The growth and recyclability of thermoplastic polyurethanes

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

DOI: 10.3144/expresspolymlett.2024.33

GRAPHICAL ABSTRACT

RELATED ARTICLES

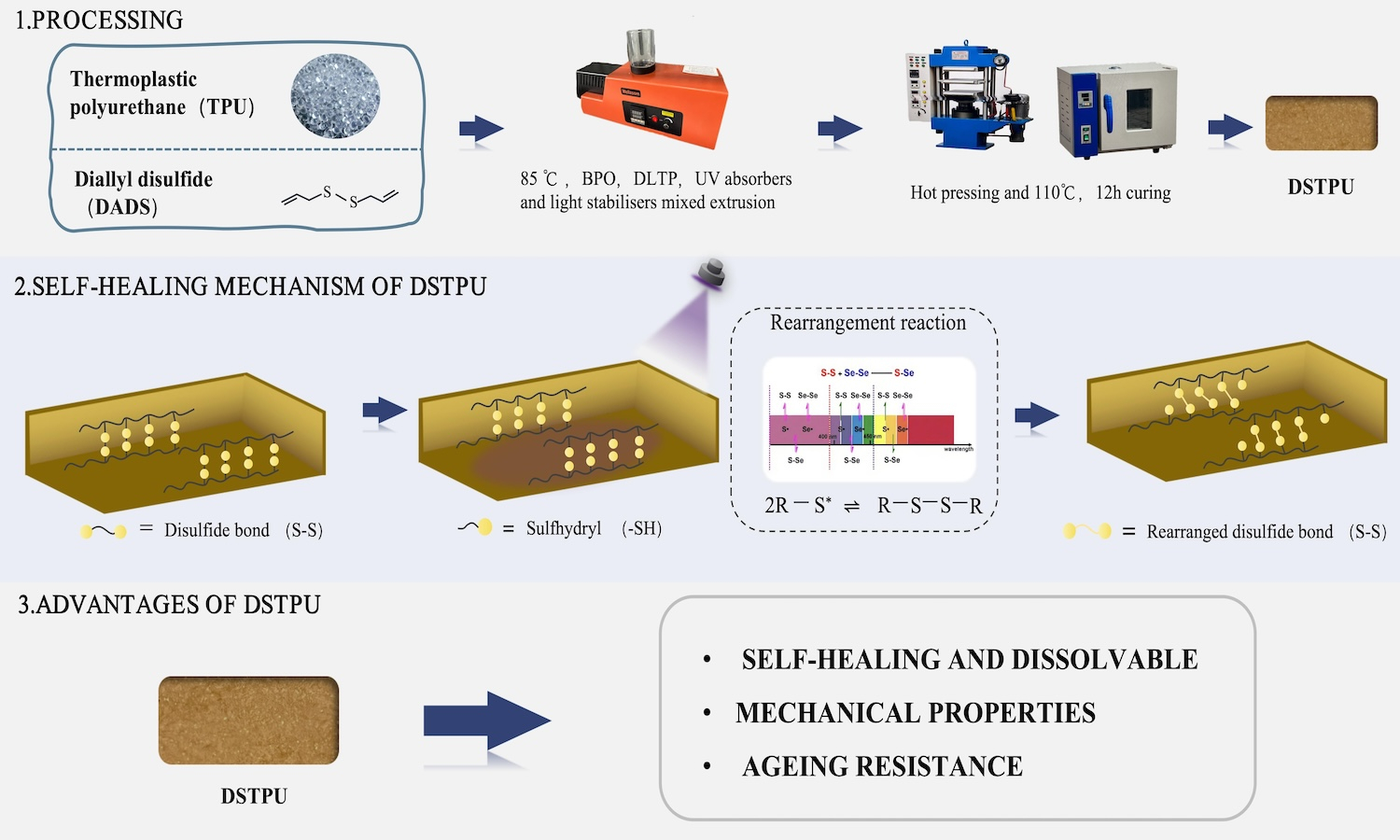

Wenxin Gan, Hanyu Xue, Hongyi Lin, Renjin Gao, Yuchi Zhang, Liwei Wang, Jiuping Rao

Vol. 19., No.3., Pages 311-325, 2025

DOI: 10.3144/expresspolymlett.2025.22

Vol. 19., No.3., Pages 311-325, 2025

DOI: 10.3144/expresspolymlett.2025.22

Cross-linking frequently enhanced the mechanical properties of linear polymeric materials; however, it also resulted in the transition from thermoplastic to thermosetting materials, which posed issues from an environmental perspective. Thermoplastic polyurethane (TPU) elastomers were extensively applied across various industries. To improve the mechanical properties of TPU while preserving its environmental benefits, this study integrated radical copolymerization technology to develop a reversible crosslinked TPU. Specifically, the linear polyurethane molecular chains were crosslinked using diallyl disulfide (DADS) as a functional cross-linking monomer. Through radical copolymerization reactions, reversible crosslinks formed from disulfide bonds were created between the linear polyurethane molecular chains, yielding a self-healing reversible crosslinked thermoplastic polyurethane (DSTPU). The study showed that DSTPU could self-heal and dissolve under UV light and alkaline N,N-dimethylformamide (DMF) conditions, achieving 82.2% self-healing efficiency at 3 phr DADS. It dissolved into fine particles in alkaline DMF. Disulfide bonds in DSTPU enhanced cross-linking, boosting 19% oxygen permeability, thermal conductivity (0.218 W/(m·K)), and mechanical properties like tensile stress (11.18 MPa), force (134.13 N), and elongation (548%). These bonds also enhanced aging resistance, cutting ΔYI to 6.0%.

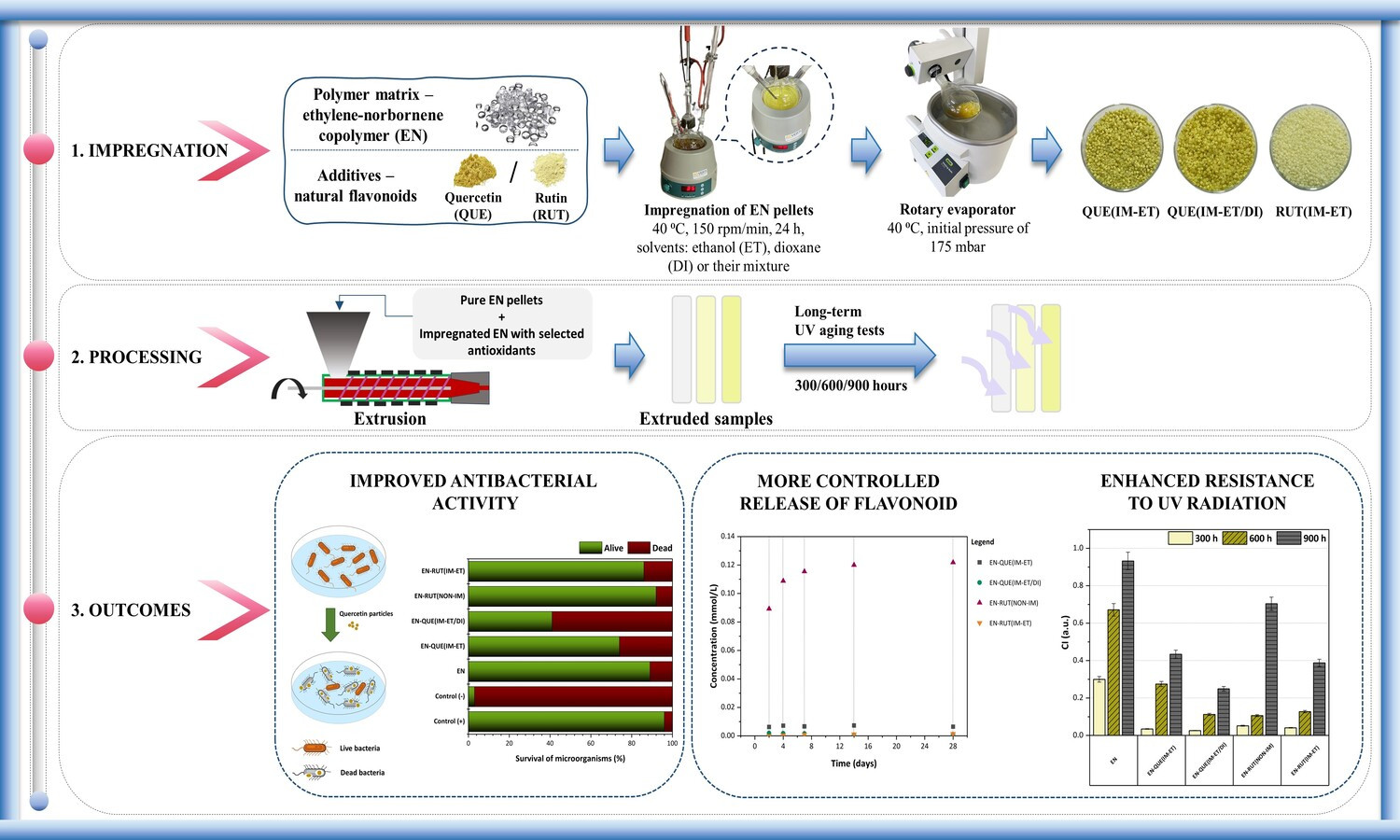

Angelika Plota-Pietrzak, Anna Masek, Aleksandra Jastrzębska

Vol. 19., No.1., Pages 60-75, 2025

DOI: 10.3144/expresspolymlett.2025.5

Vol. 19., No.1., Pages 60-75, 2025

DOI: 10.3144/expresspolymlett.2025.5

Herein, a novel approach was developed for the introduction of stabilizing compounds into polymers through a pre-impregnation process prior to processing, which is expected to improve their dispersion and, consequently, increase their efficacy. Ethylene-norbornene copolymer (EN) pellets were impregnated with quercetin or rutin in ethanol or a mixture of solvents (ethanol-dioxane (3:1)) for 24 h. Then, EN-based samples containing impregnated pellets were manufactured using a laboratory extruder. The research demonstrated that the materials containing impregnated pellets exhibited improved thermo-oxidation resistance, higher antibacterial effect (the number of dead cells increased from 8 to 59%), and satisfactory photostability. This may be a direct result of their better dispersion degree and their more gradual, controlled release from the EN during operation. If we compare the stabilizing effect of both polyphenols, quercetin was more efficient, which may be attributed to the presence of hydroxyl group at the C3 position in the C ring, which could increase the reactivity of the catechol structure of the B ring. The proposed approach effectively solves the issues that arise during the commonly used processing techniques and may facilitate the broader utilization of natural stabilizers in the polymer industry.

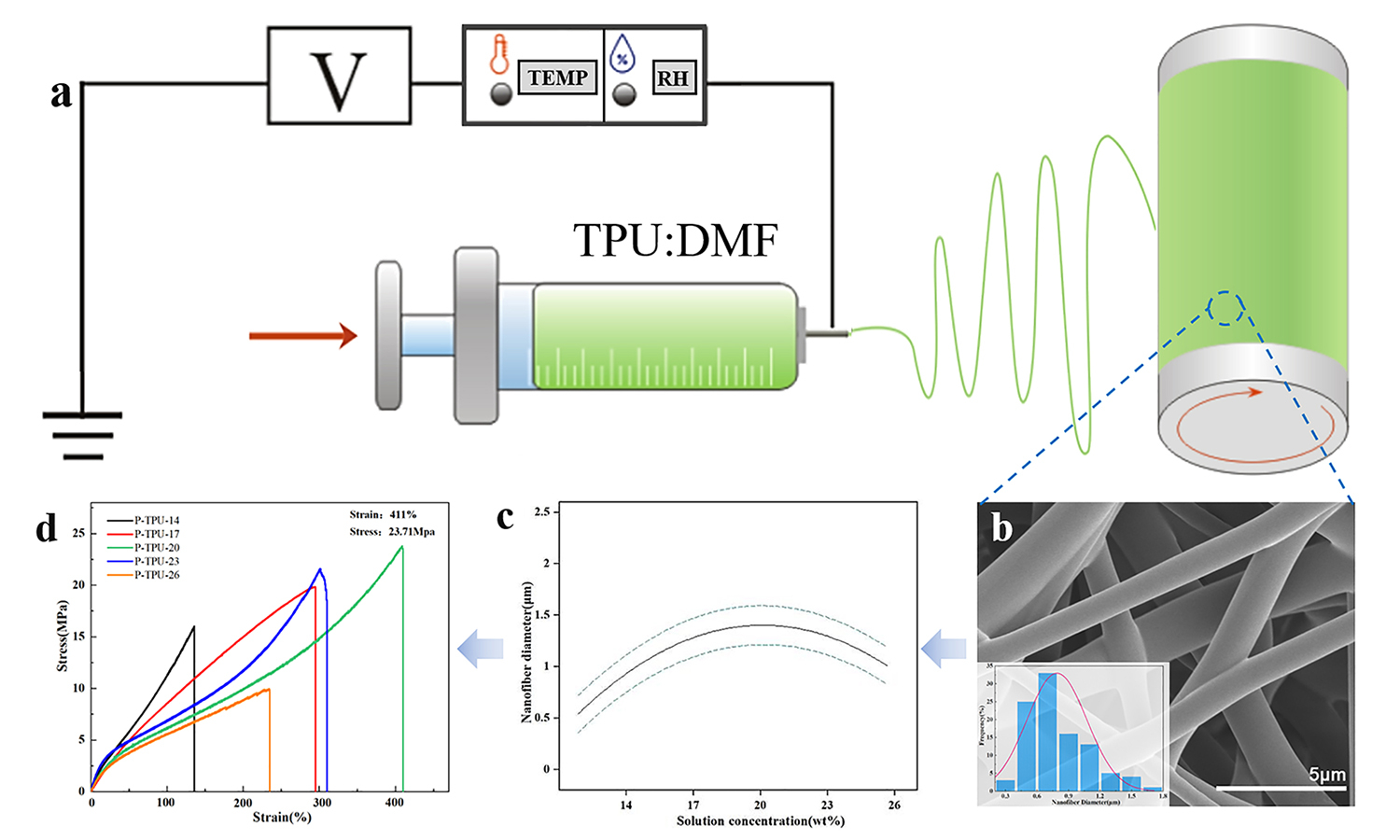

Lu Liu, Tian Luo, Xiaoju Kuang, Xiaoqian Wan, Xinhua Liang, Gaoming Jiang, Honglian Cong, Haijun He

Vol. 18., No.8., Pages 807-818, 2024

DOI: 10.3144/expresspolymlett.2024.60

Vol. 18., No.8., Pages 807-818, 2024

DOI: 10.3144/expresspolymlett.2024.60

Thermoplastic polyurethanes (TPU) have attracted increasing attention due to their excellent flexibility, chemical stability, processability and greenness. The traditional processes generally limit them to civil and industrial applications, but electrospun TPU nanofibers with high porosity, high specific surface area and superior mechanical properties are promising in emerging fields. TPU nanofibers’ properties are affected by various electrospinning parameters, such as solution concentration, applied voltage, flow rate and rotational speed. Thus, 29 sets of experiments were designed here by the efficient and low-cost response surface methodology (RSM). The analysis of variance (ANOVA) revealed that the model agrees well with experimental results, and solution concentration is the most crucial parameter affecting nanofibers’ morphology and diameter. Based on it, the impacts of solution concentration and orientation on the mechanical properties of the TPU nanofiber membrane were investigated. Benefiting from the stress transfer and network deformation, the TPU nanofiber membranes parallel to the collection direction possessed the highest stress strength (23.71 MPa), while the nanofiber membranes vertical showed the widest strain range (485%). This study provides useful guidance for the preparation of high-performance TPU nanofibers, contributing to expanding its applicability in emerging fields such as biomedical, filtration and separation, and flexible sensing.

Ivy Gan, Wen Shyang Chow, Siong Hui Khoo, Mohamad Danial Shafiq

Vol. 18., No.7., Pages 689-704, 2024

DOI: 10.3144/expresspolymlett.2024.51

Vol. 18., No.7., Pages 689-704, 2024

DOI: 10.3144/expresspolymlett.2024.51

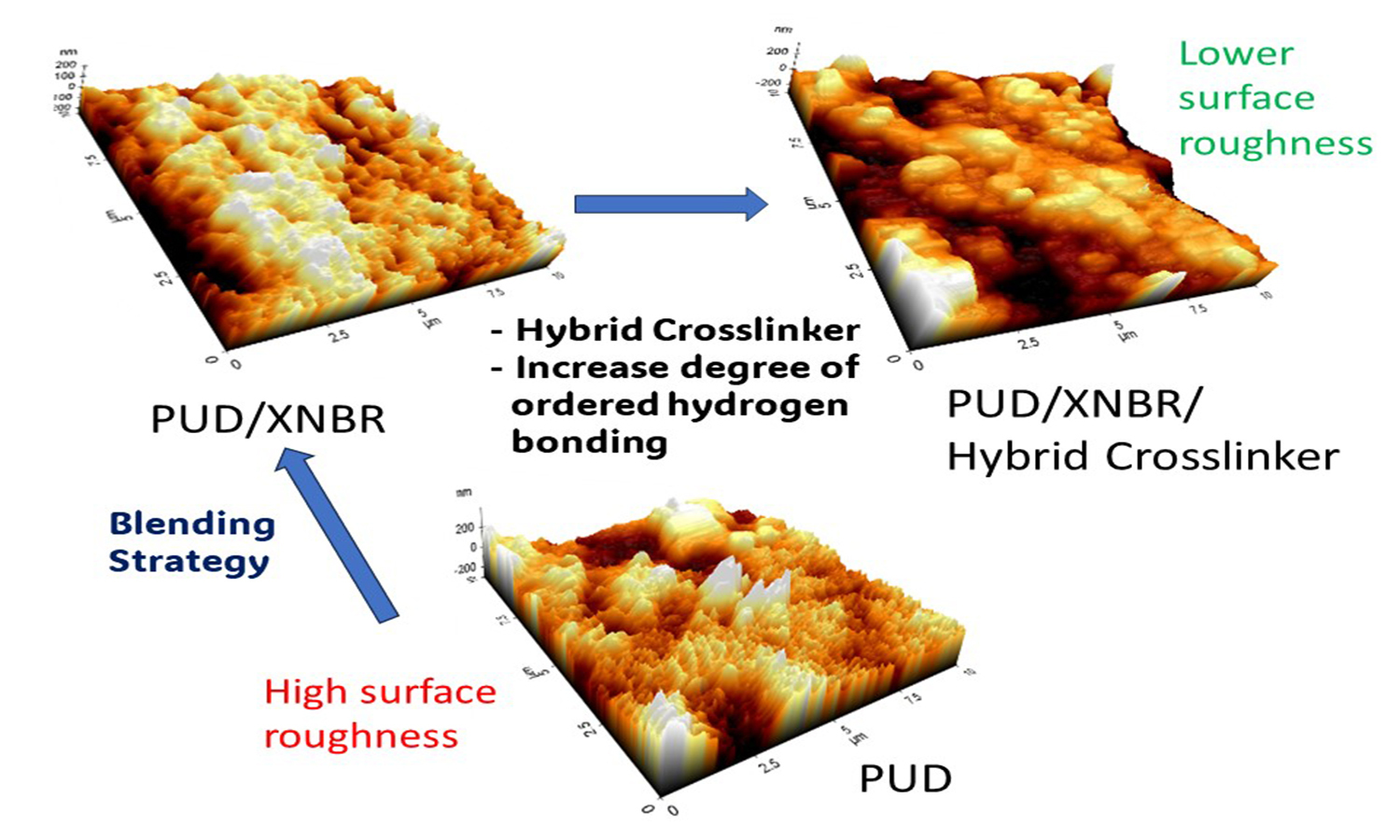

This study focuses on producing polyurethane dispersion (PUD)/carboxylated nitrile butadiene rubber (XNBR) blends with different types of crosslinkers without both accelerators and sulphur. Two types of crosslinkers: epoxide crosslinker and organo-modified siloxane, are introduced in the PUD/XNBR (blending ratio of 80:20). The zeta potential and particle size of the PUD/XNBR blends were determined using a dynamic light-scattering nanoparticle analyser. The chemical interaction and surface roughness of the PUD/XNBR blends were evaluated using Fourier transform infrared spectroscopy (FTIR) and atomic force microscopy (AFM). The zeta potential and particle size of the PUD were influenced by XNBR blending and the types of crosslinkers. FTIR observations indicate that the XNBR and the crosslinkers facilitated intermolecular hydrogen bonding and different extents of ordered hydrogen bonding. A higher degree of ordered hydrogen bonding can be associated with a higher surface roughness of the PUD/XNBR blends. Nevertheless, the hybrid crosslinkers can be used to achieve reasonable surface roughness for the easier donning of latex gloves. The research findings can be applied to design glove products with desirable surface roughness and intermolecular bonding.

Azizon Kaesaman, Rawviyanee Romin, Charoen Nakason

Vol. 17., No.10., Pages 1056-1069, 2023

DOI: 10.3144/expresspolymlett.2023.79

Vol. 17., No.10., Pages 1056-1069, 2023

DOI: 10.3144/expresspolymlett.2023.79

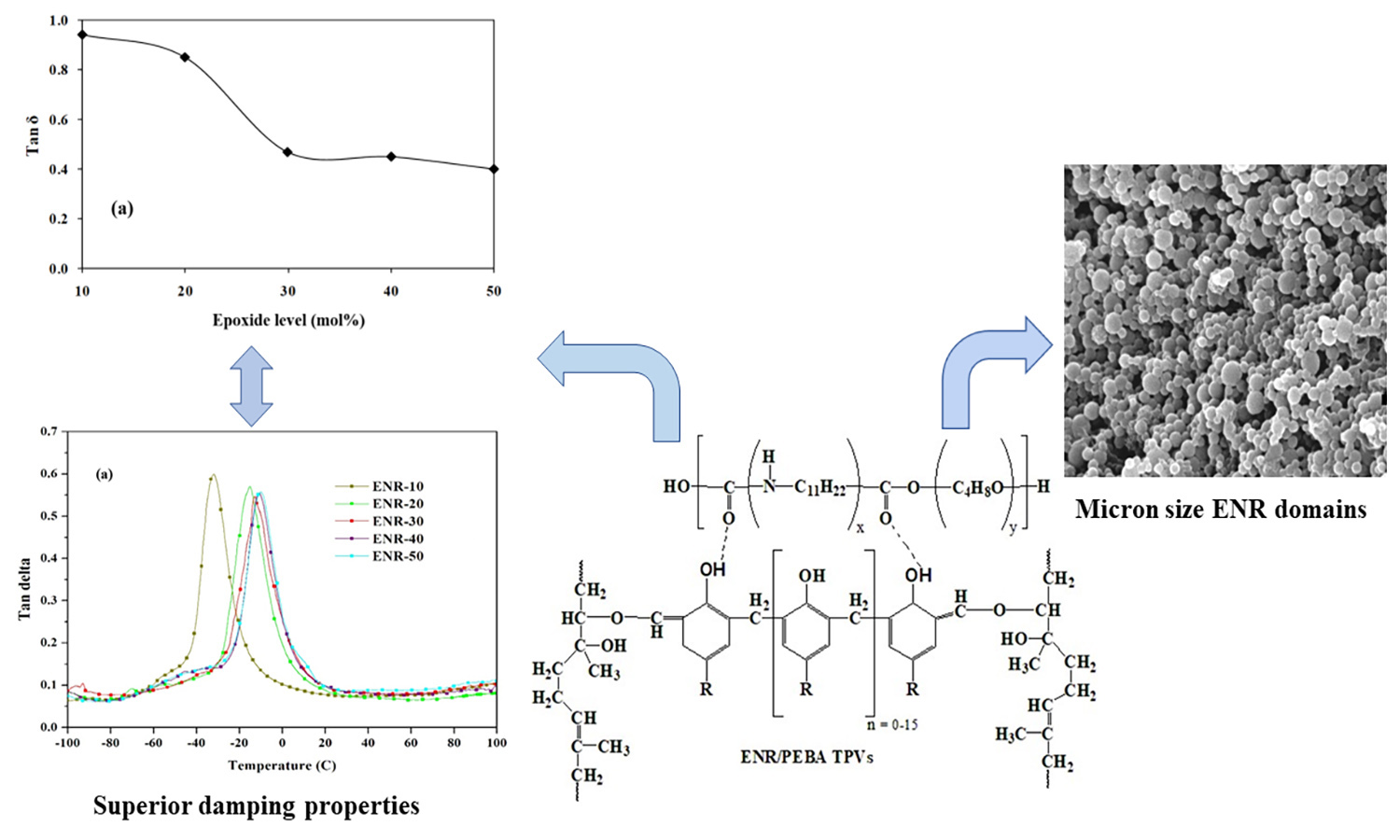

Epoxidized natural rubber (ENR) with varying levels of epoxide groups ranging from 10 to 50 mol% was prepared and dynamically phenolic vulcanized by blending it with poly(ether-block-amide) copolymer (PEBA). The results indicate that the thermoplastic vulcanizates (TPVs) of ENR/PEBA blends display a sea-island morphology and enhance a number of properties. Specifically, increasing the epoxide content and PEBA proportion enhances strength properties, including higher Young’s modulus (stiffness), toughness, tensile properties, and hardness, along with smaller vulcanized ENR domains dispersed in the PEBA matrix. Moreover, the decrease in tension set values indicates an improvement in the elastic properties. The attributed cause of this is the interaction between the polar groups present in the phenolic-cured ENR domains and the PEBA molecules. As a result, interfacial adhesion between the ENR domains and PEBA interfaces improved, contributing to the observed enhancements in the strength and elastic properties of the TPVs with smaller ENR domains. Furthermore, an increase in the epoxide content was found to be correlated with a decrease in tanδ and tension set, which further supported the observed improvements in strength and elasticity. Additionally, the ENR/PEBA blends showed a single glass transition temperature (Tg), while pure PEBA exhibited two Tgs. The presence of a single Tg in the ENR/PEBA blend is attributed to the overlapping of the Tg of the ENR and PEBA immiscible blend components.