Content

All issues / Volume 19 (2025) / Issue 4 (April)

Andrea Toldy

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

Vol. 19., No.4., Pages 350-350, 2025

DOI: 10.3144/expresspolymlett.2025.25

This is an editorial article. It has no abstract.

Jiadong Hu, Huiling Chen, Junpeng Zhong, Changming Li, Ronggui Li, Rong Zhou, Hongwei He

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

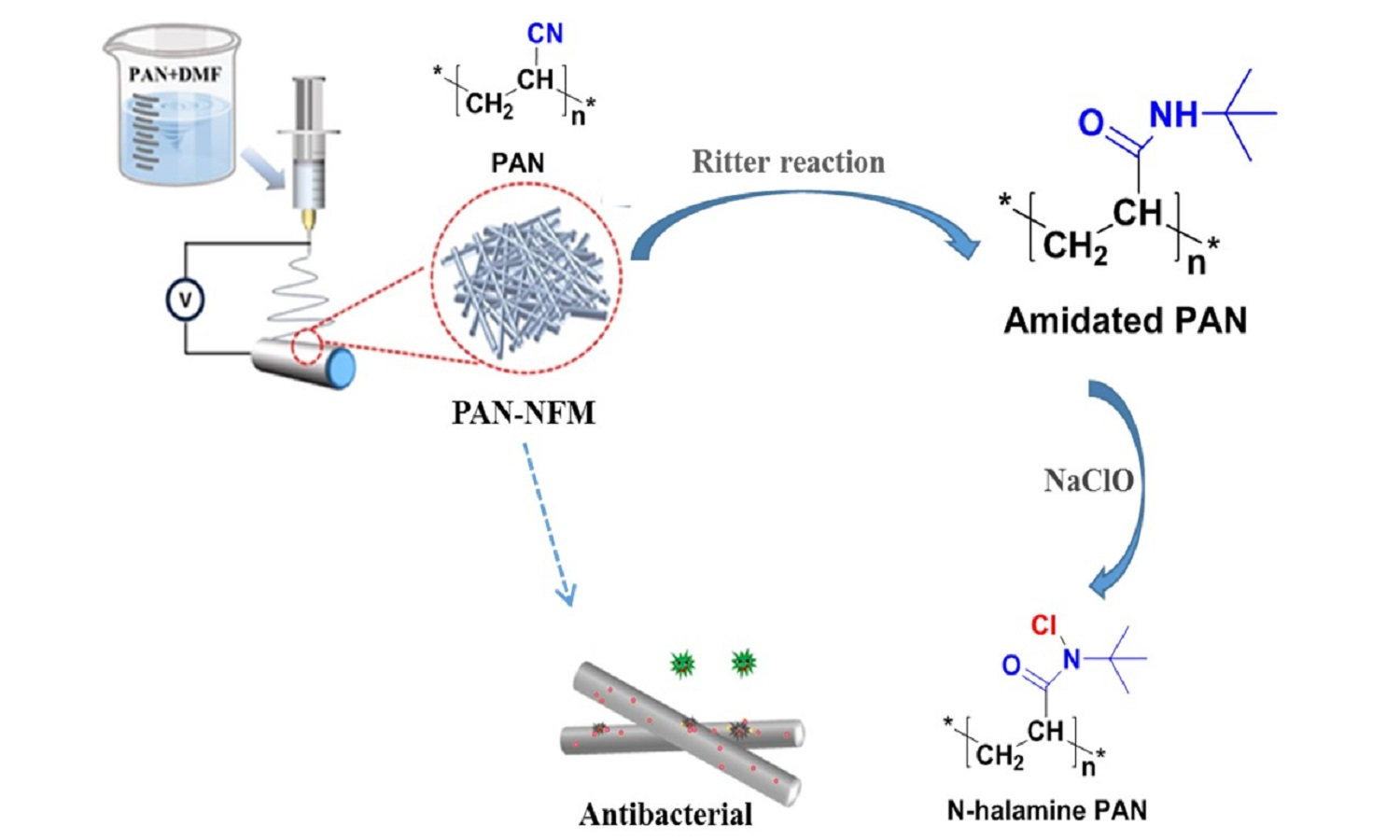

Electrospun (e-spun) nanofiber materials have emerged as a prominent research focus owing to their extensive and promising potential applications across biomedical, energy, and environmental domains. Polyacrylonitrile (PAN) is a commonly used polymer for electrospinning (e-spinning). Due to insufficient hydrophilic properties of nitrile groups of PAN, its e-spun nonwoven membranes had low water absorption and moisture absorption, which limited application in medical and health fields. In this study, it was investigated that the hydrophilic modification of e-spun PAN nanofiber membrane (NFM) was conducted via Ritter reaction to convert nitrile groups into hydrophilic amide ones, thereby improving the hydrophilicity of PAN NFMs. The surface morphologies and structure of the modified e-spun fibers were characterized and verified by SEM, FTIR and XPS. After 60–90 min of Ritter reaction, the fiber diameter of the PAN NFM became thicker, transforming from a hydrophobic membrane to a hydrophilic one, and the water contact angle decreased from 124.2 to 40.7°. The amidated PAN obtained membrane was post-treatment with sodium hypochlorite to make some amide groups change to N-halamine, which took the PAN NFM antibacterial activity or bacteriostasis. This work suggested a strategy that the espun PAN NFMs modified would have a promising application in medical dressings, air filtration, etc.

Dazhi Zhu, Junhao Wang, Yongheng Sun, Jianqiang Chu, Zhaobo Wang

Vol. 19., No.4., Pages 361-371, 2025

DOI: 10.3144/expresspolymlett.2025.27

Vol. 19., No.4., Pages 361-371, 2025

DOI: 10.3144/expresspolymlett.2025.27

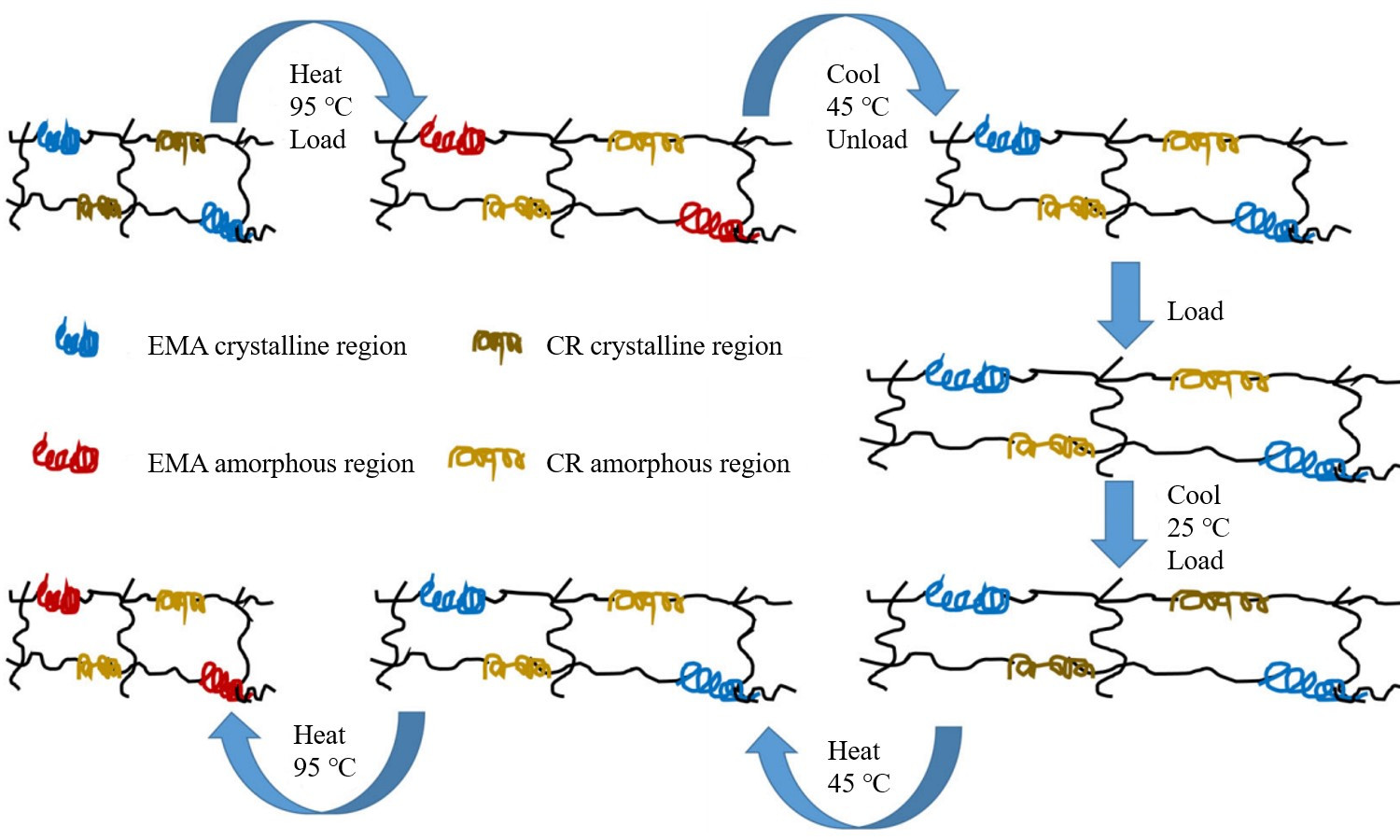

In this research, heat-triggered triple-shape memory polymers (TSMPs) based on the ethylene-methyl acrylate copolymer (EMA)/chloroprene rubber (CR) thermoplastic vulcanizates (TPVs) were prepared by dynamic vulcanization successfully; meanwhile, an effective and facile triple-shape memory strategy was designed to realize the efficient and stable shape fixity and recovery of two temporary shapes. The field-emission scanning electron microscope images showed that EMA/CR TPV surface was a sea-island structure with the CR particle size ranging from 3 to 6 μm. Differential scanning calorimeters and X-ray diffraction were used to investigate the crystallization behavior of both EMA and CR. These served as a significant basis for the two temporary shapes: fixity and recovery. The results of triple-shape memory tests showed that the EMA/CR TPV had excellent triple-shape memory properties, where the first shape fixity ratio was higher than 89% and both the first shape recovery ratio and second shape recovery ratio could be higher than 95%. It can be observed that the EMA/CR TPV exhibited rapid shape recovery speed with the first shape recovery time of 10 s and the second shape recovery time of 20 s, respectively. This research presents a novel approach to extending the application of TPV in the field of smart devices, endowing them with excellent mechanical and triple-shape memory properties.

Zeshang Jiang, Jiacheng Yu, Wuchao Cheng, Zhenxiang Xin, Jieting Geng, Lin Xia

Vol. 19., No.4., Pages 372-385, 2025

DOI: 10.3144/expresspolymlett.2025.28

Vol. 19., No.4., Pages 372-385, 2025

DOI: 10.3144/expresspolymlett.2025.28

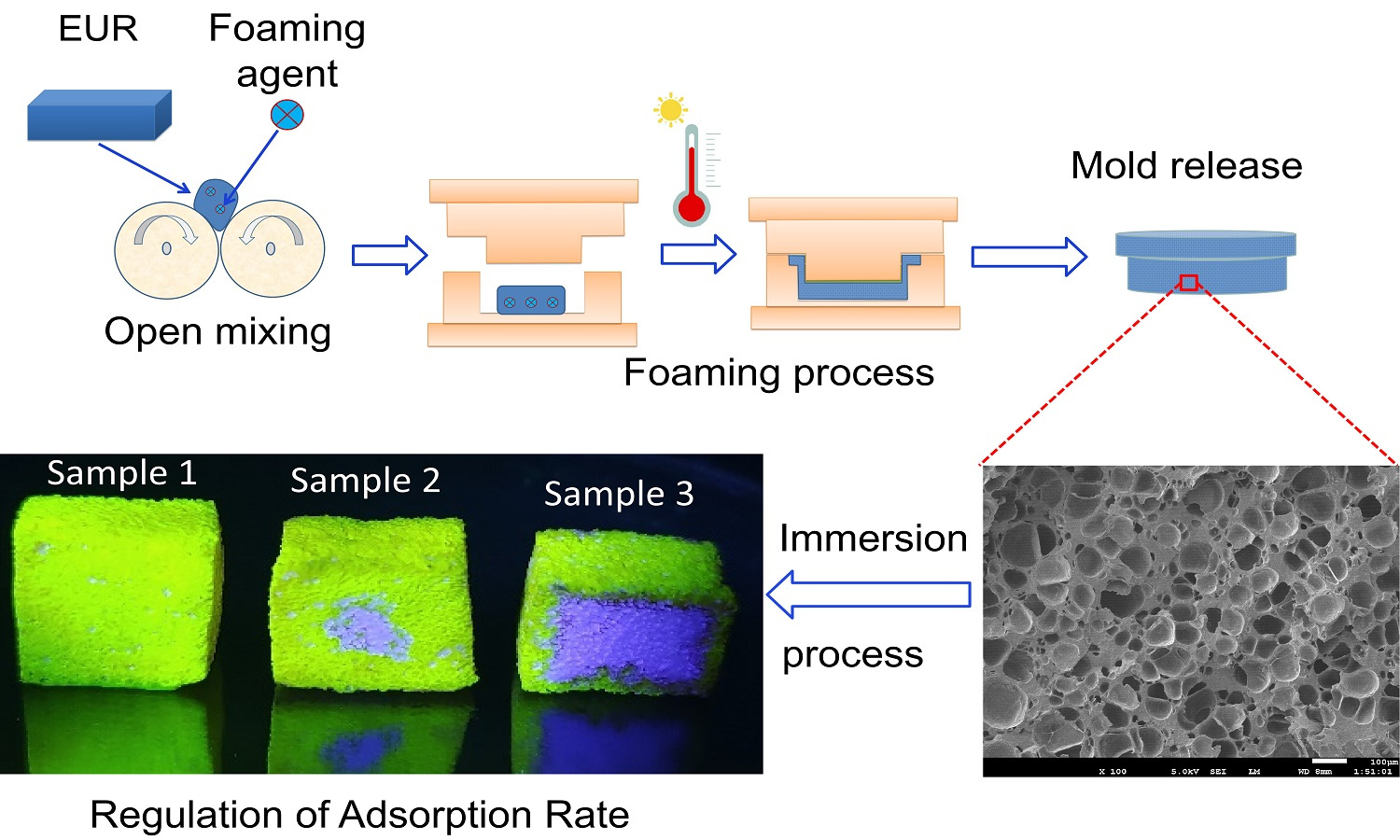

Inspired by the micro structure of loofah sponge in nature, this article successfully employs a biomimetic approach to develop a novel series of natural Eucommia rubber foamed materials with excellent shape memory properties. This article explores the characteristic features of natural Eucommia ulmoides rubber foamed materials, including the foaming process, mechanical properties, shape memory performance, and adsorption properties. This paper introduces the innovative use of natural Eucommia ulmoides rubber’s shape memory properties to create a temperature-responsive foam adsorbent material. The foamed material’s unique ability to modify its pore structure through simple compression and heating processes offers tailored adsorption speed and capacity for varied practical applications. The adjustable adsorption properties of this foamed material present novel opportunities for its utilization in adsorption applications.

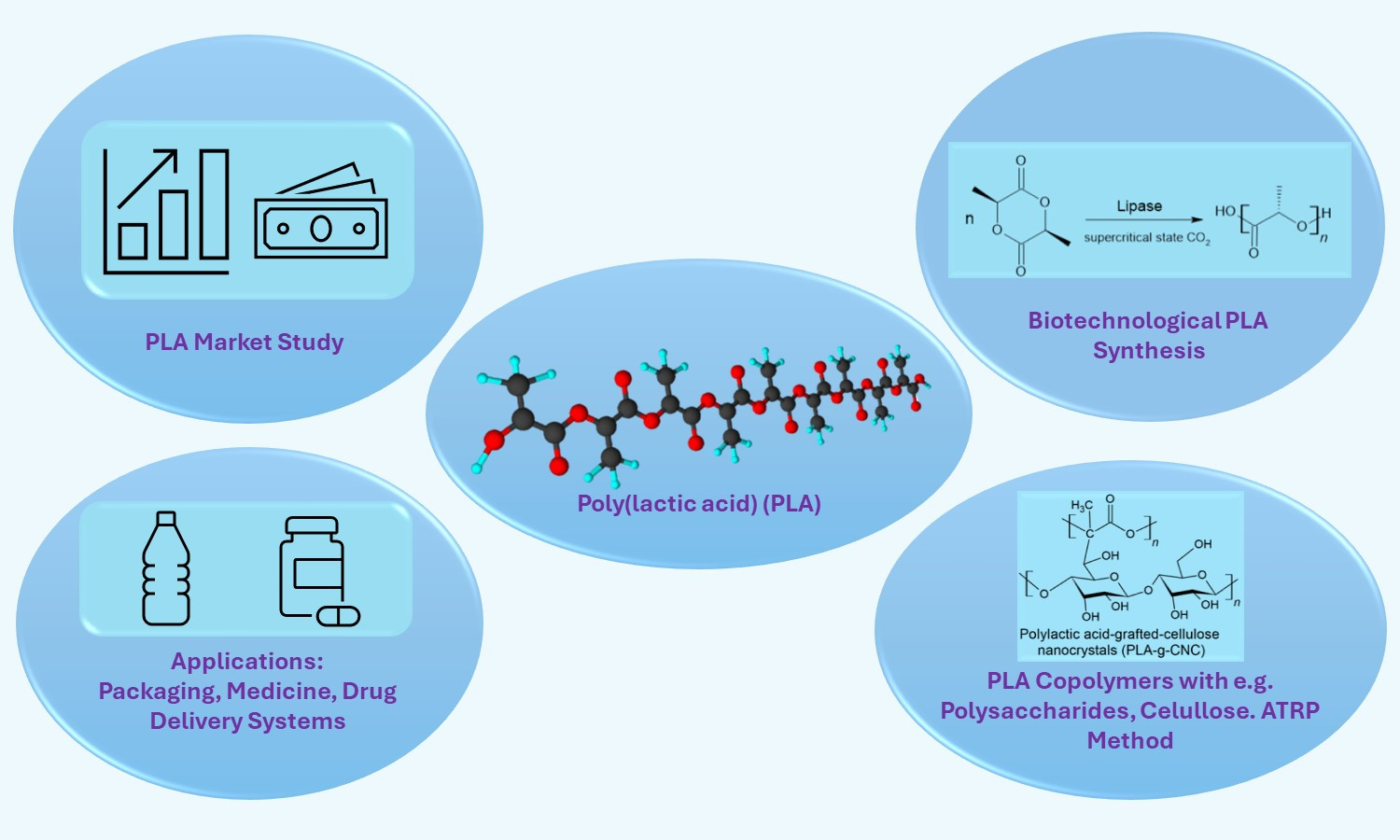

Konrad Stefaniak, Anna Masek

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

This review is focused on recent achievements in poly(lactic acid) (PLA) synthesis and copolymerization with special regard to biotechnological routes of PLA synthesis, which use bacteria/enzymes (e.g., enzymatic ring opening polymerization (eROP)). Besides PLA, also lactic acid (LA) synthesis is described and an emphasis is put on the biotechnological methods. Having regard to PLA copolymerization, this paper attempts to describe different types of PLA copolymers (such as block copolymers, PLA copolymers with polysaccharides, PLA-cellulose copolymer composites, and PLA polymer brushes). A detailed overview of the recent accomplishments in the field of PLA copolymers is presented. Various enhanced properties and applications of presented PLA copolymers are discussed. The attention is placed mainly on applications in the field of tissue engineering, drug delivery systems, and the packaging sector. Furthermore, a PLA market study and its economic forecast are presented. Eventually possible directions for future research in the field of PLA synthesis and copolymerization are indicated.

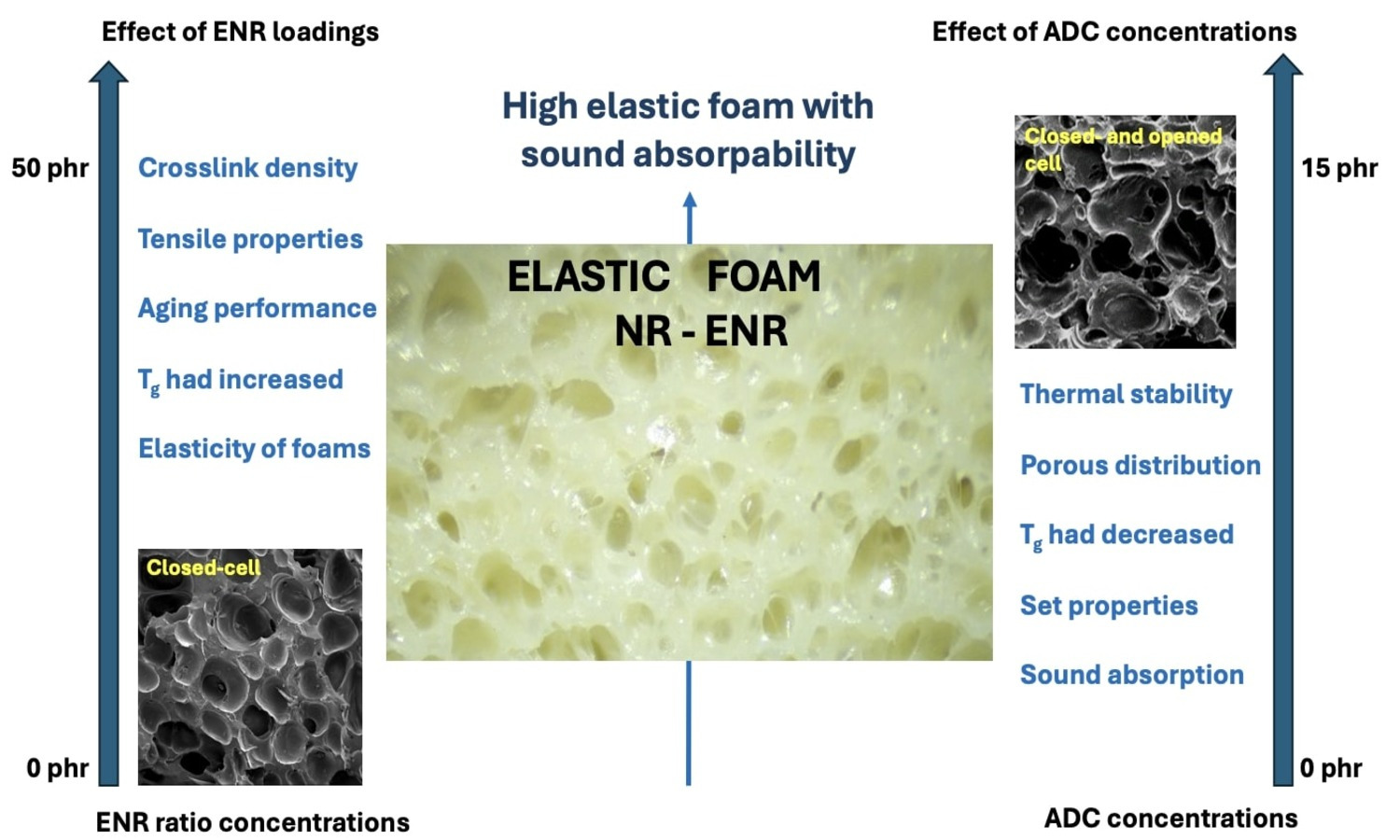

Kriengsak Damampai, Kanoknan Boonpan, Yeampon Nakaramontri

Vol. 19., No.4., Pages 409-422, 2025

DOI: 10.3144/expresspolymlett.2025.30

Vol. 19., No.4., Pages 409-422, 2025

DOI: 10.3144/expresspolymlett.2025.30

This study investigated the properties of the natural rubber (NR) foam filled with azodicarbonamide (ADC) blowing agents by combination to various ratios of epoxidized NR (ENR) for flexible foam applications. Compound operation was prepared with an open two-roll mill and the production was fabricated by compression molding. The study elucidated properties related to crosslinking behaviors, mechanical and dynamic properties, elasticity, abrasion, weathering resistance, and sound absorption efficiency. The ENR and ADC concentrations affected the tensile testing and also the durability properties of the NR/ENR. The NR and ENR foam of 60/40 filled with 10 phr of ADC demonstrated good properties across various parameters, showing acceptable tensile properties, abrasion resistance, and QVA light resistance. Additionally, the presence of a closed-cell structure in the blends reduced crack propagation in the NR matrix during aging, improving weathering resistance. The absorption coefficient increased with higher ADC content, being optimal at 15 phr, due to the lower density and higher porosity of the opened-cell material, which enhances its ability to interact more effectively with incoming energy at 1600 and 6400 Hz. The findings encourage the use of ENR for blending in NR for improved ENR and ADC concentrations since dipole-dipole interaction from ENR-ADC caused ADC dispersability, providing complexed foam structures for force expansion and aslo sound wave absorption.

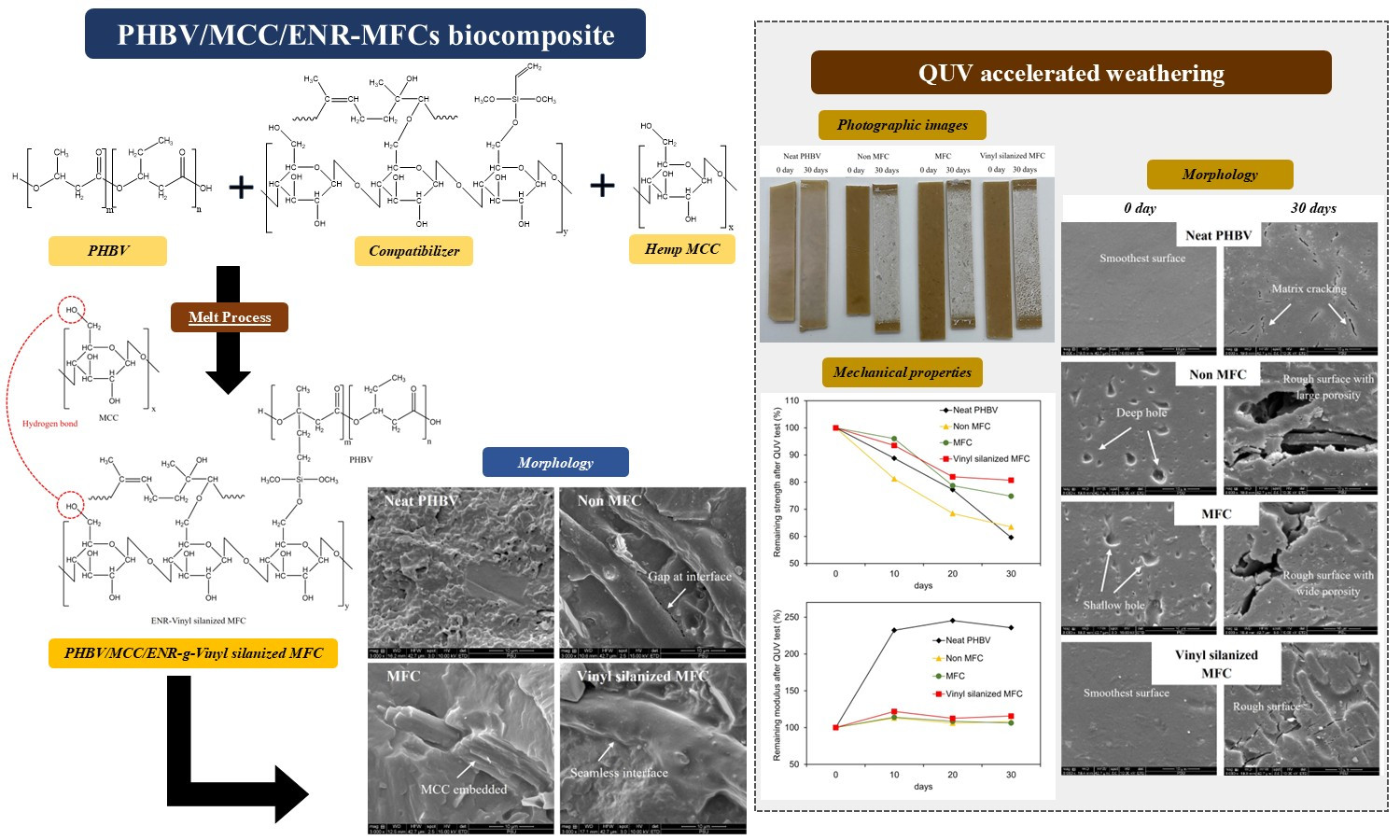

Rattanawadee Hedthong, Thorsak Kittikorn, Suding Kadea, Phuthanet Bamrungsiri

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

This research aimed to enhance the properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) biocomposites by incorporating hemp microcrystalline cellulose (MCC). Additionally, to improve interfacial adhesion between PHBV and MCC phases, a compatibilizer consisting of epoxidized natural rubber (ENR) grafted with microfibrillated cellulose (MFC) modified by vinyltrimethoxysilane (ENR-vinyl silanized MFC) was introduced. The addition of 5 wt% MCC increases the flexural modulus by approximately 65%. The use of ENR-vinyl silanized MFC as a compatibilizer demonstrated improved compatibility, as observed in scanning electron microscope (SEM) images. After 30 days of accelerated weathering (QUV) exposure, the flexural strength of the PHBV-based biocomposite with ENR-vinyl silanized MFC and MCC (vinyl silanized MFC biocomposite) was superior to that of the other samples. The remaining flexural strength can be sequentially categorized as follows: vinyl silanized MFC > MFC > non-MFC > PHBV. The Tg of PHBV-based biocomposites showed no significant change. Interestingly, the crystallinity of the vinyl silanized MFC biocomposite was the highest among all materials and demonstrated higher hydrophobicity. This makes the vinyl silanized MFC biocomposite a suitable material for construction, furniture, and both exterior and interior decoration.

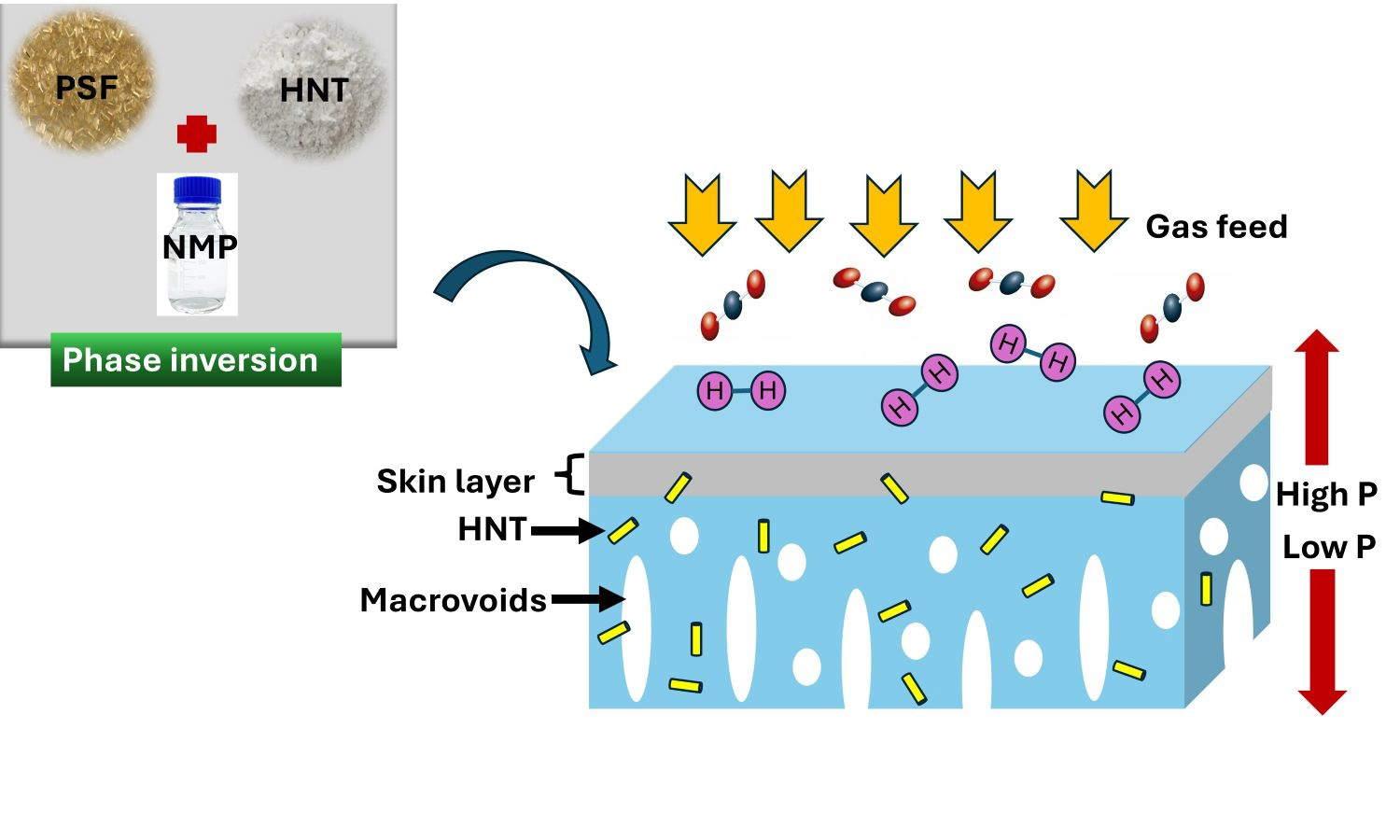

Nurul Ain Arjuna, Noor Maizura Ismail, S. M. Anisuzzaman, Rachel Fran Mansa, Murni Sundang, Akhtar Razul Razali

Vol. 19., No.4., Pages 441-454, 2025

DOI: 10.3144/expresspolymlett.2025.32

Vol. 19., No.4., Pages 441-454, 2025

DOI: 10.3144/expresspolymlett.2025.32

Membrane-based gas separation offers practical advantages for hydrogen (H2) and carbon dioxide (CO2) separation for steam methane reforming units. Modification of membrane materials can optimize membrane performance. In this study, the central focus is on investigating the effect of different loadings of halloysite nanotubes (HNTs) (0, 0.5, 1.0, 1.5, and 2.0 wt%) incorporated into a blend of cellulose acetate (CA) and polysulfone (PSF) polymers with the aim of improving the membrane properties. The Fourier transform infrared spectroscopy-attenuated total reflectance (FTIR-ATR) results confirmed that the primary functional groups of PSF and CA remained intact upon HNTs incorporation, with no distinct HNT peaks altering the main chemical functionalities. Field emission scanning electron microscopy- energy dispersive X-ray spectroscopy (FESEM-EDX) analyses showed that low concentrations of HNTs (0.5 wt%) improved surface smoothness and reduced macrovoids, beneficial for gas separation. Cross-sectional images of FESEM micrographs showed no evidence of obvious agglomeration, suggesting a good dispersion of HNTs. From the X-ray diffraction (XRD) analysis, all the membrane samples retained an amorphous structure, indicating that the incorporation of HNT has less effect on the polymer chain properties of the membranes.