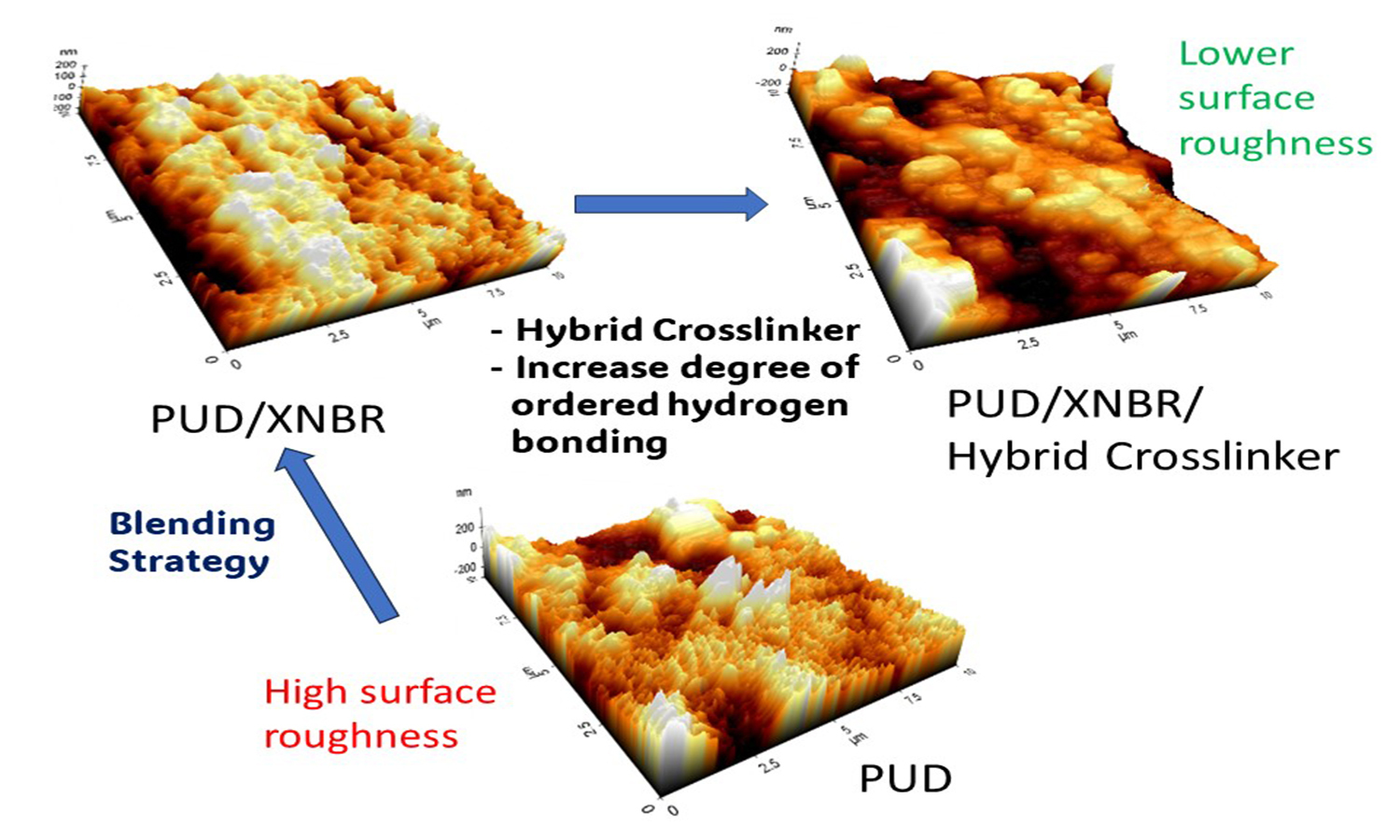

Surface properties and hydrogen bonding of accelerator-free polyurethane dispersion/carboxylated nitrile butadiene rubber using crosslinker hybridisation

Vol. 18., No.7., Pages 689-704, 2024

DOI: 10.3144/expresspolymlett.2024.51

DOI: 10.3144/expresspolymlett.2024.51

GRAPHICAL ABSTRACT

ABSTRACT

This study focuses on producing polyurethane dispersion (PUD)/carboxylated nitrile butadiene rubber (XNBR) blends with different types of crosslinkers without both accelerators and sulphur. Two types of crosslinkers: epoxide crosslinker and organo-modified siloxane, are introduced in the PUD/XNBR (blending ratio of 80:20). The zeta potential and particle size of the PUD/XNBR blends were determined using a dynamic light-scattering nanoparticle analyser. The chemical interaction and surface roughness of the PUD/XNBR blends were evaluated using Fourier transform infrared spectroscopy (FTIR) and atomic force microscopy (AFM). The zeta potential and particle size of the PUD were influenced by XNBR blending and the types of crosslinkers. FTIR observations indicate that the XNBR and the crosslinkers facilitated intermolecular hydrogen bonding and different extents of ordered hydrogen bonding. A higher degree of ordered hydrogen bonding can be associated with a higher surface roughness of the PUD/XNBR blends. Nevertheless, the hybrid crosslinkers can be used to achieve reasonable surface roughness for the easier donning of latex gloves. The research findings can be applied to design glove products with desirable surface roughness and intermolecular bonding.

RELATED ARTICLES

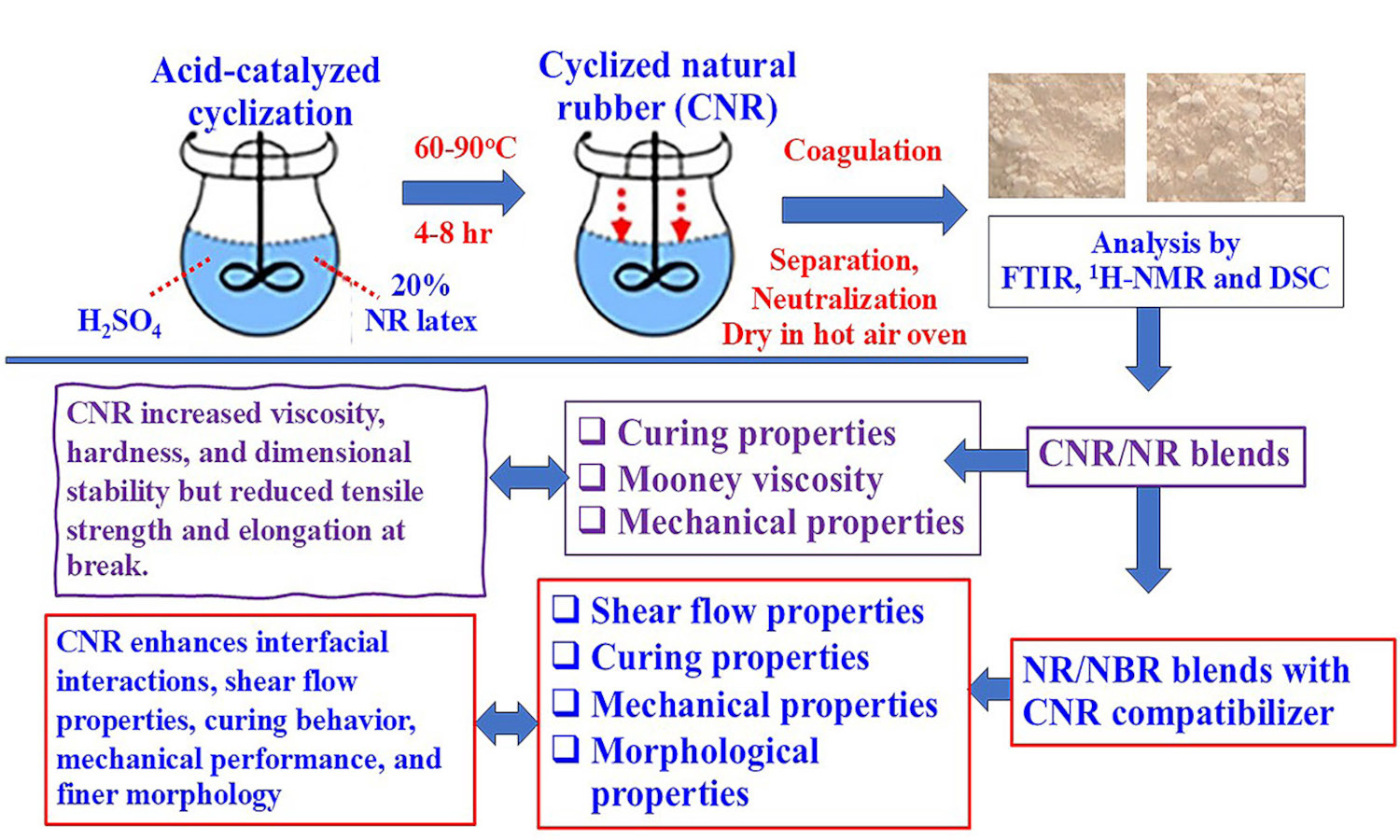

Azizon Kaesaman, Tassaneeya Khunrang, Charoen Nakason

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

Vol. 19., No.8., Pages 753-772, 2025

DOI: 10.3144/expresspolymlett.2025.58

Cyclized natural rubber (CNR) was synthesized through the acid-catalyzed reaction of natural rubber (NR) latex using sulfuric acid as a catalyst and stabilized with a non-ionic surfactant. Cyclization was evaluated by iodine numbers under varying reaction times, temperatures, and NR-to-acid ratios. Fourier transform infrared spectroscopy (FTIR) and proton nuclear magnetic resonance spectroscopy (1H-NMR) confirmed the formation of cyclic structures in CNR molecules. Differential scanning calorimetry (DSC) showed that the glass transition temperature (Tg) of CNR increased with cyclization, indicating greater rigidity and less chain flexibility. CNR was then blended with NR and used as a compatibilizer in NR/acrylonitrile butadiene rubber (NBR)blends. It increased blend viscosity, hardness, and dimensional stability but reduced tensile strength and elongation due to its rigid cyclic domains. In NR/NBR blends, CNR outperformed a commercial homogenizer in enhancing interfacial interactions, leading to superior shear flow properties, curing behavior, and mechanical performance. This is attributed to the polar groups in CNR, which enhance intermolecular interactions and phase compatibility, resulting in finer phase morphology. This study highlights the potential of CNR as a versatile material for enhancing the performance of rubber compounds, with promising applications in advanced industrial formulations.

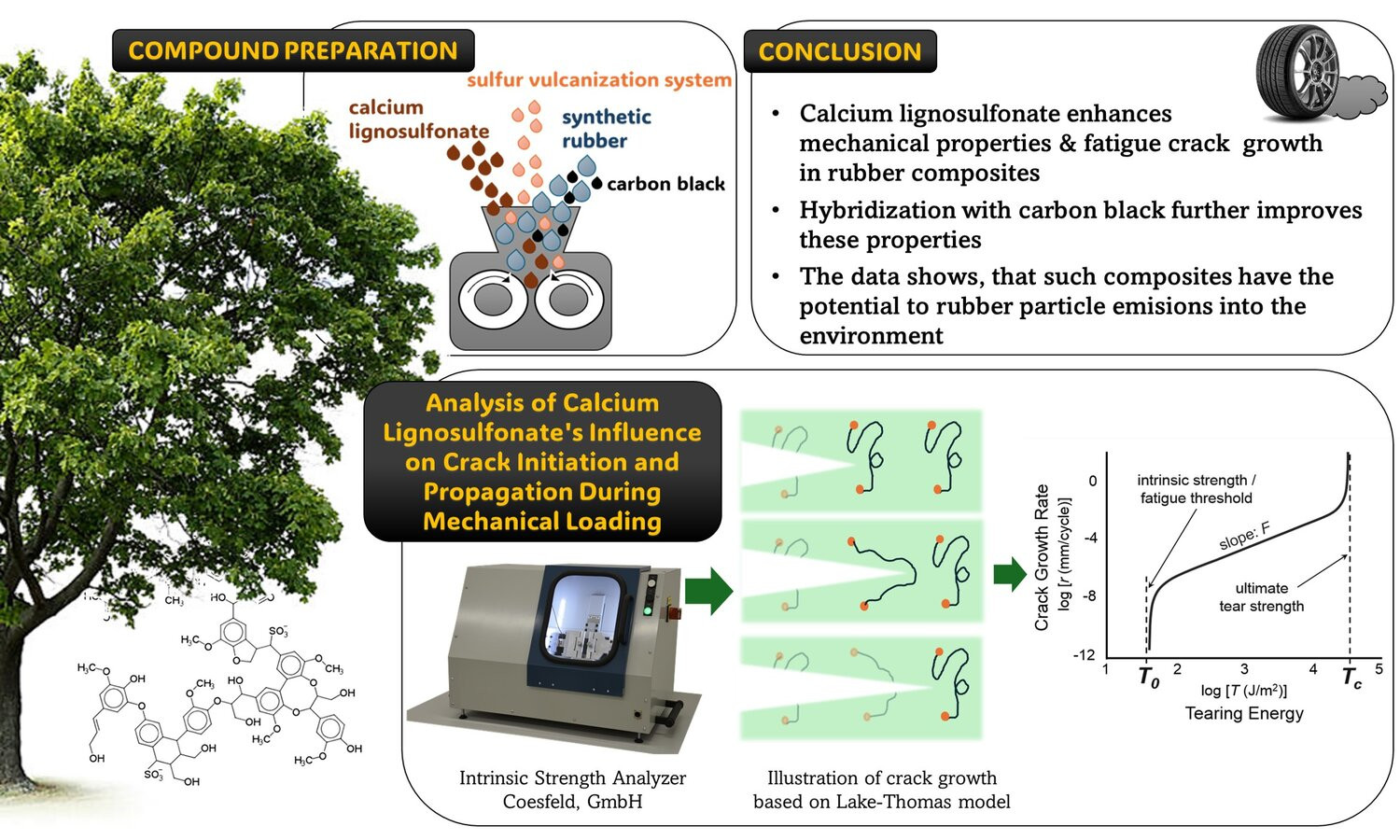

Michaela Džuganová, Radek Stoček, Marek Pöschl, Ján Kruželák, Andrea Kvasničáková, Ján Hronkovič, Jozef Preťo

Vol. 18., No.12., Pages 1277-1290, 2024

DOI: 10.3144/expresspolymlett.2024.95

Vol. 18., No.12., Pages 1277-1290, 2024

DOI: 10.3144/expresspolymlett.2024.95

This study explores the transformative potential of calcium lignosulfonate (CaL) as a sustainable additive in rubber composites based on nitrile rubber (NBR) and styrene-butadiene rubber (SBR). Through comprehensive mechanical testing, fatigue crack growth (FCG) analysis, and scanning electron microscopy (SEM), we evaluated the tensile strength, elongation at break, surface morphology, and crack growth behavior of these innovative composites. By incorporating CaL into carbon black-reinforced rubber compounds (RUB/CB) based on nitrile rubber and styrene-butadiene rubber, we achieved good dispersion of both components as well as satisfactory morphology, resulting in tensile strengths of 16.3 and 12.7 MPa, respectively. While the CB/CaL hybrid did not significantly influence the intrinsic strength of the rubber samples, the ultimate strength of these compounds increased drastically – over five-fold compared to RUB/CB – indicating great potential for real-life applications. This study underscores the promise of lignin-based additives in the development of eco-friendly, highperformance rubber materials.

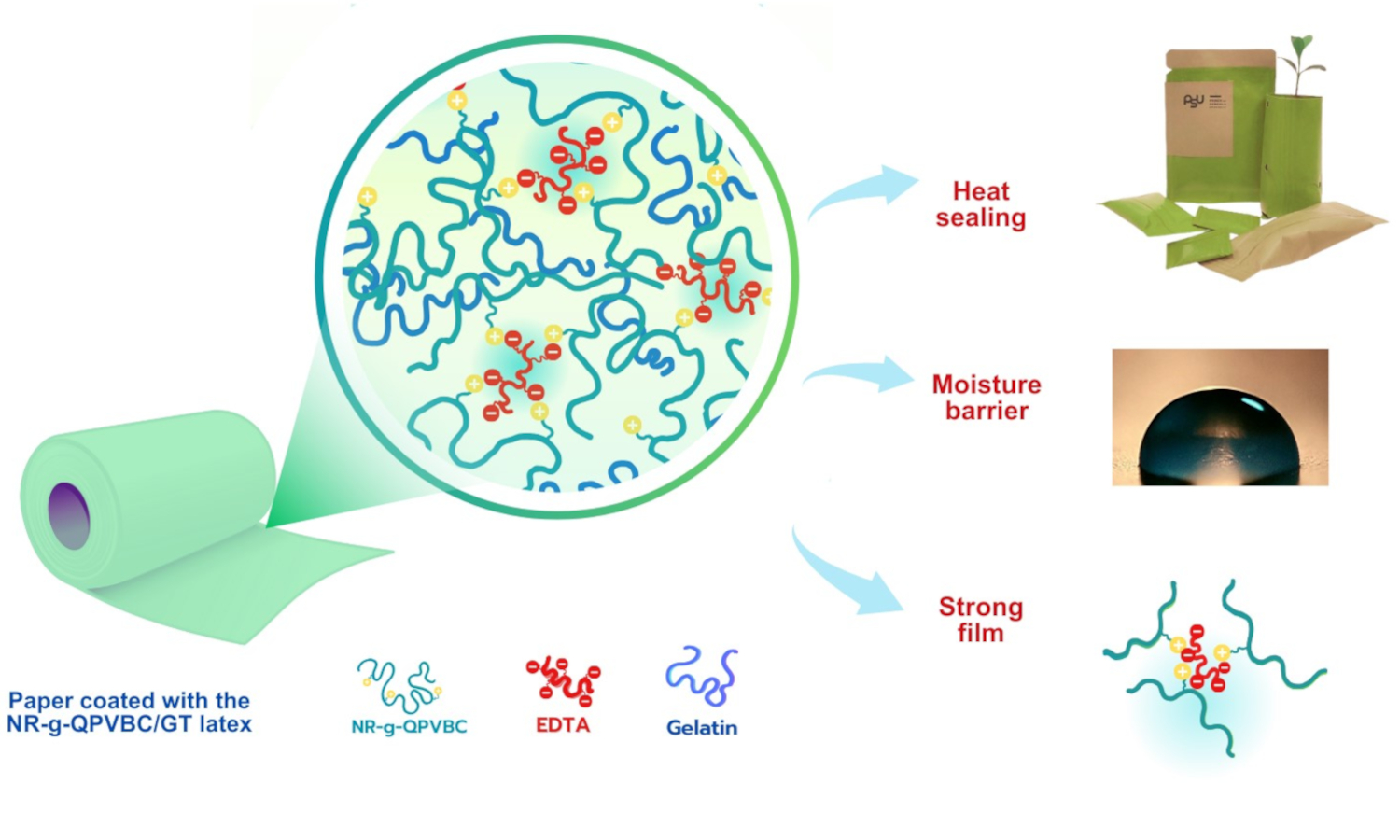

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Phakawat Thongnuanchan, Pornsuwan Buangam

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Research into sustainable packaging materials has gained increasing importance due to the pressing environmental concerns related to plastic waste. The present study focused on developing a sustainable paper coating based on modified natural rubber (NR) latex filled with gelatin (GT). The graft copolymer latex of NR and poly(vinylbenzyl chloride) bearing quaternary ammonium groups, abbreviated as NR-g-QPVBC, was first synthesized. GT was then incorporated into the latex, and the combination of these materials resulted in a heat-sealable film with good tensile properties and a water barrier. The ionic crosslinking of the latex film was achieved by the reaction with ethylenediaminetetraacetic acid (EDTA). Heat-sealing studies of the NR-g-QPVBC latex film filled with GT (NR-g-QPVBC/GT) revealed its heat-sealability at 160 °C. Scanning electron microscope (SEM) analysis further confirmed the diffusion of the chains across the interface during heat sealing. Dip coating was a method for depositing latex film on kraft paper. The paper coated with the NR-g-QPVBC/GT latex showed a significant increase in dry and wet-tensile strength compared to the uncoated paper. The sealing process was optimized to achieve a heat-seal strength of 755.31 N/m at a dwell time of 3 s and a temperature of 160 °C. The research's practical application was demonstrated by transforming the coated paper into various heat-sealable bags using a handheld bag sealer.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Anoma Thitithammawong

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

Vol. 18., No.7., Pages 742-759, 2024

DOI: 10.3144/expresspolymlett.2024.55

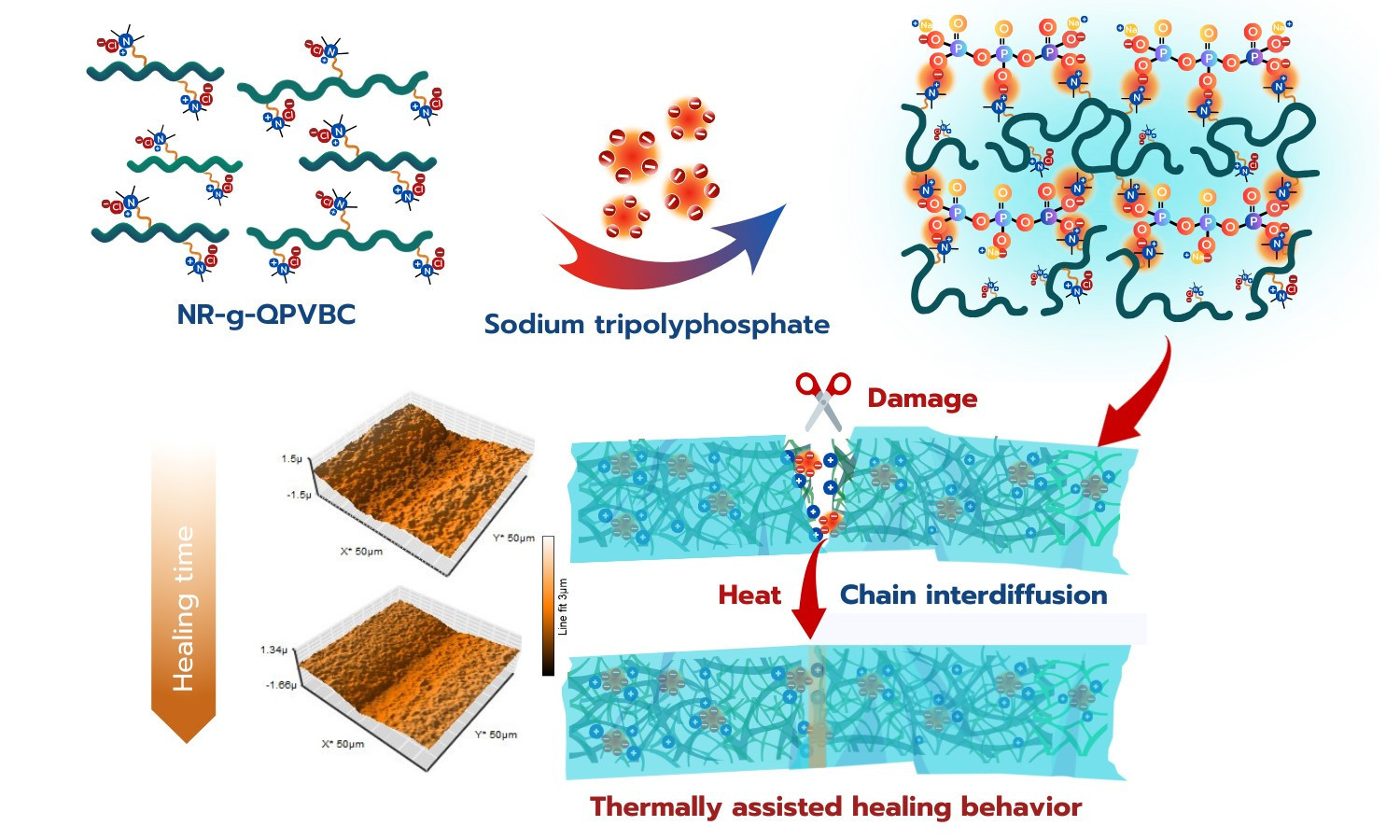

This work reported a practical approach to turning conventional natural rubber (NR) into a thermally healable rubber. 4-vinylbenzyl chloride was first polymerized in the NR latex to yield graft copolymers of NR and poly(vinylbenzyl chloride), NR-g-PVBC. The cutting and rejoining process was used to study the healing ability of latex film. The healing behavior was observed after the reassembled film was heated at 100 °C for 1 h and then allowed to heal continuously at room temperature (RT). The healed film displayed a 58.44% regain of the tensile strength (4.57 MPa) after being allowed to recover at RT for 72 h. Additionally, the chloromethyl moieties in the NR-g-PVBC could be converted into quaternary ammonium (QA) groups by reaction with trimethylamine, producing the quaternized NR-g-PVBC (NR-g-QPVBC). Ionic crosslinking of the NR-g-QPVBC film was achieved by incorporating sodium tripolyphosphate (STPP). The latex film had a tensile strength of 15.32 MPa and could withstand a strain of 868% when ionically cured with 2 phr of STPP. After the healing process, the cured film showed a healing efficiency of 49.67% in tensile strength (7.61 MPa). Furthermore, a suturing test was performed to investigate the feasibility of developing a suture training pad from the corresponding cured film. The film’s ability to heal with heat assistance was its significant practical advantage, enhancing its realism and mimicking the healing process in human skin.

Andrea Kohári, Tamás Bárány

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

This is an editorial article. It has no abstract.