Design and characterization of curcumin-loaded electrospun nanofibers based on poly(vinyl alcohol) and sodium alginate

Delia Mihaela Raţă , Anca Niculina Cadinoiu

, Anca Niculina Cadinoiu , Luiza Mădălina Grădinaru

, Luiza Mădălina Grădinaru , Paul Codrin Fuioaga

, Paul Codrin Fuioaga , Gabriela Vochita

, Gabriela Vochita , Christelle Delaite, Leonard Ionuţ Atanase

, Christelle Delaite, Leonard Ionuţ Atanase

, Anca Niculina Cadinoiu

, Anca Niculina Cadinoiu , Luiza Mădălina Grădinaru

, Luiza Mădălina Grădinaru , Paul Codrin Fuioaga

, Paul Codrin Fuioaga , Gabriela Vochita

, Gabriela Vochita , Christelle Delaite, Leonard Ionuţ Atanase

, Christelle Delaite, Leonard Ionuţ Atanase

Vol. 19., No.3., Pages 233-245, 2025

DOI: 10.3144/expresspolymlett.2025.18

DOI: 10.3144/expresspolymlett.2025.18

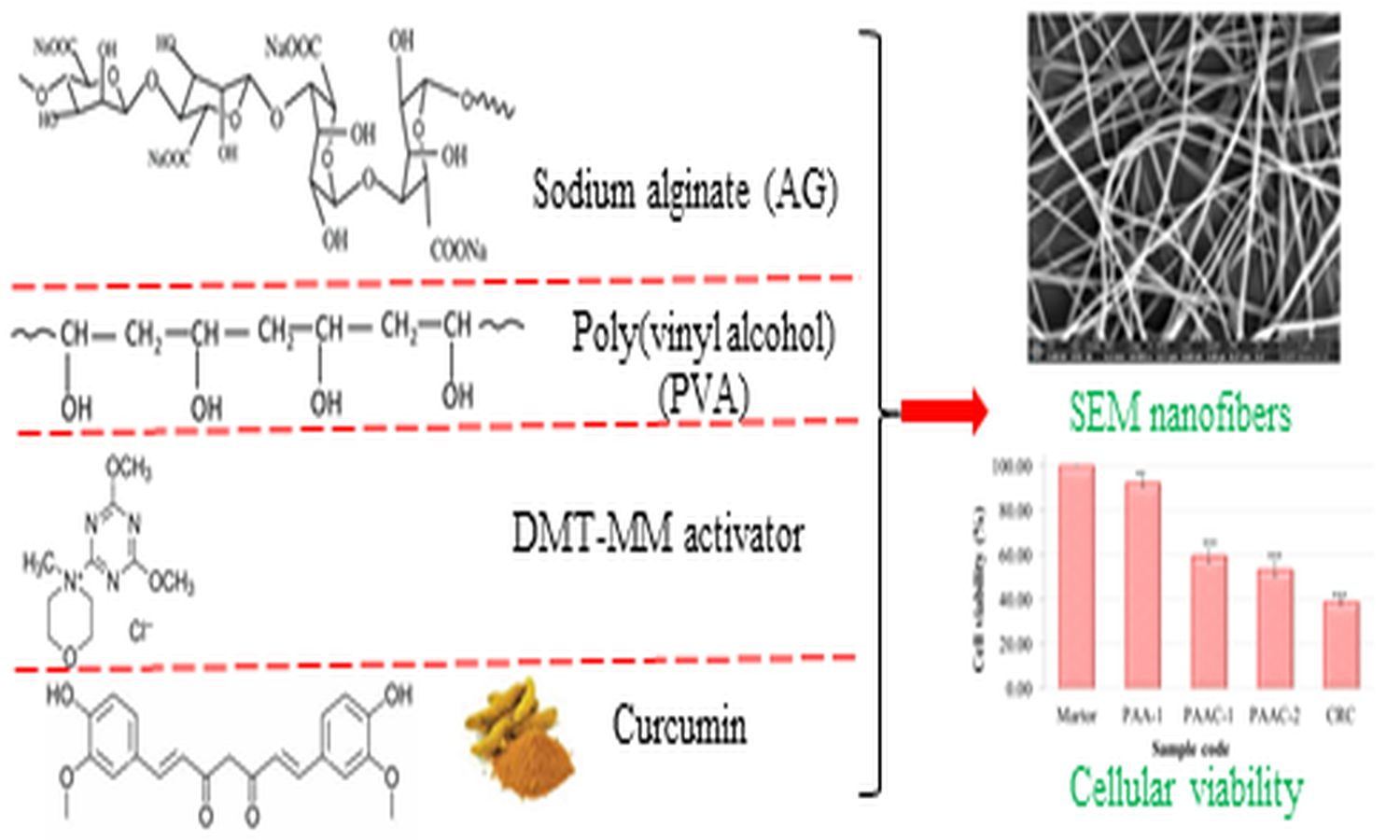

GRAPHICAL ABSTRACT

ABSTRACT

Curcumin (CRC) is a natural active principle with important anti-inflammatory, antioxidant, antibacterial, and antitumor properties but has some limitations, such as poor bioavailability, low water solubility, and rapid metabolism. To preserve CRC’s benefits and eliminate its limitations, novel CRC-loaded core-shell electrospun nanofibers were designed. The nanofibers were prepared by co-axial electrospinning method using poly(vinyl alcohol)/CRC as core and poly(vinyl alcohol)/sodium alginate as shell. Polymer coating protects the CRC, increasing its stability. The swelling degree of CRCloaded nanofibers at pH 5.4 was around 326% higher than at pH 7.4 (297%) due to the repulsions of the anion-anion COO–groups. The release efficiency of CRC at pH 7.4 was 81%, while at pH 5.4 was about 96%. In the first 6 h, there was a slower release of CRC from the nanofibers in both acidic and slightly alkaline environments. Nanofibers showed good hemocompatibility, the values being between 2.36–3.22% after the first 90 min of contact, and after 180 min of treatment, the degree of erythrocyte lysis was between 3.78 and 4.93%. Cell viability assay on V79-4 Chinese hamster fibroblasts demonstrated that treatment with free CRC led to a value of 39% whereas for CRC-loaded nanofibers, the cell viability value increased to 59.66%. The results of the present study indicated that CRC-loaded electrospun nanofibers can have great potential for biomedical applications.

RELATED ARTICLES

Kamonthip Rittimas, Skulrat Pichaiyut, Charoen Nakason

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

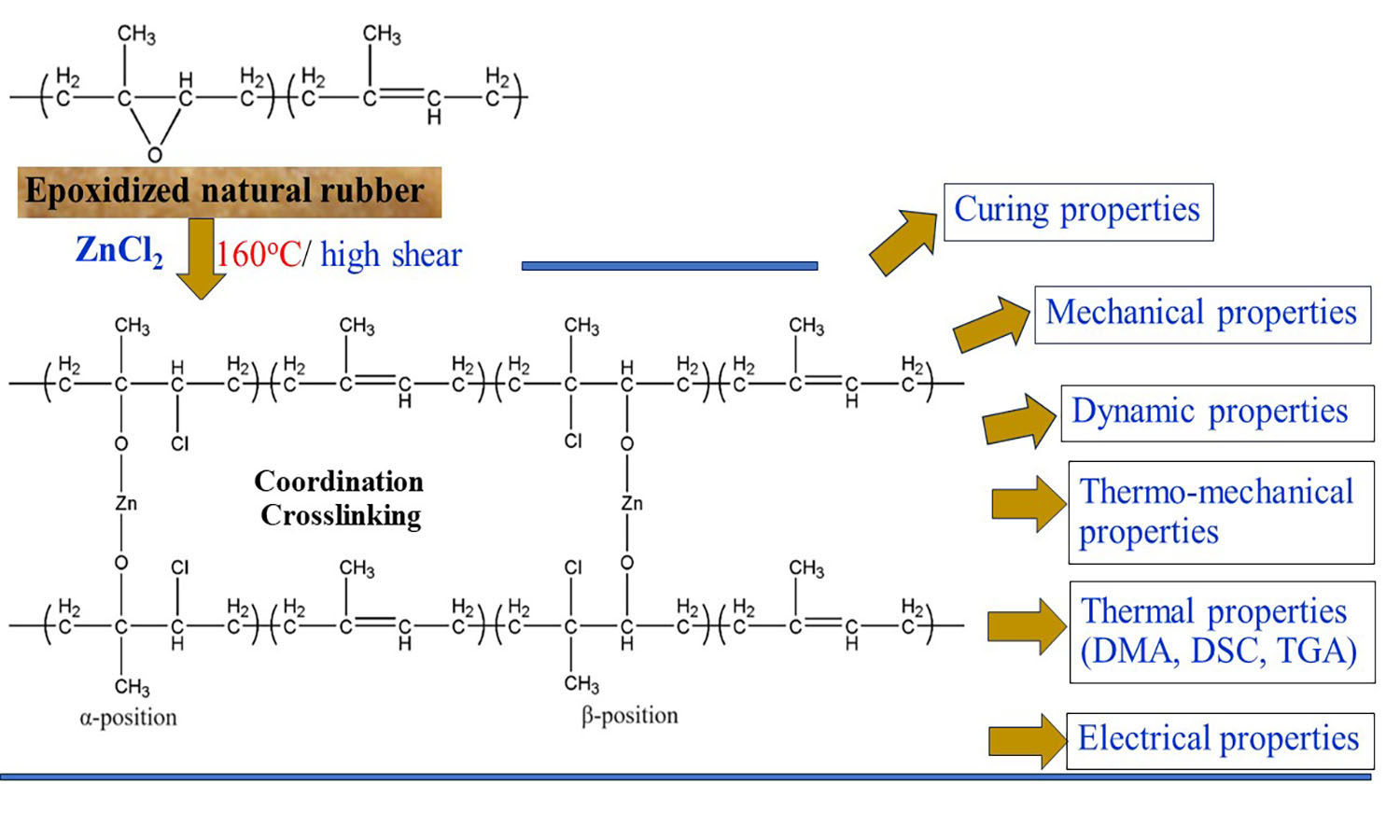

Epoxidized natural rubber with 50 mol% epoxide (ENR-50) was compounded with zinc chloride (ZnCl2) and subjected to torque response analysis using a moving die rheometer. It was found that different ZnCl2 concentrations (3, 5, 7, 9, and 12 millimoles (mmol)) mixed in ENR-50 exhibited positive torque responses, prompting further molecular characterization using Fourier transform infrared spectroscopy. The results indicated distinct absorption peaks at wavenumbers of 442 and 809 cm–1, which signify the presence of –O–Zn–O– coordination linkages. The curing characteristics of ENR and ZnCl2 compounds showed that increasing ZnCl2 content resulted in higher minimum and maximum torque values, but also led to a decrease in scorch time and cure rate index (CRI). Moreover, higher ZnCl2 concentrations enhanced the strength properties (tensile strength, moduli, stiffness, toughness, and hardness), crosslink densities, dynamic shear moduli, initial modulus during relaxation experiments, and thermal resistance, as evidenced by temperature scanning stress relaxation (TSSR), thermogravimetric analysis, and dynamic mechanical analysis. However, an increase in ZnCl2 content led to a reduction in elongation at break due to the higher crosslink density within the coordination networks in the ENR matrix, which resulted in the movement constraint of the rubber vulcanizate.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Phakawat Thongnuanchan, Pornsuwan Buangam

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

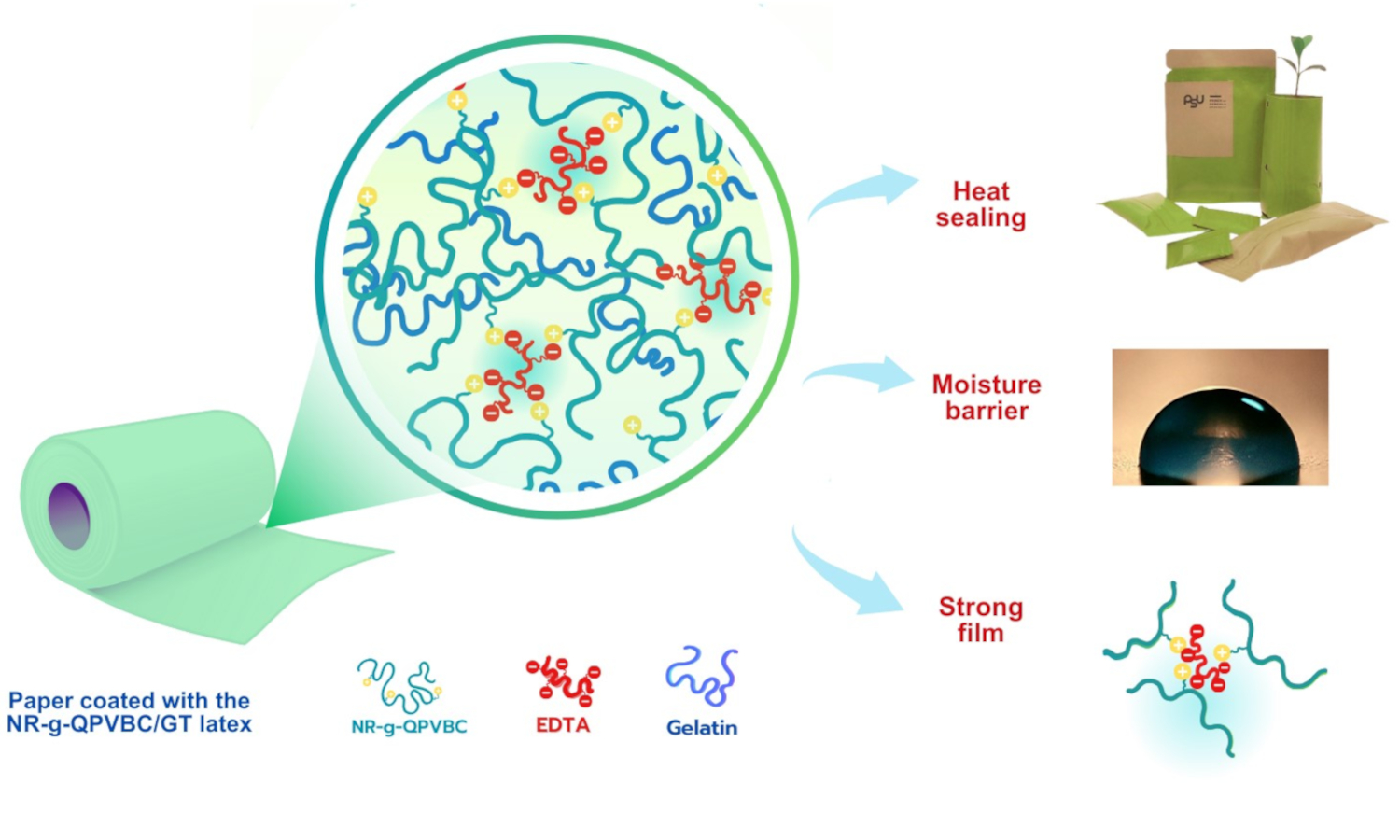

Research into sustainable packaging materials has gained increasing importance due to the pressing environmental concerns related to plastic waste. The present study focused on developing a sustainable paper coating based on modified natural rubber (NR) latex filled with gelatin (GT). The graft copolymer latex of NR and poly(vinylbenzyl chloride) bearing quaternary ammonium groups, abbreviated as NR-g-QPVBC, was first synthesized. GT was then incorporated into the latex, and the combination of these materials resulted in a heat-sealable film with good tensile properties and a water barrier. The ionic crosslinking of the latex film was achieved by the reaction with ethylenediaminetetraacetic acid (EDTA). Heat-sealing studies of the NR-g-QPVBC latex film filled with GT (NR-g-QPVBC/GT) revealed its heat-sealability at 160 °C. Scanning electron microscope (SEM) analysis further confirmed the diffusion of the chains across the interface during heat sealing. Dip coating was a method for depositing latex film on kraft paper. The paper coated with the NR-g-QPVBC/GT latex showed a significant increase in dry and wet-tensile strength compared to the uncoated paper. The sealing process was optimized to achieve a heat-seal strength of 755.31 N/m at a dwell time of 3 s and a temperature of 160 °C. The research's practical application was demonstrated by transforming the coated paper into various heat-sealable bags using a handheld bag sealer.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Anoma Thitithammawong

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

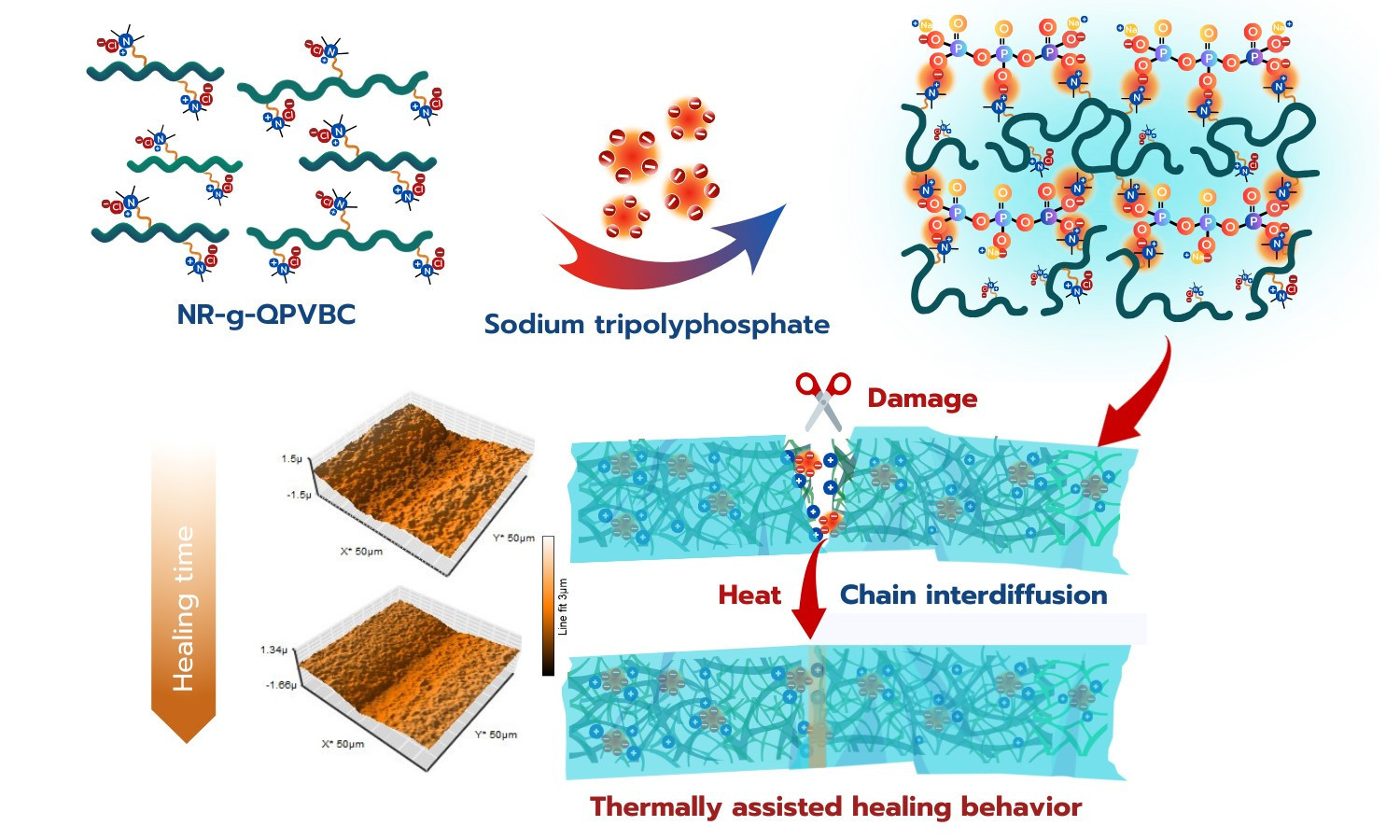

This work reported a practical approach to turning conventional natural rubber (NR) into a thermally healable rubber. 4-vinylbenzyl chloride was first polymerized in the NR latex to yield graft copolymers of NR and poly(vinylbenzyl chloride), NR-g-PVBC. The cutting and rejoining process was used to study the healing ability of latex film. The healing behavior was observed after the reassembled film was heated at 100 °C for 1 h and then allowed to heal continuously at room temperature (RT). The healed film displayed a 58.44% regain of the tensile strength (4.57 MPa) after being allowed to recover at RT for 72 h. Additionally, the chloromethyl moieties in the NR-g-PVBC could be converted into quaternary ammonium (QA) groups by reaction with trimethylamine, producing the quaternized NR-g-PVBC (NR-g-QPVBC). Ionic crosslinking of the NR-g-QPVBC film was achieved by incorporating sodium tripolyphosphate (STPP). The latex film had a tensile strength of 15.32 MPa and could withstand a strain of 868% when ionically cured with 2 phr of STPP. After the healing process, the cured film showed a healing efficiency of 49.67% in tensile strength (7.61 MPa). Furthermore, a suturing test was performed to investigate the feasibility of developing a suture training pad from the corresponding cured film. The film’s ability to heal with heat assistance was its significant practical advantage, enhancing its realism and mimicking the healing process in human skin.

Flavio Massignan, Gergő Gyulai , Kata Horváti, Szilvia Bősze, Éva Kiss

Vol. 18., No.1., Pages 72-87, 2024

DOI: 10.3144/expresspolymlett.2024.6

Vol. 18., No.1., Pages 72-87, 2024

DOI: 10.3144/expresspolymlett.2024.6

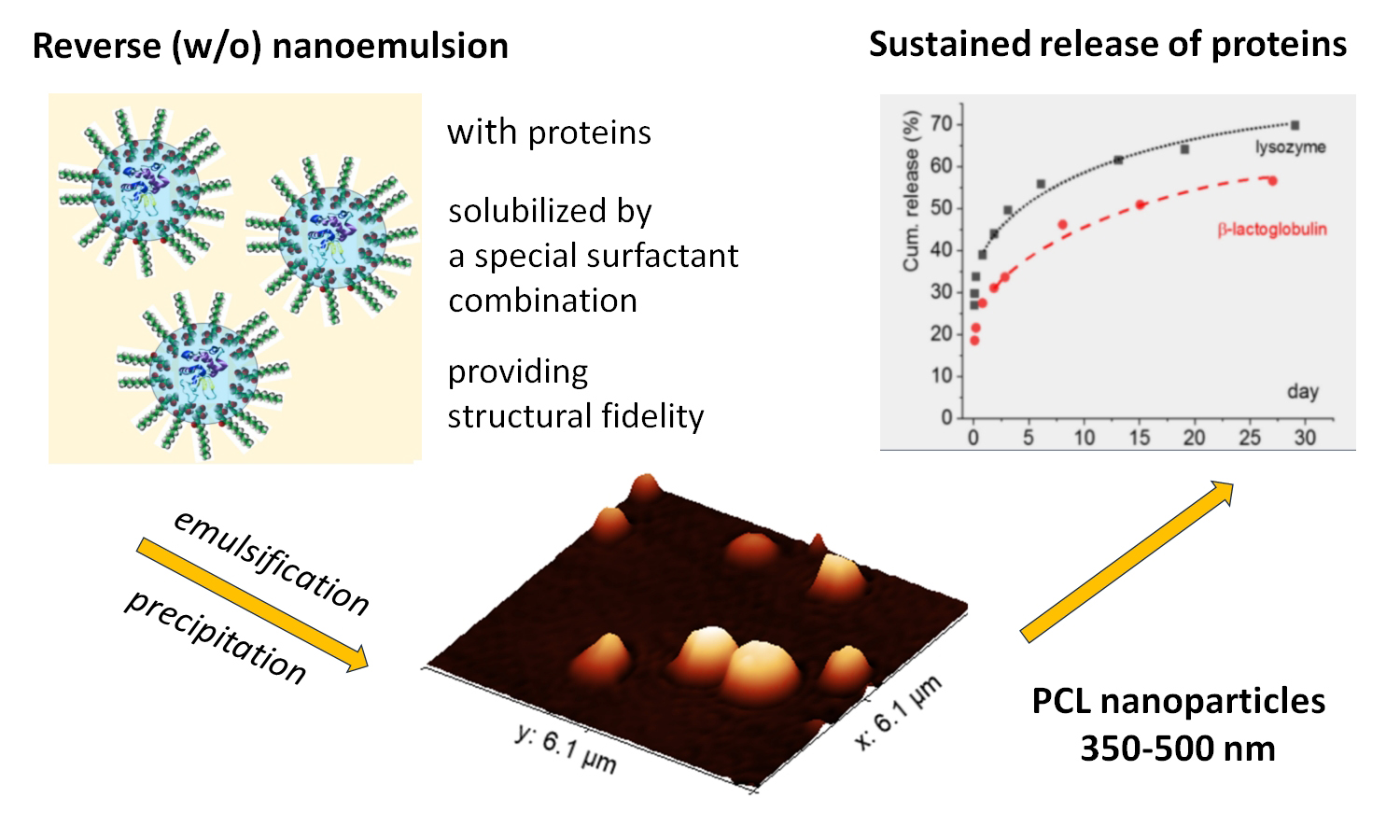

The elaboration of potent delivery systems for peptides/proteins is still a challenge but is increasingly needed in advanced therapy. In the present research, we have developed a nanoencapsulation system for peptides/proteins, which is suitable for the delivery of hydrophilic bioactive compounds. The preparation method combines the advantageous properties of reverse nanoemulsion and nanoprecipitation, resulting in the formation of nanoparticles in the size range of 350–500 nm. The polymeric coating composed of polycaprolactone allows chemical functionalization and protection while the inner microenvironment (containing 1-decanoyl-rac-glycerol and N,N-dimethyldodecylamine N-oxide surfactants) provides aqueous surrounding for the active with structural fidelity. Hen egg white lysozyme and β-lactoglobulin were successfully encapsulated, achieving protein contents of 10–60 μg/mg and encapsulation efficiencies ranging from 5–50% depending on the protein type and loading concentration. In vitro release measurement showed a biphasic sustained release profile of both proteins in the time range of one month. In vitro cytotoxicity investigation of protein-loaded nanoparticles exhibited good cell viability (above 95% at the highest treatment concentration of 0.3 mg/ml). The encapsulated membrane-active peptides have shown improved bioactivity.