Content

All issues / Volume 16 (2022) / Issue 7 (July)

Mengyu Zhou, Jun Liu, Liqun Zhang

Vol. 16., No.7., Pages 677-678, 2022

DOI: 10.3144/expresspolymlett.2022.49

Vol. 16., No.7., Pages 677-678, 2022

DOI: 10.3144/expresspolymlett.2022.49

This is an editorial article. It has no abstract.

Amir Kamyab, Ahmad Ghasemi-Ghalebahman, Abdolhossein Fereidoon, Hossein Ali Khonakdar

Vol. 16., No.7., Pages 679-693, 2022

DOI: 10.3144/expresspolymlett.2022.50

Vol. 16., No.7., Pages 679-693, 2022

DOI: 10.3144/expresspolymlett.2022.50

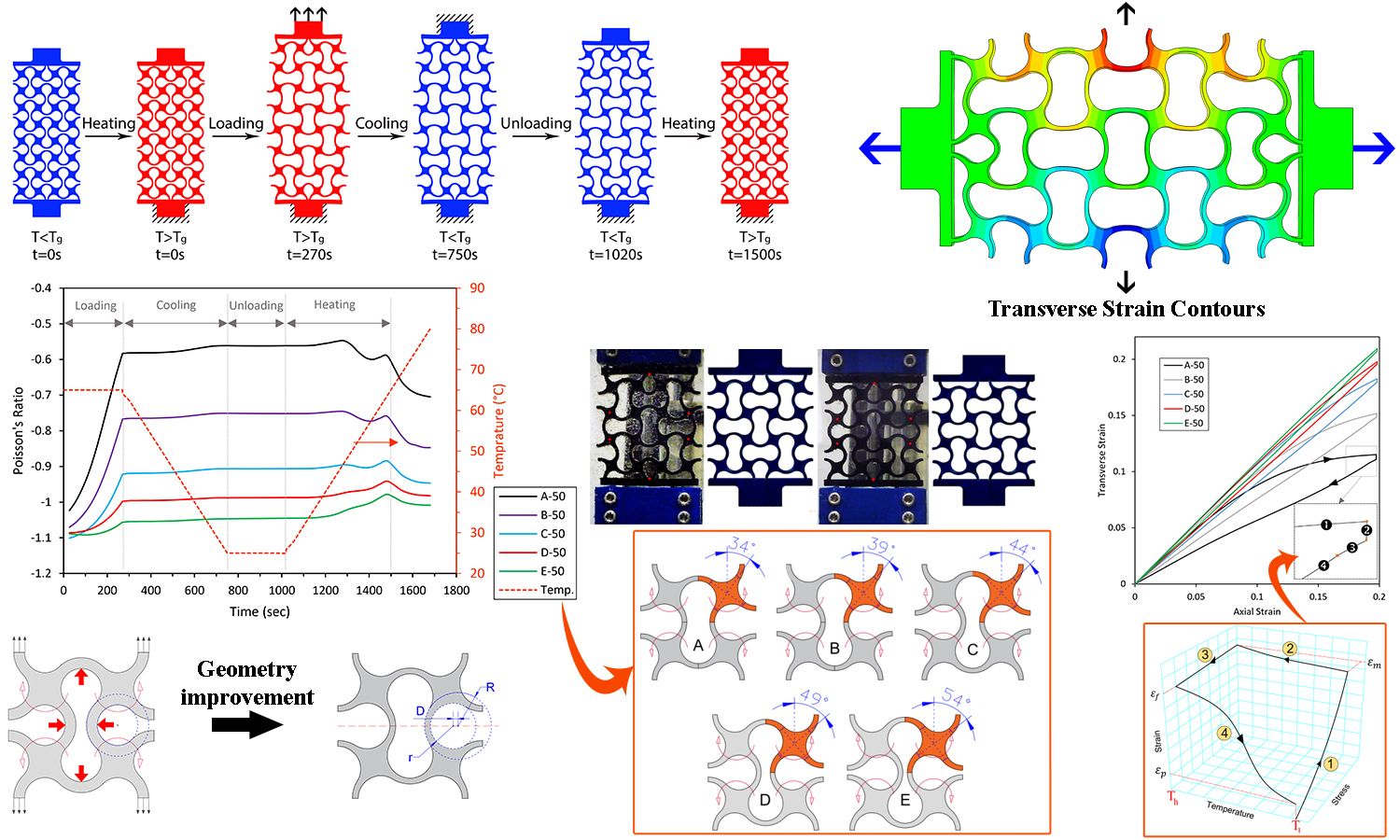

In the last decade, auxetic structures with a negative Poisson’s ratio have attracted the attention of experts in industries such as biomechanics, aerospace, and packaging due to their properties, such as energy absorption and high crack resistance. The preparation of these structures using smart polymers increases their attractiveness due to low energy expenditure at the destination and the deformation of two separate states by applying external stimuli. This study aimed to investigate the improved peanut-shaped structure that retains its auxetic properties at high elongation, the effects of changes in geometry and dimensions of the structure on the Poisson’s behavior, shape fixity ratio, and shape recovery ratio during the shape memory cycle. To this end, several samples were prepared using the 4D printing method of shape memory polymers, and laboratory results were compared with software simulations of the shape memory cycle. After validating the simulation results, more cases were examined by the modeling. The results showed that despite the complete recovery of samples, the Poisson’s ratio was not recovered. The changes in geometry and samples’ dimensions significantly enhanced their auxetic property. Due to obtaining a significantly high Poisson’s ratio by changing the geometric characteristics, this structure is suggested to be used in industrial applications such as aerospace.

Byeongjo Ko, Sanghun Shin, Hongyun So

Vol. 16., No.7., Pages 694-704, 2022

DOI: 10.3144/expresspolymlett.2022.51

Vol. 16., No.7., Pages 694-704, 2022

DOI: 10.3144/expresspolymlett.2022.51

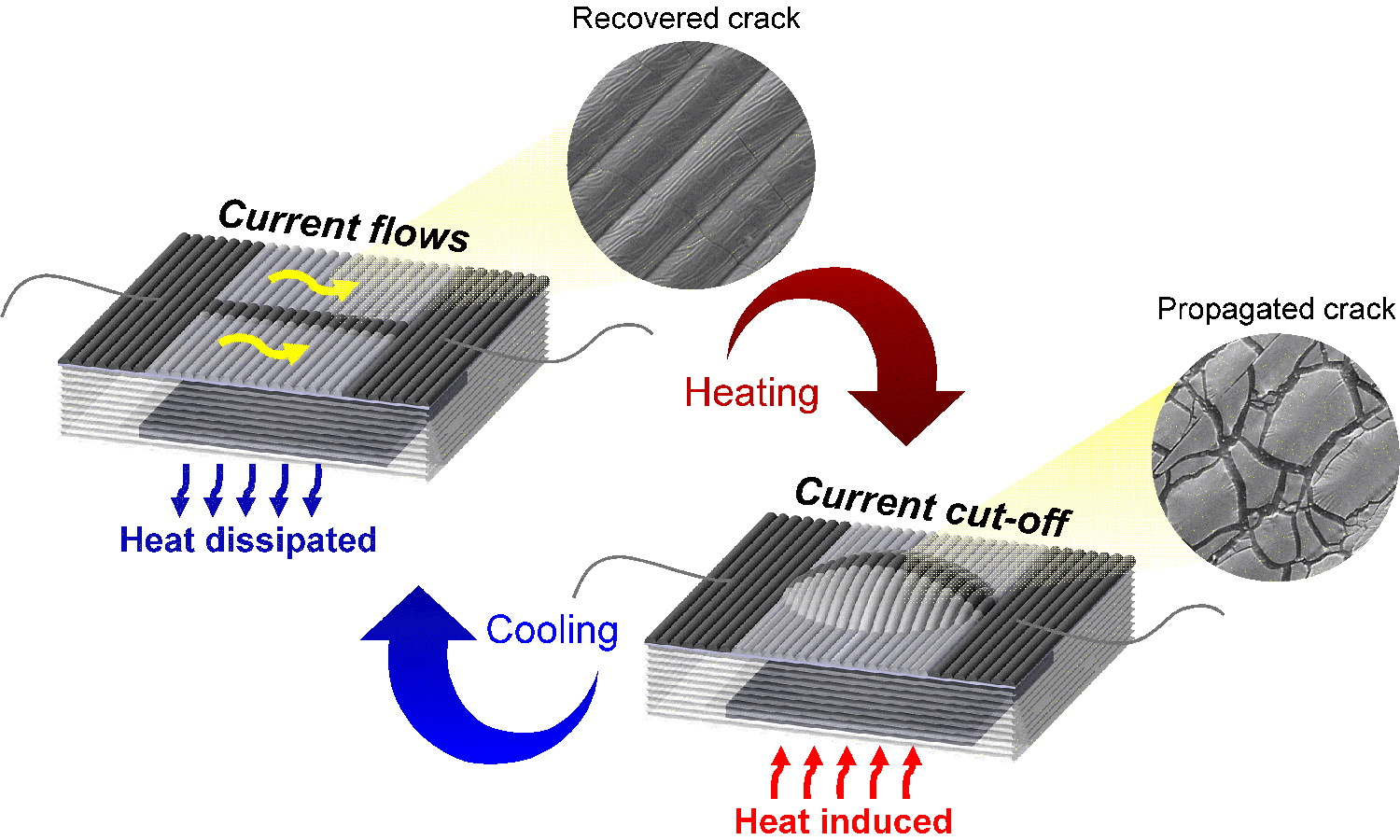

In this study, a novel, facile, and cost-efficient manufacturing process for thermal-expansive reversible fuse (TRF) was demonstrated by using a cracked conductive layer on a flexible polymer with three-dimensional (3D) groove patterns. The current cut-off mechanism was demonstrated by the actuation of a thin membrane with a conductive layer of the TRF fabricated by a 3D-patterned mold and flexible polymer. When external heat was induced, the membrane of the TRF swelled, and the platinum-coated conductive layer was stretched, resulting in a current cut-off. In contrast, the membrane shrank, and the TRF was reconnected when the heat source was removed. The major cracks parallel to the 3D-printed patterns and minor cracks across the patterns were analyzed through the scanning electron microscope images. In addition, TRFs with pattern intervals of 250 μm (low resolution) and 100 μm (high resolution) were characterized by observing the current signal and expansion thickness of the membrane simultaneously to analyze the effect of actuation on the cut-off tendency. Finally, by applying the repetitive temperature profile between 35 °C and the cut-off temperature, the reversible performance of the TRFs was demonstrated by the cut-off and reconnection processes. These results can be applied to passive cooling systems of electronic devices to prevent overheating, which can affect the performance and durability of the device.

Yaping Jin, Chao Liu, Ruihong Liu, Xuefu Che, Jingshuai Yang

Vol. 16., No.7., Pages 705-717, 2022

DOI: 10.3144/expresspolymlett.2022.52

Vol. 16., No.7., Pages 705-717, 2022

DOI: 10.3144/expresspolymlett.2022.52

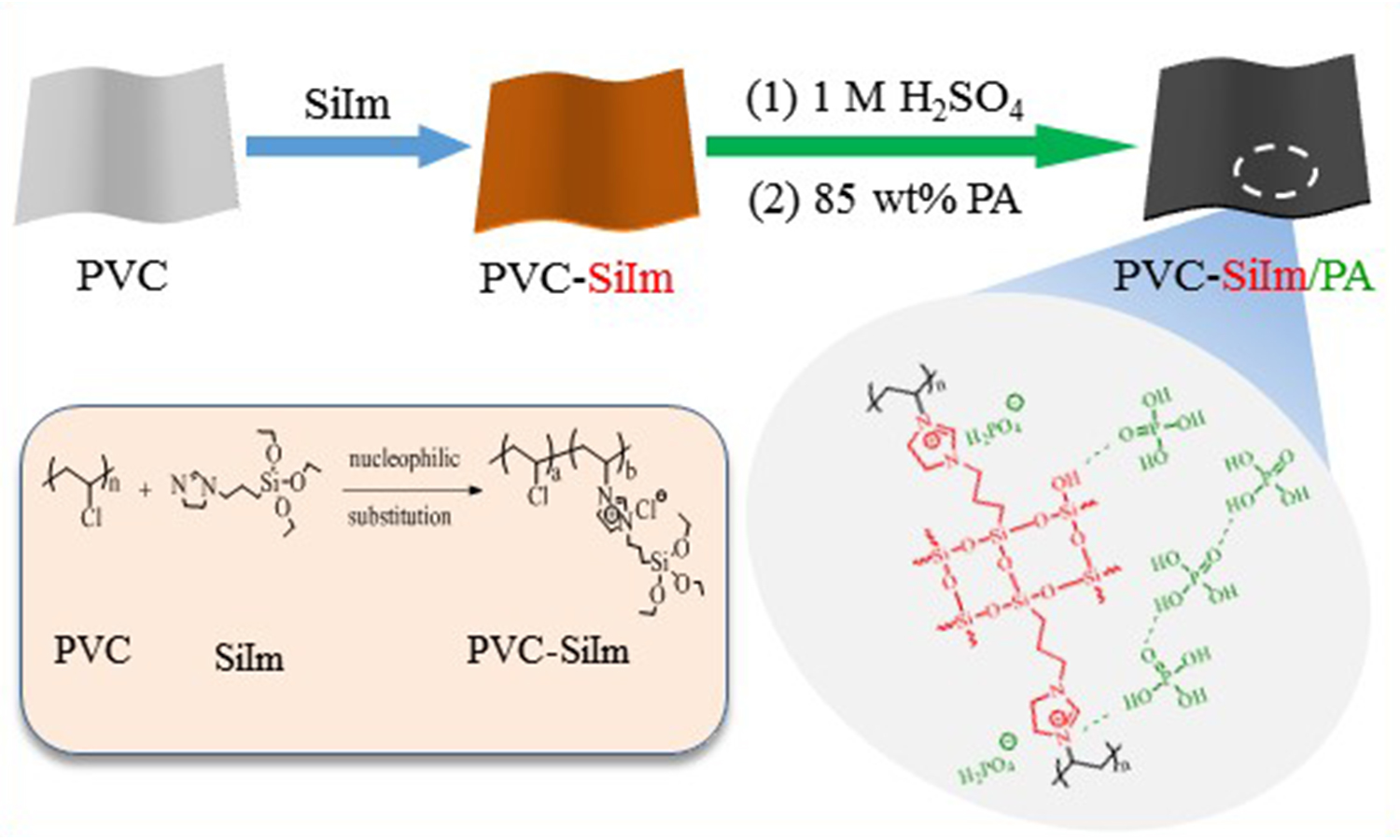

Developing high-performance and low-cost polymer membranes for high-temperature proton exchange membrane fuel cells is a big challenge to the polymer design. Herein, high-temperature proton exchange membranes are prepared based on the low-cost thermoplastic resin of poly(vinyl chloride) (PVC). However, the methylimidazolium PVC exhibits significantly low phosphoric acid (PA) doping content and low conductivity due to the compact structure. Thus, the N-[3-(triethoxysilyl) propyl]-4,5-dihydroimidazole (SiIm) is employed as a dual functionalized reagent for PVC. On the one hand, SiIm is used to quaternize PVC through the SN2 nucleophilic substitution between chloride and imidazole. On the other hand, the crosslinked siloxane network is formed via the hydrolysis reaction of SiIm in a dilute sulfuric acid solution. The obtained polysilsesquioxane crosslinked membranes (PVC-x%SiIm) display good thermal stability, excellent PA doping ability, superior proton conductivity, and moderate tensile strength. For instance, the PVC-17%SiIm membrane achieves a high PA doping content of 243% after immersing in 85 wt% PA solution and exhibits the highest conductivity of 0.111 S·cm–1 at 180 °C without humidifying and tensile strength of 6.0 MPa at room temperature.

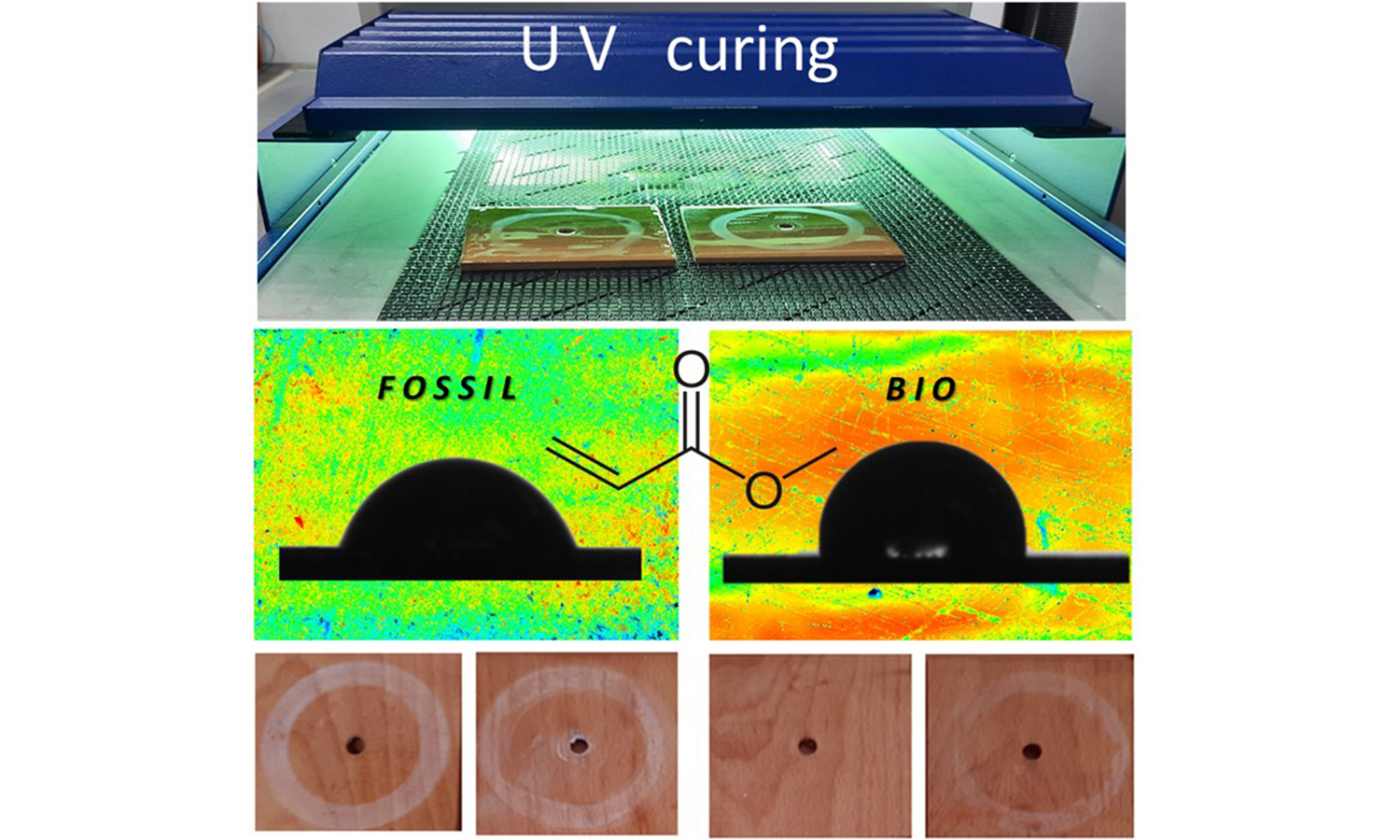

Influence of UV curing parameters for bio-based versus fossil-based acrylates in mechanical abrasion

Pieter Samyn, Joey Bosmans, Patrick Cosemans

Vol. 16., No.7., Pages 718-734, 2022

DOI: 10.3144/expresspolymlett.2022.53

Vol. 16., No.7., Pages 718-734, 2022

DOI: 10.3144/expresspolymlett.2022.53

The selection of sustainable solutions for protective coatings should consider the use of bio-based materials and environmentally-friendly processing conditions, while their performance needs to be benchmarked against traditional polymer coatings. Therefore, acrylate coatings were formulated by mixing a viscous oligomer (acrylated soybean oil) with a monomer diluent (triacrylate) and applied as a coating on softwood (beech) substrates by curing under ultraviolet (UV) light. In this study, the processing conditions and performance of coatings is explicitly compared by introducing both fossil-based and bio-based grades of the monomer with similar chemical functionality. The wear of coated wood samples was tested on a rotational Taber abrasion tester recording progressive wear loss over 1000 cycles, investigating effects of photoinitiator concentrations and UV curing parameters (light intensity and number of curing passes) on wear resistance. In parallel, the degree of conversion was investigated in relation to other properties such as hardness, water contact angles and topographical evaluation of the wear tracks. Under conditions providing fully cured coatings, the bio-based acrylate coatings systematically present lower wear. This is in agreement with lower hardness and reduced brittleness of the bio-based versus fossil-based acrylates. Alternatively, additional insight in the wear properties is obtained from transient wear conditions for partially cured coatings. Most interestingly, the presence of a surface layer with more hydrophobic properties and formation of deposits in the wear track with either island-like or more smooth features was confirmed for the bio-based acrylate coatings, in parallel with the better lubrication and progressive wear reduction. The paper illustrates the benefits in mechanical performance of bio-based coatings when applied under specific processing conditions, which can be implemented at industrial scale in the future, e.g., as protective wood coatings.

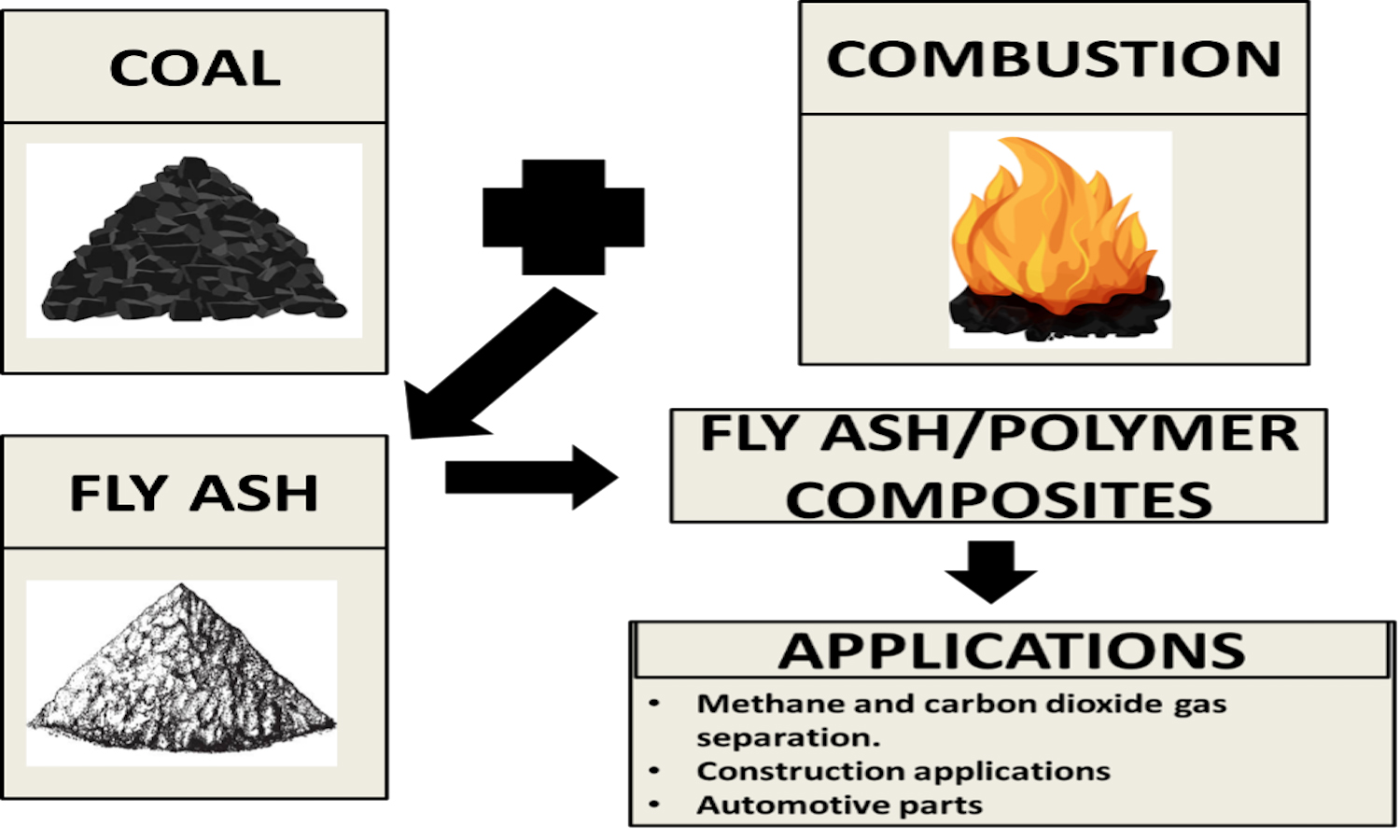

Andiswa Kaleni, Sifiso Innocent Magagula, Mary Tholwana Motloung, Mokgaotsa Jonas Mochane, Teboho Clement Mokhena

Vol. 16., No.7., Pages 735-759, 2022

DOI: 10.3144/expresspolymlett.2022.54

Vol. 16., No.7., Pages 735-759, 2022

DOI: 10.3144/expresspolymlett.2022.54

Energy and environmental protection are two major problems that are faced by the current generation. Coal has been utilized traditionally as a source of electricity globally. However, more ash is generated from the combustion of coal which is carried by gases and precipitated into fly ash. The main problem with fly ash is that, if it is not properly disposed it may cause pollution(s) in the water and soil, which in turn disturb ecological cycle and have negative impact on the environment. Based on the above statement(s), more efforts have been done to recycle fly ash or its utilization for advanced applications. One of the preferred methods for recycling fly ash, is to incorporate it in polymer matrices in order to improve the strength of polymer matrices for advanced applications. Fly ash has been utilized as a reinforcing filler for various polymer matrices due to its high strength and low cost. This review paper discusses different fabrication methods for fly ash/polymer matrices composites. The effect of particle size, modification, synergy of fly ash with other fillers reinforced polymer matrices on the mechanical properties are discussed. Furthermore, there is an in-depth discussion about the specific applications of fly ash reinforced with different polymer matrices. There is also a discussion based on the fly ash/fiber/polymer hybrid composites in relation to the preparation method and mechanical properties, since hybrid systems are known for better properties than single fillers.

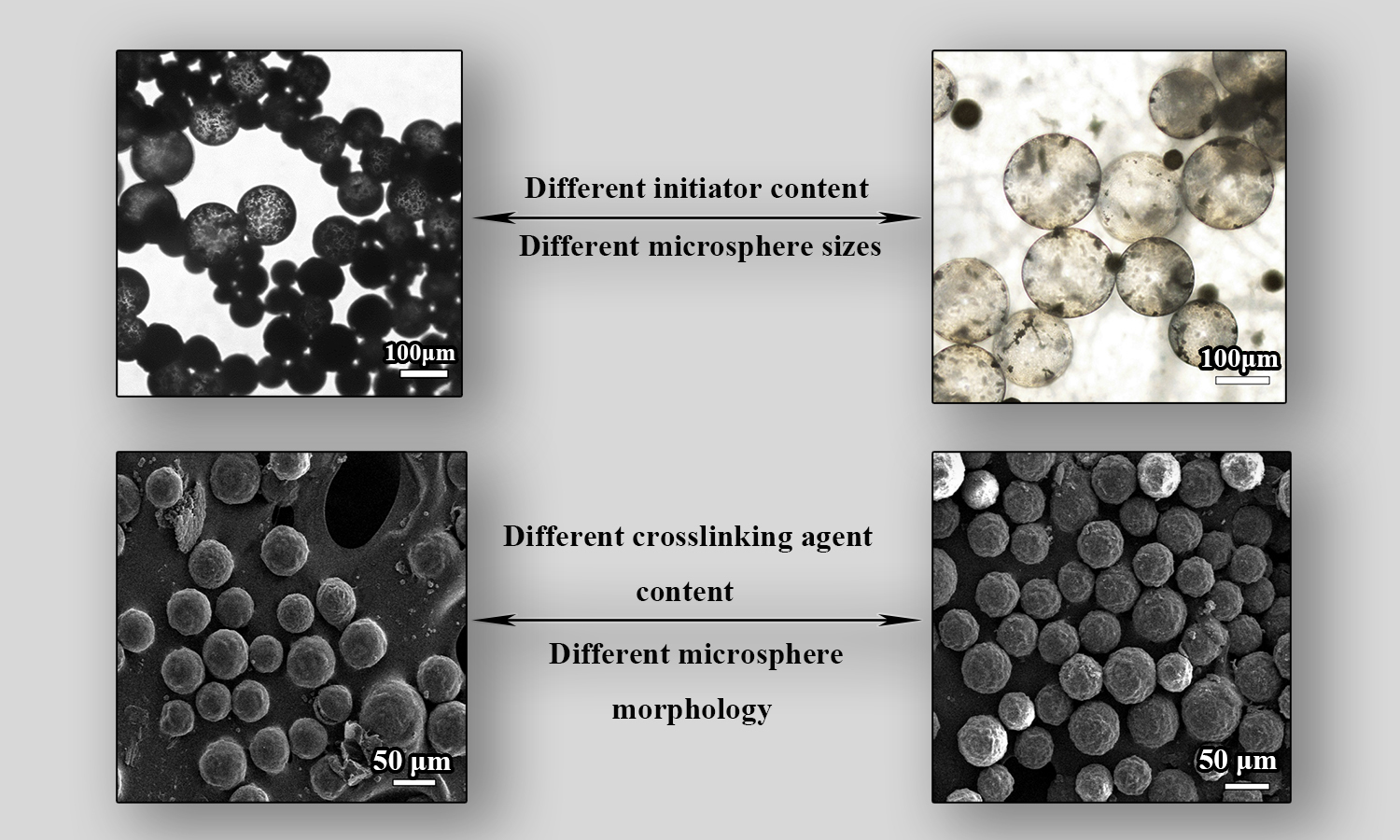

Jing Zhang, Tinghui Yan, Hongli Zhang, Ye Fang, Yuzhong Huang, Jijun Tang, Mingyang He

Vol. 16., No.7., Pages 760-771, 2022

DOI: 10.3144/expresspolymlett.2022.55

Vol. 16., No.7., Pages 760-771, 2022

DOI: 10.3144/expresspolymlett.2022.55

Core-shell thermally expandable microspheres (TEMs) were prepared via Pickering suspension polymerization. Acrylonitrile (AN), methacrylic acid (MAA) and N,N-dimethylacrylamide (DMAA) were used as the comonomers, the 2,2′-azobisisobutyronitrile (AIBN) was used as the initiator and the ethyleneglycol dimethacrylate (EGDMA) was used as the crosslinker. The effects of initiator concentration, cross-linking agent concentration and modified monomer type on the morphology, thermal properties and encapsulation content of TEMs were investigated. The results show that the small change in initiator concentration had a significant effect on the properties of TEMs. When the initiator concentration was 0.55%, the microspheres showed core-shell structure and the maximum expansion ratio was 3.06 times. According to the scanning electron microscope (SEM) image, the heat resistance of the microspheres increased with the increase of the content of crosslinking agent. The lower the water solubility of the modified monomer, the more stable the foaming of the TEMs. When methyl acrylate (MA) was used as a modified monomer, the initial expansion temperature of the microspheres was 163.2°C, the maximum expansion temperature was 223.5 °C, and the encapsulation content of the blowing agent was 14.70%.

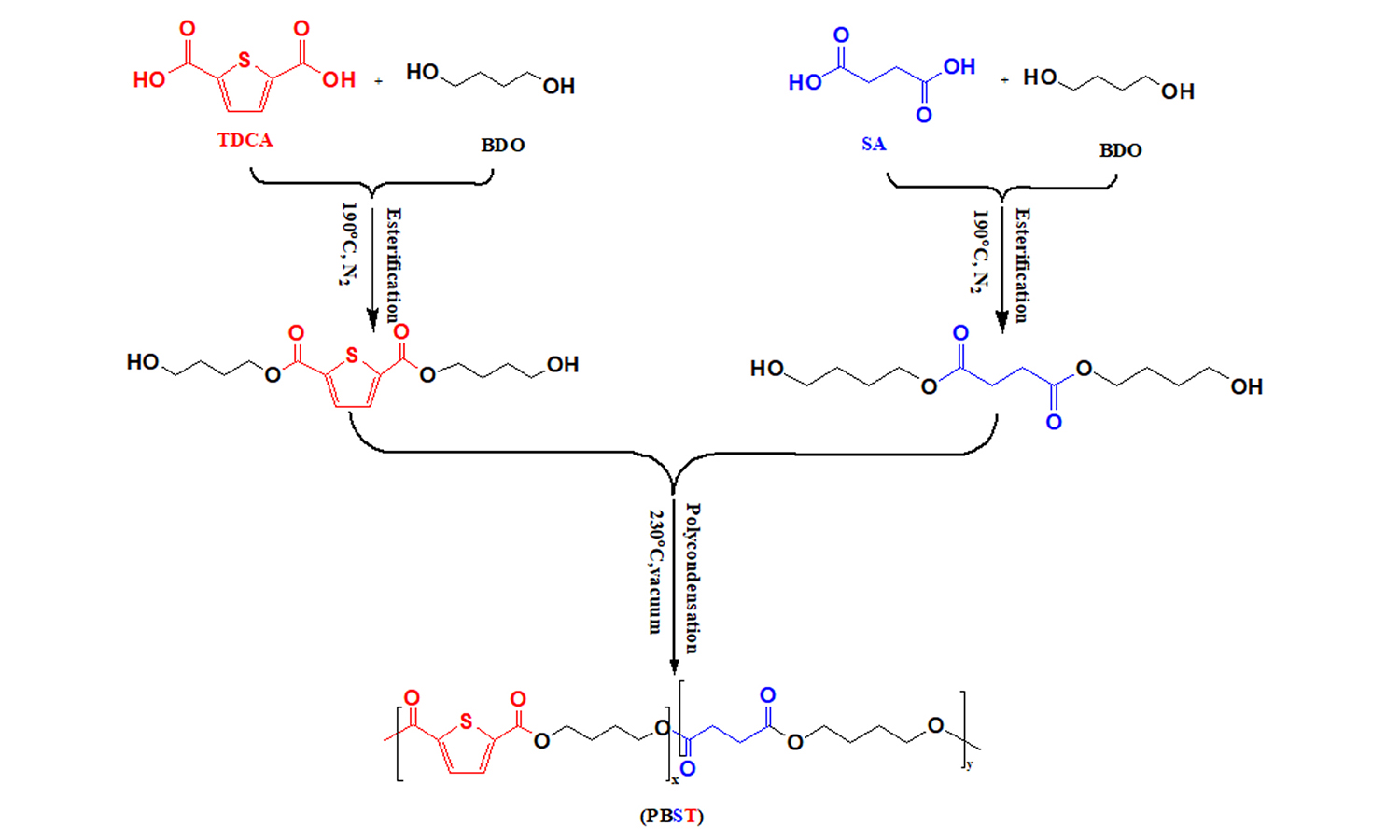

Guoqiang Wang, Xingyu Hao, Yakun Dong, Li Zhang, Rubo Sun

Vol. 16., No.7., Pages 772-784, 2022

DOI: 10.3144/expresspolymlett.2022.56

Vol. 16., No.7., Pages 772-784, 2022

DOI: 10.3144/expresspolymlett.2022.56

Novel poly(butylene succinate-co-butylene 2,5-thiophenedicarboxylate) (PBSTFs) were successfully synthesized by changing the ratio of 2,5-thiophenedicarboxylic acid (TDCA) and 1,4-succinic acid (SA) through two-step melt polycondensation. Their structure, thermal properties, crystalline properties, mechanical properties, and rheological properties were tested and characterized. The glass transition temperature increases with the increase of butylene 2,5-thiophenedicarboxylate unit (BTF). NMR results show that the copolymers are random copolymers. Differential scanning calorimetry (DSC) and wide-angle X-ray diffraction (WAXD) results show that all polyesters are semi-crystalline polymers. When the content of TDCA is 0–50%, the crystallinity and melting temperature of the samples decreased, Young’s modulus and tensile strength decreased, and the elongation at break increased obviously with the increase of BTF. When the content of TDCA is 50–100%, the tensile strength increases, but the elongation at break decreases slightly. The range of strength is between 15.4 and 38 MPa, and the maximum elongation at break can reach 1160%. Therefore, by adjusting the content of BTF, the structure of copolyesters can be adjusted to obtain fully bio-based copolyesters with excellent properties. Compared with poly(butylene succinate), when the molar percentage of TDCA in a product is 29%, the copolyester has better mechanical properties (tensile strength: 31.4 MPa and elongation at break: 1060%), higher glass transition temperature (–26.2 °C) and better processing properties.