

is driving innovation in antenna engineering.